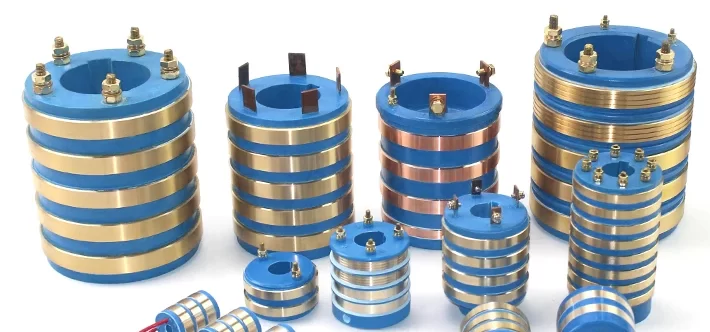

The heart of many rotating systems lies a lesser-known but critical component known as a collector ring assembly. It might not ring a bell immediately, but numerous industries and applications owe their smooth operations to this intricate piece of engineering.

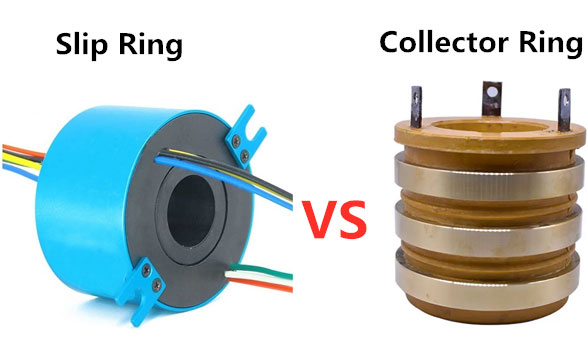

In essence, a collector ring assembly, also referred to as a slip ring or rotary electrical interface, is a device designed to transmit electrical power or signals between fixed and rotating parts in a system without hindering rotational movement. These assemblies consist of two key elements – a set of concentric rings (hence the name ‘ring’) attached to the rotating part of the appliance or machinery, and a set of brushes that connect these rings to the stationary component.

The beauty of collector ring assemblies lies in their ability to facilitate an elaborated system’s constant, unrestricted rotation while maintaining an uninterrupted electrical connection. This denotes that the power source and the equipment’s rotational element remain electrically tethered yet physically independent, enabling continuous rotation without tangled wires or interrupted signal transfer.

The true value of collector ring assemblies becomes vivid when considering their importance across a spectrum of applications. They underpin the mechanics in multiple fields – from simplifying everyday life situations to lying at the heart of sophisticated systems. Their applications are as diverse as they are vast, encompassing household appliances such as electric fans and electric shavers, to more specialized industrial systems including wind turbines, packaging machines, or even advanced medical scanners.

In the aerospace industry, for instance, collector ring assemblies are used in high-altitude satellites and are integral to the radar systems’ smooth operation within modern aircraft. Meanwhile, in the realm of renewable energy, they play a pivotal role in maintaining electrical connections with the power grid as wind turbines rotate to track the wind.

Whether they’re aiding your morning shave or contributing to powerful radar systems, their role in facilitating efficient electricity transmission and signal transfer amidst mechanical rotation is paramount.

The inherent qualities of collector ring assemblies, such as their design flexibility, the ability to transmit a large amount of data, various signals and power simultaneously, and their operational reliability make them indispensable in numerous applications. Consequently, understanding their structure, function, and the intricacies of their assembly process is vital in unlocking their full potential.

In the subsequent sections, we’ll delve deeper into the components that make up a collector ring assembly, uncover the step-by-step assembly process, and discuss their maintenance procedures and recent advancements.

Components and Function of Collector Ring Assembly

To truly grasp the significance of collector ring assemblies and their wide range of applications, it is essential to understand their various components and the roles they play in the entire system. These assemblies are carefully crafted to allow smooth interaction between each component, enabling electrical signals and power to flow consistently and reliably between the stationary and rotating parts in any system.

Collector ring assemblies typically comprise the following key components:

Rotating Component

The rotating component forms the heart of the collector ring assembly, featuring a set of conductive rings (collector rings), mounted concentrically on a rotating shaft or spindle. The rings are generally manufactured from metals with high electrical conductivity and low resistance, such as copper or brass. Each ring serves as a pathway for electrical signals or power to flow, allowing multiple, independent circuits to be established concurrently. Varying the number, size, and spacing between these rings can accommodate the assembly for different voltage levels and current requirements.

Stationary Component

Partnering with the rotating rings to establish electrical contact is the stationary component, which consists of brushes and brush holders. The brushes, usually composed of graphite, metal alloys, or precious metals, are carefully crafted to maintain continuous contact with the collector rings as they rotate. By doing this, they facilitate the transmission of electrical signals and power from the stationary part to the rotating component in the system. The brush holders, on the other hand, ensure that the brushes are correctly positioned and aligned while enabling easy adjustments and replacements when necessary.

Housing and Bearings

As the collector ring assembly is designed to operate in various environmental conditions and withstand potential physical impacts, it is enclosed within a protective housing. This housing safeguards the internal components from dust, moisture, and other contaminating factors, ensuring the longevity and reliability of the assembly. Additionally, it may also include features such as seals or gaskets to enhance protection against harsh environments.

Bearings are another crucial element of the collector ring assembly, allowing the rotating component to spin freely while maintaining the alignment of the entire system. They contribute to minimizing friction and wear, ensuring that the assembly operates smoothly, efficiently, and with minimal noise.

Overall Function of the Assembly

The combined efforts of these components culminate in the fundamental function of the collector ring assembly – facilitating the transfer of electrical power and signals between stationary and rotating parts in a system. As the collector rings rotate in unison with the equipment, the brushes maintain contact with the rings, enabling the flow of electricity without impeding the rotation. The housing and bearings ensure that the assembly operates seamlessly, securely, and under varying conditions.

In conclusion, the complexity and coherence of a collector ring assembly lie in its ability to amalgamate each component’s role into a cohesive, efficient system. The intricate design and function of these components allow electrical signals and power to be transferred accurately and consistently, making the assembly indispensable in numerous applications.

Process of Assembling a Collector Ring

Assembling a collector ring requires precision and adherence to a systematic process to ensure that each component works in harmony to facilitate the transfer of electrical signals and power between stationary and rotating parts. In this section, we will provide a step-by-step guide on how to assemble a collector ring, discuss the tools required for the assembly process, and outline safety measures to consider during assembly.

Step-by-Step Guide to Assembling a Collector Ring

- Prepare the necessary tools and components: Gather the required tools such as a wrench, screwdriver, retaining clips, and other equipment specified by the manufacturer. You’ll also need the components of the collector ring assembly, including the rotating rings, brushes, brush holders, housing, and bearings.

- Align the collector rings and brushes: Based on the design and specifications of the specific collector ring assembly, carefully position and align the collector rings and brushes to ensure optimal contact, minimizing friction and wear during operation.

- Install the brushes and brush holders: Place the brushes in their designated holders within the stationary component, making sure that they’re correctly positioned and aligned for effective contact with the rotating rings.

- Mount the conductive rings onto the rotating component: Attach the conductive rings (collector rings) onto the rotating component, which is usually the shaft or spindle. Ensure that the rings are correctly seated and aligned for smooth rotational motion.

- Secure the stationary and rotating components within the housing: Place both stationary and rotating components within the protective housing, making sure that they are properly aligned and secured. This step might require fastening retaining clips, screws, or bolts to hold the components in place.

- Lubricate bearings and other moving parts: Apply lubricants or other protective coatings if necessary, following the manufacturer’s recommendations. Proper lubrication is essential to minimize friction and wear and prolong the lifespan of the assembly.

Tools Required for Assembly

The assembly process might require various tools depending on the scale and complexity of the collector ring assembly. Some common tools used during assembly are:

- Wrenches

- Screwdrivers

- Retaining clips or fasteners

- Pliers

- Hammer and punch (if needed for securing components)

- Alignment tools (such as measurement instruments or gauges)

Always follow the manufacturer’s recommendations and guidelines when selecting and using the tools for assembly.

Safety Measures for Collector Ring Assembly

Maintaining a safe and controlled environment during the assembly process is crucial to avoid accidents or damage to the equipment. Some safety measures to consider are:

- Always wear appropriate personal protective equipment, such as safety goggles and gloves.

- Keep the assembly area clean, organized, and free from clutter to prevent accidents.

- Use properly maintained tools and equipment to minimize the risk of injury or damage.

- Follow the manufacturer’s guidelines for assembling, handling, and testing the collector ring assembly.

- Be aware of the electrical hazards associated with the assembly, especially when testing and connecting the assembly to power sources.

By following this step-by-step guide, adhering to the recommended tools and guidelines, and prioritizing safety measures, you can ensure a successful and safe collector ring assembly process. This will yield a robust and reliable collector ring assembly, ensuring optimal performance and longevity in diverse applications.

Common Applications of Collector Ring Assemblies

Collector ring assemblies are a cornerstone of a myriad of industries, owing to their pivotal role in transmitting electrical power and signals between stationary and rotating parts in a machine or appliance. Below, we survey some of the most prominent applications of collector ring assemblies across diverse industries:

Household Appliances

Perhaps one of the most commonplace applications of collector ring assemblies can be found in everyday household appliances. Devices such as microwave turntables, electrical fans, and electric shavers all house these assemblies to facilitate their core functions. The continuous power connection and rotational freedom enabled by the collector ring assembly allow these appliances to support our everyday lives seamlessly.

Industrial Machinery

Industrial sectors heavily rely on collector ring assemblies for various purposes. For instance, packaging machines and assembly line conveyors utilize these components to ensure continuous operation without power or signal interruption. Cable reels, used to lay, retrieve, or store cables or hoses, also incorporate collector ring assemblies to enable unhindered rotation while maintaining an electrical connection with the conductor cable or hose.

Wind Turbines

Significant advancements in renewable energy have encouraged the extensive use of wind turbines, which employ collector ring assemblies extensively. They are crucial in maintaining electrical connections with the power grid while the turbine blades continuously rotate to harness wind power.

Medical Equipment

Collector ring assemblies play an instrumental role within the healthcare industry as well. They are notable components in sophisticated devices such as MRI or CT scanners, which require constant rotation to image the body from different angles. These assemblies ensure an uninterrupted power supply and signal transmission during the scanning process.

Aerospace and Defense

In the realm of aerospace and defense, slip ring assemblies are indispensable. They are integral to the smooth operation of radar systems within modern aircraft and satellites. These systems require uninterrupted rotation and signal transmission, a need catered to by collector ring assemblies.

Amusement Park Rides

Amusement and theme parks often feature rides that involve significant rotational movement, such as Ferris wheels or whirlaround rides. These rides require lighting and sound system components that remain electrified while in motion – an application perfectly served by collector ring assemblies.

Marine and Underwater Devices

Marine applications like remotely operated underwater vehicles (ROVs) or underwater cameras require continuous rotation and signal/power transmission. Collector ring assemblies fulfill these requirements, bolstering unbroken operation even in complex marine environments.

In essence, collector ring assemblies serve a broad spectrum of applications in varying capacities. The recurring theme across these industries is the need for a constant electrical connection in a rotating system, demonstrating the universal utility and versatility of these assemblies. With each application comes distinct requirements and challenges, pushing the envelope for even more innovative and tailored designs of collector ring assemblies.

Maintenance Procedures for Collector Rings

Collector rings are critical components that require consistent maintenance to extend their lifespan, reduce unwanted downtimes, and ensure peak performance. In this section, we will discuss routine maintenance guidelines to help maintain optimal collector ring function and address common challenges associated with maintenance and troubleshooting.

Routine Maintenance Guidelines

- Visual inspection: Periodically inspect collector rings and brushes to check for evidence of wear, discoloration, or excessive residue buildup. This simple step will help identify potential problems before they escalate and lead to downtime or component failure.

- Cleaning: Remove any dirt or contaminant accumulation on the collector rings, brushes, and brush holders. Regular cleaning helps ensure optimal electrical contact and minimizes the chances of arcing or increased resistance.

- Friction and wear monitoring: Monitor collector rings and brushes for signs of excessive friction or wear. Measure the remaining brush length to see if replacement is necessary. Consider replacing brushes when they reach around 75% of their initial length.

- Alignment and leveling: Ensure that the collector rings and brushes are properly aligned and leveled. Misalignment can cause uneven wear or improper electrical contact, adversely impacting system performance and lifespan.

- Bearing lubrication: Inspect and lubricate the bearings as per the manufacturer’s recommendations to minimize friction and wear, ensuring smooth and efficient rotation.

Common Challenges in Maintenance and Troubleshooting

- Excessive wear: If the collector rings or brushes show signs of excessive wear, it may indicate a need for replacement, or it could be a symptom of misalignment, inadequate brush tension, or poor contact. To counteract this issue, inspect the assembly for alignment, adjust the brush holder position if necessary, and verify proper spring tension to maintain optimal contact.

- Arcing: Arcing may occur when there is poor contact between the collector ring and the brush, or if an excessive amount of electrical noise is present. To resolve arcing, clean the collector rings and brushes, ensuring no contaminants or debris interfere with the connection. Also, consider using a brush grade with increased conductivity to minimize electrical noise.

- Increased resistance: Accumulated dirt and contaminants can lead to increased resistance between the collector ring and brush, hindering proper signal and power transmission. To overcome this challenge, thoroughly clean the collector ring assembly, focusing on points of electrical contact.

- Corrosion: Collector ring assemblies exposed to corrosive or moist environments may develop increased wear and corrosion, harming overall efficiency. To tackle this issue, use corrosion-resistant materials and coatings for the assembly. Additionally, ensure proper sealing and protection of the housing against moisture ingress.

In summary, routine maintenance and addressing common challenges with a proactive approach are imperative in optimizing the performance and longevity of collector ring assemblies. By adhering to the guidelines provided and understanding the intricacies of proper maintenance, the likelihood of unforeseen complications can be significantly reduced, ensuring consistent and reliable operation in various applications.

Common User Concerns Regarding Collector Ring Assembly

Collector ring assemblies are pivotal components in a myriad of applications ranging from household appliances to industrial machinery. Naturally, potential users and operators have legitimate concerns about aspects such as lifespan and reliability, compatibility, maintenance, and cost. In this section, we explore these concerns and provide clarifying information to empower users with knowledge and confidence.

Lifespan and Reliability

Collector ring assemblies’ lifespan can significantly vary, depending primarily on the operating conditions, maintenance, and the quality of the components used. A well-maintained collector ring assembly carefully engineered with high-quality materials could efficiently serve for several years. Factors affecting longevity include environmental factors (heat, dust, moisture, etc.), electrical load conditions, rotational speed, and preventative maintenance practices. By mitigating adverse conditions and regularly assessing and maintaining the assembly, users can significantly enhance their collector ring assembly’s lifespan and reliability.

Compatibility

Each collector ring assembly is typically designed for a specific application, considering the electrical, mechanical, and environmental needs of that application. Therefore, it’s crucial to match the correct collector ring assembly specifications with the intended use. Variables such as current and voltage ratings, number of circuits, speed of operation, environmental sealing, and size constraints all need to be taken into account to select the compatible collector ring assembly. It’s always advisable to consult with the manufacturer or a knowledgeable professional to help specify the right model.

Maintenance

The maintenance requirements for collector ring assemblies can vary widely. Some may require regular inspection and upkeep every few months, while others with sealed units might need only minimal maintenance over a longer period. Generally, a maintenance schedule including visual inspection, cleaning, wear monitoring, and lubrication should be followed. The complexity of the maintenance depends largely on the specific type of collector ring assembly, with some needing specialized knowledge and tools. Therefore, understanding the manufacturer’s maintenance guidelines is vital in ensuring continuous optimal performance.

Cost

The upfront cost of collector ring assemblies can differ substantially based on the model’s complexity, the materials used, and the application requirements. However, given their critical role in maintaining operational efficiency, they are an investment that pays dividends in reducing the costs of downtime and maintenance.

Maintenance cost is another concern that largely hinges on the operating conditions and maintenance practices of the equipment in which the assembly is installed. Regular preventive maintenance can help avoid surprise repair expenses and prolong the assembly’s service life, decreasing the overall lifecycle cost.

Potential cost-saving tips can include investing in a high-quality assembly to reduce the frequency of replacements, regularly performing preventative maintenance to avoid costly repairs, and consulting with professionals to ensure the correct assembly is selected in the first place, preventing wasted expenditure on incompatible equipment.

In conclusion, while valid, these common concerns can be effectively addressed with knowledge, proactive maintenance, and the correct specifications. Understanding these crucial aspects allows for an informed approach to using collector ring assemblies, improving their effectiveness and efficiency in the long run.

Recent Technological Advancements in Collector Ring Assembly

As critical components in various machines and applications, collector ring assemblies have evolved substantially with technological advancements. These innovations have led to enhanced performance, utility, and convenience. Here, we delve into some of the remarkable developments in this field and shed light on how they’ve improved collector ring assemblies.

Latest Advancements and Trends

- Material Innovations: One of the most significant advancements is the introduction of advanced materials for brushes, rings, and bearing systems. These include precious metals, composite materials, and advanced ceramics. These materials offer superior electrical conductivity, durability, wear resistance, and thermal management. It has led to increased lifespan and reliability of the collector ring assemblies.

- Sealed and Modular Units: Technological innovation has created sealed and modular collector ring assemblies that provide enhanced protection from external environmental factors. These units offer improved durability, especially in challenging conditions like dust, temperature extremes, or corrosive environments.

- Intelligent Monitoring Systems: Collector ring assemblies now often incorporate real-time monitoring systems. These intelligent systems provide valuable data regarding the performance and health of the assemblies. They can alert operators to excessive wear, misalignment, increased resistance, heat, or other potential problems before they lead to equipment failure or costly downtime.

- Miniaturization: With technology trends towards compactness and efficiency, collector ring assemblies have followed suit. Miniaturization of these components has allowed for their incorporation in smaller devices or applications where space is at a premium.

Improvements in Performance, Utility and Convenience

The recent advancements have brought across various benefits that have positively impacted the performance, utility, and convenience of collector ring assemblies:

- Increased Lifespan and Reliability: Advanced materials and sealed units can resist wear and external environmental effects, respectively, leading to longer useful life and reduced chances of unexpected failures.

- Better Performance: Advanced materials and design methods have resulted in collector assemblies capable of functioning more efficiently under higher electrical loads and rotational speeds.

- Preventive Maintenance and Spotting Problems Early: The integration of intelligent monitoring systems provides real-time information about the performance and health of collector ring assemblies. This allows for preventive maintenance and can identify potential problems early, potentially saving significant downtime and maintenance costs.

- Flexibility in Design: The trend towards miniaturization has allowed collector ring assemblies to be used in a wider range of applications. They can now fit into smaller devices while still offering the same utility.

In conclusion, the cutting-edge advancements in collector ring assembly technology have not only streamlined their application across myriad industries but have also significantly raised the bar for their performance, utility, and convenience.

Conclusion

Understanding the fundamentals of collector ring assembly and staying informed about technological advances is crucial for making informed decisions and addressing user concerns. Regular maintenance and embracing the latest technology trends will ensure the optimal performance, reliability, and cost-effectiveness of collector ring assemblies across various applications.