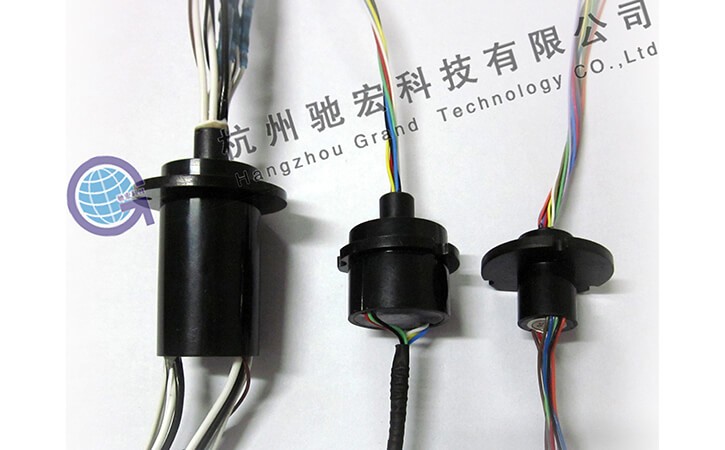

Capsule slip rings are often offered in a compact size with flange like miniature slip rings, used for electrical power transmission and data transfer between a stationary and a rotating part. Capsule Slip Rings also have the rotor, stator, brush block, bearing, and housing. They are easily installed and widely used in small and medium-sized equipment, such as speed dome cameras, intelligent toys, stage lights drones, etc.

What Is Capsule Slip Ring?

Capsule Slip Rings - HM Series

Available for Custom, Standard OD 6.5-25 mm

GRAND offers capsule slip rings in various forms, maintenance free, gold contact, silver fiber brush, and low voltage. Also can be combined with other types of rotary joints like Ethernet, fiber optic rotary joint (FORJ), hydraulic, and radio frequency.

Although GRAND offers modularized & standardized designs for various application solutions as an original slip ring manufacturer. To create your most suitable capsule slip ring connector, please feel free to contact us.

Feature

- 360° rotating signal and power transmission, such as control signals, video signals, HD signals, Ethernet, sensor

- Can reach military quality, gold-gold contacts, fiber brushes technology

- Low torque, low insertion loss, low contact resistance, long working life

- Stator flange or without flange installation for option

- Integrated structure design, easy installation

Option

- Operation speed, current &voltage

- Connector

- Type of flange

- No. of rings

- Housing material

- Position of wire outlet

- Protection level (dust and water)

- Power ring with 5A, 10A, 15A, 20A is available upon 2A rings combination

Model Breakdown

Capsule Slip Rings: Overview and Benefits

Grand Capsule slip rings are compact, sealed electromechanical devices designed to transmit electrical power and signals between stationary and rotating parts of a system. These small slip rings are engineered for a variety of applications where space is limited, but reliable power and data transmission are still critical. Their mini slip ring design allows them to fit into tight or restricted spaces while maintaining performance. Capsule slip ring assemblies are commonly used in industries such as robotics, aerospace, renewable energy, industrial automation, and medical equipment, where both compactness and efficiency are essential.

Key Features of Capsule Slip Rings:

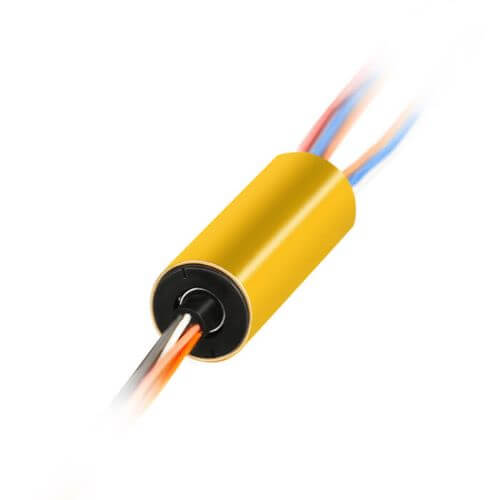

Compact Design

Capsule slip rings are designed to be smaller and more compact compared to traditional slip rings. Their streamlined form makes them an excellent choice for systems where space constraints are a concern, such as small robotic arms, medical devices, and portable machinery. The small slip ring design ensures that slip rings can fit into tight or restricted spaces while maintaining performance, making them ideal for applications where both size and efficiency matter. The compact flange rings offer a solution to mount slip rings securely while maintaining their small footprint.

Sealed Protection

One of the main advantages of capsule slip rings is their sealed construction. The sealed design protects the internal components of the capsule slip ring from dust, moisture, dirt, and other environmental contaminants, ensuring smooth and reliable operation. This feature is especially important in outdoor or harsh environments, such as wind turbines, offshore rigs, or industrial machinery exposed to water or chemicals. The slip ring flange provides added durability by securing the slip ring in place, preventing misalignment that could result in signal loss or power failures.

Multiple Circuit Capabilities

Capsule slip rings can be configured with multiple circuits, allowing them to transmit both power and signals (including data, video, and communications) simultaneously. This multi-circuit design makes them versatile and suitable for complex systems that require both electrical power and signal transmission, such as in robotics, industrial automation, or advanced manufacturing systems. The 4 wire slip ring configuration is commonly used to handle both power and data transmission efficiently. For systems requiring secure mounting, slip ring with flange options are also available to ensure the assembly remains stable during rotation.

Durable and Long-Lasting

The sealed construction not only protects the slip rings from contamination but also contributes to their durability and longevity. With fewer moving parts exposed to the environment, capsule slip rings generally require less maintenance, offering a longer operational lifespan compared to non-sealed models. This reduces the need for frequent repairs or replacements, saving both time and money in the long run. The miniature slip ring design is especially beneficial for applications where space and reliability are essential, and the compact flange rings ensure that the slip rings remain securely mounted even in high-vibration environments.

Cost-Effective Solution

Capsule slip rings provide a more affordable solution compared to larger, more complex slip ring system. Despite their lower cost, they offer high performance, making them a great option for projects that need both quality and budget-conscious solutions. Their compact and simplified design reduces manufacturing and installation costs, helping to keep overall project expenses in check. The type mc400 slip ring is an economical yet high-performance option for smaller applications that require a cost-effective, reliable slip ring solution.

Applications of Capsule Slip Rings:

Robotics

In robotic systems, capsule slip rings allow continuous power and signal transfer between the rotating parts (such as robotic arms) and the stationary control system. Their compact design ensures that they fit into tight spaces, providing the necessary electrical connections without impeding the robot’s movement or performance. The small slip ring is commonly used in such applications for small robotic systems that require efficient power transmission. Additionally, the slip ring with flange option helps secure the slip ring in place, providing stability for systems with high rotational speeds or vibrations.

Aerospace and Aviation

Capsule slip rings are used in various aerospace applications, such as in satellites, aircraft systems, and rotary actuators, where reliability and compactness are essential. Their sealed design helps protect against the environmental challenges faced in aerospace, including extreme temperatures, vibrations, and exposure to atmospheric conditions. The slip ring capsule offers the perfect solution for transmitting power and signals in these critical systems, and slip ring flanges are often used to mount the slip ring assembly securely within the rotating parts of these systems.

Industrial Equipment

In industrial automation and machinery, capsule slip rings are used to transmit power and signals between rotating and stationary components. They are ideal for applications such as CNC machines, wind turbines, and packaging equipment, where space is limited, but continuous power transmission is crucial. The 4 wire slip ring configuration is often used for transmitting multiple types of signals and power, ensuring flexibility in industrial setups. The slip ring flange ensures that the slip ring remains firmly mounted, even during high-speed operations or when subjected to mechanical stress.

Medical Devices

Capsule slip rings are also used in medical imaging equipment, such as CT scanners and MRI machines, where they help transmit electrical signals while allowing the rotating parts of the machinery to function smoothly. The compact and sealed nature of these slip rings ensures that the sensitive electronic components are protected in clean, sterile environments. The miniature slip ring design is particularly useful in medical devices with small, intricate components, and the slip ring with flange option ensures that these components are securely mounted for reliable operation.

Renewable Energy

In renewable energy systems like wind turbines, capsule slip rings are used to transmit power and data from the rotating blades to the stationary hub or base. Their ability to withstand harsh weather conditions and their compact form factor make them a reliable choice for these energy systems. The type mc400 slip ring is commonly employed in wind turbine applications where both power and signal transmission are needed, and compact flange rings are used to securely mount the slip ring in place, even in high-vibration and outdoor environments.

Benefits of Capsule Slip Rings:

Space Efficiency: The compact design allows them to be used in applications where size is a critical factor, offering a space-efficient solution for rotating systems. The small slip ring design is perfect for such applications.

Enhanced Durability: The sealed construction provides protection against environmental factors, extending the lifespan and reducing maintenance needs. The capsule ring design ensures that the internal components remain free from contaminants. The slip ring flange adds to the durability by securing the slip ring in place.

High Performance: Capsule slip rings offer reliable transmission of both power and data signals, ensuring continuous operation without signal loss or interference. The slips ring ensures high-quality performance even in demanding environments.

Customization: They can be customized to meet the specific needs of various applications, with options for multi-circuit configurations, different materials, and environmental seals. The type mc400 slip ring, for example, offers a customizable design for specialized applications.

Cost-Effective: Their compact design and simplified structure make them an affordable solution for a wide range of applications, providing both quality and value. The slip ring with flange option provides a secure and affordable solution for high-performance systems.

Collector Ring Market: Overview and Trends

Collector rings, often referred to as slip rings, are electromechanical devices used to transmit electrical power or signals between stationary and rotating parts of a system. They are essential components in various rotating machinery and equipment, enabling continuous electrical contact without interruption. These devices are used in applications such as motors, wind turbines, radar systems, robotics, and more.

The collector ring market is driven by the increasing demand for automation, renewable energy, robotics, and industrial machinery across various sectors. As industries continue to modernize and automate, the need for efficient and reliable electrical transmission systems becomes critical. The collector ring market is evolving with innovations in design and materials, leading to the development of more efficient, compact, and durable collector rings suitable for a wide range of applications.

Key Factors Driving the Collector Ring Market:

Rising Demand for Automation and Robotics

The global trend toward automation and robotics is one of the primary factors driving the growth of the collector ring market. Industries like automotive manufacturing, food and beverage, electronics, and pharmaceuticals are increasingly adopting robotic systems for various tasks, such as assembly, material handling, and quality control. Collector rings are essential in these systems to enable continuous power and signal transmission between rotating robotic arms and stationary controllers.

Growth of Renewable Energy

The renewable energy sector, particularly wind energy, is a major contributor to the demand for collector rings. Collector rings are used in wind turbines to transmit power from the rotating blades to the stationary base, making them critical components in modern wind farms. As governments and organizations continue to invest in renewable energy solutions, the demand for durable, high-performance collector rings will increase.

Advancements in Technology

The development of advanced materials and technologies has led to the creation of more efficient, compact, and high-performance collector rings. Innovations like capsule slip rings, mini slip rings, and sealed collector rings are enabling manufacturers to produce more reliable and durable devices for specialized applications. These technological advancements are expected to boost the growth of the collector ring market, particularly in niche sectors such as aerospace, medical equipment, and industrial automation.

Increase in Aerospace and Defense Applications

The aerospace and defense sectors are increasingly relying on advanced electrical systems for radar, satellite communications, and missile guidance systems. Collector rings are widely used in these applications to maintain continuous power and signal transmission between stationary and rotating parts. With the growing demand for advanced aerospace technologies, the collector ring market is poised for significant expansion.

Miniaturization and Customization

The increasing trend toward miniaturization in various industries, especially in robotics and medical devices, is driving the demand for smaller, compact collector rings. Manufacturers are focusing on producing mini slip rings and compact flange rings that can fit into smaller spaces without compromising on performance. Customization is also a growing trend, with many manufacturers offering tailored solutions to meet specific customer needs.

Market Segmentation:

By Type

Slip Rings: These are the most commonly used collector rings in various applications, including motors, wind turbines, and robotics.

Collector Rings with Flange: These provide enhanced stability and secure mounting, particularly in high-vibration applications.

Miniature Slip Rings: These collector rings are designed for small, space-limited systems such as medical equipment, small robots, and precision machinery.

Sealed Collector Rings: These are designed to prevent dust, moisture, and other environmental contaminants from entering the slip ring mechanism, making them ideal for harsh environments such as offshore oil rigs and outdoor machinery.

By Application

Wind Energy: Collector rings are crucial in wind turbines, where they transmit power from the rotating blades to the stationary components.

Robotics and Automation: These systems require continuous power and data transmission between rotating and stationary parts, which collector rings facilitate.

Aerospace and Defense: Collector rings are used in radar, satellite, and aircraft systems to maintain electrical contact in rotating components.

Medical Devices: In medical imaging equipment, collector rings help transmit electrical signals between rotating and stationary components, ensuring smooth functionality.

Industrial Machinery: Collector rings are used in various industrial machines, such as CNC machines and conveyor belts, to provide reliable power transmission.

By Material

Copper: Copper is widely used in collector rings due to its excellent electrical conductivity.

Gold: In high-precision applications, gold-plated collector rings are preferred due to their superior corrosion resistance and conductivity.

Alloys: Alloy-based collector rings are used in harsh environments where higher strength and durability are required.

By Region

North America: The demand for collector rings is growing in North America due to the robust automation and robotics sectors, as well as increasing investments in renewable energy projects, particularly wind energy.

Europe: Europe is a major market for collector rings, driven by advancements in industrial automation, aerospace, and defense applications.

Asia-Pacific: The Asia-Pacific region is expected to experience significant growth in the collector ring market due to the rapid industrialization of countries like China, Japan, and India, along with the growing demand for robotics and manufacturing automation.

Latin America and Middle East & Africa: These regions are seeing an increase in demand for collector rings driven by infrastructure development and the expansion of renewable energy projects.

Challenges in the Collector Ring Market:

Complexity in Design: The design and manufacturing of collector rings require precision and expertise, especially for complex applications. Customization and miniaturization can increase production complexity.

Cost Pressure: High-performance collector rings made from advanced materials such as gold or precious metals can be expensive, which may limit their adoption in cost-sensitive industries.

Environmental Factors: In outdoor or harsh environments, collector rings must withstand extreme temperatures, humidity, and corrosive elements, which can increase the demand for sealed and durable solutions.

FAQs about Capsule Slip Ring

What is the purpose of the slip ring?

The primary purpose of a slip ring is to provide a continuous, reliable transfer of electrical power and signals from a stationary structure to a rotating one, or vice versa. Slip rings are commonly used in applications where rotating parts need to maintain an electrical connection with stationary parts without using wires that can twist, tangle, or wear out over time. In many industries, such as robotics, industrial automation, renewable energy, and medical imaging, slip rings ensure smooth and uninterrupted power and data transmission between moving and fixed parts of equipment. Whether it’s for robotic arms that need continuous electrical signals or wind turbines requiring consistent power transmission from rotating blades to stationary hubs, slip rings play a critical role in ensuring that these systems operate effectively and efficiently.

What is slip ring vs twist capsule?

A slip ring and a twist capsule are both used for electrical transmission between rotating and stationary parts, but they function differently and are typically used in different applications. A slip ring is an electromechanical device designed to transfer electrical power and signals continuously through rotating and stationary connections. Slip rings allow uninterrupted transmission without the risk of wires tangling, making them essential for systems with continuous rotation, like robotics, CCTV systems, or wind turbines. On the other hand, a twist capsule is a type of slip ring that combines the functions of a slip ring with a torsional element, designed to transmit both power and data while also accommodating the rotational movement and twisting of cables in certain applications. While slip rings allow electrical transmission through a simple rotating connection, twist capsules are ideal for more specific applications where cable twisting is a concern or where a higher degree of rotation and movement is needed.

Why are slip rings so expensive?

The cost of slip rings can vary greatly depending on factors such as design complexity, size, and material requirements. However, the reason why slip rings are often considered expensive is due to the precision engineering and high-quality materials required to manufacture them. Slip rings, especially those designed for high-performance applications, must be durable, reliable, and capable of withstanding harsh environments such as high temperatures, moisture, and vibration. For example, capsule slip rings or sealed slip rings often require additional protection to ensure their longevity and performance, which adds to their cost. Moreover, slip rings used in military or aerospace applications need to meet stringent standards, and their manufacturing involves more sophisticated materials and more intensive testing procedures. Additionally, the customization needed to tailor slip rings to specific applications, such as with multi-circuit configurations or mini slip rings, further increases their price. Finally, the high demand for reliability and long-term performance, especially in mission-critical industries like medical equipment and renewable energy, drives up the cost of these components.

Looking to customize a capsule slip ring? Leave us your specifications in this form.