In this rapidly evolving digital age, technological innovation is advancing at an unprecedented pace, ushering in a broad spectrum of applications across various industries. Amidst this landscape, the role of specific yet less-known components like compact slip rings becomes increasingly vital. These miniature devices play an integral part in many modern systems and have a significant impact on their performance, making an in-depth understanding of them crucial.

This comprehensive guide intends to provide exactly that – a thorough understanding of compact slip rings. We shall begin our exploration with a fundamental definition of compact slip rings, outlining their core functions and widespread applications in multiple sectors. From there, we will delve into the numerous benefits of deploying these compact powerhouses in different systems, highlighting their efficiency and versatility.

Selecting the suitable compact slip ring for your specific usage shouldn’t be a trial-and-error exercise. This guide will unravel the intricacies involved, helping your decision-making process by evaluating key parameters, comparing various offerings, and even addressing the critical aspect of supplier selection. Economics always plays a vital role, and we will throw light on balancing cost and performance considerations as well.

Equally important to selection, we will cover the aspects of maintenance and longevity of compact slip rings. Proper care and handling of these devices can significantly enhance their lifespan and ensure seamless functioning over the long term. The guide will also share related best practices.

Given the pace of technological improvements, it’s only natural to wonder about the recent trends and future potential of compact slip rings. We will devote a significant portion of this guide to that curiosity, discussing ongoing innovations and potential trajectories. Moreover, we will deal with the frequently asked questions and misconceptions around compact slip rings to ensure there are no lingering doubts in your mind about their efficacy.

Lastly, knowing the theory is one thing, but seeing its application in the real world is quite another. That’s why this guide will conclude with a range of real-world case studies that demonstrate compact slip rings’ versatile use across various industries.

Understanding compact slip rings and their implications in specific applications can greatly enhance both the design and performance of many systems. This guide will equip you with that understanding, whether you’re a professional seeking to optimize your project or a curious mind yearning to decode the workings of our modern world.

What are Compact Slip Rings?

On any given day, we interact with and utilize numerous systems and devices, often without pausing to consider the precision-engineered components that enable their functionality. One such crucial component widely deployed, but seldom acknowledged, is the compact slip ring. But what exactly are these miniature mechanisms? Let’s delve deeper.

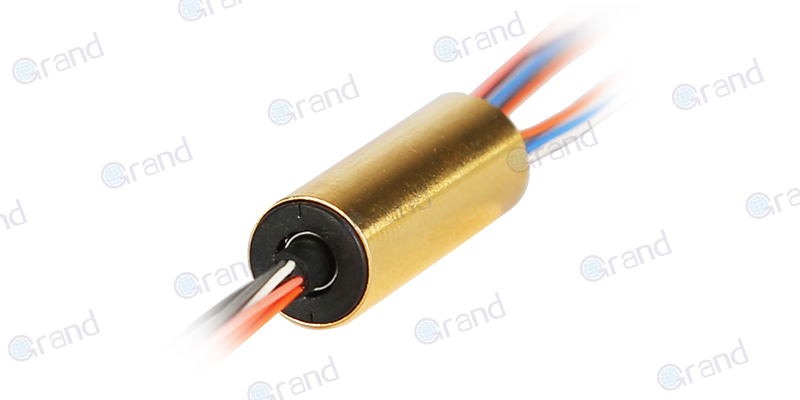

At its core, compact slip rings form a specialized type of electrical connector designed to transfer electrical power and signals from static to rotating parts within various equipment and machinery. To visualize this, imagine a simple wind turbine. Its blades continuously rotate, but its base remains fixed. Here, the compact slip ring enables continuous electrical signal transmission from the stationary base to the moving parts (and vice versa), ensuring an uninterrupted, smooth operation, despite the continuous movement.

Compact slip rings, as the name implies, are designed to be small and lightweight without compromising their efficiency. This miniature design allows them to integrate seamlessly into complex systems where space and weight are significant constraints, making them an attractive solution for various applications.

Speaking of applications, you’ll find compact slip rings playing pivotal roles in a plethora of sectors. Let’s briefly touch upon some of the more common ones. In the realm of healthcare, compact slip rings are an integral part of medical imaging machines, including MRI and CT scanners, aiding in the apparatus’s smooth rotation while ensuring the reliable transmission of high-resolution data. In renewable energy systems, like wind turbines, compact slip rings facilitate signal transmission between the stationary and rotating components. They are also widely utilized in the defense sector in satellite communication systems and radars. Additionally, sophisticated robotics systems and various automated devices also rely on these crucial components to ensure seamless operations.

Understanding compact slip rings and their diverse applications is the first step towards appreciating their value in our ever-evolving technological landscape.

Benefits of Using Compact Slip Rings

As we delve into the world of compact slip rings, it becomes increasingly clear why these miniature devices hold such significant importance in various applications. Here, we’ll explore some of the key benefits of using compact slip rings, factors that make them appealing, and strategic inclusions in numerous designs and systems.

An evident advantage of compact slip rings lies in their dimensions. Their small, streamlined design is purposefully crafted to save space, making them a ‘go-to’ solution for compact assemblies and systems. For instance, in applications like drones, surgical robots, and even some wearable devices, the space available for incorporating components is profoundly constrained. Here, compact slip rings fit perfectly, providing the necessary functionality without consuming invaluable device real estate.

Going beyond their physical size and fit, compact slip rings demonstrate enviable versatility when it comes to signal and data transmission. These components are intrinsically multi-tasking marvels. They are designed not only to transmit electrical power but also to a variety of signals, be it analog, digital, or a mix of both. By efficiently surpassing the limitations of separate power and data cables, compact slip rings can effectively manage the transmission of information, power, or a combination thereof within a single unit. This multipurpose competency contributes to a clean, organized, and simplified design process across industries.

Lastly, and arguably one of the most noteworthy benefits, is the ability to customize compact slip rings to match specific applications. Understanding that ‘one size fits all’ rarely applies to complex engineering systems, manufacturers often design compact slip rings to be inherently customizable. This adaptability ensures that these devices can meet the different requirements of various applications, assuring optimum performance in a wide range of environments. From altering their dimensions to customizing the type and number of signals they can accommodate, the flexibility of compact slip rings paves the way for context-specific configurations and promotes enhanced efficiency.

In conclusion, the benefits of compact slip rings – space-saving, versatile signal transmission, and customizability – significantly contribute to their growing usage in various sectors. Their ability to seamlessly combine functionality with adaptability makes them an invaluable component of many modern systems.

Compact Slip Rings Specification And Size

Compact slip rings are small, lightweight electromechanical devices designed to transmit power, electrical signals, or data between a rotating part and a stationary part. They are optimized for limited space applications while ensuring high performance, low maintenance, and reliable operation. Below is a detailed explanation of their specifications and typical sizes.

Key Specifications of Compact Slip Rings

- Outer Diameter (OD)

- Compact slip rings are typically designed with an outer diameter ranging from 12 mm to 50 mm, depending on the number of circuits and current capacity.

- Smaller diameters (around 12–20 mm) are common for signal-only transmission, while larger diameters (30–50 mm) are used for combined power and signal circuits.

- Length (Axial Height)

- The length of a compact slip ring varies based on the number of circuits and the current rating. It can range from 10 mm to 70 mm.

- Slim models are available for highly confined spaces, with lengths as small as 10–20 mm.

- Number of Circuits

- Compact slip rings support 1 to 24 circuits, with each circuit isolated to prevent interference.

- Circuits can handle a mix of power and signal transmission, depending on the application.

- Low-circuit models (2–6 circuits) are used in signal-heavy applications, while higher-circuit models (12–24) are suited for hybrid power and signal systems.

- Current Rating

- Current capacity typically ranges from 2 A to 10 A per circuit.

- For applications requiring higher currents, models with parallel circuits are available to increase the effective current-carrying capacity.

- Voltage Rating

- Standard compact slip rings support voltages up to 240 VAC/DC per circuit.

- Specialized models are designed for higher voltage loads (e.g., 380 VAC) if required by the application.

- Signal Transmission Capabilities

- Compact slip rings support various signal types, such as Ethernet, USB, CAN-bus, RS485, analog signals, and high-frequency signals.

- Models designed for data transmission maintain low electrical noise and minimal signal loss, ensuring smooth communication between the rotating and stationary components.

- Materials

- Slip Rings: Made from copper, brass, or gold-plated alloys to ensure high conductivity and corrosion resistance.

- Brushes: Typically made from graphite, carbon, or precious metals (such as gold) for low friction and long life.

- Housing: Uses aluminum or polymer enclosures for lightweight durability and protection from environmental factors.

- Rotational Speed (RPM)

- Compact slip rings can operate at speeds ranging from 100 to 5000 RPM, depending on the model and application.

- Higher RPM models are often used in high-speed robotic systems or medical imaging equipment.

- Operating Temperature Range

- Standard models operate between -20°C to 80°C.

- High-performance models are available for extreme environments, capable of functioning from -40°C to 120°C.

- Protection Rating (IP Rating)

- Compact slip rings can have an IP54 to IP67 rating, providing resistance to dust and moisture.

- Higher IP-rated models are used in outdoor or harsh environments, such as wind turbines or offshore equipment.

- Electrical Noise

- Low-noise models ensure minimal interference in signal transmission. Electrical noise is usually kept below 10 milliohms to avoid signal distortion.

- Contact Resistance

- Contact resistance is generally less than 10 milliohms, ensuring efficient power transfer with minimal loss.

Common Sizes of Compact Slip Rings

| Specification | Range |

|---|---|

| Outer Diameter (OD) | 12 mm – 50 mm |

| Length (Axial Height) | 10 mm – 70 mm |

| Number of Circuits | 1 – 24 |

| Current per Circuit | 2 A – 10 A |

| Voltage per Circuit | Up to 240 VAC/DC (standard) |

| Operating Temperature | -20°C to 80°C (standard) |

| Rotational Speed | 100 – 5000 RPM |

| Protection Rating (IP) | IP54 – IP67 |

Compact slip rings are essential components in applications requiring efficient transmission of power or signals within a limited space. Their small size, high rotational speeds, and ability to handle both power and data make them ideal for modern technologies, such as robotics, medical equipment, and drones. Selecting the right compact slip ring involves considering key specifications such as current capacity, number of circuits, voltage rating, and protection levels to meet the application’s specific requirements. Proper selection ensures long-lasting and reliable operation in even the most demanding environments.

Compact Slip Rings Technical Details And Characteristics

Compact slip rings are miniaturized electrical connectors designed for applications where space is limited. They allow continuous transmission of power, electrical signals, or data between stationary and rotating parts. Below is a detailed description of their technical specifications and key characteristics.

Technical Details of Compact Slip Rings

Compact slip rings are available in a range of sizes and configurations to suit different requirements.

- Outer Diameter (OD)

Compact slip rings typically have an outer diameter ranging from 12 mm to 50 mm, with smaller models optimized for signal transmission and larger ones for power and hybrid applications. - Length (Axial Height)

Depending on the number of circuits and current requirements, the length can range from 10 mm to 70 mm. Ultra-slim designs are available for applications with very limited space. - Number of Circuits

Compact slip rings generally support between 1 and 24 circuits. Each circuit is electrically isolated to prevent interference, making these slip rings suitable for hybrid power and signal applications. - Current Rating per Circuit

The current capacity usually ranges from 2 A to 10 A per circuit. If higher currents are needed, multiple circuits can be connected in parallel to share the load. - voltage Rating per Circuit

Standard models are rated for voltages up to 240 VAC or DC. Some specialized models can handle up to 380 VAC for industrial use. - Rotational Speed (RPM)

Compact slip rings can operate at speeds between 100 and 5000 RPM. High-speed versions are commonly used in robotic systems and medical imaging devices to ensure uninterrupted signal transmission. - Contact Materials

Conductive rings are made from copper, brass, or gold-plated materials for optimal conductivity and corrosion resistance. Brushes use graphite, carbon, or precious metals to minimize friction and enhance performance. - Operating Temperature Range

Standard compact slip rings operate between -20°C and 80°C, but advanced models can function in extreme environments, with operating ranges from -40°C to 120°C. - Protection Rating (IP)

Protection levels range from IP54 to IP67. Models with higher IP ratings are dust- and water-resistant, making them suitable for harsh environments like wind turbines and offshore equipment. - Signal Transmission

Compact slip rings can transmit both analog and digital signals, such as Ethernet, USB, HDMI, CAN-bus, RS485, and video signals. They are designed to minimize electrical noise and signal loss. - Electrical Noise

Low electrical noise models ensure stable signal transmission, typically achieving noise levels under 10 milliohms, essential for precise applications. - Contact Resistance

Contact resistance is generally less than 10 milliohms, ensuring efficient power transfer and minimizing energy loss.

Key Characteristics of Compact Slip Rings

Compact slip rings are lightweight, versatile, and built for high reliability.

- Small Size and Lightweight Design

Their compact form factor makes them ideal for applications with limited space, such as drones, medical equipment, and robotics. - 360-Degree Continuous Rotation

Compact slip rings allow unrestricted rotation while maintaining continuous electrical connection, preventing wire twisting. - Low Friction and Long Service Life

Optimized contact materials reduce friction, enhancing durability and reducing maintenance needs. - Easy to Install and Integrate

Pre-wired connectors and terminals simplify installation, making compact slip rings easy to incorporate into various systems. - High Reliability and Minimal Maintenance

Precious metal brushes and gold-plated rings ensure consistent electrical contact and low wear, extending service life.

Compact slip rings are essential components in modern technologies where space constraints demand efficient, high-performance solutions. They offer reliable power and signal transmission in compact and lightweight designs, making them ideal for use in robotics, medical equipment, drones, and industrial applications. Proper selection of compact slip rings based on specifications like size, number of circuits, current rating, and protection levels ensures optimal performance and long-term reliability.

Compact Slip Rings for Power- and Signal Transmission

Compact slip rings are advanced connectors that facilitate the simultaneous transmission of power and electrical signals between a stationary and rotating component within a limited space. These slip rings are used in applications requiring seamless rotation without compromising the integrity of power or signal transfer.

Characteristics of Compact Slip Rings for Power and Signal Transmission

- Simultaneous Power and Signal Handling

Compact slip rings are designed to transmit both power and signals through isolated circuits, ensuring no interference or crosstalk between them. - High Electrical Isolation

Each circuit is electrically isolated to avoid interference, especially between power lines and sensitive signal circuits. - Low Electrical Noise

Compact slip rings minimize contact resistance and electrical noise, ensuring clean signal transmission. Models optimized for digital signals often maintain noise levels below 10 milliohms. - Durable Contact Materials

Rings are typically made of copper, brass, or gold-plated materials for reliable conductivity, while graphite or carbon brushes ensure smooth, low-friction contact. - Hybrid Circuit Capability

Compact slip rings can combine circuits carrying high current for power with circuits designed for data and signal transmission, such as Ethernet or USB.

Specifications for Power and Signal Transmission

- Power Circuits

- Current: 2 A to 10 A per circuit

- Voltage: Up to 240 VAC/DC (Some industrial models support up to 380 VAC)

- High-current circuits are designed with parallel wiring to handle larger loads efficiently.

- Signal Circuits

- Capable of transmitting analog and digital signals, including:

- Ethernet, USB, HDMI, RS485, CAN-bus, and video signals

- Signal integrity is maintained by minimizing electrical noise and crosstalk between circuits.

- Capable of transmitting analog and digital signals, including:

- Rotational Speed

- Compact slip rings can operate smoothly at speeds of 100 to 5000 RPM, depending on the application.

- Size and Circuit Count

- Outer diameters range from 12 mm to 50 mm, with lengths between 10 mm to 70 mm.

- Models support 1 to 24 circuits, with some units offering both power and signal channels in a hybrid configuration.

Compact slip rings for power and signal transmission provide a reliable solution for rotating systems that require both electrical power and data transmission. Their compact design, high electrical isolation, and low-noise performance make them ideal for advanced technologies such as robotics, medical devices, drones, and surveillance systems. Proper selection ensures optimal performance and long-term durability in demanding environments.

Compact Slip Rings Applications Industrial Automation

Compact slip rings play a vital role in industrial automation by enabling seamless power and signal transmission between rotating and stationary components. They enhance system efficiency by ensuring uninterrupted rotation without compromising electrical connectivity. In an era where automation is essential for precision and productivity, compact slip rings are ideal for applications requiring small size, high reliability, and long service life.

Key Applications of Compact Slip Rings in Industrial Automation

- Robotic Arms

- Compact slip rings allow continuous rotation of robotic joints without restricting movement.

- They transmit power, control signals, and sensor data, ensuring accurate and uninterrupted operation.

- Used in pick-and-place robots, welding robots, and assembly line robotics.

- Packaging Machines

- Compact slip rings are used in labeling, wrapping, and sealing machines to transfer power and signals to rotating components.

- They enable precise control of sensors, motors, and heating elements in high-speed operations.

- Continuous rotation ensures smooth packaging processes with minimal downtime.

- CNC Machines (Computer Numerical Control)

- In CNC machines, compact slip rings transmit control signals to spindles and tool changers.

- They allow continuous rotation of axes and transmit real-time data between sensors and the control unit.

- Slip rings enhance the flexibility and precision of CNC machines used in milling, drilling, and lathing.

- Rotary Tables and Indexers

- Compact slip rings provide power and control signals to rotary tables, which are essential for positioning parts during machining or assembly processes.

- They ensure smooth and precise rotation with 360-degree movement, improving productivity on automated production lines.

- Slip Ring Induction Motors

- Compact slip rings transmit current to the rotor windings in slip ring induction motors, enhancing torque control.

- Used in motors that require variable speed or high starting torque, such as in cranes, conveyors, and hoists.

- Material Handling Systems

- In conveyors, rotary sorters, and carousels, slip rings transmit power and data to motors and sensors for smooth operation.

- They ensure reliable communication between moving parts, reducing downtime and improving system performance.

- Turntables and Rotating Platforms

- Used in inspection systems, carousels, and production line turntables, compact slip rings enable uninterrupted movement and data transmission.

- They provide real-time feedback to control systems for quality inspection or material placement.

Benefits of Compact Slip Rings in Industrial Automation

- Space-Saving Design

Compact slip rings fit into confined spaces within robotic arms, rotary tables, and CNC machines without affecting performance. - Low Electrical Noise

Their low-noise signal transmission ensures reliable data communication, critical for precision control systems. - Durability and Long Life

Made from wear-resistant materials such as carbon brushes and gold-plated rings, compact slip rings are built for continuous operation with minimal maintenance. - High-Speed Operation

They support rotational speeds of up to 5000 RPM, making them suitable for high-speed machinery and robotics. - Multi-Circuit Capability

Compact slip rings can handle both power and data transmission through multiple isolated circuits, ensuring efficiency in complex automation systems. - Easy Integration

Pre-assembled connectors and terminals simplify installation and integration into existing automation equipment.

Compact slip rings are essential in modern industrial automation, where continuous rotation, real-time communication, and reliable power transfer are critical. Their ability to transmit power and signals in a compact form factor makes them indispensable for robotics, packaging machines, CNC tools, and material handling systems. By ensuring smooth and uninterrupted operation, compact slip rings help increase productivity and reduce downtime, making them a cornerstone of efficient automated manufacturing processes.

Selecting the Right Compact Slip Ring

As we’ve established, compact slip rings serve as the crucial linchpin in a variety of applications, ensuring seamless signal transmission across static and rotating interfaces. However, the daunting task for most users is choosing the right compact slip ring that fits their specific needs like a glove. This section will offer a roadmap to navigate this critical process and pinpoint the most suitable compact slip ring for your needs.

One of the fundamental steps in this selection process is a detailed evaluation of application-specific requirements. It’s paramount to consider factors such as the operating environment (temperature extremes, dust, moisture), rotational speed, required power, signal types (analog, digital, or combo), and the available space within the device. For instance, a compact slip ring used in a medical imaging system might prioritize high-precision signal transmission and biomedical compatibility, while one used in a wind turbine would need to withstand a harsh outdoor environment and operate at high rotational speeds.

Equally imperative is conducting a thorough comparison of different product specifications and features. Compact slip rings come in different sizes, weights, number of circuits, types of materials used, and even methods of signal transmission. All these features can significantly influence a slip ring’s performance in specific applications. By comparing available products on these parameters, you can identify the ones that align closely with your requirements.

Supplier selection and ongoing customer support are also important considerations. This choice goes beyond the initial purchase and can impact the performance and longevity of your compact slip ring. Look for suppliers recognized for their expertise, product quality, and after-sales service. Their technical guidance and customer service can be invaluable in helping you select, install, and maintain the right compact slip ring.

Lastly, the cost and budget should not be overlooked. While cost considerations are indeed vital, it’s helpful to remember that the cheapest option may not always be the most cost-effective in the long run. Striking a balance between initial purchase cost, maintenance expenses, and expected lifespan can result in a more accurate understanding of a product’s total cost of ownership.

In conclusion, selecting the right compact slip ring demands a thoughtful evaluation of application-specific requirements, product specifications, supplier credibility, and cost considerations. This multi-faceted approach ensures the chosen compact slip ring delivers optimal performance consistently, across a variety of application scenarios.

Compact Slip Ring Maintenance and Longevity

Ensuring seamless operation and maximum lifespan of compact slip rings is a priority for users in various industries. To achieve this, it’s essential to adhere to proper maintenance practices and adopt measures that can extend their life. Let’s examine the best practices for maintaining compact slip rings, understand their expected lifespan, and explore tips for maximizing their longevity.

Best Practices for Maintaining Compact Slip Rings

- Regular inspections and cleaning: Dust and debris accumulation can impair the performance of compact slip rings. Periodic visual inspections and cleaning, using air or a soft brush, can help maintain optimal contact between brushes and rings, ensuring smooth signal transmission.

- Lubrication: In some slip ring models, lubrication plays a vital role in reducing wear and tear on contact surfaces. Consult the manufacturer’s guidelines on the recommended lubricant type and frequency to keep the interface functioning efficiently.

- Wear monitoring: Monitor the wear of brushes and rings. Over time, wear can result in reduced contact quality, leading to intermittent signal transmission or power loss. Regularly checking for signs of excessive wear and replacing components as needed will help maintain peak performance.

- Monitoring performance indicators: Keep tabs on crucial indicators like voltage drop, temperature rise, and electrical noise. Deviations from normal operational ranges can signal emerging issues that may require attention.

- Compliance with manufacturer’s guidelines: Adhering to the manufacturer’s recommended maintenance schedule and guidelines can go a long way in sustaining the optimal performance of your compact slip rings.

Expected Lifespan of Compact Slip Rings

The lifespan of a compact slip ring is influenced by various factors, including the specifications, materials used, quality of the product, and operating conditions. While the expected lifespan may vary depending on these factors, following proper maintenance practices and addressing issues proactively can considerably extend your compact slip ring’s service life.

Tips for Maximizing Longevity of Compact Slip Rings

- Select the right compact slip ring: Ensuring maximum lifespan starts with selecting the right compact slip ring that fits your application requirements closely. Factors like material selection and design can also impact longevity.

- Operate within specified parameters: Adhering to the manufacturer’s defined operating parameters, including rotational speed, temperature limits, and maximum current capacity, protects your compact slip ring from excessive stress and premature wear.

- Prevent harsh environmental conditions: Shielding compact slip rings from harsh environmental factors like extreme temperatures, moisture, and corrosive chemicals can improve their durability and lifespan.

By following the outlined best practices, monitoring performance indicators, and adhering to the manufacturer’s guidelines, you can ensure not only a prolonged lifespan for your compact slip rings but also a consistent, high-quality performance throughout their operational lives.

Innovations and Trends in Compact Slip Rings

In the ever-evolving landscape of technology and design, the field of compact slip rings is not left behind. The drive for superior performance continues to pave the way for impressive innovations and trends. This section will discuss recent advancements and look into how compact slip rings might continue to evolve in the future.

Recent advancements in the field of compact slip rings largely revolve around miniaturization and the use of advanced materials and design. As demands for small, lightweight, but highly functional devices continue to grow in sectors like medical, telecommunications, aerospace, and defense, miniaturization has become a pivotal trend. This has led to the creation of ultra-compact slip rings capable of fitting into highly restrictive spaces without compromising on their performance and durability.

Moreover, the exploration and use of advanced materials and design approaches have significantly transformed the construction of compact slip rings. The integration of exotic, low-resistance materials for contacts, such as gold alloys, has brought about enhanced electrical performance and reduced wear. Furthermore, designs capitalizing on encapsulated or sealed structures have added robustness against harsh environments, ensuring reliability even under extreme conditions.

Looking forward, the future of compact slip rings seems poised for exciting evolutions. The continued drive towards miniaturization, combined with ever-increasing demands for operational efficiency, points towards further refinement in size, weight, and configuration while improving overall performance.

Additionally, the rise of smart technologies and connectivity might influence compact slip ring evolution. As more devices integrate IoT capabilities, we could see future compact slip rings designed to seamlessly accommodate these requirements.

Finally, the push for sustainable and eco-friendly technologies might guide the development of energy-efficient slip rings. These might leverage low-energy materials and smart designs that optimize current flow, consequently reducing energy loss and carbon footprints.

In summary, given the swift pace of technological advancement, compact slip rings are continuously evolving, embracing miniaturization, advanced materials, and improved design approaches. And by aligning with global trends, like IoT and sustainability, the future of compact slip rings indeed holds great potential.

Real-world Applications and Case Studies

Compact slip rings have proven instrumental across various industries and applications, effectively addressing challenges of power and data transmission in multitudes of rotating systems. They have made a conspicuous impact in fields such as medical equipment, military technology, and industrial machinery. This section showcases examples of how compact slip rings have made a considerable difference in real-world scenarios.

Medical Imaging Systems

Advanced medical imaging systems like CT and MRI scanners hinge on the efficient transfer of electrical signals and power in a rotating setup. Compact slip rings play a crucial role, in ensuring uninterruptable data flow and power supply during high-precision imaging processes.

For instance, a leading manufacturer of CT scanners needed a solution for seamless data transfer between stationary and rotating parts of the scanner. A compact slip ring, meticulously engineered for precision and reduced electrical noise, was employed. This solution dramatically improved the quality and accuracy of images, ultimately leading to better diagnostic outcomes.

Wind Turbines

The green energy sector, especially wind turbines, heavily relies on compact slip rings. These rings orchestrate energy and data transmission from the rotating blades to the stationary part of the wind turbine.

A wind energy company once faced a challenge with their turbines experiencing intermittent signal transmission, leading to inefficient energy production. The solution was a robust compact slip ring customized for high rotational speeds and designed to withstand harsh outdoor conditions. The implementation of this slip ring boosted the reliability and efficiency of the turbines, propelling the company towards its energy production targets.

Surveillance Systems

High-end security and surveillance systems rely on compact slip rings for the continuous operation of swiveling cameras. These slip rings ensure power and data transmission across rotating interfaces, enabling cameras to provide 360-degree uninterrupted coverage.

In one such case, a security service provider was grappling with the limited coverage of their surveillance cameras. The introduction of a compact slip ring allowed their cameras to rotate continuously, enhancing security coverage in monitored areas.

The flexibility and design of compact slip rings fit various applications, emphasizing their significance across a spectrum of industries. By ensuring uninterrupted power and signal transmission, they contribute substantially to operational efficiency, reliability, and advances in technology.

Conclusion

As compact slip rings continue to play a pivotal role in various industries, understanding their capabilities and the factors that influence their effective use is crucial. By keeping the information presented in this comprehensive guide in mind, professionals can make well-informed decisions and harness the full potential of these seemingly small yet powerful devices.

Need technical support for compact slip rings? Submit your request now.

FAQs about Compact Slip Rings

Q: Can I use a compact slip ring in any environment?

A: While compact slip rings are generally robust, the specific environment in which they can operate depends on their design and construction. Some are built to withstand extreme temperatures and harsh conditions, while others may be more suitable for controlled environments. Therefore, always check the product specifications or consult with the manufacturer.

Q: How often do I need to replace the brushes in a compact slip ring?

A: The frequency of brush replacement depends on the operating conditions, brush, and ring material. Regular inspection and monitoring of your compact slip ring’s performance can give you a better idea of when replacements become necessary.

Q: What’s the maximum speed a compact slip ring can handle?

A: The maximum operational speed of a compact slip ring varies based on its design and construction. Always refer to the manufacturer’s guidelines for this information to prevent potential damage from exceeding the design parameters.

See What We Can Do