Slip ring motors have long been hailed for their exceptional performance and adaptability in various industrial applications. However, the emergence of Variable Frequency Drives (VFDs) has sparked a compelling question: Can we use VFD for slip ring motors?

Today, we are thrilled to unveil an eye-opening exploration of this topic, shedding light on the potential of VFDs to revolutionize slip ring motor control. Engineers, technicians, and industry enthusiasts will gain valuable insights into the compatibility and benefits of using VFDs with slip ring motors.

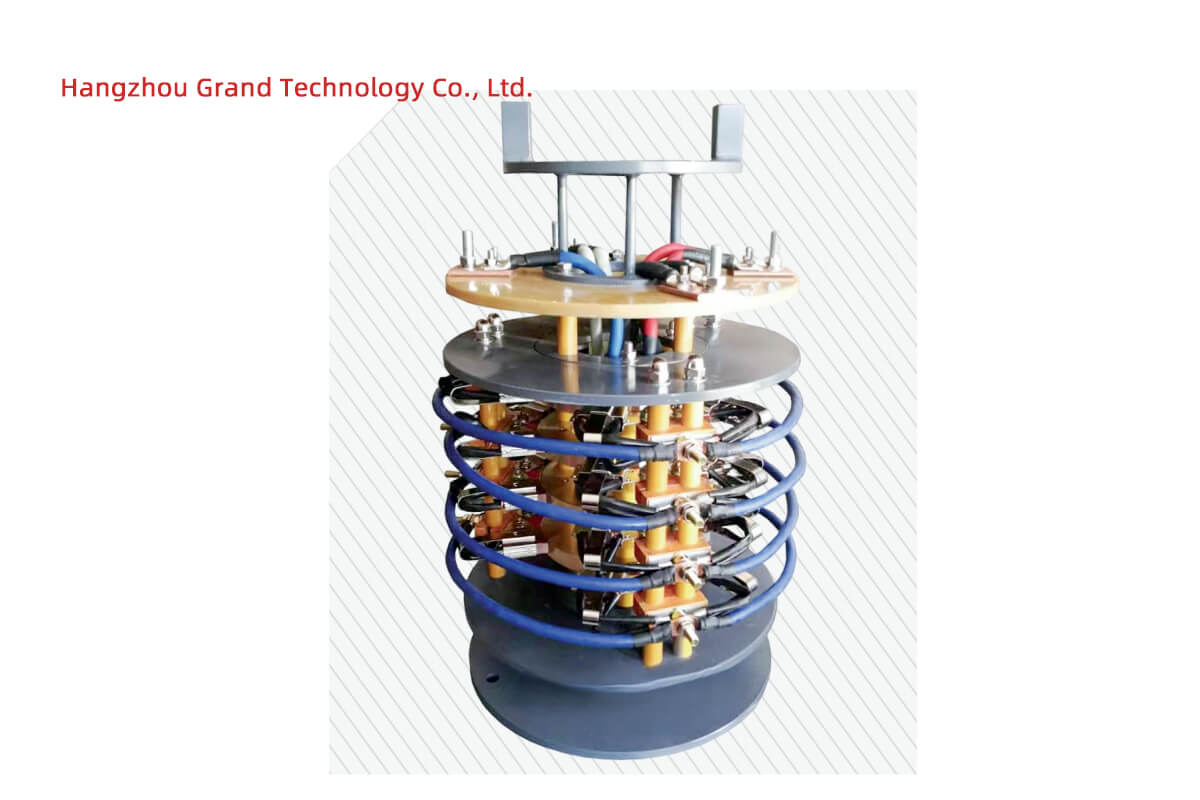

Traditionally, slip ring motors have been controlled using external resistance connected to the rotor circuit. While this method offers adjustable speed control, it presents challenges such as energy losses, maintenance requirements, and limited control precision. The introduction of VFDs has opened up new possibilities for slip ring motor control, offering enhanced performance, efficiency, and flexibility.

To delve into this exciting realm of slip ring motor control, let’s explore the key aspects of using VFDs:

1. Compatibility: The first question that arises is whether slip ring motors are compatible with VFDs. The answer is a resounding “Yes!”

Slip ring motors can be effectively operated using VFDs, given that the VFD is designed to accommodate the unique characteristics and requirements of slip ring motors. It is essential to select a VFD that supports the voltage and power ratings of the slip ring motor.

2. Advantages of VFDs for Slip Ring Motors:

Precise Speed Control: VFDs offer unparalleled precision in speed control. By adjusting the frequency and voltage supplied to the motor, the rotational speed can be precisely regulated, allowing for optimal performance in various operating conditions.

Soft Starting: Slip ring motors connected to VFDs benefit from soft starting capabilities, which reduce mechanical stress and power surges during motor startup. This feature enhances equipment lifespan and minimizes downtime.

Improved Energy Efficiency: VFDs enable energy optimization by matching the motor speed with the load requirements. By varying the frequency and voltage, the motor operates at the most efficient point, resulting in energy savings and reduced operating costs.

Enhanced Process Control: VFDs offer advanced control features such as torque control, acceleration/deceleration ramps, and motor protection mechanisms. These features contribute to precise and reliable process control, ensuring smooth operation and minimizing the risk of motor damage.

3. Considerations for VFD Application:

Motor Design: When considering VFD application for slip ring motors, it is crucial to ensure that the motor is designed to withstand the voltage and frequency variations associated with VFD operation. Motor insulation class and bearing selection should be compatible with VFD-induced electrical stresses.

External Resistance: In some cases, slip ring motors may still require external resistance for specific applications. In such scenarios, VFDs can be integrated with additional equipment to emulate the effect of resistance control.

Harmonics and Filtering: VFDs generate harmonics that can affect the power quality of the electrical system. Proper filtering and harmonic mitigation techniques should be employed to ensure compliance with standards and prevent potential issues.

To empower professionals and enthusiasts in leveraging VFDs for slip ring motor control, we are excited to announce the launch of our comprehensive online course, “Optimizing Slip Ring Motors with VFDs.”

This course, developed by industry experts, provides in-depth knowledge, practical examples, and case studies to guide learners through the process of integrating VFDs with slip ring motors. Enroll today and unlock the potential to revolutionize your understanding of slip ring motor control. For more information and to enroll in our course, please visit Hangzhou Grand Technology.

About Hangzhou Grand Technology

Hangzhou Grand Technology is a leading provider of cutting-edge educational resources and training programs in the field of electrical engineering. With a commitment to empowering individuals and organizations with practical knowledge and expertise, we bridge the gap between theory and application. Our team of industry professionals is dedicated to creating comprehensive and accessible learning experiences that cater to the needs of learners worldwide.

See What We Can Do