Wind turbines are specially designed to rotate to face the wind and extract as much power as possible. As the wind direction changes frequently, this can cause the wind turbine generator to become twisted. They usually untwist themselves amid the windless periods. Otherwise, the wires can be damaged, and contacts are lost with severe consequences. Wind rings and slip rings are the right solution for dealing with this problem.

Importance of Wind Turbine Slip Ring

The market for wind turbine service is rising exponentially as turbines age, and asset owners are looking for different methods to control maintenance expenses while increasing the accessibility of the wind turbines and their yields. Innovative solutions are required to replace the traditional slip rings in turbines with high-reliability, long-term designs that could operate without maintenance for extended periods. Many models used today require regular maintenance to clean corrosion residue, remove oils, dirt, and re-lubricate, with slip ring replacement occurring at short intervals. As producers are pushed to use more cost-effective gears, operators are encouraged to fit in products that reduce the need for expert maintenance, thereby increasing profitability. This highlights the importance of wind turbine slip ring selection—choosing the right slip ring for the turbine system can significantly reduce maintenance costs and increase operational efficiency. Advanced slip ring solutions with robust designs, capable of withstanding harsh environmental conditions, can ensure longer intervals between replacements and minimal maintenance, ultimately boosting the turbine’s performance and profitability.

The application of wind turbine slip rings focuses on at least two main points. First, as the design of the turbines increases the production and power output, the demand for a slip ring is a higher energy transfer. Secondly, the data as well as the signal processing necessities rise to offer added monitoring of the hub’s status. Communication technologies must be robust enough to handle energy spikes at the end of the process. It is also essential to keep the data lines safe from potential interference from the lines. In the case of slip ring failure, the communication data as well as the data cannot be conveyed to the pitch mechanisms along with other control that could stop wind turbines. This is the reason why producers have introduced slip rings specially designed for wind turbines that last longer and require less maintenance.

The Functioning of Wind Turbine Slip Rings

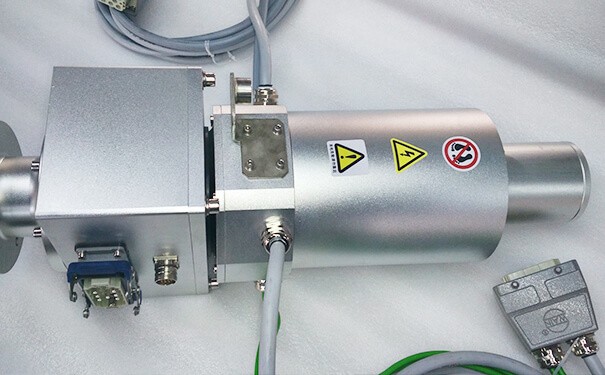

The wind turbine slip rings are in charge of the power of the whole wind system and data transmission and control signals. Its reliability, lifetime, and accuracy will affect wind power generation system performance directly. Wind turbines need a consistent power supply along with a signal for data transmission between the control system and the cabin of rotary blades. Wind turbine slip rings are based on the design of an adjustable lap joint, an ingenious seal and movement structure, a rolling lap as well as precision parts, a selection of reasonable materials, etc. Form a stable and reliable rotary communication system. The wind turbine slip rings offer the performance and quality required in this challenging environment. Slip ring for pitch control for wind turbine design directions at least two points, one requiring higher energy transfer for pitch slip ring due to the increase in power and size. Another monitors the conditions to indicate data and signal handling in the center as additional requirements. In the face of maximum strength under extreme operating conditions, knowing about the real situations and the durable brush technology and the brush contact must be lasting.

The slip ring offers reliable signal and power transmission from the stationary cables from the creel to the hub rotary equipment. The slip ring grouping is frequently a wire brush that is made of precious and strong metal, which comes into contact with the external diameter of the rotating metal ring. As the ring rotates, the electrical current or signal passes through the brush to the metal ring for connection. Extra ring brush groupings are placed along the rotating axis for the added electrical circuits. Look for the increased slip ring activity to control the new step in the aftermarket.

How can Wind Turbine Slip Ring be Beneficial?

If you are thinking of the application trend of wind turbine slip rings, here are some of them mentioned as follows

Complete Pitch Control

The search for high reliability has prompted some companies to design non-contact slip rings. One is a power transmission device coupled by induction. Complete pitch control is another application of a wind turbine slip ring. This will consist of blade monitoring, pitch-drive motors, slip ring channels, hub controls as well as power back-up to transport control signals as well as power employing a rotary interface.

Reliable Power and Data Signals Transmission

Reliable power and data signal transmission is required from the nacelle to the rotary blade control system. A slip ring is utilized to convert electric current from a fixed to a rotating unit. Slip rings are small components, but the hardware does an important job. Like other turbine components, faults or malfunctions in the device can cause interference in the functioning of the turbine.

Ensures Efficiency

A wide range of circuits is available depending on energy needs, with many combinations of current and voltage (AC or DC). Today’s advanced designs can transfer more energy with less energy loss. Power transmission capacity and power loss can be affected by several factors, so slip rings specially designed for wind turbine applications, are often recommended to ensure correct power and operation. The slip ring delivers wireless power along with the data to control the path of wind turbines, consequently improving productivity by cutting maintenance as well as replacing the current mechanical slip ring expenditures.

Reduced Maintenance and Increased Output

Most wind turbine operators agree that fewer maintenance towers in the upper tower are preferable. Replacing slip ring brushes is time-consuming and expensive, making long maintenance times ideal. However, the traditional slip rings need frequent maintenance to avoid the degradation of the rotating electrical connection that is caused by regular wear. Manual cleaning and lubrication are mainly eliminated with metallic steel slip rings. Higher spring pressure than the traditional slip rings can help clean the ring as it turns.

Summing It UP

Wind turbine slip rings deliver the quality and performance required in challenging environments. Excessive downtime is removed by using fiber brushes along with powerful mechanical gears while designing the slip rings.

See What We Can Do