The sip ring is a very important component that can rotate continuously by 360 degrees and transfer electricity to an ever-revolving, boundary portion of the assemblage. In electromechanical devices, such as revolving boards, monitoring systems such as radars, medical devices such as microscopes and arm lamps, batteries, wind turbines, automation equipment, etc. A slip ring is a normal electromechanical device that makes electrical power and signal transfer from a static to a moving part easier. They are used in almost all electromechanical machinery, where power and signals are conducted unlimited, interrupted, or continuously spinning. Slip rings can enhance the machine’s mechanical efficiency, maximize device reliability, and remove damage-prone wires from rotating joints. We function by linking stationary systems to rotary systems continuously. Slippers, rotating joints, collectors, or switches can also be called swivels. A glittered ring assembly includes brush blocks, which are precisely harmonized and are generally available as a ring and brush assemblage.

Types and Uses

Slip rings are an essential component of any system that rotates in working processes. The power transfer from a static to a rotating unit is carried out by an electrical slip ring in the middle of any automation system. Almost every computer needing power and data connectivity is used. This is why slip rings have an essential effect on the consistency, action, and performance of the equipment. Slip rings enrich mechanical performance, modernize the system utility, and eliminate damage-prone wires from rotating joints. The rotary connectors, swivels, and switches are also known as slip rings. A brush ring requires coordination of brush blocks which are available as a ring pair and brush. Almost every product these days has a slip loop. The market offers all sorts of slip rings, such as ring collectors, high-speed slip rings, disk slip rings, and many others. The intent and application of each slip ring are different. We are going to look at various types of slip rings in this post today and their uses. So let’s continue with the Slip Rings ‘ Types and Use.

Wireless Slip Rings

They don’t depend on licensing procedures for the use of a carbon contact brush and slip ring resistance wire. They depend on the data and power transfer using the electromagnetic field wirelessly as an alternative. The coils which are mounted in a rotating receiver and immobile receiver are used to generate it. They are regarded as an addition to the traditional slip ring that is easy to preserve and can stand in a harsh environment.

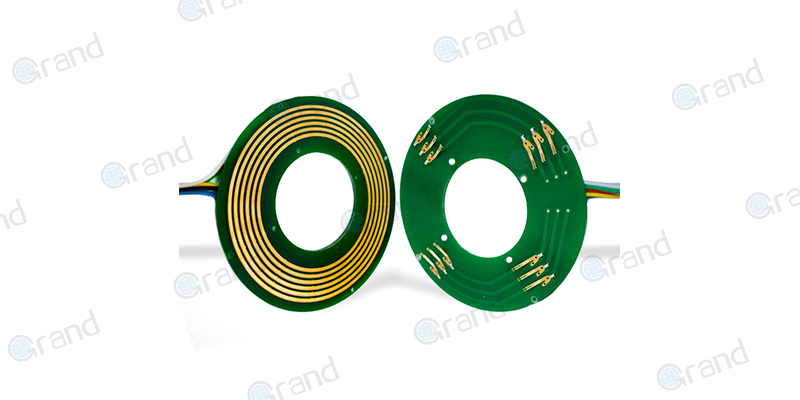

Pancake Slip Rings

Electrodes are mounted on a flat disk in the pancake slip ring. It is the kind of condensed ring positioned inside the rotating shaft. This system has a high burden and advanced capacity, and it successfully collects wear on its vertical axis. In some cases, the axial length has been condensed, which has proved appropriate for specific applications.

Mercury Wetted Slip Rings

Their persistent relationship and low-slung resistance differentiate them. A pool of liquid metal, confined to the ties, will replace here sliding brush touch. The liquid metal initiates a connection between a revolving and immobile touch when spinning. The decision needs to be made sensibly while choosing valuable metal contacts when applications for the slip ring include food products and pharmaceutical equipment.

Pneumatic slip ring

This ring is used for transportation to a revolving outlet of pneumatic pressures or vault from a static inlet. In the meantime, the liquid relation stabilizes and splits as 360 rotates. The pneumatic rings are primarily used in facilities used for commercial and industrial plants, offshore drilling equipment, and geotechnical instruments.

Fibre Optic Slip Rings

Often known as rotary fiber optic joints, when a large amount of data is transmitted, it should send signals through rotating interfaces. The rotator fiber optic joints hold critical fiber advantages from end to end. The primary communication system is two-way fiber optic and four-way connectors. Therefore, the design should be carefully designed because the diameter of the fiber is small, and the diameter of the single-mode fiber is only 9 nm. The specification should, therefore, be accurately preserved, making it difficult to process the product structure.

USB Slip Rings

While moving 360 continuously, USB slip rings are used to transmit a USB signal from the static part to the moving part. It also guarantees at the same time that the USB wires do not twist. These USB rings are used on King USB devices, USB equipment, etc.

Ethernet Slip Rings

Ethernet rings are turning electric device that transfers power from static inlets to turning outlets while controlling circuits or data. Their innovative design meets the requirements of matching impedance, loss reduction, and crosstalk power.

Large Current Slip Ring

Long current rings are used to transmit high power and high electricity from a static part to a turning part. During this cycle, the power supply is maintained and separated. These often act as rotating connectors if they need a large amount of power. They are also well suited for heating purposes.

Miniature Slip Rings

These little rings are designed to meet the requirements of small equipment where power and signal from a standstill to a rotating part are to be transferred. They are ideal for sensors, video transmitters, and control panels because of their small size. These are particularly suitable for rotating systems that require low signal control.

Waterproof Slip Rings

In an area where heat, corrosion, and underwater are present, waterproof slip rings are used. The waterproof slipper ring can be divided into several fortification categories, including IP65, IP67, IP68, and much more, depending on its operating environment. In an environment with liquid ingredients, such as seawater, cold water, oil, etc., the protection design and material range for the ring of the slip are connected with the usage.

Capsule Slip Rings

They are best used for signals and power transmission applications. A compact footprint and low cost are also significant. It is a blend of a condensed range and a high function which makes it ideal for video and other space-critical stimulus transfers. They use gold-on gold connectors to make them accessible for video signals to be transmitted in applications like CCTV, with long, low noise and reduced distortion.