Air slip rings occupy a unique space within the engineering landscape, carrying out a role that is both specialized and crucially important to many industries. As a distinct class of slip rings, their design and function are dedicated to the unobstructed transmission of air and electrical signals, making them pivotal in applications where a consistent air supply between stationary and rotating components is essential.

Aiming to be more than a mere conduit for transmitting air and electrical signals, air slip rings are rapidly evolving, broadening their relevance beyond traditional sectors to newer applications. These sophisticated devices leverage the principles of sealed passageways, minimal friction, and leak-proof connections to function efficiently in a myriad of settings, from automation to the medical field, and even the aviation industry.

These specific functionalities and ever-growing applications signify that a clear understanding of air slip rings is essential for professionals vested in relevant sectors. This article, therefore, aims to serve as a comprehensive guide on air slip rings, demystifying their core operational principles, examining their applications, highlighting their strengths and potential limitations, shedding light on their selection criteria, discussing their maintenance, and even glimpsing into their future in keeping with the incessant stride of technology.

We will systematically delve into each of these areas, peeling back the layers to offer a practical and informative discourse for all readers, whether they are industry insiders or simply tech enthusiasts looking to broaden their knowledge spectrum. The ultimate aim is to ensure that after reading this article, one would not just understand air slip rings better, but also be aware of their significance, utility, and the promise they hold for the future.

Understanding Air Slip Rings

Air slip rings, also known as pneumatic slip rings or rotary unions, occupy a unique place in the pantheon of rotation-based mechanical devices. Essentially serving as pathways for air and sometimes electrical signals, they perform a pivotal function at the intersection of stationary and rotating components. Their main role is to provide a continuous flow of compressed air from a stationary input to a moving output, a function that is simple in concept yet complicated in execution.

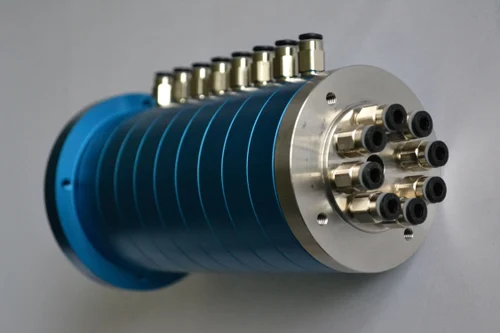

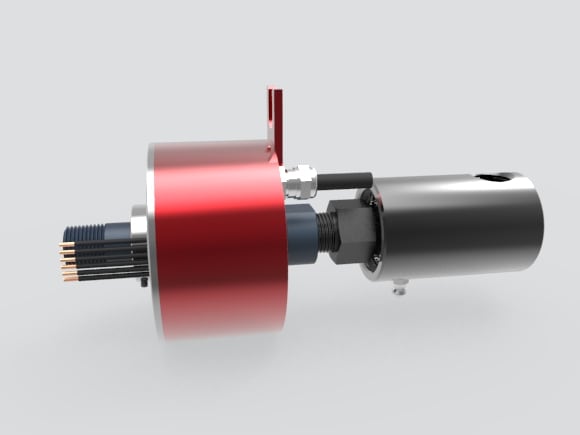

Elaborating on their structure, air slip rings generally comprise a rotor and a stator, with the rotor typically being the rotating part while the stator remains stationary. They employ rotary seals, ensuring an airtight connection as the internal part rotates. These special seals are designed to withstand the abrasion of constant rotation while still maintaining a leak-proof state, allowing for fluid or air to pass without loss of pressure.

However, it is when we place them alongside other types of slip rings that their unique design and functionality become fully apparent. Unlike electrical slip rings that transmit electrical signals or power, or fluid slip rings, which shuttle various types of fluids, air slip rings specialize in the passage of air. This gives them a significant edge in scenarios where a constant supply of compressed air is required while handling rotation, especially when a leak could lead to harmful outcomes. They also take up the mantle when a combination of air and electrical transmission is demanded in the industry, making them unique in their capacity.

Moreover, air slip rings come with certain intrinsic advantages such as minimal friction, which results in less wear of components and longer service life. Additionally, the absence of fluid leakage not only maintains the efficiency of the system but also minimizes the risk of contamination – a critical value proposition when working in sensitive industries like medicine or food processing. This comparison helps to unveil the true value of air slip rings, showcasing how their unique capabilities and advantages deem them a pivotal inclusion across several applications.

Working Principle of Air Slip Rings

Understanding the function of a rather complex device like an air slip ring requires a closer look into its fundamental working principle. Essentially, air slip rings operate around the key premise of creating a continuous, unbroken channel of airflow between a stationary and rotating component. This justifies their core role in systems that rely on the transmission of pneumatic power.

To carry out this function, air slip rings are composed of a stationary input, called a stator, and a rotating output referred to as the rotor. These two parts are fitted together but with a tiny gap in between, allowing the rotor to spin freely. The compressed air enters the stator and travels through this particular connection to reach the rotor, which then channels the air to the desired application. The cornerstone of this entire operation is the precision-engineered rotary seal that resides between the stator and the rotor. This seal ensures a leak-proof connection between the two parts, maintaining the integrity of the pressurized air as the components rotate.

The magic of air slip rings, however, is not confined to the realm of pneumatic power alone. When the application calls for it, air slip rings can also accommodate the simultaneous transmission of electrical signals. Embedded within the same unit, these ‘hybrid’ slip rings use separate pathways to ensure the electricity does not interfere with the airflow. If you picture an air slip ring as a kind of specialized pipe, the air and electricity would be like separate streams flowing within the same pipe. Just as the air is allowed to flow unhindered, the electrical signals are transmitted smoothly from the stationary part to the rotating part, enriching the functionality of the system by adding electrical communication to the pneumatic power supply.

So the working principle of air slip rings is a fine example of engineering ingenuity, where a simple yet essential task – like ensuring a steady flow of air – is accompanied by the seamless transmission of electrical signals, all within the enclosed cycle of the stationary and rotating components.

Key Applications of Air Slip Rings

Embodying a blend of versatility and precision, air slip rings find a place in a broad array of industries and applications that require a continuous air supply along with the provision for rotation. Their unique proficiency to provide continual, leak-proof transmission of pneumatic power, and sometimes electrical signals, makes them a silent yet significant hero in many sectors.

One of the most prominent industries that benefit from air slip rings is the aerospace sector. Their application is often found in pressurization systems of aircraft, turbine engines, and even space satellites, where they facilitate the supply of compressed air in a rotating setup without any loss of pressure.

Similarly, in the world of automation and robotics, air slip rings play an integral role. They find use in automated assembly lines, rotary tables, and robotic arms where regulation of air supply and electrical signals is crucial for precision tasks like assembly or painting.

In medical imaging systems, especially magnetic resonance imaging (MRI) machines, the spinning Gantries demand a steady supply of cooled air. Here, air slip rings step in to ensure an uninterrupted flow of coolant air while concurrently transmitting crucial electrical signals.

Wind turbines also employ air slip rings for an unbroken air supply to the rotating nacelle, enabling the systems to work efficiently even in the harshest weather conditions.

Even in mundane equipment like packaging machines or cable drums, air slip rings play a key role in allowing the rotating parts to perform their function without hampering the air supply or electrical communication.

In summary, air slip rings’ applications span across industries, underscoring their importance in systems that demand precise and continuous pneumatic power under rotating conditions. From soaring aircraft and advanced medical equipment to everyday industrial machinery – you’ll find these unique rotary unions silently at work, ensuring smooth operation. The possibilities, indeed, are vast and varied, testifying to their diverse utility.

Advantages and Limitations of Air Slip Rings

Air slip rings, with their incredible capacity to deliver both pneumatic power and electrical signals, certainly bring a host of benefits to the table. Yet, like any technology, they aren’t without their potential challenges or limitations.

Advantages

Arguably the most prized advantage of air slip rings is the elimination of fluid leakage. They ensure an airtight seal between the stator and rotor, resulting in an efficient system where the risk of contamination, consequential damage, or loss of pressure through leakage is minimized.

The inherently low friction of air slip rings is another significant advantage. This reduced friction not only provides a smooth and near-silent operation, it also elongates the lifespan of the slip ring by curtailing wear and tear, thus reducing maintenance demand and operational costs.

Notably, air slip rings can also provide simultaneous transmission of pneumatic power and electrical signals. Their hybrid variants, incorporating both functionalities within a single unit, offer a compact solution with added utility which is a boon for industries looking to maximize efficiency in limited spaces.

Limitations

Despite the commendable benefits, air slip rings are not immune to some inherent constraints. Ensuring airtight seals might be their forte, but the potential loss of pressurization through time and use can be an issue. This may eventually necessitate maintenance or replacement of seals to maintain the integrity of the pressurized airflow.

Given the sophistication of their design, air slip rings are generally more expensive compared to their non-pneumatic counterparts. The complex engineering, the precise parts and materials used, and the production processes all contribute to their increased cost. This necessitates a thorough cost-benefit analysis before they are chosen for a specific application.

Additionally, while they indeed reduce maintenance requirements due to their low friction, the maintenance they do require is usually specialized, needing skilled technicians. This potentially increases the cost of upkeep.

In conclusion, while air slip rings offer a myriad of advantages from eliminating fluid leakages to ensuring low friction operations, it is imperative to consider the potential constraints. These limitations in no way diminish the importance of air slip rings, but rather highlight the need for thorough understanding and strategic planning when employing them in practical applications. Those industries that perform a detailed analysis to align the advantages with their requirements and prepare for the constraints, can make optimal and efficient use of air slip rings.

Selection Criteria for Air Slip Rings

Choosing a suitable air slip ring requires prudent consideration of numerous factors to ensure it meets the demands of your application. Essentially, it’s about finding the right balance between your needs and the slip ring’s capabilities. Here are some key factors to consider.

- Application Needs: The very first consideration is the specific needs of your application. Do you require only air transmission or a combination of pneumatic and electric? Understanding your requirements will streamline your search, helping you pick the most suitable variety of air slip rings.

- Rotational Speed: The Rotations Per Minute (RPM) that your system will function at is a significant factor in choosing an air slip ring. High speeds may necessitate specialized design features to prevent seal wear hence impacting the slip ring choice.

- Pressure Handling Capacity: The pressure of the air to be transmitted is a crucial determinant. Systems working at high pressures will warrant air slip rings designed to handle such pressure levels without succumbing to leaks or seal failures.

- Material Compatibility: The choice of material for the slip ring should be compatible with the application conditions. For instance, certain chemicals might necessitate specific materials to withstand corrosion; specific heat conditions might call for heat-resistant materials for the slip ring.

- Temperature Conditions: Depending on whether your equipment will operate in high or low temperatures, your air slip ring should be able to function effectively. Heat can degrade certain seal materials over time, while cold could make some materials brittle.

- Cost: While it should never be the only deciding factor, cost is undoubtedly an important consideration. The operative question here is whether the value offered by a specific air slip ring, in terms of its features and longevity, justifies its purchase and maintenance cost.

By keeping these selection criteria in mind, you can navigate the multitude of choices available in the market and select an air slip ring that perfectly aligns with your specific needs, delivering optimal efficiency and maximizing the operational life of your rotary systems.

Maintenance and Troubleshooting Guide for Air Slip Rings

Ensuring the optimal performance of an air slip ring necessitates regular maintenance and efficient troubleshooting. By adhering to certain recommendations and advice, users can enhance the longevity and performance of air slip rings while swiftly addressing any issues that arise.

Maintenance Recommendations

- Cleaning: Regular cleaning of the air slip ring is vital to prevent the build-up of dust and other particles that can interfere with the airflow and the rotation. Compressed air can be used to clean the slip ring at regular intervals, depending on the working conditions.

- Inspection: Regular inspection for any wear and tear on the seals and the overall unit is a proactive way to prevent potential failures. Any visible damage should be addressed promptly to prevent further degradation.

- Seal Replacement: Seals are crucial in maintaining the air pressure and preventing leakage in the slip ring. It’s important to monitor their conditions and replace them when worn out, according to manufacturer guidelines.

- Routine Lubrication: Depending on the specifications provided by the manufacturer, periodic lubrication may be necessary for certain models to reduce friction and prolong the lifespan of the slip ring.

Troubleshooting Advice

- Pressure Reduction: A common issue could be a reduction in the air pressure. This is often due to wear and tear on the seals, necessitating their immediate replacement.

- Rotation Issues: If there are issues with the rotation of the slip ring, check for any obstructions or dust accumulation. Cleaning the slip ring usually resolves this issue.

- Temperature Rise: Air slip rings that run at high temperatures could indicate friction due to worn-out parts or insufficient lubrication. An inspection should be conducted to identify the worn parts for replacement and lubrication should be applied where required.

- Unexpected Noise: Any buzzing or hissing noises from the slip ring could indicate air leakage. In such cases, reviewing the sealing parts and replacing damaged ones would resolve the problem.

With appropriate maintenance and efficient troubleshooting, air slip rings can be kept in excellent working condition, offering continuous, optimal performance. The longevity and durability of these powerful tools can certainly be maximized through regular, thorough care.

Future Trends and Developments in Air Slip Rings

As industries evolve and expand, so do their requirements and demands. Consequently, air slip ring technologies are experiencing a dynamic push towards advancements in design and efficiency. By examining these potential trends and developments, we can catch a glimpse of their future trajectory and harness the potential offered by innovations in the field.

Advancements in Design and Efficiency

- Compact Designs: There is an ongoing drive to miniaturize the air slip rings for applications with limited space. This entails finding the sweet spot between size reduction and maintaining performance specifications, catering particularly to industries like aerospace, medical devices, and robotics.

- Higher Pressure Handling Capacity: Increasing demands to handle higher air pressures dictate the need for air slip rings that can reliably perform at such elevated levels. The response to these expectations is seen in research focused on materials, design, and sealing techniques that can withstand higher pressures.

- Greater Power and Signal Transmission: Air slip rings that can accommodate higher power capacities and multiple signal channels simultaneously are soon to witness a surge in demand. This integrated functionality will give rise to even more efficient and versatile rotary solutions.

Exploration of Innovations and Emerging Technologies

- Smart Slip Rings: With the rise of the Internet of Things (IoT) and Industry 4.0, integrating sensors and monitoring systems directly into air slip rings may become increasingly common. This fusion enables real-time data collection, inspection, and maintenance alerts, allowing users to optimize their system performance while minimizing downtime.

- Advanced Material Usage: The continuous quest for materials with improved properties is driving researchers to explore composites, advanced polymers, and even nanotechnology. The future may see significantly enhanced air slip ring designs, with greater resistance to wear and tear and heightened performance attributes.

- Environmentally Friendly Solutions: As sustainability becomes a higher priority for industries across the board, the development of eco-friendly air slip rings is vitally important. This entails increased efficiency, reduced maintenance requirements, and minimized use of hazardous materials.

The future trends and developments in air slip rings present an exciting outlook, marked by innovation and an emphasis on efficiency. The integration of cutting-edge technologies and advanced materials promises to catapult these essential devices to new heights. As industries worldwide continue to embrace revolutionary technologies and strive for higher levels of sustainability, air slip rings will be no exception, powering these modern pursuits with their robust, versatile capabilities.

Conclusion

In conclusion, air slip rings offer impressive capabilities, with their specialized role in facilitating continuous, efficient pneumatic power supply. This guide aims to provide a comprehensive view into the intricate world of air slip rings, affirming their importance and value within a wide spectrum of industries and applications. As technological advancements march forward, air slip rings are anticipated to evolve, offering improved performance and additional features to serve the ever-demanding industrial needs.

See What We Can Do