The alternator is a key component in your car’s electrical system, acting as a mini power station that generates the necessary electrical energy used to operate various functions, from powering your vehicle’s lights and radio to charging your car’s battery.

At the heart of the alternator is the slip ring. The slip ring is a crucial piece of the alternator system. Serving as an electrical interface, it is designed to ensure a continuous flow of electrical current between stationary and rotating parts. Essentially, it facilitates the transfer of electricity to the parts of the alternator that are always moving, maintaining an uninterrupted electrical connection regardless of their motion. This rotational motion is what allows the alternator to generate an electrical charge.

The efficiency and smooth operation of your alternator and, by extension, your vehicle’s electrical supply, hinges heavily on the condition of the slip ring. Given the immense importance of the slip ring’s function, they must be kept in good condition. Regular checks and maintenance are instrumental in ensuring the slip ring, and thus the alternator, function properly. Without such attention, the slip ring can wear down, impairing the functioning of the alternator, and causing a range of electrical issues in your vehicle.

Hence, understanding the alternator, the role of the slip ring, and the importance of its maintenance can help you avoid unexpected breakdowns, enhance your vehicle’s electrical performance, and even extend the lifespan of your vehicle’s alternator. In this article, we will delve further into the issues related to the alternator slip ring, recognizing signs of issues, and what you can do about them.

Symptoms of a Faulty Alternator Slip Ring

Being alert and understanding the possible signs of a failing alternator slip ring will help in early detection and rectification of issues, ensuring the longevity of the electrical system in your vehicle. So, what are these potential signs?

One common indication is irregular power output from your vehicle’s electrical system. You may notice that the dashboard lights dim or flicker, or your radio and other electrical accessories might intermittently lose power. All these could be warning signs of an issue with the alternator slip ring.

Unusual noises are another symptom you should not ignore. The slip ring makes contact with brushes that help to transmit the electrical current. When these components wear out, they may generate unusual grinding or whirring sounds. So, if you notice any strange noises coming from the area where your vehicle’s alternator is located, that could be a sign of a deteriorating alternator slip ring.

Yet another glaring symptom is if the ‘Check Engine’ or ‘Battery’ warning lights illuminate on your vehicle’s dashboard. While these signals may not be directly tied to the slip ring, they often hint at alternator-related issues, which could mean a faulty slip ring is one of the underlying problems.

Misinterpreting or overlooking these symptoms can lead to severe consequences. The alternator is responsible for generating electrical power for a multitude of your vehicle’s functionalities. Therefore, allowing the issue to persist will not only affect these functions but also can lead to a total alternator failure, leaving your vehicle without an essential point of power. That might mean your vehicle may even stop running altogether.

Ignoring these symptoms could leave you stranded with a vehicle that won’t start or, worse, abruptly give out while on the road. Furthermore, continual neglect of a faulting alternator slip ring may eventually damage the vehicle’s battery and other connected components, leading to higher repair costs.

Therefore, it’s necessary to be aware of these symptoms of a potentially defective alternator slip ring and take immediate action to rectify any observed issues to prevent more significant, costly problems and ensure your vehicle stays on the move.

What Causes Slip Ring Damage?

Understanding the probable causes of slip ring damage in your alternator is essential as it allows you to take preventative measures and timely actions to avoid potential breakdowns.

First, the very nature of the slip ring’s function can lead to its degradation over time. The slip ring is in continuous operation whenever your vehicle is running, spinning non-stop to facilitate the electrical transmission. This ceaseless movement leads to normal wear and tear. Over time, friction created during this process can cause the slip ring to deteriorate, leading to less efficient power transmission.

Secondly, the slip ring is susceptible to damage from exposure to harsh environments. If it is exposed to humidity, dirt, debris, or excessive heat, these factors can expedite the wear and tear process. For instance, extreme heat can cause the slip ring to warp or distort, interrupting its electrical transmission capabilities.

Lastly, poor maintenance practices can also contribute significantly to slip ring damage. For instance, if the alternator belt—also known as the serpentine belt—isn’t properly adjusted, it can put undue stress on the alternator and, as a consequence, the slip ring. A belt that is too tight tends to cause friction that could erode the slip ring, while a belt that is too loose might not stimulate enough rotation for effective power generation.

Additionally, failure to carry out regular checks on your alternator and slip ring can result in potential issues going unnoticed and untreated. Ignoring vehicle maintenance can transform what could have been minor, easily rectifiable issues into major ones that might require expensive repairs or replacements.

In conclusion, it’s essential to understand these common causes of slip ring damage and take necessary measures to address them. Regular maintenance, adherence to proper practices, and keeping your vehicle protected from harsh conditions will help maintain the functionality of your alternator’s slip ring and by extension, ensure smoother performance of your vehicle’s electrical system overall.

Alternator Slip Ring Repair: Inspection and Diagnosis

Before undertaking any repair or maintenance plan, it is crucial to first inspect the alternator and slip ring for potential damage. This will allow you to confirm whether the problem lies with the slip ring or another component in the alternator system.

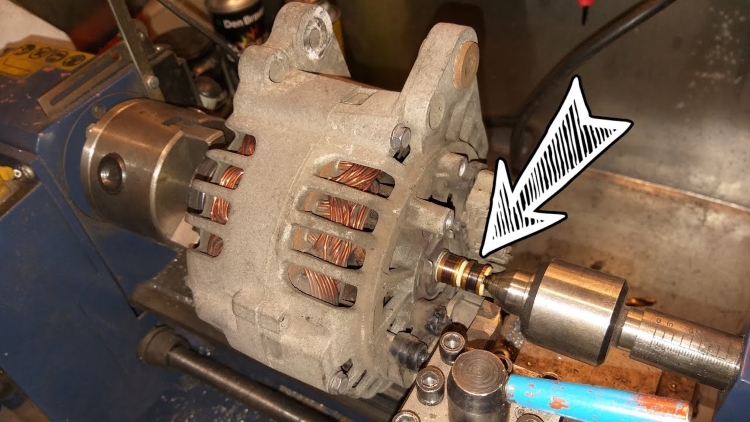

To inspect the alternator and its slip ring, you’ll need a few simple tools. Generally, you’ll require a multimeter or a voltmeter to test the electrical output of the alternator and verify its proper functioning. Besides, a good flashlight could help you visually inspect the alternator and slip ring, especially in less illuminated engine compartments. Keep in mind, that the lip ring is located at the rear of the alternator, so you may need to remove the alternator from the vehicle for a thorough inspection.

Safety is paramount during this process. Before you begin, make sure the engine is turned off and has had sufficient time to cool down. This will prevent accidental injuries from hot engine parts or electric shock. Also, you should disconnect the battery before performing any electrical work on your vehicle. This is a basic safety measure to prevent accidental grounding or short circuits that can lead to fires or damage to the electrical components.

When examining the alternator and slip ring, look for visible signs of wear and tear or damage. This could include grooves or pitting on the slip ring, which could indicate excessive friction or heat damage. Consider using a multimeter to test the alternator’s output as well. If the output is lower than the vehicle’s specified voltage (usually around 14 volts for most vehicles), this may indicate a problem with the slip ring, as it plays a central role in power transmission.

These checks can help determine whether your alternator’s slip ring is in good working order or requires repair or replacement. Proper inspection and diagnosis are crucial first steps in addressing any electrical issues you might encounter with your vehicle.

Alternator Slip Ring Repair: Repair Process

Fixing or replacing an alternator slip ring may seem complex, but with the right tools, parts, and a clear understanding of the process, it can be accomplished. Here’s a simple step-by-step guide to help you:

Step 1: Gather Your Tools and Parts

Before starting the repair process, assemble all the necessary tools and parts required. These might typically include:

- New slip ring

- Screwdrivers (Flathead & Phillips)

- Wrench set

- The alternator pulley puller and installer set

- Soldering iron and solder (if you will be replacing the slip ring yourself)

Please note that the tools required might differ based on your vehicle’s specific model.

Step 2: Remove the Alternator

To begin, disconnect the battery’s negative terminal to prevent accidental electrical discharge. Then, locate the alternator and remove it from your car by disconnecting the wires attached to it and unscrewing the bolts that hold it in place.

Step 3: Disassemble the Alternator

Next, disassemble the alternator by removing the pulley and the back casing, using the alternator pulley puller and wrench set. This will expose the rotor where the slip ring is located.

Step 4: Replace the Slip Ring

Once you see the rotor, you can remove the worn-out slip ring. To replace it with the name, use your soldering iron and solder to attach the new slip ring to the rotor. Please exercise extreme caution when using the soldering iron.

Step 5: Reassemble the Alternator and Install it Back

Once you’ve successfully replaced the slip ring, you can reassemble the alternator and reinstall it on your car. Secure it properly with the bolts and reconnect the wires you disconnected earlier.

Remember, if you do not have the right tools or encounter difficulties, it may be best to leave this work to the professionals to avoid damaging your alternator or the new slip ring.

As for diagrams or visuals, it might be interesting to check the car’s service manual or watch instructional videos online. They often provide relevant visuals and diagrams that match specific car models, aiding you in understanding the process more clearly.

By following these steps and precautions, you should be successful in repairing or replacing the alternator slip ring, ensuring the smooth performance of your vehicle’s electrical system.

Please Note: The procedures mentioned above are generalized. Actual repair methods may vary depending on your car’s make, and model, and the specific problem with the slip ring.

Alternator Slip Ring Repair: When to Seek Professional Help

While it’s often rewarding to handle car repairs by ourselves, there are certain situations where seeking professional help might be essential. This advice stands especially true when it comes to alternator slip ring repairs, which can be quite intricate and require high levels of expertise.

One such scenario is if you lack the required tools for the job. Specialized tools are needed for tasks such as removing the alternator pulley and replacing the slip ring. Without these, you may struggle to complete the job effectively and could potentially cause further damage to your vehicle.

Another situation would be if you’re uncomfortable dealing with electrical components. Alternators feature some elements that carry a high voltage. Unless you are confident and understand what you’re doing, it’s safer to leave such tasks to the professionals to avoid accidental electrical shocks or potential fires.

Additionally, if you’ve done your initial inspection and diagnosis but are uncertain about the exact cause of the problem, it’s best to consult with a professional mechanic. Alternator slip rings interact with numerous other parts within the alternator, and sometimes, the problem might not exclusively originate from the slip ring. Misdiagnosis could lead to unnecessary replacements or overlooking other problematic components.

Taking a DIY approach to any car repair comes with its risks. In the case of the alternator slip ring, the biggest risk is potential damage to the alternator itself or related components, which can result in costly repairs or replacements. Moreover, improper handling could put your person at risk, especially if you’re not confident or familiar with electrical systems.

In conclusion, it’s key to assess your skills, tools, and the precise scenario before deciding to carry yourself. If in doubt, it’s usually wiser—and potentially much safer—to reach out to a professional mechanic. They can provide the necessary expertise and tools to ensure the repair process is safe, efficient, and effective, ultimately saving you time and potential future repair costs.

Alternator Slip Ring Repair: Preventive Maintenance and Care

As the old a goes, “Prevention is better than cure”. It’s no different when it comes to maintaining the slip ring in your alternator. Here are some tips to ensure its longevity and avoid frequent repairs:

Regular Cleaning: Regularly clean the alternator and its components to prevent the accumulation of dirt and debris. This could help reduce unnecessary wear and tear, hence prolonging the life of the slip ring.

Periodic Inspections: Keep an eye on the overall condition of your alternator. Look out for any signs of damage or wear on the slip ring. If you find any sign of pitting or grooving, it may be time to consider a replacement.

Correct Belt Tension: Ensure the alternator’s belt, also known as the serpentine belt, is correctly tensioned. If the belt tension is too much, it can cause excessive wear on the slip ring.

Use Quality Replacement Parts: If you need to replace the slip ring, opt for high-quality replacement parts. Although they may cost a bit more initially, they will prove to be more cost-effective in the long run as they generally last longer and perform better.

Vehicle Electrical System Check: Regularly get your vehicle’s electrical system checked. An over-stressed or faulty electrical system can cause excessive wear to the slip ring, leading to premature failure.

Regular maintenance checks have several benefits, here are a few highlighted:

Early Detection of Problems: Checks make it easier to detect and repair minor problems before they escalate, reducing the likelihood of serious damage and expensive repair costs.

Improved Vehicle Performance: Regularly maintaining the alternator and its slip ring ensures your vehicle’s electrical system operates efficiently. This means smoother running and less of a chance of being stranded due to a breakdown.

Cost-Effective: In the long run, maintenance is cheaper than repairs. By preventing serious damage through regular checks, you save on potentially high repair or replacement costs.

Extended Alternator Life: Regular checks can extend the life of your alternator by ensuring that any components, including the slip ring, are replaced before they fail.

By incorporating these tips into your vehicle’s maintenance routine, you can help extend the life of the slip ring and the alternator, resulting in better performance and potentially significant cost savings.

Conclusion

Regular maintenance and immediate address of any issues that crop up can save you from costly repairs. Whether you choose a DIY approach or professional help for alternator slip ring repair, a deeper insight into the subject can contribute immensely towards your vehicle’s durability and performance.

FAQs about Alternator Slip Ring Repair

Here are some common queries about alternator slip ring repairs, preventive measures, associated costs, and indicators for replacement:

Q1: What are some preventive measures to prolong the lifespan of my alternator slip ring?

A: To prolong the lifespan of your alternator slip ring, regular maintenance of your vehicle’s alternator is crucial. This includes regular checks and cleaning to remove dirt or debris that might have accumulated which could cause friction or block electrical transmission. Additionally, ensure the serpentine belt (alternator belt) is properly adjusted to prevent undue stress on the slip ring.

Q2: How much does it cost to repair or replace an alternator slip ring?

A: The cost of replacing an alternator slip ring largely depends on your vehicle’s make and model and the labor costs in your area. On average, you might expect it to range from $100 to $400 for parts and labor.

Q3: Can I drive my car with a damaged alternator slip ring?

A: While you might be able to drive your car with a damaged slip ring for a brief period, it’s not recommended. A defective slip ring affects the alternator’s ability to charge the battery and power your vehicle’s electrical systems, which could potentially lead to a total breakdown.

Q4: At what point should the slip ring be replaced?

A: Typically, the slip ring should be replaced if it’s severely worn or damaged. This often manifests in symptoms such as erratic electrical function, like dimming lights or difficulty starting your vehicle. Regular inspections can help identify such wear and damage early, and a professional mechanic can advise you if replacement is necessary.

Q5: Is it necessary to replace the whole alternator if the slip ring is damaged?

A: Not necessarily. If the rest of the alternator is in good condition, then only the slip ring may need to be replaced. However, if other parts are also worn out or failing, it might be more cost-effective in the long run to replace the entire alternator.

See What We Can Do