A critical component in many high voltage and high current applications is the high voltage slip ring, used to transmit high voltage power and signals from stationary to rotating components. The integration of high voltage/high current slip ring technology further enhances their capability to handle both high voltage and high current transmission in demanding environments. A high voltage slip ring is an electrical connector widely used in wind turbines, medical equipment, military radar, and other industries. In this article, we will explore the basics of high voltage slip rings and their operation.

Answering the Questions

What is a High Voltage Slip Ring?

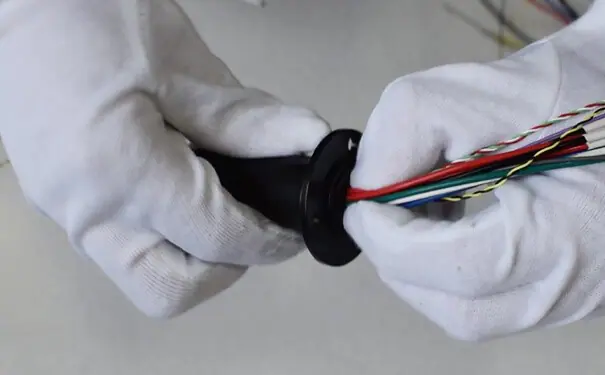

A high voltage slip ring is an electrical connector that allows the transmission of high voltage electrical power and signals from a stationary to a rotating component. It consists of a stationary brush holder, a rotating brush holder, and a rotating ring assembly. The rotating ring assembly is typically made of high-quality insulating materials and conductive metal alloys.

Key Characteristics:

- High Voltage Capacity: Capable of transmitting electrical power at high voltages, often exceeding several kilovolts, without compromising performance or safety.

- Insulation: Equipped with superior insulation materials to prevent electrical arcing and ensure safe operation under high voltage conditions.

- Durability: Built to withstand the mechanical stresses and thermal loads associated with high voltage transmission in rotating applications.

- Customizability: Often tailored to meet specific requirements, including the number of circuits, voltage ratings, and physical dimensions.

Uses:

- Wind Turbines: Used to transfer power from the rotating blades to the stationary nacelle, enabling efficient energy generation.

- Medical Equipment: Essential in high-voltage medical imaging devices, such as MRI and CT scanners, where reliable power transmission is crucial.

- Industrial Machinery: Employed in rotating machinery and equipment that requires high voltage power transmission, such as heavy-duty cranes and cable reels.

- Aerospace and Defense: Utilized in various aerospace and defense applications, including radar systems and rotating communication antennas, where high voltage and reliable power transmission are necessary.

Benefits:

- Efficient Power Transfer: Ensures seamless transmission of high voltage power from stationary to rotating parts, enhancing the efficiency of the system.

- Enhanced Safety: Designed with advanced insulation and protective features to minimize the risk of electrical hazards.

- Reliability: Provides consistent performance in demanding applications, ensuring uninterrupted operation of high voltage systems.

- Versatility: Can be customized to suit a wide range of high voltage applications, making it a versatile solution for various industries.

High Voltage Slip Rings play a critical role in enabling the safe and efficient transmission of high voltage power in rotating systems across multiple industries.

How Does a High Voltage Slip Ring Work?

A high voltage slip ring works by providing a rotating electrical connection between a stationary and a rotating component.When the rotating part rotates, the rotating brush holder and rotating ring assembly contact the fixed brush holder connected to the fixed part. This allows power and signals to be transmitted from stationary to rotating parts without the need for cables or wires.

A High Voltage Slip Ring works by providing a continuous electrical connection between stationary and rotating parts of a system, allowing the transmission of high voltage power and signals. Here is a detailed explanation of how it operates:

Components:

- Rotating Ring (Rotor): The part of the slip ring that rotates along with the equipment it is attached to.

- Stationary Brushes (Stator): The part that remains stationary and maintains contact with the rotating ring.

- Insulation: High-grade insulating materials used to prevent electrical arcing and ensure safe transmission of high voltage.

- Housing: The protective casing that encloses the internal components and provides structural integrity.

Operation:

- Electrical Connection: The stationary brushes are connected to the high voltage power source or signal source. The rotating ring is connected to the load that requires the power or signal.

- Continuous Contact: As the rotating ring (rotor) spins, the stationary brushes (stator) maintain continuous electrical contact with the ring. This ensures an uninterrupted flow of electricity from the stationary part to the rotating part.

- Transmission of Power/Signals: The high voltage power or signals are transmitted through the brushes to the rotating ring. The electrical current flows from the stationary brushes to the rotating ring, then to the load.

- Insulation and Safety: The slip ring is designed with high-quality insulation to prevent electrical arcing, which can occur when high voltage electricity jumps from one conductor to another. The insulation ensures that the electricity flows through the designated path, maintaining safety and efficiency.

- Heat Dissipation: High voltage slip rings are often equipped with mechanisms to dissipate heat generated due to electrical resistance and friction between the brushes and the rotating ring. This helps maintain the slip ring’s performance and longevity.

A High Voltage Slip Ring functions by maintaining continuous electrical contact between stationary brushes and a rotating ring, allowing the safe and efficient transmission of high voltage power and signals from stationary to rotating components. Its design includes high-grade insulation and heat dissipation mechanisms to ensure safety, reliability, and longevity in various high voltage applications.

What Are the Applications of High Voltage Slip Rings?

High Voltage Slip Rings are used in various industries where there is a need to transmit high voltage power and signals from a stationary part to a rotating part. Here are some of the key applications:

Wind Turbines

- Function: Transfer the electrical power generated by the rotating blades to the stationary nacelle.

- Importance: Enables efficient energy transmission from the turbine to the grid, ensuring consistent power output.

Medical Equipment

- Devices: MRI machines, CT scanners, and other high-voltage imaging systems.

- Function: Transmit high voltage signals required for imaging processes from stationary components to rotating parts.

- Importance: Ensures the accurate and efficient operation of medical imaging equipment.

Industrial Machinery

- Machinery: Heavy-duty cranes, cable reels, rotating machinery.

- Function: Transmit high voltage power to rotating components, such as motors and control systems.

- Importance: Enhances the operational efficiency and safety of industrial equipment.

Aerospace and Defense

- Applications: Rotating radar systems, communication antennas, satellite systems.

- Function: Ensure reliable transmission of high voltage power and signals to rotating parts of the systems.

- Importance: Critical for the precise and uninterrupted operation of defense and aerospace equipment.

Energy and Power Generation

- Applications: Hydro turbines, gas turbines, and other power generation systems.

- Function: Transmit power generated in rotating parts to the stationary parts of the system.

- Importance: Facilitates efficient energy transmission, contributing to overall power generation efficiency.

Rotating Platforms and Tables

- Applications: Rotary indexing tables, rotating stages, and platforms used in manufacturing and testing.

- Function: Provide continuous power and signal transmission to rotating platforms.

- Importance: Ensures uninterrupted operation of rotating machinery in manufacturing and testing processes.

Robotics and Automation

- Applications: Rotating joints in robotic arms, automated manufacturing systems.

- Function: Transmit power and signals to the rotating joints and components.

- Importance: Enhances the flexibility and functionality of robotic and automated systems.

Marine and Offshore Equipment

- Applications: Rotating equipment on ships and offshore drilling platforms.

- Function: Provide reliable transmission of power and signals to rotating parts in harsh marine environments.

- Importance: Ensures the safety and efficiency of marine operations and offshore drilling activities.

Amusement Rides

- Applications: Rotating rides and attractions in amusement parks.

- Function: Transmit power and control signals to the rotating parts of rides.

- Importance: Enhances the safety and reliability of amusement park rides.

Renewable Energy Systems

- Applications: Solar tracking systems, wind energy converters.

- Function: Transmit power and signals in systems that involve rotating components for optimal energy capture.

- Importance: Contributes to the efficiency and effectiveness of renewable energy systems.

High Voltage Slip Rings are essential components in these applications due to their ability to handle high voltage levels while ensuring continuous and reliable transmission of power and signals. They are designed to withstand the specific demands of each application, including environmental factors, mechanical stress, and electrical requirements.

High Voltage Slip Rings VS Low Voltage Slip Rings

High Voltage Slip Rings and Low Voltage Slip Rings are designed to transmit electrical power and signals between stationary and rotating components, but they differ significantly in their applications, design, and capabilities. Here’s a detailed comparison:

Voltage Capacity

- High Voltage Slip Rings:

- Capacity: Can handle high voltage levels, typically in the range of several kilovolts (kV) or more.

- Applications: Suitable for systems requiring high voltage power transmission, such as wind turbines, medical imaging equipment, and industrial machinery.

- Low Voltage Slip Rings:

- Capacity: Designed for lower voltage levels, usually up to a few hundred volts.

- Applications: Used in applications where only low voltage power and signals are required, such as consumer electronics, small industrial equipment, and automation systems.

Insulation

- High Voltage Slip Rings:

- Insulation: Features superior insulation materials to prevent electrical arcing and ensure safe operation under high voltage conditions.

- Design Considerations: Requires robust insulation to handle high electrical stresses.

- Low Voltage Slip Rings:

- Insulation: Uses standard insulation materials adequate for lower voltage levels.

- Design Considerations: Insulation needs are less stringent compared to high voltage slip rings.

Applications

- High Voltage Slip Rings:

- Wind Turbines: Transmitting power from rotating blades to the stationary nacelle.

- Medical Equipment: MRI machines and CT scanners.

- Industrial Machinery: Heavy-duty cranes, rotating machinery.

- Aerospace and Defense: Rotating radar systems, communication antennas.

- Low Voltage Slip Rings:

- Automation Systems: Rotating joints in robotic arms.

- Consumer Electronics: Devices that require rotating electrical connections.

- Office Equipment: Rotating mechanisms in printers and scanners.

- Light Industrial Equipment: Small rotating machinery.

Durability and Maintenance

- High Voltage Slip Rings:

- Durability: Built to withstand mechanical stresses and thermal loads associated with high voltage transmission.

- Maintenance: Typically requires more maintenance due to higher operational stresses and potential for wear in high voltage environments.

- Low Voltage Slip Rings:

- Durability: Designed for less demanding environments.

- Maintenance: Generally requires less maintenance, given the lower operational stresses.

Size and Complexity

- High Voltage Slip Rings:

- Size: Often larger due to the need for additional insulation and cooling mechanisms.

- Complexity: More complex design to ensure safety and reliability under high voltage conditions.

- Low Voltage Slip Rings:

- Size: Typically smaller and more compact.

- Complexity: Simpler design, as high voltage safety measures are not required.

Cost

- High Voltage Slip Rings:

- Cost: Generally more expensive due to the use of high-grade materials and complex manufacturing processes.

- Investment: Represents a significant investment due to their specialized applications and robust construction.

- Low Voltage Slip Rings:

- Cost: Less expensive, with lower material and manufacturing costs.

- Investment: More affordable and suitable for a wide range of standard applications.

High Voltage Slip Rings are essential for applications requiring the transmission of high voltage power and signals, characterized by their robust insulation, durability, and ability to handle significant electrical and mechanical stresses. They are used in critical and demanding environments like wind turbines, medical imaging, and industrial machinery.

Low Voltage Slip Rings, on the other hand, are suitable for less demanding applications where lower voltage power and signals are sufficient. They are more compact, easier to maintain, and cost-effective, making them ideal for consumer electronics, automation systems, and light industrial equipment.

Choosing between High Voltage and Low Voltage Slip Rings depends on the specific requirements of the application, including the voltage level, environmental conditions, and budget considerations.

What Makes High Voltage Slip Rings Different?

If you are using high-voltage and high-current applications and want to transmit high-voltage and high-current but do not want to use cables or wires, you can consider using high-voltage slip rings; worry that high-voltage slip rings cannot perform their due functions in harsh environments? Don’t worry, even the environment of high temperature, high corrosion and high humidity, high pressure slip ring can adapt.

Conclusion

From the above introduction of basic information on how high voltage slip rings work, scope of application, etc., it can be concluded that high voltage slip rings can transmit power and signals from stationary parts to rotating parts without cables or wires; suitable for many high voltage and high current applications ; It can also play a good role in harsh environments.

Frequently Asked Questions

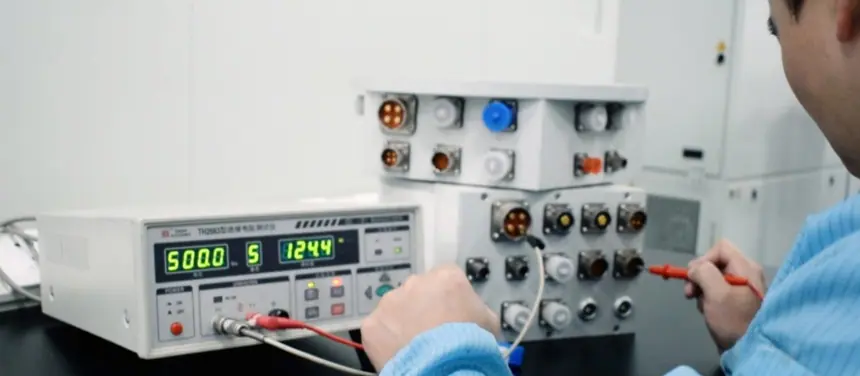

Q: How Much Rated Voltage or Current Can High-Voltage Slip Rings Withstand?

A: Rated voltage: hundreds of volts to tens of thousands of volts; rated current: several amps to hundreds of amps; of course, accurate ratings can also be selected according to the application.

Q: How Are High Voltage Slip Rings Constructed?

A: High voltage slip rings are typically constructed using high-quality insulating materials and conductive metal alloys, such as copper, silver, and gold.

Q: What Are Some Common Applications of High Voltage Slip Rings?

A: High voltage slip rings are commonly used in wind turbines, medical equipment, military radars, robotics, and many other high voltage and high current applications.

See What We Can Do