As we delve into the evolving realms of technology and engineering, the demonstration of miniaturization and precision in components is not only crucial but also fascinating. This article, focusing primarily on micro slip rings, seeks to dissect and explore this compelling subject in depth. With this piece, we aim to provide an illuminating study about these small but hugely essential components while elucidating their phenomenal ability to streamline operations across several industries.

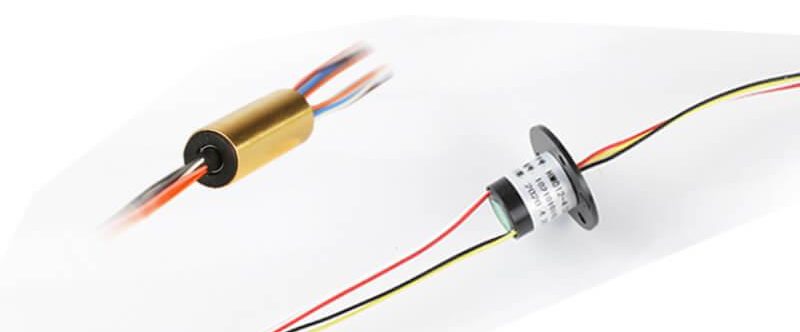

Micro slip rings, often unnoticed but remarkably vital, serve as a pivotal conduit for power and signal transmission. Notwithstanding their petite size, these electro-mechanical devices play a paramount role in many applications where unfettered rotation, coupled with the transmission of power and data, is necessary. Ranging from consumer electronics and security systems to advanced robotics and medical equipment, micro slip rings have been gaining increasingly significant influence in a myriad of sectors.

Throughout this discourse, we will closely examine the various facets and characteristics that make micro slip rings indispensable. Not only will we decode its working principles and key attributes but also dive into its multifarious applications, exploring how these compact devices can help reinvent the technical narrative across various industries. Further, this comprehensive exploration will lead us to understand how the customization and sophistication of micro slip rings can shape and elevate the broader dynamics of technology-intensive sectors in the coming years.

What Is a Micro Slip Ring?

When you hear the term ‘micro slip ring’, you may wonder what it exactly refers to. To elucidate, a micro slip ring is a diminutive yet intricate mechanical device designed to bridge the gap between stationary and rotating parts of various equipment. Its principal function is to facilitate uninterrupted electrical connections while allowing free 360-degree rotation. This is particularly useful in systems where continuous rotation is involved and power or signal transmission needs to be maintained simultaneously.

Essentially, the micro slip ring acts as a powerful conduit of power and communication, allowing for seamless energy transfer and signal propagation amidst rotating systems. It features a cleverly compact design, embodying the mantra that great things often come in small packages. Despite its miniaturized form factor, a micro slip ring carries an array of circuits — sometimes even in the hundreds — each capable of transmitting either power or signals or in some cases, both.

One of the key characteristics of the micro slip ring is its versatility owing to its small size. These devices can be readily incorporated within a wider range of systems, including those where space constraints pose substantial challenges. It is also notable for its ability to reduce mechanical noise during operation and its extended lifespan compared with traditional slip rings, given its superior design and modern manufacturing techniques.

In essence, the micro slip ring is more than just an electrical component. It’s a remarkably versatile facilitator, a critical companion to many rotating systems, all packaged in an adroitly compact design. As we venture forward, we’ll see just how deep the rabbit hole goes when it comes to the applications and adaptations of micro slip rings in various sectors.

A micro slip ring assembly is made for places that have smaller installation space left on them. These micro slip rings are commonly called miniature slip rings, mini slip rings, and compact slip rings. The basic design of a micro slip ring encompasses an extension of a capsule slip ring and a through-hole slip ring. These micro slip rings have changed the industry for good. They are offering more compact and economical solutions to their clients. Its key feature is that it provides both the power and signals to the desired components. Along with transmitting the data from the static to the rotary side, the micro slip ring is minimalistic.

The Evolution of Micro Slip Rings

Understanding the historical context and the progression of micro slip ring technology sheds light on the remarkable journey that these devices have embarked upon. This voyage began with the inception of traditional slip rings, bulky and mechanically-impaired components that served as the precursors to today’s highly sophisticated micro slip rings. As with any development, the course of evolution for this highly important electrical component has been driven by technological advancements, material breakthroughs, and innovative manufacturing practices.

Throughout the history of slip rings, numerous breakthroughs have contributed to their success. The advent of modern manufacturing methods has enabled the reduction of component size and weight while improving performance. One major milestone was the incorporation of precious metal alloys such as gold or silver in contact materials. These precious metals not only reduce mechanical wear but also significantly enhance electrical conductivity, ensuring reliable and low-noise signal transmission. Furthermore, advances in material science have resulted in improved resistance properties, safeguarding against harsh environmental conditions, vibration, and extreme temperatures.

Another impressive leap in micro slip ring evolution emerged from the understanding and strategic incorporation of design elements such as capacitance, inductance, and impedance matching—essential for maintaining signal integrity and mitigating EMI (electromagnetic interference). Implementing these elements, coupled with innovative mechanical structures, has led to the development of highly reliable and adaptable micro slip rings suitable for a plethora of applications.

As the transformative accomplishments in micro slip ring technology stack up, demand for these versatile devices naturally surged. Industries such as aerospace, automation, robotics, and medical equipment were quick to capitalize on the remarkable opportunities presented by these miniaturized marvels. Manufacturing precision and scalability also contributed to propelling consumption, making it possible for many organizations to deploy micro slip rings as transformative agents for their respective engineering ecosystems.

In a nutshell, the continued innovations in micro slip ring technology have not only led to their ever-expanding list of applications but also forged an indelible impact on the technological landscape. With each successive breakthrough, the stature of micro slip rings has been elevated, fortifying their position as key enablers in numerous industries worldwide.

How Does a Micro Slip Ring Work?

In small toys and assemblies that require smaller components, slip rings act as a joint that connects two rotating parts of the machine. These micro slip rings provide the current along with transmitting the signal data. A slip ring is essential when it comes to smaller spaces. The main idea and theme behind making these slip rings was to shrink the size of the assembly lines to give more space to other things. The micro slip ring solution not only made the production process better but is feasible for machine operators too.

Peeling back the layers of a micro slip ring to comprehend its inner workings allows us to appreciate the intricate design and mechanisms that underpin its functionality. The operation of a micro slip ring is built upon the principle of enabling 360-degree rotation while concurrently facilitating the transmission of power, data, or both. This seemingly simple concept is materialized through the harmonious synergy of three primary components: the rotating part (rotor), the stationary part (stator), and the brushes (contact points).

The rotor, typically connected to the rotating structure of a system, houses the conductive rings that are engineered to transfer electricity. The stator, conversely, remains fixed and serves as the counterpart to the rotor, linking the power source and signal inputs. Brushes, which are made from precious metal alloys like gold, silver, or platinum, act as the intermediaries between the rotor and stator, forging electrical contact points. The purpose of these brushes is to maintain a persistent connection, thus enabling the seamless transmission of electrical current or signals even as the rotor undergoes continuous motion.

The quintessential aspect of the micro slip ring that sets it apart from its predecessors is its ability to maintain low contact resistance and noise while ensuring high signal quality, even with the small size of the contact points. This delicate balancing act is achieved through the combined efforts of precise material selection, clean assembly environments, and thoughtful design approaches.

An intriguing exploration of this topic reveals that micro slip ring designs are far from being uniform. Each design variation can substantially impact the performance, durability, and suitability of the slip ring for various applications. Factors such as circuit numbers, brush pressure, signal types like digital or analog, and even the choice of lubricants, play essential roles in configuring micro slip rings to cater to different requirements.

In conclusion, the operating mechanics of a micro slip ring embody a marvelous fusion of intricate design, materials science, and innovative engineering practices. The ability to adapt designs to suit specific applications ensures micro slip rings’ incredible versatility, making them a cornerstone in numerous industries and applications.

Key Features and Options of Micro Slip Rings

A micro slip ring can work under heavy conditions such as when there is high current involved, and the overall environment is prone to voltage drops. Micro slip rings are a speedy solution to these problems, and their wires are unbreakable. Due to its compact design, most of the machines that use micro slip rings are more productive. There is another key feature involved in the micro slip ring, and that is, that it can support the transmission of digital signals, analog signals, power, and ethernet signals.

For custom orders, there are some options that you need to think about. These options include how much operation speed you need. How much current and voltage will the device be prone to? What type of connector do you require, and what type of flange is your necessity? Other options encompass the number of circuits that the machines require and where will the wire outlet be positioned. The companies also require you to instruct them that the machine will be prone to dust or water to further secure your assets.

Every complex machinery or system depends on the meticulous design of its components. When it comes to micro slip rings, this concept rings particularly true, given the multitude of features and variables that govern their efficiency, reliability, and adaptability. Additionally, the option for customization and enhancement plays a crucial role in enabling the seamless incorporation of micro slip rings across a wide array of applications.

To begin with, the size of the micro slip ring forms a pivotal characteristic. This is of utmost importance in compact systems or environments where space is at a premium. Micro slip rings can be astoundingly small, some even shrinking to the size of a pencil eraser, making them ideal for applications in miniaturized electronics and precision instruments.

Closely linked with size is the number of circuits or channels a micro slip ring can support. This signifies the amount of separate electrical connections that can be concurrently maintained. While some micro slip rings might have only a handful of circuits, others can feature hundreds of them, each capable of transmitting different types of signals or varying power levels.

The operational speed of the micro slip ring further distinguishes its capacity and optimization for certain applications. For instance, while some slip rings may be comfortable in high-speed robotics operations exceeding hundreds of RPM (Rotations Per Minute), others could be tailored for slower, more precise movements in medical devices or imaging systems.

Customization options for micro slip rings are incredibly vast, giving them an added edge of adaptability. Some slip rings are engineered to carry different types of signals such as Ethernet, USB, HDMI, or even fiber-optic data transmission. Meanwhile, others might be enhanced for higher environmental resistance, capable of withstanding extreme weather conditions, high levels of moisture, or even corrosive materials.

To sum up, the key features and options offered by micro slip rings make them an exceedingly versatile electrical component. The ability to fine-tune these key features, combined with the myriad of enhancement options, ensures that micro slip rings are capable of fulfilling a broad spectrum of industrial needs and requirements.

Model Breakdown

There are six brands that Grand is offering right now, and each has its own specifications.

HM006: it has 4 to 12 rings and has an overall diameter of about 6.5 millimeters. The rated current of this device is 1a, and the rated voltage is 240 volts with an average rpm of about 0 to 250.

HM008: it has 4 to 12 rings and has an overall diameter of about 12 millimeters. The rated current of this device is 1a, and the rated voltage is 240 volts with an average rpm of about 0 to 250.

HM010: it has 4 to 18 rings and has an overall diameter of about 15 millimeters. The rated current of this device is 1a, and the rated voltage is 240 volts with an average rpm of about 0 to 250.

HM012: it has 6 to 18 rings and has an overall diameter of about 12 millimeters. The rated current of this device is 1a, and the rated voltage is 240 volts with an average rpm of about 0 to 250.

HM015: it has 6 to 24 rings and has an overall diameter of about 15 millimeters. The rated current of this device is 1a, and the rated voltage is 240 volts with an average rpm of about 0 to 250.

HM020: it has 12 to 18 rings and has an overall diameter of about 20 millimeters. The rated current of this device is 1a, and the rated voltage is 240 volts with an average rpm of about 0 to 250.

Can Micro Slip Rings Be Made in Custom Versions?

As described above, the standard micro slip rings are the best possible answer to every installation that you require. Although if there is a different machine that requires something distinct from that, the company is offering there are a variety of choices that one can choose from. These options can vary from the output to the working environment and the expected life. Grand is a tried and tested seller who has been offering reliable products for quite a while now. We ensure that the demands of our clients are met.

At the heart of scientific innovation lies the propensity to refine and adapt—to mold solutions that cater to precise needs. For micro slip rings, the wide berth for customization and adaptability emerges as one of their most formidable strengths. Essentially, they offer the flexibility for design, size, and function modifications to suit virtually any specific requirement or application.

As for the customization possibilities, they are practically limitless. Factors such as rotor and stator designs, the structure of conductive rings, and the materials used for the brushes can all be adjusted as per the requirement. The size of the micro slip ring can be varied, crafting extraordinarily petite versions for intricate applications or elaborating them for higher power capacities or more extensive circuit arrays. The function of the micro slip ring can also be tailored, where one could opt for just power or signal transmission, or in many cases, a simultaneous transmission of both.

In terms of examples, one noteworthy instance could be the development of custom micro slip rings for the space exploration industry. The extraordinarily punishing environment of outer space necessitates designs that can withstand extreme temperature swings, radiation, and vacuum. Hence, space-grade micro slip rings would likely employ specialized low-degradation materials and incorporate designs to increase endurance and longevity.

Another illustrative example can be found in the realm of medical technology. Delicate and precise medical appliances or diagnostic machines often require very compact, low-noise, and highly reliable micro slip rings. These are typically custom-made to ensure accuracy, longevity, and safety, ensuring the optimum performance of life-saving equipment.

In essence, the customization capabilities inherent to micro slip rings underscore their remarkable adaptability. No matter how niche or stringent the requirements, the ability to create bespoke micro slip ring designs ensures their foothold in many fields, catering to a myriad of unique operational demands and technological innovations.

Applications of Micro Slip Rings

The diversity and adaptation capacity of micro slip rings has paved the way for their broad-based adoption across numerous industries. Their capability to deliver reliable and interference-free transmission, despite their compact size and endless rotational possibility, makes them indispensable in certain sectors requiring both rotation and signal or electricity transmission.

An impressive realm of micro slip ring application is within the medical device industry. In computed tomography (CT) scanners, for instance, Medical IP22 micro slip ring play a critical role in ensuring smooth operation. These slip rings facilitate the 360-degree rotation of the X-ray tube and detectors around the patient while maintaining the real-time transmission of significant volumes of high-resolution digital data. The Medical micro slip ring is specifically designed to offer reliable performance in medical environments, providing protection against dust and moisture while ensuring continuous signal transfer. This allows for the production of detailed three-dimensional scan images, which are invaluable for diagnosis and treatment planning.

The world of robotics, particularly industrial automation, and military drones, is another sphere where micro slip rings have established a solid foothold. For instance, in an automated factory assembly line, micro slip rings enable the transmission of power and signals to the rotating parts in robotic arms. Similarly, military drones, provide the continuous power and data transmission required for real-time surveillance and operations.

Furthermore, in defense and aerospace applications, micro slip rings play an essential role, underpinning indispensable systems. For instance, in advanced radar systems, micro slip rings are responsible for uninterrupted signal and power transmission during the radar antenna’s constant rotation, ensuring consistent and real-time updates for security operations.

Surveillance camera systems also harness the power of micro slip rings. They enable the continuous 360-degree pan of the surveillance cameras while maintaining the undisturbed flow of power and live video feeds. Hence, it aids in maintaining continuous observation and far-reaching coverage for the surveillance systems.

Finally, in renewable energy systems — particularly wind turbines, micro slip rings enable the collection and transmission of power from the constantly rotating blades. They also help relay commands and valuable monitoring data between the fixed and rotating components of the wind turbine.

In essence, the applications of micro slip rings stretch to virtually every corner of the modern technological landscape. Their unique features and the possibilities for customization to fit the need make them an integral part of numerous industry sectors, powering vital systems and driving innovations.

Which Company Is Offering the Best Micro Slip Rings?

Navigating the landscape of micro slip ring manufacturers might seem like a herculean task given the several competitors each claiming superiority. While it’s difficult to single out one entity as the absolute best due to varying user requirements, some companies have distinguished themselves through exceptional product quality, unparalleled service, competitive prices, and reputation.

One such company that has left a significant imprint on the micro slip ring industry is Moog Inc. Noted for their attention to detail, innovative design, and the delivery of robust and reliable solutions, Moog’s slip rings have found their way into numerous applications, from medical devices to aeronautics. Case in point, the model 176 Miniature Slip Ring, a compact solution offered by Moog, stands out for its flexible, modular design and its proficiency in handling data and video signals alongside power transfer in a limited space environment.

Another reputable contender is Schleifring, a German manufacturer renowned for its tailored solutions catering to a broad range of applications. Schleifring’s unique advantage lies in its dedicated focus on customizing each product according to client specifications, ensuring precise alignments with specific system requirements. Their multifunctional MF Series, for instance, is revered for its capability to transmit power, signals, and data in one compact unit, marking a game-changer in industries like medical technology and industrial automation.

SenRing Electronics Co., Ltd, a leading Chinese manufacturer, also commands an influential presence in the global market. Their edge lies primarily in their competitive pricing strategy without compromising product quality, making them a favorite among cost-conscious clients. Their SNM012 series, for instance, offers an affordable yet reliable micro slip ring solution for light and compact devices.

In the realm of high-performance and specialty slip rings, Stemmann-Technik stands out. Their expertise in managing complex client demands and providing high-grade custom solutions has made them a favorite within the wind energy sector and heavy industries. An illustrative example would be their extensive portfolio of wind turbine slip rings engineered for high efficiency and durability.

Till now, Grand is providing the best possible answer to this question. The company takes pride in offering a micro slip ring that has low electrical noise, low torque, and isn’t easily destroyed. Although the company is offering standard and general designs in the arena of slip rings, however, it encourages its buyers to contact them for custom orders.

While these companies undoubtedly offer superior quality and services within the micro slip ring industry, users are advised to consider their specific application needs, budget constraints, and specific manufacturer’s proficiency. By doing so, they’ll be able to identify the company that best aligns with their unique requirements, ultimately ensuring their purchase is a value-for-money investment.

Which Micro Ring Is the Best?

This is a question that you need to ask yourself. What kind of machine that you desire to operate? The question is dependent upon many factors, such as the desired volume, the desired size, the space, and where it will be placed. It is also based on characteristic impedance, bandwidth, resistance variation, temperature, rotational speed, voltage drop, and current density. Our Grand slip ring-making company ensures that we make the best use of our knowledge and experience and make products that are of international standards. Our offering the best minimalistic, economical, and micro solutions to its top valued customers.

Determining the “best” micro slip ring hinges on a multitude of factors, including the specific requirements of the user, the intended application, and the environment in which it will operate. Before diving into the recommendations, it’s essential to outline the key evaluation criteria that should be considered when choosing the ideal micro slip ring.

- Needs and Requirements: Ascertain the specific electrical and mechanical requirements needed for the application, such as the number of circuits, the types of signals to be transmitted, and the desired rotational speed.

- Application Environment: Consider the environmental conditions in which the slip ring will operate, including temperature range, humidity, dust, and any other exposure to harsh elements that could impact performance and longevity.

- Size and Integration: Assess the size constraints and mounting options of the slip ring, ensuring it seamlessly integrates with the existing system or device.

- Reliability and Life Expectancy: Evaluate the required durability and life expectancy of the slip ring based on the application’s operational demands, such as continuous or intermittent functioning, number of rotations, and maintenance accessibility.

- Cost and Budget: Weigh the cost of the micro slip ring against its quality and performance, as well as the long-term benefits of reliability and reduced maintenance.

Taking these criteria into account, here are some recommendations for top-rated micro slip rings on the market:

- Moog offers the 176 Miniature Slip Ring: This compact and modular slip ring solution boasts exceptional handling of power, data, and video signals in space-constrained applications. Its excellent performance, especially in medical and robotics applications, makes it a worthy contender.

- Schleifring presents the Multifunctional MF Series: This versatile series excels in transmitting power, signals, and data in a single compact unit. It’s particularly suitable for medical technology, industrial automation, and other environments that require high-precision transmission.

- SenRing’s SNM012 Series: This affordable and reliable micro slip ring solution is ideal for cost-conscious users in need of a compact design for light and small-scale applications, such as miniature sensors, equipment, or devices.

Remember that specific user needs and application requirements play a pivotal role in determining the ideal micro slip ring. To that end, evaluating potential options based on the criteria outlined above will help users identify the micro slip ring that best caters to their unique circumstances and specifications.

The Future of Micro Slip Rings

The future of micro slip rings looks promising, driven by constant technological advancements, the evolution of industry needs, and the continuous push for more compact, efficient, and reliable rotating electrical connectors. Innovations in related fields like material science, computer modeling, and miniaturization techniques are promising exciting developments that will likely revolutionize the way we understand and use micro slip rings.

One of the key trends taking shape in the industry is the integration of smart technology into slip rings. Increased focus on real-time monitoring, predictive maintenance, and enhancing reliability will drive the growth of smart micro slip rings with built-in sensors capable of monitoring various operational parameters. These innovative units could potentially alert users about maintenance needs or potential breakdowns before they occur, thus minimizing downtime and ensuring constant operational efficiency.

Moreover, material advances, particularly the exploration and use of more conductive, durable, and wear-resistant materials in micro slip ring design, will further drive their performance and longevity. This improvement will undoubtedly increase their appeal in industries that prioritize robustness and longevity, such as defense, aerospace, and heavy machinery.

The miniaturization trend is also set to dominate the future of micro slip rings. As industries like healthcare, consumer electronics, and nanotechnology continue to demand more compact and intricate solutions, the development of even smaller yet highly efficient slip rings will become increasingly prevalent.

Finally, the possibility of wireless power and data transmission could potentially impact the future of micro slip rings. However, considering the current limitations in terms of transmission distance, efficiency, and safety of wireless technologies, micro slip rings still hold an inherent advantage, particularly in applications where unending rotations are required.

In conclusion, the continuous evolution and adaptation of micro slip rings to meet emerging industry needs and take advantage of technological advancements is poised to drive significant strides in the field. Through constant research, development, and innovation, the future of micro slip rings holds exciting potential and promises a paradigm shift in how we understand and employ these essential connectors.

Conclusion

The journey through the realm of micro slip rings brings us to a point of reverence for these versatile, tiny devices. From their evolution to the prediction of their promising future, micro slip rings prove to be instruments of progressive change in various industries.

FAQ about Micro Slip Ring

Answering common questions concerning micro slip rings can be conducive to enhancing understanding and clarifying any misconceptions one might harbor. Here are some frequently asked queries and explanations meant to provide insights and facilitate a better comprehension of micro slip rings:

Q: What is a micro slip ring?

A: A micro slip ring is a compact device that enables the transmission of power or data signals from a stationary structure to a rotating one. Designed with a small form factor, these slip rings are particularly apt for applications with space constraints, yet require continuous rotation and signal transmission.

Q: How does a micro slip ring work?

A: The working principle of micro slip rings revolves around the concept of continuous electrical connectivity. Comprised of rotating and stationary components, the micro slip ring maintains an uninterrupted electrical connection regardless of the motion involved. The signals or power is transferred through brushes that come into contact with the rotating element.

Q: Where are micro slip rings used?

A: Micro slip rings find application in several industry sectors such as medical (CT scanners and MRI machines), defense (radar systems), surveillance (CCTV cameras), robotics, and renewable energy (wind turbines). Their value lies in providing undisturbed electricity or signal transmission, despite continuous 360-degree rotation.

Q: How long does a micro slip ring last?

A: The lifespan of a micro slip ring can significantly vary based on factors like operational conditions, usage intensity, and the quality of the slip ring itself. However, high-quality micro slip rings designed for demanding applications usually possess a life expectancy of millions of rotations when employed under recommended conditions.

Q: Can micro slip rings transmit data?

A: Yes, micro slip rings can transmit various types of signals, including data. They are capable of handling everything from analog and digital signals to high-speed data, and even video signals linked to high-resolution surveillance or medical imaging.

Q: Are micro slip rings expensive?

A: The cost of micro slip rings can vary widely based on their specification, size, and manufacturer. High-performance or highly customized slip rings may command a higher price compared to their standard counterparts. However, with the market’s expansion, there are solutions available for various budget constraints without compromising crucial performance characteristics.

See What We Can Do