This article serves as an all-encompassing guide to understanding Air Rotary Unions, a critical component in modern industries. From its basic definition, historical background, and types, to its applications, benefits, and maintenance, we explore every facet to provide a thorough perspective on these indispensable devices.

Introduction to Air Rotary Union

The very essence of most industrial processes is the efficient and precise transfer of various forms of energy, fluids, or gases. At this intersection, a simple yet critical device known as the Air Rotary Union plays a pivotal role.

Definition of Air Rotary Union

An Air Rotary Union, also termed a rotary joint or swivel joint, is a mechanical device designed specifically to transmit air or gas from a stationary supply line and into a rotating piece of machinery while maintaining a perfect seal. It alleviates the challenge of preserving a leak-proof connection between a stationary input and a rotating output. Typically, the stationary component—connected to a pneumatic or gas source—serves to supply a rotating part with pressurized air or gas. In essence, the Air Rotary Union ensures a constant, uninterrupted flow of air or gas to some parts of a machine that are in continuous rotational or oscillatory motion.

The Importance of Air Rotary Union in Different Industries

Air Rotary Unions are vital cogs in the machinery of a multitude of industries. Their role in facilitating seamless operations is indisputable and varied in terms of application.

In the automotive industry, for instance, Air Rotary Unions are integral to operating rotary tables and other pneumatic controls. They underlie the operational mechanisms of winders and textile machines in the textile industry, aiding crucial processes like fabric rolling. In the automation sector, these unions help in the smooth transmission of pneumatic signals and controls, which is pivotal for running automated industrial processes.

The printing industry owes its fast-paced and efficient workflow to these ingenious units. They ensure that chilled water or hot oil is transferred into the rotating drum to cool or heat it as required. Without such dynamic sealing solutions as air rotary unions, the rotation-induced friction could lead to ineffective media transfer, hence loss of cooling or heating efficiency, and perhaps even machine damage.

In the context of the steel industry, the air rotary unions are found in continuous casting machines providing hydraulic transmission, and in spray bars of cooling beds providing uniform cooling.

Appreciating the crucial role of the Air Rotary Union opens a new perspective to understanding the intricate design and efficient operation of modern industrial machinery across a vast range of sectors.

Air Rotary Union Background and History

Delving into the background and history of the Air Rotary Union explores the origins of this indispensable component and understands just how significant the technological advancements have been in shaping the modern industry.

Brief History of Air Rotary Union

The concept and basic functioning of a rotary union can be traced back to the early 1900s. Initially, they were straightforward and rudimentary devices primarily used for transmitting steam or water. However, as industry demands grew, so too did the requirements for these machines. The need for a more efficient and reliable way to transfer various media, particularly air and gas, led to the development of the Air Rotary Union.

Rotary unions started making their mark in various sectors like textile, paper, printing, automotive, and others during the Industrial Revolution. The advent of sophisticated and fast-paced machines necessitated a component to facilitate fluid and air transfer in these devices, spurring the interest and development of air rotary unions.

Evolution and Technological Advancements in Air Rotary Union

The growth and evolution of Air Rotary Unions have been shaped significantly by advancements in technology and materials science. Modern air rotary unions are meticulously designed using advanced engineered materials and sophisticated sealing technologies, providing them the ability to withstand high pressures, temperatures, and rotational speeds.

The inclusion of high-performance materials like stainless steel, carbon-filled Teflon, ceramics, and other proprietary composites has substantially boosted the performance, durability, and lifespan of Air Rotary Unions. Technological advancements have also spurred the development of various designs to cater to a broad spectrum of industrial needs – from single passage units for simplistic media transfer applications to multi-passage units handling multiple simultaneous inputs and outputs.

Furthermore, advancements in Computational Fluid Dynamics (CFD) and Finite Element Analysis (FEA) tools have allowed for more precise designs and custom solutions tailored to unique industry requirements. The ability to predict and analyze the performance of the union before manufacturing has improved efficiency and longevity, and significantly reduced costs.

Over the years, innovations in sealing technologies have been instrumental in overcoming leakages, one of the most common problems faced by rotary unions. From the early days of simple sealing mechanisms, the development journey has seen significant milestones such as dynamic multi-contact sealing systems, improving the operational reliability of air rotary unions in demanding operational conditions.

This continual evolution and relentless pace of innovation within the field of Air Rotary Unions stands testament to the importance of these components in modern industrial applications. It’s a reflection of the drive to enhance efficiency, reliability, and longevity to fulfill the ever-increasing demands of industrial processes.

Types and Applications of Air Rotary Union

Air Rotary Unions are integral to the operational efficiency of myriad industries, and as such, they have been diversified in design to meet the specific needs of different applications. Understanding these types will illuminate just how versatile and crucial these components are.

Different Types of Air Rotary Union

Air Rotary Unions are designed to cater to a broad range of operating environments and to serve various functionalities. Here we explore some of the most prevalent types:

- Single-Passage Rotary Unions: These are the simplest form, providing a single channel for transferring a medium from a stationary source to a rotating part. They’re commonly used where only one type of media needs to be transferred.

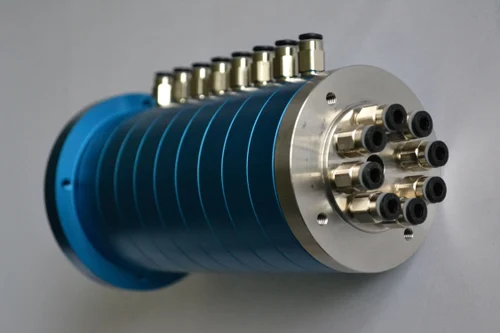

- Multi-Passage Rotary Unions: Equipped with multiple ports, these unions allow the simultaneous transfer of different media types. This complexity is essential in applications where space and efficiency are critical.

- High-Speed Rotary Unions: Constructed to withstand high rotational speeds, these unions are often employed in applications like high-speed printing and cutting machinery.

- High-Pressure Rotary Unions: Designed to maintain integrity under high pressure, these are typically used in equipment like high-pressure industrial hoses and hydraulic systems.

- High-Temperature Rotary Unions: These variants can withstand extreme temperatures and are used in processes like steel manufacturing, where molten metal must be handled.

Each type serves a distinct purpose and is engineered to maintain system integrity and prevent media leakage under their specific operational conditions.

Unique Applications in Various Industries

In the printing industry, Air Rotary Unions are instrumental in maintaining the functionality of printing presses, where they facilitate the transfer of air for pneumatic controls and coolants to regulate the temperature of the pressing rollers.

In the pulp and paper industry, these unions are fundamental in the drying sections of paper machines, where large heated rollers are used. They transfer thermal oil or steam into the rollers to heat them, ensuring the paper dries quickly and uniformly.

In the world of steel production, the Air Rotary Union is key in the continuous casting process, where it transmits hydraulic power to withdraw strands from molds and in cooling systems that regulate the temperature of the steel during processing.

For the plastic manufacturing industry, these unions are part of the extrusion machinery, allowing for the precise temperature control needed to maintain the quality of plastic products.

In textile industries, Air Rotary Unions ensure the seamless operation of spinning, weaving, and processing equipment – their task is to provide a constant supply of compressed air to keep the machinery operational with high efficiency.

Case Study: The Use of Air Rotary Union in a Specific Sector

Let’s focus on the pulp & paper industry – a sector that relies heavily on the utilization of Air Rotary Unions. A specific paper manufacturing plant faced the challenge of maintaining the efficiency of its dryer section, which is essential for ensuring the strength and quality of paper.

The introduction of a specially designed multi-passage Air Rotary Union enabled the plant to transfer not just thermal oil to heat the dryer cylinders, but also to integrate the pneumatic control systems within the same unit. This integration significantly improved the efficiency of the heat transfer process, reduced maintenance needs by minimizing the number of rotary union components, and boosted overall production speeds.

This adoption led to a marked improvement in paper quality, reduced the incidence of web breaks, and increased the longevity of the equipment due to enhanced thermal and pressure regulation. The results were staggering – a noticeable increase in productivity and a reduction in downtime, ultimately fulfilling the plant’s objective of optimizing performance and efficiency.

Through these examples, it is evident that the versatility and application of Air Rotary Unions are vast, and their impact on industrial proficiency is profound. The adaptation and innovation within this component range are continual, reflecting the dynamic needs of every industry it serves.

How Air Rotary Union Works

Air Rotary Unions play an indispensable role in various industrial processes by ensuring the seamless transfer of air and gases from a stationary source to a rotating component. Understanding their fundamental working principles, the intricate roles of their parts, and visualizing them through a diagrammatic representation sheds light on their essential function in machinery.

Basic Working Principle

At its core, the basic working principle of an Air Rotary Union is to maintain a continuous and leak-proof connection between a stationary input (such as a compressed air line) and a rotating output (such as a rotating drum or cylinder). This is achieved through a tight seal that allows for rotation without affecting the integrity of the air or gas transfer. The stationary part of the union is connected to the air supply, and the rotating part is connected to the rotating machinery. As the machine part spins, the air rotary union ensures a stable and continuous flow of air or gases, enabling the machinery to perform its intended function without interruption.

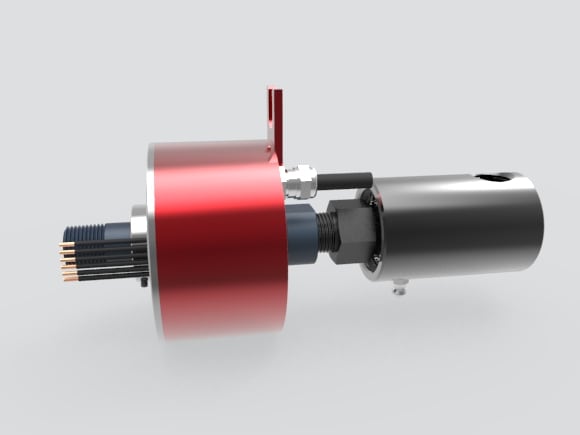

Detailed Description of Parts and Their Roles

- Housing: This is the outer part that encases the rotary union. It is typically made from durable materials such as stainless steel to withstand pressure and environmental factors.

- Shaft/Rotor: The shaft, or rotor, is the part that connects to the rotating machinery. It rotates within the housing and has one or multiple channels through which the air or gas passes.

- Bearings: Bearings are used to support the rotating shaft within the fixed housing, allowing it to rotate smoothly. They are critical in reducing friction and wear on the moving parts.

- Seal: One of the most crucial components, the seal prevents the escape of air or gas from the system. Seals must be carefully selected to withstand the specific pressure, temperature, and rotational speed of the application.

- Inlet/Outlet Ports: The stationary part of the union features an inlet port for the air or gas to enter and an outlet port through which it is directed to the rotating machinery. These ports are precisely machined for airtight connections.

Diagrammatic Representation

As I’m currently unable to create or display images directly, I’ll describe how you can visualize or sketch a simple diagram of an Air Rotary Union:

- Start with the Housing/Body: Draw a cylindrical shape to represent the housing. This is the stationary part that contains all other components.

- Incorporate the Shaft/Rotor: Inside the cylindrical housing, draw a smaller cylinder to represent the shaft or rotor. This part should be central and run the full length of the housing, protruding slightly at both ends to indicate the connection to rotating machinery.

- Indicate the Bearings: Around the shaft, at both ends within the housing, depict bearings. These can be shown as small circles or narrow bands encircling the shaft.

- Highlight the Seal: Just inside the housing and around the shaft, draw a thin line or a small circle to represent the seal. This critical part prevents air or gas leakage.

- Mark the Inlet/Outlet Ports: On the outer surface of the housing, designate one end with an arrow pointing inward to indicate the inlet port where the air enters. Similarly, mark an arrow on the shaft pointing outward to indicate the air’s path to the rotating machinery, representing the outlet.

Remember, the diagrammatic representation is a simplified abstraction of a more complex mechanism, but it serves to convey the basic configuration and operation of an Air Rotary Union. Through these descriptions, one gains an insight into how these vital components work together seamlessly to facilitate the smooth operation of various industrial machinery.

Benefits of Using Air Rotary Union

Air Rotary Unions serve as a pivotal part of many industrial applications due to their efficient design, high-quality construction, and cost-effective operation. The various benefits they provide come together to enhance the overall performance and longevity of machinery, contributing significantly to the optimization of industrial processes.

Efficiency and Functionality

Air Rotary Unions are engineered to facilitate smooth operation and to increase the efficiency of machinery. They enable the transfer of media without the need for detaching hoses or tubes when the equipment must rotate, which reduces the downtime and potential for human error, significantly improving operational flow. Additionally, the ability of these unions to handle multiple media types through multi-passage designs increases the functionality of a single unit, streamlining the process and making complex rotations and operations possible. This adaptability ensures that machines can work faster, longer, and more reliably, directly contributing to increased productivity.

Quality and Durability

The construction of Air Rotary Unions involves high-quality materials and precision engineering. Stainless steel, aluminum, and engineered polymers are commonly used, selected for their ability to withstand the stresses of industrial environments, such as exposure to high pressures, corrosive substances, and extreme temperatures. The seals within the unions are crafted from robust materials that can endure wear and maintain integrity over time, which is imperative in preventing leaks and ensuring that the unit functions correctly. These materials, combined with advanced manufacturing techniques, result in a product that is not only reliable but also durable, leading to a longer lifespan and reduced need for replacement or repair, thus ensuring consistent production quality over time.

Cost-effectiveness

Implementing Air Rotary Unions within industrial machinery is a cost-effective move. Due to their design efficiency and the high-grade materials used in their construction, these unions have lower maintenance requirements and longer service intervals. This reduces the costs associated with downtime and frequent servicing. Moreover, their durability means that equipment managers incur fewer replacement costs over the machinery’s lifetime. By optimizing operational time and minimizing both direct and indirect costs, Air Rotary Unions represents a smart investment for industries looking to maximize the value of their equipment and processes.

Through their combination of enhanced efficiency, superior quality, and cost-saving potential, Air Rotary Unions provide substantial benefits that impact the bottom line of industrial operations and ensure the smooth and uninterrupted functionality of machinery. The consistent inclusion of these components across various sectors underscores their significance and reflects their value in maintaining and improving industrial productivity and sustainability.

Choosing the Right Air Rotary Union

Selecting the appropriate Air Rotary Union is critical for ensuring the optimal performance and longevity of both the union itself and the machinery it serves. This decision-making process involves understanding the unique demands of your application and navigating the vast offerings from leading manufacturers. Let’s delve into the factors to consider when making this choice and review some of the key players in the industry.

Factors to Consider

When selecting an Air Rotary Union, it is essential to consider several interrelated factors to ensure a match that meets the specific needs of your application. Here are some of the pivotal considerations:

- Size and Configuration: The physical size of the rotary union and its port configuration must be compatible with the machinery. This includes considerations for space constraints and the need for alignment with existing piping or tubing.

- Rotational Speed: Different applications operate at varying rotational speeds. Ensuring that the rotary union can handle the maximum operational speed is crucial to prevent premature wear or failure.

- Temperature Range: Depending on the application, the rotary union may be exposed to extreme temperatures. Selecting a unit designed to withstand the specific temperature range it will encounter is vital for maintaining seal integrity and overall functionality.

- Media Type: The type of media (air, hydraulic oil, coolant, etc.) being transferred greatly influences rotary union selection. Material compatibility between the media and the union’s components ensures efficiency and prolongs the life of the union.

- Pressure Requirements: The operating pressure within the rotary union should be within the designed pressure range of the unit. Exceeding this range can lead to leaks or catastrophic failure, so ensuring compatibility is key.

- Environment: Environmental conditions such as the presence of corrosive substances, dust, and moisture can impact the durability and function of a rotary union. Models designed to withstand specific environmental conditions may be necessary.

Overview of Leading Manufacturers and Their Product Ranges

Several manufacturers are known for their quality, innovation, and comprehensive product ranges in the field of Air Rotary Unions. Below are some of the industry leaders:

- Deublin: Deublin is renowned for its wide array of rotary unions for various media, including air, water, hydraulic oil, and coolant. Their products cater to a broad spectrum of speeds, temperatures, and pressures, making Deublin a go-to for industries ranging from manufacturing to renewable energy.

- Co-ax® Valves Inc.: Specializing in valves and rotary unions, Co-ax® Valves Inc. offers products known for their robustness and reliability. Their range includes solutions for high-speed and high-pressure applications, focusing on performance and longevity.

- Duff-Norton: Offering a diverse selection of rotary unions, Duff-Norton’s products are designed for a variety of applications, including water, steam, air, and hot oil. They are known for their durability and efficiency across different industrial settings.

- Kadant: Kadant’s offerings include custom and standard rotary unions for a plethora of media. Known for their innovative sealing technologies, Kadant products serve industries like paper, corrugating, and general industrial processes.

- MAIER Heidenheim: With a focus on high-quality materials and precision engineering, MAIER Heidenheim produces rotary joints and unions for a wide range of applications, emphasizing reliability and performance under demanding conditions.

Each manufacturer brings a unique focus and specialization to the table, offering options for virtually every application. By deeply understanding the requirements of their operation and carefully analyzing the products available from these leaders in the field, professionals can select the most appropriate, efficient, and cost-effective Air Rotary Union for their needs. This thoughtful selection process ensures the seamless integration of the rotary union into industrial processes, maximizing performance and reliability.

Air Rotary Union Maintenance and Troubleshooting

Maintaining an Air Rotary Union in top condition is vital for the smooth operation of an industrial process. Regular maintenance, systematic troubleshooting, and timely repairs can prevent failures, extend the life of the machine, and save costs. Let’s delve deeper into the details of these areas for clearer comprehension.

Regular Maintenance Guidelines

Adherence to a regular maintenance schedule is fundamental for the optimal performance of an Air Rotary Union.

- Inspection: Regular visual inspections can help to spot obvious issues such as leaks or wear and tear.

- Cleaning: Regular cleaning of the Air Rotary Union is crucial, particularly if it is operating in an environment with particles/dust or corrosive substances.

- Lubrication: The moving parts, like the bearings and seals, require regular lubrication to reduce friction and avoid overheating. Always use a lubricant that is suitable for the intended operating conditions of the machinery.

- Seal and Bearing Maintenance: Depending on the application, seals, and bearings may need to be replaced periodically to maintain optimal performance. Ensure you always follow the manufacturer’s guidance.

- Operational Parameters Checking: Regularly monitor and record operational parameters such as rotation speed, temperature, and pressure. Any major deviations from the standard parameters might indicate an issue that requires troubleshooting.

Common Problems and Solutions

Despite regular maintenance, problems can occur, and knowing how to identify and address common issues is significant.

- Leakage: This could result from wear and tear of the seal, improper installation, or exceeding the operational parameters of the rotary union. Identify the cause of the leakage and replace the seal or the entire union as necessary.

- Overheating: Overheating might occur due to insufficient lubrication, excessive rotational speed, or high operating pressure. Tackle this issue by adjusting the operational parameters, augmenting lubrication, or even replacing parts, if required.

- Abrasive Wear: Unwanted particles can cause abrasive wear over time. Regularly clean the unit and ensure the seals and bearings are in good condition.

Importance of Timely Repairs and Replacements

Timely service and replacement play a significant role in reducing downtime and preventing further damage to the machinery.

- Preventive Action: Addressing minor issues before they escalate into serious problems can save significant time and resources in the long run.

- Avoiding Prolonged Downtime: Timely repairs mean machinery can be put back into service quickly, reducing the costs associated with prolonged downtime.

- Extending Lifespan: Regularly serviced and well-maintained rotary unions tend to have longer service lives, enhancing their cost-effectiveness.

- Preserving Quality: Well-functioning Air Rotary Unions play a critical role in preserving product quality by keeping processes running smoothly and efficiently.

In conclusion, while Air Rotary Unions are robust and durable, they are not invulnerable. They require regular maintenance and prompt, appropriate troubleshooting to function optimally. By investing in timely and efficient maintenance and repairs, industries can benefit from prolonged service life, efficiency, and reduced costs.

Conclusion

Air Rotary Unions are vital components across various industries, ensuring the efficiency of machinery that depends on the transfer of air or gas during rotation. Understanding their types, applications, and maintenance can significantly contribute to optimizing industrial operations.

FAQs about Air Rotary Union

Q: Can Air Rotary Unions be used with liquids?

A: While specifically designed for air or gas, there are rotary unions for liquids; however, selecting a suitable model for the media type is crucial.

Q: How often should I inspect my Air Rotary Union?

A: The inspection frequency depends on usage intensity, but a general guideline is to conduct a thorough check during regular machinery maintenance intervals.

Q: What are the signs that an Air Rotary Union needs replacing?

A: Signs include noticeable leaks, unusual noises during operation, or a decline in machinery efficiency, indicating it’s time for a replacement.

Q: What is an Air Rotary Union, and how does it work?

A: An Air Rotary Union is a mechanical device designed to transfer air or gas from a stationary inlet to a rotating outlet, maintaining a tight seal between the stationary and rotating parts. It consists of a rotating shaft and a stationary housing that holds a seal. The design allows for continuous rotation while air or gas is transferred, which is essential in machinery where parts need to both rotate and be supplied with air or gas simultaneously.

Q: How do I choose the right Air Rotary Union for my application?

A: Selecting the right Air Rotary Union involves considering several factors, including:

- The type of media (air, gas, etc.) to be transferred.

- Operational pressure and temperature.

- The rotational speed of the equipment.

- The desired lifespan and the environment in which the union will operate.

Compatibility with the media, the capacity to withstand operational conditions, and meeting the technical specifications of your machinery are crucial in making the right choice.

Q: What regular maintenance does an Air Rotary Union require?

A: Regular maintenance for an Air Rotary Union typically includes:

- Visual inspections for signs of wear or leaks.

- Cleaning to remove any debris or contaminants.

- Lubricating moving parts as necessary.

- Checking and replacing worn seals and bearings according to the manufacturer’s recommendations.

Following these steps can prolong the life of the unit and ensure its efficient operation.

Q: What common problems should I look out for, and how can they be solved?

A: Common problems with Air Rotary Unions include leaks, overheating, and abrasive wear. These can be addressed as follows:

- Leaks: Check and replace worn seals or gaskets.

- Overheating: Ensure adequate lubrication and check for excessive speed or pressure.

- Abrasive Wear: Regular cleaning and maintenance to remove particulates and prevent wear.

Addressing these issues promptly can prevent more severe problems and downtime.

Q: Why is it important to perform timely repairs and replacements on an Air Rotary Union?

A: Timely repairs and replacements are critical to:

- Avoiding prolonged downtime, which can be costly.

- Preventing minor issues from developing into major problems that require more extensive and expensive repairs.

- Ensuring the longevity of the Air Rotary Union.

- Maintaining optimal performance and efficiency in machinery operations.

Adhering to a regular maintenance schedule and addressing issues as they arise will contribute to the reliable and efficient operation of your equipment.