As technology advances, devices become more complex and require specialized components to function efficiently. Rotary Joints are a critical part of these advancements, enhancing performance and endurance in various systems they play integral roles in today’s tech-driven world. This guide seeks to inform you about the best Rotary Joints of 2023 and provide insights that will help you make an informed choice.

Table of Contents

How We Chose the Best Rotary Joints of 2023

To determine the best rotary joints for 2023, our selection process followed a comprehensive, methodical, and unbiased approach. Our team consists of experienced engineers, product reviewers, and research analysts. We evaluated joints for quality, durability, price, technical specifications, and customer reviews to create an informed list of the best rotary joints in 2023.

It was also crucial to our research to consider the user’s first-hand experience. To do this, we conducted a survey of customer reviews from various online marketplaces and technology forums.

Extracting information about customer experience allows us to evaluate the actual performance, life, and efficiency of rotary joints in the field. We see this user feedback phase as an opportunity to understand the pros and cons of each product from an unbiased end-user perspective.

Equally important to our research process is the testing phase. A selected number of rotary joints are rigorously tested in a carefully controlled environment. We evaluate projects based on functionality, efficiency, durability, and ease of use. Each product is tested under different conditions and settings to fully understand its capabilities and limitations.

In addition, cost-effectiveness is also a major consideration. The best choice of rotary joints has to be worth the money and impress us not only with its quality but also with its economy. We looked at the cost of repairs, maintenance, and replacement parts because they all affect the total cost of ownership.

The Basics of Rotary Joints

What are Rotary Joints?

Rotary joints, also known as rotary unions or swivels, serve as pivotal components in many machine systems, acting as liaisons between static and rotating parts. Essential in diverse industries, from aerospace to food and beverage, they are mechanical devices designed to sustain fluid transfer under rotation, which is especially beneficial in cooling, heating, or transferring power purposes.

In essence, these devices enable a stationary input (usually fluid or gas) to be transported into a rotating part while preserving a fluid-tight condition. They essentially offer a seal between the stationary supply pipe and the rotating equipment such as drums, rolls, or cylinders. This way, they help keep the fluid moving smoothly within the system, preventing leaks and maintaining the overall efficiency of the system’s operation.

Rotary joints are designed with a balanced mechanical seal and bearing system to handle different pressure variations, rotational speed, and temperatures, which adapts to the requirements of their application environments. This flexibility and versatility make them a fundamental piece in numerous manufacturing and industrial applications, ranging from molding machines, oil and gas systems, steam handling, and even within the medical sector.

Characteristics of Rotary Joints

Rotary joints possess some distinctive characteristics:

- Flexibility: The nature of rotary joints allows them to facilitate relative movement or rotation between the parts they connect. Their design caters to different degrees of rotation, from moderate to high rotational movements, depending on their application. This flexibility is critical as it enables the connected components to operate seamlessly under various working conditions. Some rotary joints also offer multi-passage options, allowing multiple types of media (fluid, gas, etc.) to be transferred simultaneously.

- Durability: Rotary joints are built to withstand demanding operating environments. They are equipped to handle high pressures and temperatures, making them very reliable in various fields, such as machine tools, plastic, paper, or textile industries, where such conditions are prevalent. The substance of the rotary joint, generally made out of hard-wearing materials like stainless steel or other high-strength alloys, adds to its durability. This allows the rotary joint to resist wear and tear, prolonging its lifespan even in rigorous conditions.

- Variety: Rotary joints come in a diverse range of shapes and sizes to accommodate multiple applications. They can be as straightforward as a single passage rotary joint that transfers a single medium, to as complex as a multi-passage rotary joint designed to transfer multiple distinct mediums concurrently. Furthermore, the design of the rotary joint can significantly vary depending on its usage. For example, a heavy-duty rotary joint used in a high-temperature steam application would be built differently from a light-duty rotary joint used in an air conditioning system.

This variety ensures that there is a suitable rotary joint for virtually any application, making them incredibly versatile in the engineering field.

Pros and Cons of Rotary Joints

Like every mechanical component, they have their benefits and limitations.

Pros

Rotary joints are revered for the multitude of benefits they bring to various applications. Streamlined operation is one of the key advantages – rotary joints enable fluids to be transferred between static and rotating components without leakage. This steadiness in operation reduces the risk of system failures, which can lead to expensive downtime.

The resilience of rotary joints warrants their use in varied environments. They’re designed to withstand a multitude of pressures and temperatures, making them incredibly versatile. This resilience also makes rotary joints worth the investment as their durability ensures a lengthier lifespan even in harsh conditions.

Another advantage is their minimal maintenance needs. A well-designed rotary joint can run for long periods without needing frequent repair or replacements, thus saving time and costs.

Lastly, there is a great deal of versatility associated with rotary joints. They’re available in a variety of sizes and types to accommodate a range of applications. These varied configurations mean they can be customized to fit virtually any system need.

Cons

Despite their various advantages, Rotary joints also come with certain drawbacks. For one, their complexity can sometimes lead to a steep learning curve. A proper understanding of how rotary joints work, and how to install and maintain them, is necessary. Otherwise, incorrect installation can lead to inefficiency and faster wear and tear.

Then, there’s the fact that using the wrong type of rotary joint for a certain application can lead to complications or even system failures. For example, using a rotary joint designed for low-pressure systems in a high-pressure system can result in premature failure. It is therefore imperative to choose the correct type of rotary union for each specific application.

Another pain point can be the cost. High-quality, industry-grade rotary joints, especially those designed to withstand noticeably high-pressure and temperature systems, can be quite expensive. Although the initial investment can be high, it’s important to remember that a quality rotary joint can provide more dependable service and a longer lifespan, leading to cost savings in the long run.

Lastly, like all mechanical parts, rotary joints are still liable to wear and tear. Although they’re designed to be durable, they can still suffer breakdowns and failures if not properly maintained or when exposed to conditions beyond their design range. This underscores the importance of regular maintenance and checks to ensure smooth operation.

Various Types of Rotary Joints

Several types of rotary joints are available, tailored for different applications.

- Pneumatic/Hydraulic Electrical Rotary Joints

- Pneumatic Rotary Unions

- Hydraulic Rotary Unions

- Wind Turbine Hydraulic Rotary Joints

Best Rotary Joints of 2023

Pneumatic/Hydraulic Electrical Rotary Joints

Pneumatic electrical slip rings are devices that allow the transmission of electrical signals and power while also accommodating the flow of pressurized air or other gases. Hydraulic electric slip rings are devices that allow the transmission of power and signals while accommodating hydraulic fluid flow. Both consist of a rotor and a stator. Slip rings are customized to meet specific requirements for the number of circuits and the type of gas that needs to be transported.

1 Passage Pneumatic + Electrical Rotary Joints

Introduction

◆ Support M5, G1 / 8, G1 / 4, G3 / 8, G1 / 2, G3 / 4, G1 thread for pneumatic

◆ Dynamic sealing technology

◆ With NSK high precision bearing

◆ Abrasion resistant, low torque, high speed

◆ Can be combined to transfer 2~96 circuits power and signal

Description

| Electrical Data | Mechanical Data | ||

|---|---|---|---|

| Rated Voltage | Power: 0~440 VAC/VDC Signal: 0~240 VAC/VDC | Max. Speed | 400RPM |

| Insulation Resistance | Power: ≥1000MΩ/500VDC Signal: ≥1000MΩ/500VDC | Max. Pressure | 10Bar |

| Insulation Strength | 500VAC@50Hz, 60s | Working Temperature | -30℃~+80℃ |

| Lead Wires | Standard (adjustable) | Working Humidity | 0~85% RH |

| Lead Length | Standard 300mm (adjustable) | Housing Material | Aluminum Alloy |

| Electrical Noise | <0.01Ω | Protection Grade | IP51 |

2 Passage Pneumatic/Hydraulic + Electrical Rotary Joint

Introduction

◆ Can replace SMC series pneumatic rotary joint

◆ Can combine to transmit power and signals

◆ Standard ports M5, can be G1/8, G1/4, G3/8, G1/2, G3/4

◆ Specification can be customized

◆ Housing Material, Stainless Steel/Aluminum Alloy

◆ Working Temperature, -40℃-+80℃

◆ Working Humidity, 10-85% RH

◆ Protection Grade, IP51

Description

| Model | Passages | Circuits(2A) | Torque | Negative Vacuum | Max. Pressure | Max. Speed |

|---|---|---|---|---|---|---|

| MQR2 | 2 Passages, Port M5 | / | 0.2N.m | -1.5kPa | 1Mpa | 300rpm |

| MQR2-S12 | 2 Passages, Port M5 | 12 Circuits | 0.2N.m | -1.5kPa | 1Mpa | 300rpm |

| MQR2-S24 | 2 Passages, Port M5 | 24 Circuits | 0.2N.m | -1.5kPa | 1Mpa | 300rpm |

4 Passage Pneumatic/Hydraulic + Electrical Rotary Joint

Introduction

◆ Can replace SMC series pneumatic rotary joint

◆ Can combine to transmit power and signals

◆ Standard ports M5, can be G1/8, G1/4, G3/8, G1/2, G3/4

◆ Specification can be customized

◆ Housing Material, Stainless Steel/Aluminum Alloy

◆ Working Temperature, -40℃-+80℃

◆ Working Humidity, 10-85% RH

◆ Protection Grade, IP51

Description

| Model | Passages | Circuits(2A) | Torque | Negative Vacuum | Max. Pressure | Max. Speed |

|---|---|---|---|---|---|---|

| MQR4 | 4 Passages, Port M5 | / | 0.3N.m | -1.5kPa | 1Mpa | 300rpm |

| MQR4-S12 | 4 Passages, Port M5 | 12 Circuits | 0.3N.m | -1.5kPa | 1Mpa | 300rpm |

| MQR4-S24 | 4 Passages, Port M5 | 24 Circuits | 0.3N.m | -1.5kPa | 1Mpa | 300rpm |

6 Passage Pneumatic/Hydraulic + Electrical Rotary Joint

Introduction

◆ Can replace SMC series pneumatic rotary joint

◆ Can combine to transmit power and signals

◆ Standard ports M5, can be G1/8, G1/4, G3/8, G1/2, G3/4

◆ Specification can be customized

◆ Housing Material, Stainless Steel/Aluminum Alloy

◆ Working Temperature, -40℃-+80℃

◆ Working Humidity, 10-85% RH

◆ Protection Grade, IP51

Description

| Model | Passages | Circuits(2A) | Torque | Negative Vacuum | Max. Pressure | Max. Speed |

|---|---|---|---|---|---|---|

| MQR6 | 6 Passages, Port M5 | / | 0.5N.m | -1.5kPa | 1Mpa | 300rpm |

| MQR6-S12 | 6 Passages, Port M5 | 12 Circuits | 0.5N.m | -1.5kPa | 1Mpa | 300rpm |

| MQR6-S24 | 6 Passages, Port M5 | 24 Circuits | 0.5N.m | -1.5kPa | 1Mpa | 300rpm |

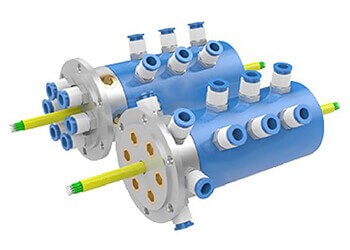

8 Passage Pneumatic/Hydraulic + Electrical Rotary Joint

Introduction

◆ Can replace SMC series pneumatic rotary joint

◆ Can combine to transmit power and signals

◆ Standard ports M5, can be G1/8, G1/4, G3/8, G1/2, G3/4

◆ Specification can be customized

◆ Housing Material, Stainless Steel/Aluminum Alloy

◆ Working Temperature, -40℃-+80℃

◆ Working Humidity, 10-85% RH

◆ Protection Grade, IP51

Description

| Model | Passages | Circuits(2A) | Torque | Negative Vacuum | Max. Pressure | Max. Speed |

|---|---|---|---|---|---|---|

| MQR8 | 8 Passages, Port M5 | / | 0.7N.m | -1.5kPa | 1Mpa | 300rpm |

| MQR8-S12 | 8 Passages, Port M5 | 12 Circuits | 0.7N.m | -1.5kPa | 1Mpa | 300rpm |

| MQR8-S24 | 8 Passages, Port M5 | 24 Circuits | 0.7N.m | -1.5kPa | 1Mpa | 300rpm |

10 Passage Pneumatic/Hydraulic + Electrical Rotary Joints

Introduction

◆ Support M5, G1 / 8, G1 / 4, G3 / 8, G1 / 2, G3 / 4, G1 thread for pneumatic

◆ Dynamic sealing technology

◆ With NSK high precision bearing

◆ Abrasion resistant, low torque, high speed

◆ Can be combined to transfer 2~96 circuits power and signal

Description

| Electrical Data | Mechanical Data | ||

|---|---|---|---|

| Rated Voltage | Power: 0~440 VAC/VDC Signal: 0~240 VAC/VDC | Max. Speed | 400RPM |

| Insulation Resistance | Power: ≥1000MΩ/500VDC Signal: ≥1000MΩ/500VDC | Max. Pressure | 10Bar |

| Insulation Strength | 500VAC@50Hz, 60s | Working Temperature | -30℃~+80℃ |

| Lead Wires | Standard (adjustable) | Working Humidity | 0~85% RH |

| Lead Length | Standard 300mm (adjustable) | Housing Material | Aluminum Alloy |

| Electrical Noise | <0.01Ω | Protection Grade | IP51 |

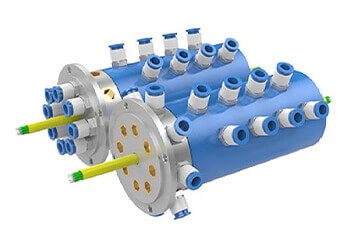

12 Passage Pneumatic/Hydraulic + Electrical Rotary Joint

Introduction

◆ Can replace SMC series pneumatic rotary joint

◆ Can combine to transmit power and signals

◆ Standard ports M5, can be G1/8, G1/4, G3/8, G1/2, G3/4

◆ Specification can be customized

◆ Housing Material, Stainless Steel/Aluminum Alloy

◆ Working Temperature, -40℃-+80℃

◆ Working Humidity, 10-85% RH

◆ Protection Grade, IP51

Description

| Model | Passages | Circuits(2A) | Torque | Negative Vacuum | Max. Pressure | Max. Speed |

|---|---|---|---|---|---|---|

| MQR12 | 12 Passages, Port M5 | / | 1.0N.m | -1.5kPa | 1Mpa | 300rpm |

| MQR12-S12 | 12 Passages, Port M5 | 12 Circuits | 1.0N.m | -1.5kPa | 1Mpa | 300rpm |

| MQR12-S24 | 12 Passages, Port M5 | 24 Circuits | 1.0N.m | -1.5kPa | 1Mpa | 300rpm |

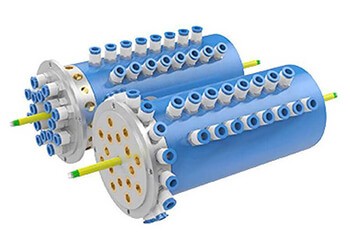

16 Passage Pneumatic/Hydraulic + Electrical Rotary Joint

Introduction

◆ Can replace SMC series pneumatic rotary joint

◆ Can combine to transmit power and signals

◆ Standard ports M5, can be G1/8, G1/4, G3/8, G1/2, G3/4

◆ Specification can be customized

◆ Housing Material, Stainless Steel/Aluminum Alloy

◆ Working Temperature, -40℃-+80℃

◆ Working Humidity, 10-85% RH

◆ Protection Grade, IP51

Description

| Model | Passages | Circuits(2A) | Torque | Negative Vacuum | Max. Pressure | Max. Speed |

|---|---|---|---|---|---|---|

| MQR16 | 16 Passages, Port M5 | / | 1.3N.m | -1.5kPa | 1Mpa | 300rpm |

| MQR16-S12 | 16 Passages, Port M5 | 12 Circuits | 1.3N.m | -1.5kPa | 1Mpa | 300rpm |

| MQR16-S24 | 16 Passages, Port M5 | 24 Circuits | 1.3N.m | -1.5kPa | 1Mpa | 300rpm |

Pneumatic Rotary Unions

Pneumatic rotary joints, also known as pneumatic swivels, are devices that allow the transmission of compressed air or other gases while accommodating the rotational movement between two components. The Grand pneumatic rotary joint adopts the dynamic sealing technology of NSK high-precision bearings to meet the specific requirements for the number of channels, pressure level, and the type of gas that needs to be transmitted.

MQR Series Pneumatic Rotary Joints

Introduction

◆ Supported by double high-precision maintenance-free bearing for high stability

◆ High-quality imported sealing parts for prolonged service life

◆ Stainless steel rotor with special treatment to provide good durability

◆ Housing material available in aluminum, stainless steel, or brass

◆ Special leakage reflux design to avoid exterior contamination

◆ Customization available for different applications

Description

| Technical Ratings | |||

|---|---|---|---|

| Max. Speed | Max. Pressure | Temperature | Media |

| 2000r/min | 1.1 Mpa | -10℃~+80℃ | Air |

MP Series Pneumatic/Hydraulic Rotary Joints

Introduction

◆ Multichannel mechanical sealing structure suitable for high-speed rotating applications also

◆ Double imported ball bearing for high stability

◆ Multi-spring design efficient spring compensation

◆ Balanced mechanical sealing structure for prolonged service life

◆ Drainage hole design for wearing and leakage observation

Description

| Technical Ratings | |||

|---|---|---|---|

| Max Speed | Temperature | Media | Media |

| 3000r/min | -30℃~+120℃ | Air or Water, Max. Pressure 1.1 Mpa | Hydraulic Oil, Max. Pressure 7 Mpa |

MLA Series Pneumatic Rotary Joints

Introduction

◆ Supported by double high-precision maintenance-free bearing for high stability

◆ High-quality imported sealing parts for prolonged service life

◆ Stainless steel rotor with special treatment to provide good durability

◆ Housing material available in aluminum, stainless steel, or brass

◆ Special leakage reflux design to avoid exterior contamination

◆ Customization available for different applications

Description

| Technical Ratings | |||

|---|---|---|---|

| Max Speed | Max Pressure | Temperature | Media |

| 2000r/min | 1.1 Mpa | -30℃~+80℃ | Air |

Hydraulic Rotary Unions

Hydraulic rotary joints, also known as hydraulic swivels, is a device that allows the transmission of hydraulic fluid while accommodating rotational movement between two components. Grand supports customized double high-precision maintenance-free bearing with UKS sealing parts.

MH Series Hydraulic Rotary Joints

Introduction

◆ Supported by double high-precision maintenance-free bearing for high stability

◆ High-quality imported sealing parts for prolonged service life

◆ Stainless steel rotor with special treatment to provide good durability

◆ Housing material available in aluminum, stainless steel, or brass

◆ Special leakage reflux design to avoid exterior contamination

◆ Customization available for different applications

Description

| Technical Ratings | |||

|---|---|---|---|

| Max. Speed | Max. Pressure | Temperature | Media |

| 300r/min | 30 Mpa | -30℃~+80℃ | Oil, Air or Similar |

Note

- Operations under extreme ratings should be avoided. Maximal working speed is in reverse proportion to working pressure and is also influenced by the media lubricity and the heat dissipation ability of the sealing components. When the rotation speed is lower than 10RPM, the maximal pressure can be up to 30Mpa.

- Inner leakage is allowed between each passage. Please pay attention to the compatibility of different working media to avoid cross-contamination.

- The working fluid or hydraulic media should be filtered before being used. The filtration precision should be no lower than 10um.

- A drainage hole is accompanied for observation and collection of escaping media.

- For other applications, please consult AIKE SEALING beforehand.

Wind Turbine Hydraulic Rotary Joints

Wind turbine hydraulic rotary joints are specialized hydraulic swivels that are used in wind turbines to transfer hydraulic fluid between the rotating and stationary components of the turbine. Special hydraulic sealing structure designed for high-speed and high-pressure applications.

Introduction

◆ Supported by double high-precision maintenance-free bearing for high stability

◆ Special sealing structure designed for high-speed and high-pressure application that provides prolonged failure-free operation

◆ Low rotation torque

◆ Special structure to be free from friction heat under high-speed

◆ Running torque unaffected by working pressure and temperature change.

◆ Max working speed up to 6500RPM

◆ Drainage hole design to avoid exterior contamination

◆ Customization available for different customer applications

Description

| Technical Ratings | |||

|---|---|---|---|

| Max Speed | Max Pressure | Temperature | Media |

| 6500r/min | 30 Mpa | -30℃~+80℃ | Hydraulic, Oil |

Note

- MK Series uses a labyrinth sealing structure. During installation and operation, the drainage hole L must be connected by an oil pipe to the oil collection tank. And the oil pipe must not be blocked to avoid back pressure.

- Inner leakage is allowed between each passage. Please pay attention to the compatibility of different working media to avoid cross-contamination.

- The working fluid or hydraulic media should be filtered before being used. The filtration precision should be no lower than 10um.

- Working temperature rise will reduce the viscosity of the working fluid to increase the leakage volume. So during operation, the cooling device should be accompanied.

- The hydraulic system should be equipped with an automatic pressure regulator to compensate for the pressure loss caused by inner leakage.

Considerations When Selecting Rotary Joints

Before choosing a particular rotary joint, consider the following:

- Application: Understanding the specific needs and requirements of your system is the first step in choosing the right rotary joint. This includes knowing the type of medium to be transferred (liquid, gas, etc.), the rotational speed of the system, and other specific operational requirements. Identifying these requirements will help in selecting a rotary joint that will serve your needs seamlessly and enhance the performance of your system.

- Operating Conditions: Operating conditions such as pressure and temperature ranges are paramount in the selection process. Some joints are designed to work best under high pressures and temperatures, while others are better suited for low to moderate conditions. Misjudging the operating conditions could lead to premature failure of the rotary joint and even disrupt the entire system.

- Size and Type: Rotary joints come in various sizes and types. The right size should fit well within the existing system without necessitating drastic modifications. The type of joint determines the kind of application it’s best suited for. Various types include hydraulic, pneumatic, steam, and water rotary joints, all designed to work optimally in specific applications.

- Material: The construction material of the rotary joint is critical because it affects its resistance to the type of fluid transferred and its overall durability. Materials such as stainless steel and bronze are popular due to their strength and resistance to corrosion. The environment in which the rotary joint will operate also informs the material choice, such as whether it needs to be resistant to seawater or to a high saline environment.

- Cost: While it’s important to note that a low-priced rotary joint may be less reliable, cost still remains a significant factor to consider when purchasing rotary joints. It would be best if you strive to strike a balance between cost and quality. The high initial investment in a reliable joint can indeed save future costs related to breakdowns, maintenance, and replacements. Therefore, investing in higher-quality joints may be beneficial in the long run.

- Manufacturer’s Reputation: Last but not least, the reputation of the manufacturer shouldn’t be overlooked. A manufacturer with a strong track record for reliability and quality should offer better assurance. You can research the company, look at its past customer reviews, and consider its warranty policies to get a clear picture of how it handles customer grievances and product faults. This can make a big difference when looking for the best long-term solution.

FAQs about Rotary Joints

Q1: How long do rotary joints last?

A: It depends on the working conditions and maintenance, but generally, rotary joints can last several years.

Q2: How to maintain rotary joints?

A: Regular checkups, proper cleaning, and lubing of the joints will increase their lifespan.

Q3: Can I use one type of rotary joint for any application?

A: No, each joint type is designed for a particular application. Misusage may lead to inefficiency or damage.

Q4: Where can I purchase the best rotary joint?

A: There are multiple suppliers, both online and physical stores. However, ensure you buy from reputable vendors.

Q5: Is there a significant difference between the rotary joints of different brands?

A: Brands may have certain unique attributes but what matters is the quality, operability, price, and the manufacturer’s reputation.

This roundup provides valuable insights into the best Rotary Joints of 2023. With this information at your disposal, you are well-equipped to choose the perfect rotary joint for your application.