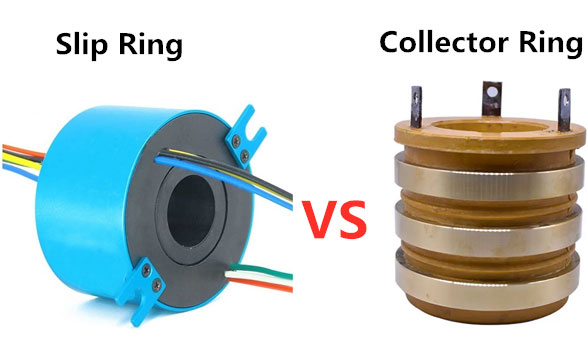

Are you looking for a device that can meet your needs for signal or power transmission between stationary and rotating devices? Then you need slip ring collectors. Of course, you can also choose slip rings as an option. What needs to be understood is that slip rings and slip ring collectors have their own applicable scenarios due to different manufacturing process methods. In the following article, we will introduce you to the differences between the two through various aspects, and help users find the best choice.

Product Introduction

| Collector Ring | |

| |

| Summary | A collector ring is a connector consisting of a fixed metal ring and rotating metal brushes, divided into several sections, each connected to a separate circuit. As the ring rotates, the brushes make contact with the segments, allowing current to flow from the stationary part to the rotating part. |

| Manufacturing Process | Adopt carbon brush technology that is close to the copper ring |

| Transfer Content | Generally, the transmission of large current is limited. During the transmission process, a large amount of carbon alloy powder will be generated due to its friction, and the carbon brush needs to be cleaned or replaced regularly. From the perspective of its transmission effect, due to the friction of its contact points, the friction is not smooth and the resistance is uneven, which leads to problems such as heat generation and lightning strikes. |

| Structure Size | The collector ring requires a large current, so a copper ring with an outer diameter and thickness is required as a contact friction body, and the overall volume is relatively large. |

| Structure and Contact | Collector ring using segmented rings and brushes |

| Applicable Scene | Collector rings are typically used in applications that require power and signal transfer from stationary components to rotating components with a limited number of circuits. For example, collector rings are commonly used in electric motors to transmit power from a stationary source to a rotating motor. They are also used in certain types of machinery, such as cranes or cranes, to transmit power and control signals to rotating drums or reels. |

| Slip Ring | |

| |

| Summary | A slip ring is a connector consisting of a fixed metal ring and a rotating metal contact, which is a continuous circular conductor divided into multiple circuits. Slip rings employ rotating contacts in the form of brushes or series of brushes that make contact with the ring, allowing electrical current to flow between the stationary and rotating parts. The main function of the slip ring is to realize the contact between two components for relative rotation power, electrical signal or current transmission. |

| Manufacturing Process | Sliding transmission method using precious metal alloy contacts for power and signals |

| Transfer Content | On the basis of the original rotation transmission function, it is a conductive slip ring with wider transmission medium, more precise transmission structure, more flexible transmission mode and better transmission effect. |

| Structure Size | Precision conductive slip rings not only need to be small in size and compact in structure, but also require multi-channel transmission of different energy sources and signals. |

| Structure and Contact | Slip rings use continuous rings and brushes or series of brushes |

| Applicable Scene | Slip rings are commonly used in applications that require the transmission of power and signals from stationary components to rotating components with extensive electrical circuitry or where continuous rotation is required. For example, slip rings are commonly used in wind turbines to transmit power and control signals from the stationary part of the turbine to the rotating blades. They are also used in other types of machinery, such as robots, to transmit power and control signals to rotary joints or other components. |

Common Ground

Both collector ring and slip ring are two types of electrical connectors used to transmit power and signals between fixed and rotating components. While they are constructed and approached differently, they have some things in common, including:

Rotating machinery: Both collector rings and slip rings are commonly used in rotating machinery, such as electric motors, wind turbines, and cranes, which need to transmit power and signals between stationary and rotating parts.

Circuits: Both collector rings and slip rings can be designed into multiple circuits, allowing multiple signals or power to be transmitted between stationary and rotating parts.

Wear and tear: Both collector rings and slip rings wear over time and may require periodic maintenance or replacement to ensure continued performance.

Customization: Both collector rings and slip rings can be designed and customized to meet specific application requirements, including the number of circuits, rotational speed, and type of signal or power transmitted.

Overall, collector rings and slip rings share many similarities in use and function, but differ in construction and the specific applications for which they are best suited.

Advantages of Slip Rings

Long service life: Once the precision conductive slip rings used in aerospace (such as satellites) are launched, they need to work in space for more than 10 years and cannot be repaired. Therefore, the life of this slip ring is very high, and the life needs to reach more than 150 million revolutions. Stable performance, no trouble. Once there is a failure or the life does not meet the requirements, it will cause the entire microsystem to collapse.

High speed: In the fields of high-speed rail, aero-engine, large aircraft, high-speed weapons, high-speed and high-precision turntable, etc., the speed requirements of conductive slip rings are very high, and the speed requirements exceed 1000rpm. However, when the speed is too high, there are two main problems, one is the damage of the mechanical structure, and the other is the heating of the transmission contacts.

Miniaturization of structural size: Due to the high-precision requirements of high-end manufacturing, the space requirements for parts are very strict. The miniaturization of the structure size of the precision conductive slip ring is also the basis for realizing the high speed and long life of the slip ring. However, the manufacturing process of small precision conductive slip rings is very complicated.

Conclusion

Both collector ring and slip ring are electrical connectors, which are used to transmit power and signals between fixed components and rotating components, but because of their manufacturing process and other characteristics, they are suitable for different scenarios. Collector rings are cheaper than slip rings, but slip rings are applicable to a wider range of scenarios.

Frequently Asked Questions

Q: What is a Slip Ring Collector?

A: The slip ring collectors are a variant of the electromechanical device which is used in rotating equipment.

Q: How Does a Slip Ring Collector Work?

A: The slip ring collectors allow electrical field currents to pass through while rotating. The brushes within the alternator ride on the slip rings.

Q: What Are the Applications of Slip Ring Collectors?

A: Slip ring collectors have a similar function to slip rings and are used to transmit power or signals. Because of its manufacturing process and cost-effectiveness, it is very versatile, and you can see its shadow in robots, cranes, wind turbines, and other equipment.

Q: What Are the Benefits of Using a Slip Ring Collector?

A: One of the most important reasons for choosing to use slip ring collectors is the cost performance, in addition to the reasons for high efficiency and low maintenance. Proven over time, slip-ring collectors are a reliable choice for power transmission. Of course, if the models sold on the market are not suitable for you, you can contact us for customization. We have a professional R&D team and also support a small amount of customization business.

Q: What Factors Should Be Considered when Selecting a Slip Ring Collector?

A: *Number of rings required

*Operating Voltage

*Current

*Speed of work

*Using environment

*Reliability

*Maintenance requirements

Get in touch with our sales team by filling out the form below.