Designed for high-speed operation and frictionless performance, air precision slip rings have created a significant impact in numerous industries. This article provides comprehensive insights into these innovative devices, discussing their key components, operation principles, advantages, applications, selection considerations, and future trends.

Introduction to Air Precision Slip Rings

In the realm of electro-mechanical devices that facilitate power, data, or signal transmission from a fixed to a rotating structure, a particular type of slip ring has begun garnering widespread attention for its superior performance and design—air precision slip rings.

The fundamental purpose of an air precision slip ring is nearly identical to a traditional slip ring; they facilitate seamless electricity or signal transfer between a stationary and rotating part, enabling continuous rotation without the hindrance of entangled wires. The uniqueness of air precision slip rings lies in their operational mechanism. Unlike conventional models that depend on direct physical contact for the transmission, these devices employ precision air gaps, creating a contactless communication link. The sophisticated technology behind this design eliminates issues related to mechanical wear, enhancing durability and reducing the need for recurrent maintenance.

If manufacturing industries were to be thought of as a well-orchestrated symphony, then air precision slip rings are the unsung maestros behind the seamless harmony. The promise of constant, uninterrupted rotations has profound implications across vast sectors, from wind turbines that generate renewable energy to medical imaging devices that pivot around a patient, or even in the realm of telecommunications where satellite dishes must orient themselves towards their respective satellites. By ensuring that these components can rotate without any hindrance or degradation in power or signal quality, air precision slip rings play a quietly pivotal role in keeping numerous industries operational and efficient.

Their applicability is equally significant in the field of robotics, where precision, durability, and minimal maintenance are paramount. In the ever-evolving world of robotics, where reliable, constant rotations are key to successful functioning, air precision slip rings provide the reliability and performance needed.

Therefore, while the concept of air precision slip rings might initially seem relegated to very niche technological and industrial applications, their influence is interwoven deeply into the fabric of numerous systems and industries. As we progress further into the era of automation and advanced technology, the relevance and applications of these innovative devices only continue to proliferate.

Key Components and Working Principles of Air Precision Slip Rings

To fully appreciate the role of air precision slip rings, understanding their fundamental components and working principles is essential. These devices encompass some critical elements that serve unique functions, contributing to the coherent operation of the entire system.

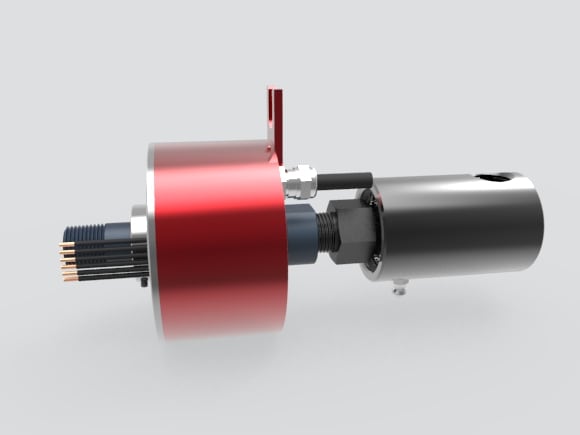

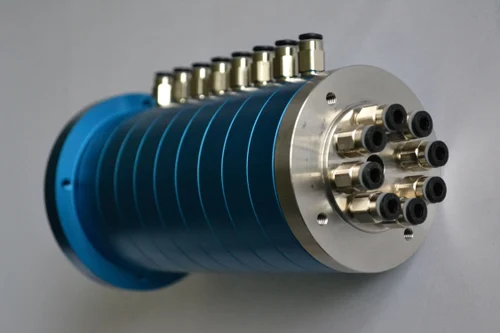

The core of every air precision slip ring is divided into two main parts: the rotor and the stator. The rotor – a rotating part of the slip ring, carries a conductive circle attached to the device that needs to rotate. The stator, on the other hand, remains stationary and contains brushes that align with the conductive circle on the rotor. In conventional slip rings, these brushes physically contact the rotating part, leading to inevitable wear and tear over time.

Air precision slip rings, however, incorporate a vital twist into this arrangement. Instead of the physical contact that defines the stator and rotor relationship, these slip rings employ precision air gaps. These gaps create an almost contactless link between the stationary and rotating parts, a novel approach that significantly reduces mechanical friction and related wear.

The fundamental working principle of air precision slip rings is deeply rooted in the laws of electromagnetic induction. As the rotor containing the conductive circle rotates, the alternating magnetic field generated crosses the air gap and interacts with the brushes on the stator. This induces a current in the stator brushes, transmitting electric power or signal without any physical contact. Contactless communication ensures a smooth, frictionless operation, reducing wear and tear, and increasing the lifespan of the devices they are used in.

The method of operation of air precision slip rings is defined by seamless, practically maintenance-free operation. By maintaining a small but critical air gap, these slip rings ensure consistent, noiseless transmission of power and signals, advancing the application’s performance and efficiency.

Hence, the intrusion of air precision slip rings into numerous industries is largely driven by their innovative design and working principle. By strategically leveraging the principles of electromagnetic induction, these slip rings have perpetuated a new age of operational efficiency with minimal mechanical wear, bearing substantial implications for various technological and industrial applications.

Advantages of Air Precision Slip Rings

Air precision slip rings are rapidly growing in popularity due to the landmark advantages they bring to numerous industries. These benefits range from performance improvement to minimized wear, and reduced maintenance, greatly magnifying the efficient functioning of devices in which they are incorporated.

When comparing these high-tech slip rings to conventional ones, a variety of distinct advantages come into play. One of the biggest selling points of air precision slip rings lies in their ability to improve performance drastically. The non-contact method of operation allows for frictionless, high-speed rotations, ensuring a smooth, uninterrupted flow of power or signals. This makes them ideal for applications that require constant and reliable rotations, like wind turbines, medical imaging devices, and satellite communication systems. Conventional slip rings, due to their contact-based operation, often face performance degradation over time from wear and tear— a problem air precision slip rings effectively bypass.

Moreover, minimized wear is a monumental advantage of these innovative slip rings. Traditional slip rings experience steady mechanical wear due to continuous physical friction between the brushes and the rotating parts. This frequent friction results in wear and tear, reducing the overall life of the device. Air precision slip rings, thanks to the air gap in their design, operate virtually without any physical friction. This gameplay of physics allows for significantly less wear on the slip ring components, extending the lifespan while maintaining performance quality.

As a direct consequence of reduced wear and tear, air precision slip rings also require substantially less maintenance than conventional slip rings. For industries where any downtime can lead to significant losses, this feature is particularly beneficial. The lower maintenance requirements equate to fewer interruptions to operations, lower maintenance costs, and ultimately, higher productivity. With minimal wear, there’s less need for regular brush or rotor replacements, hence lowering the overall operational expenses.

In sum, air precision slip rings offer a slew of advantages over their conventional counterparts. By improving performance, minimizing wear, and reducing maintenance burden, these ground-breaking devices are revolutionizing various industrial and technological applications, rendering the incumbents a part of a bygone era.

Applications and Industries Benefiting from Air Precision Slip Rings

Air precision slip rings serve as the innovative backbone of numerous applications across a plethora of industries. With their seamless, high-speed operation, and maintenance-friendly design, these devices have found their footing in various avenues ranging from robotics to aerospace, medical equipment, and beyond.

Starting with the rapidly advancing realm of robotics, air precision slip rings prove to be a boon. In this automation-heavy sector, the need for constant, reliable rotation is ever-present, be it for robotic arms in a production line or advanced drones used for exploration. The frictionless, high-speed functionality of these slip rings ensures an uninterrupted flow of power and data, enabling fluid and precise movements in robots, and enhancing the efficiency of robotic systems. Their minimized wear and maintenance requirements further make them an ideal choice for the heavy-duty operations involved in robotics, reducing the downtime significantly.

In medical technology, precision and reliability are paramount. Applications such as CT scanners and MRI machines, which rely heavily on rotating structures, greatly benefit from the use of air precision slip rings. These devices ensure a predictable, smooth operation, providing accurate and consistent data transmission—an essential aspect when dealing with life-saving medical equipment.

The aerospace industry is another important sector where these innovative slip rings come into play. In satellite communication systems, the capability of seamless data and signal transmissions is crucial, making air precision slip rings a valuable asset. They ensure the unhindered transmission of power, data, or signals from a stationary structure to a rotating satellite dish—an operation that would be difficult, if not impossible, without them.

In conclusion, the versatility and robustness of air precision slip rings have far-reaching applications covering several industries. By revolutionizing the operations in sectors such as robotics, medical imaging technology, and aerospace, they effectively enhance productivity and efficiency. Their role in shaping industrial standards and catalyzing advancements is undeniable, paving the way for a future driven by innovation and performance reliability.

Selection Criteria for Air Precision Slip Rings

The decision to select an ideal air precision slip ring requires an intricate understanding of various factors. It is not merely a box-checking exercise but involves considering an array of key aspects such as material quality, performance specifications, manufacturer reputation, and customization options.

Foremost, the quality of materials used in the slip ring is vital in its durability and performance. High-quality materials denote a well-constructed, robust slip ring that can withstand extensive use over the long term. It ensures that the slip ring will effectively maintain the air gap, which is essential for the contactless transmission of signals and power. Material selection is especially crucial for applications experiencing harsh or extreme operating conditions, where lower-quality materials might degrade rapidly, resulting in premature failure or performance issues.

Next, performance specifications represent an indispensable aspect of the selection process. Every application has unique demands, and the selected slip ring should deliver optimal performance under these specific conditions. Key performance indicators include rates of data or power transmission, rotational speed, and the ability to function in the intended environmental conditions. Understanding these specific performance requirements can help ensure the chosen air precision slip ring meets or exceeds the application’s operational demands.

The reputation of the manufacturer carries significant weight in the selection process. Manufacturers with a solid track record for delivering reliable, high-quality air precision slip rings can often be a safer choice. Customer reviews, industry awards, and years in service can all shed light on the standing of the manufacturer in the market – a cue that might speak volumes about the product quality they offer.

Finally, customization options warrant consideration. No two applications are identical, and sometimes, a one-size-fits-all solution might fall short. In such cases, the availability of customization becomes crucial. Whether it’s a specific shape or size, unique electrical configurations, or provision for special cables, manufacturers who offer customization can help tailor the air precision slip ring to the precise needs of an application.

In summary, selecting the ideal air precision slip ring involves a detailed examination of the material quality, performance specifications, manufacturer’s reputation, and availability of customization. By prioritizing these key factors, one can ensure a wise and informed selection that effectively caters to the unique requirements of the application, thereby enhancing its overall efficiency and longevity.

Maintenance and Lifespan of Air Precision Slip Rings

Despite their design that promises reduced wear and tear, air precision slip rings still require a certain degree of maintenance to ensure their optimal functioning and maximize their lifespan. Adopting best practices for maintaining these devices is critical to their performance and longevity.

One fundamental practice is regular inspections. Even though air precision slip rings aren’t susceptible to typical wear from physical contact, periodic visual inspections can help detect any irregularities or potential problems early, such as damaged wires or abnormal vibrations. Early detection can lead to prompt corrective measures, preventing possible complications and costly breakdowns.

Another important maintenance routine is cleaning. Dust, moisture, or accumulated debris within the slip ring can adversely impact its performance. They may obstruct the air gap, thus interfering with the contactless transfer of data or power. Regularly cleaning the slip ring with suitable cleaning agents decreases the likelihood of such disruptions thereby sustaining performance.

Lubrication, too, holds an essential place in the maintenance schedule. Although the air gap reduces friction, the rotational parts of the slip ring may still require occasional lubrication to ensure smooth operation. It’s important to use the correct type and quantity of lubricant, as indicated by the manufacturer, to avoid any adverse effects.

Adopting preventive maintenance measures can drastically extend the lifespan of air precision slip rings. This includes routinely tracking performance metrics and addressing any performance degradation proactively. Additionally, strictly adhering to the operating conditions stipulated by the manufacturer—like temperature, rotational speed, and maximum power or data transfer rates—will also enhance the longevity of these devices.

In conclusion, despite the reduced maintenance needs of air precision slip rings as compared to their conventional counterparts, the implementation of regular inspections, timely cleanings, appropriate lubrication, and preventive maintenance can greatly prolong their lifespan. These practices not only extend the operational life of the slip ring but also ensure repeated rounds of reliable performance, making them an asset to any application they serve.

Innovations and Future Trends in Air Precision Slip Rings

The landscape of air precision slip rings is teeming with innovative trends and technological advancements that illuminate a promising future. Several cutting-edge developments are poised to shape the way these components operate and are integrated into diverse systems, bolstering their functionality.

One of the significant trends underway is miniaturization. As devices become more compact and space-saving designs become a priority, the demand for smaller yet efficient air precision slip rings is on the rise. Engineers are finding ways to shrink the size of these slip rings without compromising their performance, opening up possibilities for new applications in space-constrained environments, for instance in compact drones or miniature medical devices.

The advent of IoT (Internet of Things) technology is also leaving its mark on the sector. Implementing IoT in the design of air precision slip rings could enable real-time performance monitoring, predictive maintenance, and even advanced connectivity options. This development would not only streamline operations and maintenance routines but also amplify the interoperability of the slip rings with the connected ecosystem, thereby enhancing system-level performance.

Further, the exploration of smart materials brings in a wave of potential advancements. Nanotechnology, for instance, might give rise to slip rings that can self-repair minor wear or automatically adjust functions in response to environmental changes. Deploying such smart materials could significantly improve durability, performance, and maintenance practices.

Improved integration emerges as another promising trend in this sector. Close collaboration between slip ring engineers and system designers could facilitate the creation of slip rings that are intuitively integrated into the systems they serve. Such holistic designs can improve system efficiency, streamline installation processes, and reduce the occurrences of integration-related issues.

In conclusion, the future of air precision slip rings is brimming with innovation, thanks to miniaturization, IoT technology, smart materials, and improved integration. These trends are likely to augment the capabilities of these crucial components, making them even more adaptive, responsive, and efficient in the evolving landscape of industrial and technological applications.

Conclusion

With their innovative design and advantages, air precision slip rings are reinventing the wings of various industries and technological applications. Enhancing operational efficiency while minimizing maintenance, they set the stage for more complex and efficient systems, propelling us further into a heightened technological era.