A slip ring is one of the most versatile electromechanical devices used in broad applications in a variety of industries. Primarily, these devices help to transmit power and data signals from a static component (stator) to a rotating element (rotor). They are used in various motors, including electrical generators, wind turbines, satellites, microwave antennas, showrooms, medical, mining, and military equipment, and more. Industrial-grade slip rings are readily available from various manufacturers. Because of their broad applications, there are multiple types of slip rings, and each comes with unique specifications depending on the equipment it will be installed and the operating environment. Some of the popular slip rings include:

- Through-hole (also through bore) slip rings

- Pancake slip rings

- Fiber optic rotary joints (FORJs)

- USB slip rings

- PCB and Miniature slip rings

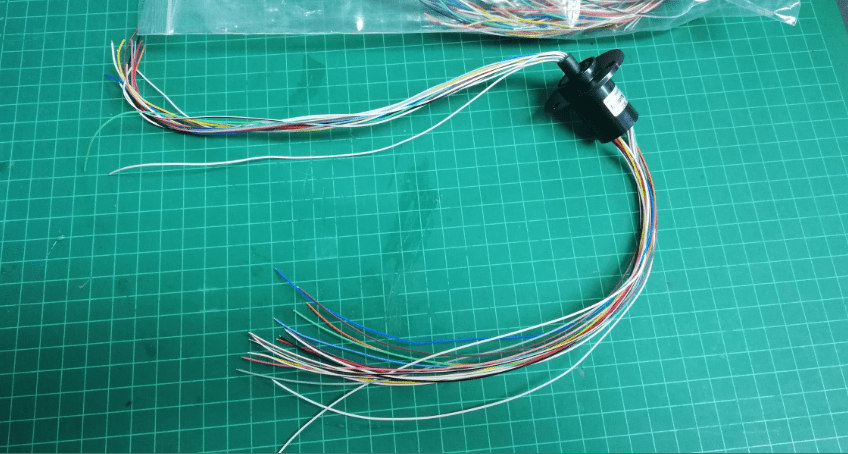

Making a slip ring

Slip rings have several other distinctions, depending on their application. A model designed for CCTV cameras will reflect significant differences from those used in heavy-duty drilling and mining. These devices also come with unique specifications influenced by the equipment and operating environment requirements. As such, there is no standard way to make slip rings. Each model and instruction are different. Nonetheless, there are various fundamental steps involved in making slip rings. These include:

1. Pick a Slip Ring

Before making a slip ring, you should identify the slip ring you want to make and all the specifications it will need. Many unique slip rings are used, which means you must understand the required components and envision their functionality within the intended equipment and operating environment. There are different types of slip rings and each type has broad mechanical and electrical distinctions. It is essential to identify all the slip ring specifications, based on its application. This phase also involves selecting the materials required for the particular slip ring.

2. Sketching and Drawing

Once you know what slip ring to make, you can start sketching all the parts required for the design. A standard electric motor slip ring will feature fixed carbon graphite brushes and a rotating centerpiece made using metal alloy. Purchased kits usually feature mounting fixtures and other structural components required to complete the installation. Sketching and drawing all the parts is essential before starting any manufacturing process. This requires a clear understanding of the slip ring functionality and required specifications. The sketches will be used to produce exact matches and contain the useful specifications needed for machining.

3. Start the Production

Now that you have completed the drawings and identified the materials required for all the parts, you can begin production. The order for what part you make first is largely influenced by personal preferences and the type of slip ring you are making. For a standard slip ring, you can start by finishing all-around parts before you begin milling. Essentially, it would be best if you made every single component, including housing and mounting, as shown in your sketches and drawings. Once you have every part, you can start mounting them together. The easiest way is to include step-by-step procedures for assembly and mounting in the sketches.

4. Test the Slip Ring

If you followed the necessary steps and precautions required for making a functional slip ring, everything should work as intended. Like every other step, testing will depend on the slip ring you are making. Standard slip rings that feature carbon graphite and brass parts can be tested using LED lights. If the LED lights are blinking rapidly, it means there is a problem. You can also use a standard 230V AC 3A tester to ensure all connectors are functioning correctly before installing the slip ring in its device. If the connections are working, your slip ring will be able to transmit signals.

Using an Instructable to Make Slip Rings

An instructable offer the best chance at making a functional slip ring. There are several types and specifications for these devices, which mean you need specific instruction for the model you want to make. An instructable, specifically intended for the device you seek, will provide all necessary steps and recommendations. Various resources offer Instructables for homemade and DIY slip rings as well as professional manufacturing manuals for premium grade models. You should read through the entire instructable to determine whether it addresses the specific slip ring you want to make. Once you find a reliable instructable, the rest is assembling all materials and tools to start work. The steps still involve sketching, manufacturing, assembling, and testing.

Things to Consider When Making a Slip Ring

Making a slip ring is best suited to experienced professionals and manufacturers that have been doing it for years. The manufacturing process will depend on the slip ring type and specifications. However, there are various general observations to keep when making slip rings. These include:

1. Identify Primary Specifications

You should identify the critical mechanical and electrical specifications required for the slip ring you are making. This will help you create functional slip rings that can fit in your equipment and provide the conductivity you seek. For instance, if you are making USB slip rings, video, Ethernet, and power specifications are the primary areas you should decide on before you start production. Specifications, such as weatherproofing, insulation, and anti-abrasion, are also critical.

2. Choose Materials Early

Slip rings can be made using various materials, depending on the application. If you are making miniature slip rings, printed circuit boards offer the ideal canvas. On the other hand, CCTV cameras can benefit from pancake FORJs that facilitate high-speed transmission and withstand harsh outdoor conditions. The material strength, conductivity, resistance, and coating options are all critical aspects.

Conclusion

Making a slip ring should be an effortless process once you have all materials and a step-by-step procedure. Instructables also come with precautions and observations to keep, so you can safely and quickly finish making a functional slip ring for your device. If you are looking for premium slip rings for unique applications, it is essential to choose reliable manufacturers that can guarantee top-quality industrial-grade slip rings. Make sure the slip ring is optimized for unique applications and environments.

See What We Can Do