Electrical Slip rings from https://www.grandslipring.com/electrical-slip-ring/ are used in electrical engineering to transfer power, motion, and energy. Electrical Slip rings have many different uses such as electric motors, generators, generators for induction machines, electric power transmission lines, and high-voltage circuits.

What Are Electrical Slip Rings?

They are used to transmit electrical energy from a stationary to a rotating machine. They are mainly used in heavy machinery, and for the transmission of power from one point to another. The Electrical slip rings are also known as rotary electrical contacts. It consists of a number of conductive elements that are connected to the rotating shaft of the machine.

There is a mechanical arrangement by which these conductive elements rotate on their axis while moving in an arc over the surface of the shaft. These rings consist of:

- Electrical slip ring segments or brush assemblies

- Segment housing or carrier, and;

- Segment mounting hardware (screws, etc.)

Industrial Applications for Electrical Slip Rings

Electrical slip rings are used in the power industry to connect rotating machines with electrical generators, motors, or other devices. They can be made of metal and have a magnetic field that allows them to rotate freely around an axis without slipping. The ring is connected by means of brushes which make contact when they move past each other on opposite sides (or poles) of the ring’s center point – this creates a closed circuit where energy can flow from one side to another as needed.

The Electrical slip rings are used in the following applications:

- In rotating machines and motors, and;

- In other industrial applications where rotation is required.

How to Choose the Best Electrical Slip Rings?

The following are the factors to be considered before choosing Electrical slip rings:

- Type of Industry: – the selection of Electrical slip rings depends on the type of industry where it is going to be used. The type of application will determine how much current the motor will draw, how high the voltage will be, and other such factors.

- Process requirements: – whether or not the process requires a permanent or removable connection, whether or not there should be an interruption in power when making connections, and if so what kind of interruption are they looking for (a momentary loss, a break contact, etc.).

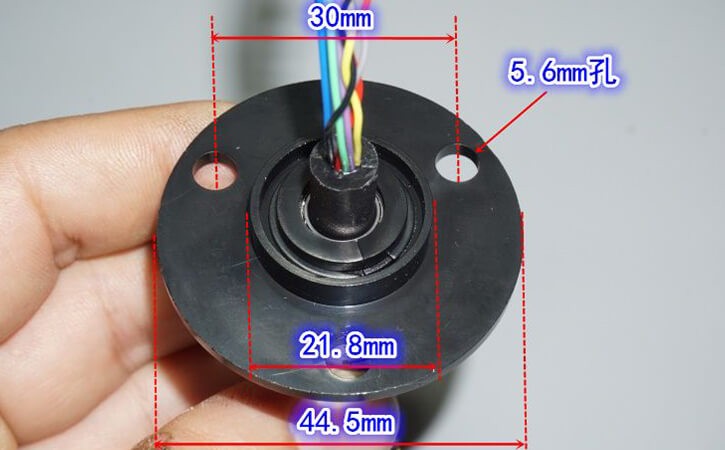

- Size and shape: – this will depend on whether you need a single axis or multi-axis Electrical slip rings, and whether you need single or dual concentric Electrical slip rings.

- The environment: – will the Electrical slip rings be exposed to extreme heat, extreme cold, or both? Will it be used in an electrically noisy environment? Is there any possibility of water damage? Will the Electrical slip rings be used in a corrosive environment? All these factors will determine the type of material required to make the Electrical slip rings and also the coating that needs to be applied to them.

- Other considerations: – what is the voltage rating of the Electrical slip rings? What is its current rating? Is it required to have any special features like disconnect switches or fuse protection? What is its life expectancy (in hours)? What is its cost?