Data Slip Rings are key elements in technology connecting stationary and rotating parts, enabling a seamless data transfer across rotating interfaces—an essential phenomenon in various industries. Through this article, we take an insightful journey exploring these vital devices.

Introduction to Data Slip Rings

Data slip rings, also known as rotary electrical connectors, are electromechanical devices designed to facilitate the transmission of electrical signals, power, and data between a stationary component and a rotating structure. As an essential element in various technological systems, data slip rings overcome the challenges posed by the need for constant or high-speed rotation while ensuring that data transmission remains smooth and uninterrupted.

Data slip rings can be found in a diverse range of industries catering to specific demands, such as aerospace, military, robotics, automation equipment, renewable energy generation, and more. They serve as a vital solution in situations where traditional cable connections are impractical, inefficient, or contribute to equipment failure due to tangling, bending stress, and wear. With their innovative design and adaptable specifications, data slip rings stand out as a versatile and necessary technology, playing a significant role in optimizing and streamlining numerous modern applications. Consequently, understanding the intricacies of these powerful devices unlocks countless possibilities for enhanced system performance and heightened operational efficiency.

Working Principle of Data Slip Rings

At the core of a data slip ring’s operation, there lies a simple yet effective mechanism that is the cornerstone for its various applications. The primary purpose of a data slip ring is to transfer data from a stationary part to a rotating part in a machine or system setup without limiting the relative rotation speed or introducing significant noise levels that could disrupt the data transfer process.

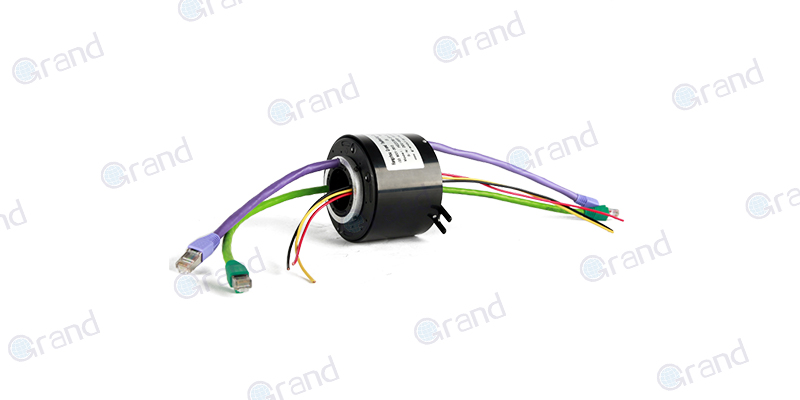

As a fundamentally electromechanical device, a data slip ring is composed of stationary brushes that maintain constant contact with a rotating ring, often made of high-conductivity materials like gold or silver alloys. The brushes are wired to the stationary part of the system and carry signals to the rotating disc. As the ring rotates, the electrical signals, or data, are transferred through the contact points allowing smooth and near-continuous transmission of power, analog, or digital signals.

Depending on the type and make, slip rings can work with a range of data protocols like Ethernet, USB, and Canbus among others, making them compatible with various devices and systems. Furthermore, different models of slip rings support different rotational speeds, giving users the flexibility to choose a slip ring that best fits their system’s rotation speed requirements.

However, it is important to emphasize that proper design, material selection, and manufacturing techniques are key to ensuring low electrical noise, minimal signal interference, and high durability—a crucial trifecta, especially in high-speed applications or those operating in demanding environmental conditions.

As such, a deep understanding of the data slip ring’s working mechanism can provide crucial insights, allowing for optimized usage and better system performance.

Features of Data Slip Ring

Types of Data Slip Rings

As versatile as data slip rings are in their applications, they are just as varied in their forms. Different types of data slip rings are designed and optimized for specific protocols and application scenarios, ensuring they precisely cater to the task at hand.

Firstly, Ethernet Slip Rings are designed specifically for Ethernet protocol transmission, which makes them the preferred choice in IT and network-focused applications where high-speed and large data volume transmission is requisite. These slip rings provide a reliable communication solution for systems such as radar arrays, wind turbines, and high-definition video surveillance equipment.

Next, USB Slip Rings cater to instances where USB interfaces are predominant. These devices facilitate seamless data transmission between a USB device and a computer even during constant or high-speed rotation of the USB device. Their usage is found in diverse applications such as industrial automation systems, security cameras, and even in robotic arms where quick and efficient data transfer is essential.

Canbus Slip Rings are another variant, designed to support CAN (Controller Area Network) protocol, an industry standard in automotive and industrial communication networks. With their robust design and high reliability, these slip rings are superbly positioned to work optimally in these demanding environments.

Furthermore, there are other protocol-specific slip rings such as HDMI, Fiber Optic, and Coaxial Interface slip rings. HDMI slip rings are often used in multimedia displays and broadcast systems. Fiber Optic Slip Rings, which use optical fibers for data transmission, exhibit extremely high bandwidth capabilities and are fit for cutting-edge applications requiring high-speed data transfers like satellite communications and advanced radar systems. Coaxial Interface slip rings cater to high-frequency signal transmission requirements and find utility in telecommunication systems and medical imaging devices.

Through this lens of diversity, it becomes more apparent that the range of data slip rings available allows them to be fine-tuned for specific applications, ensuring an efficient, effective, and seamless performance that meets the precise needs of each industry.

What are Data Slip Rings used for?

Data slip rings are used in a wide range of industries and applications where continuous, reliable transmission of data is required between rotating and stationary parts of a system. Below are the key areas where data slip rings are commonly used:

1. Industrial Automation

- Robotics: In automated robots, data slip rings are used to transmit control signals and sensor data while allowing the robotic arm or body to rotate continuously. This ensures smooth and uninterrupted operation in applications such as manufacturing, assembly, and material handling.

- CNC Machines: Computer Numerical Control (CNC) machines require precise control and data communication during their rotation and operation. Data slip rings allow for the transmission of control signals and feedback data, which is essential for accuracy in milling, drilling, and cutting processes.

2. Medical Imaging Devices

- MRI and CT Scanners: These devices require continuous rotation to create detailed images of the human body. Data slip rings allow high-speed transmission of imaging data from the rotating scanner to the stationary processing systems, ensuring that real-time data is sent without interruptions.

- Surgical Robots: In medical robotics, data slip rings are used to transmit control signals and feedback data from surgical tools that rotate during complex procedures.

3. Wind Turbines

- Data Transmission from Sensors: Wind turbines use data slip rings to transfer signals from sensors located on the rotating blades to the stationary hub. These sensors monitor important parameters like wind speed, blade angle, and vibration, ensuring optimal turbine performance and safety.

- Power and Data Hybrid Systems: In some wind turbines, data slip rings are used in hybrid configurations to transfer both power and data simultaneously, reducing the need for multiple components and simplifying system design.

4. Radar Systems

- Military and Civilian Radar: In rotating radar systems, whether for air traffic control, weather monitoring, or military applications, data slip rings transmit radar signals and data from the rotating antenna to stationary processing units. This is crucial for providing real-time radar imagery and data analysis.

5. Surveillance and Security

- Pan-Tilt-Zoom (PTZ) Cameras: In security and surveillance systems, PTZ cameras use data slip rings to allow 360-degree continuous rotation while transmitting video data to monitoring stations. This enables constant, uninterrupted video feed from rotating cameras.

- Drones and UAVs: Unmanned Aerial Vehicles (UAVs) and drones equipped with cameras and sensors use data slip rings to ensure continuous data transfer between rotating parts, such as gimbals, and the main control system.

6. Renewable Energy Systems

- Solar Trackers: In solar energy systems, particularly those with solar trackers, data slip rings transmit control signals that adjust the position of the solar panels to track the sun’s movement throughout the day. This improves the efficiency of the energy generation process.

- Offshore Wind Farms: Data slip rings are critical in offshore wind turbines where both harsh environmental conditions and constant rotation require reliable data transmission for monitoring and control.

7. Aerospace and Defense

- Satellite Communication Systems: Data slip rings are used in satellite systems to transmit data from rotating parts, such as antennas, to stationary systems, allowing for uninterrupted communication and data transmission.

- Missile Guidance Systems: In missile and defense systems, data slip rings are crucial for transmitting signals from sensors or control units on rotating parts to the missile’s central control system, ensuring accurate targeting and guidance.

8. Marine Applications

- Rov Systems: Remotely Operated Vehicles (ROVs), commonly used in underwater exploration and marine research, utilize data slip rings to transmit data from sensors, cameras, and other devices as the vehicle rotates or moves underwater.

- Rotating Sonar Systems: Sonar systems used in submarines or ships often rotate to scan the underwater environment. Data slip rings allow for continuous data transmission as the sonar rotates.

9. Entertainment and Simulation

- 360-Degree Video and VR Systems: In virtual reality (VR) and 360-degree video systems, especially those used in entertainment, data slip rings enable smooth data transmission between the rotating camera rigs and the processing systems, providing immersive experiences.

- Amusement Park Rides: Some amusement rides that involve rotating platforms or components use data slip rings to transmit control signals and sensor data to ensure the ride operates safely and smoothly.

10. Test and Measurement Equipment

- Rotating Test Benches: In industries such as automotive and aerospace, rotating test benches use data slip rings to collect data from sensors on moving parts like engines, axles, or wheels during tests. This allows for real-time monitoring of performance metrics such as speed, torque, and temperature.

- Turbine Testing: Data slip rings are also used in turbine testing facilities, where they transmit sensor data from the rotating components of gas or steam turbines to the stationary monitoring system.

11. Broadcast and Communication Systems

- Rotating Antennas: In broadcast and communication towers, rotating antennas use data slip rings to maintain a continuous connection with the control system while sending signals. This allows the antenna to adjust and rotate freely without interrupting the signal transmission.

- Mobile Broadcasting Units: Data slip rings are also found in mobile broadcasting units, where they help transmit video and audio data from rotating camera platforms to stationary equipment, ensuring high-quality, live transmission in real-time.

12. Instrumentation and Measurement

- Wind Tunnels: In aerospace research, wind tunnels often involve rotating components that require real-time data acquisition. Data slip rings allow for continuous transmission of sensor data while the components are in motion, enabling precise measurements.

- Rotating Machinery Monitoring: In large industrial plants, rotating machinery such as turbines, compressors, or generators requires constant monitoring. Data slip rings help transmit sensor data (vibration, temperature, pressure, etc.) from these rotating machines to the central control systems.

13. Oil and Gas Industry

- Rotating Drilling Systems: In oil rigs and drilling platforms, data slip rings are used in rotary drilling equipment to transmit signals from sensors that monitor drilling parameters. This real-time data transmission is crucial for optimizing drilling operations and ensuring safety.

14. Electric Vehicle Testing

- Rotary Test Systems: In the development and testing of electric vehicles, data slip rings are used to transmit data from rotating components like wheels or drive shafts to the data acquisition systems, ensuring accurate measurement of performance and efficiency.

In summary, data slip rings are essential in any application where continuous, reliable data transmission is required between rotating and stationary components. They play a critical role in industries such as industrial automation, medical imaging, wind energy, radar systems, robotics, aerospace, and more, enabling efficient and uninterrupted data flow for a wide variety of processes.

Data Slip Rings Key Features and Specifications

Data slip rings come equipped with a host of features and specifications meticulously tailored to meet user needs and operational requirements. Depending on their type, different data slip rings may focus on specific aspects, giving them a competitive edge in certain applications.

- Number of Circuits: The number of circuits refers to the individual paths for the transmission of electrical signals. Some slip rings are unifilar with only a single circuit, while others are multifilar with multiple independent circuits. The selection of the number of circuits depends on the complexity and needs of the user’s system.

- Rotational Speed: Data slip rings are designed to handle various rotational speeds, with some specialized for low-speed operations and others built for high-speed applications. The choice of rotational speed directly impacts signal quality and the device’s longevity.

- Data Rate: The data rate or bandwidth of a data slip ring determines how much data it can successfully transmit per second. Higher bandwidth is necessary for applications involving large volumes of data transfer such as high-definition video streaming or fast-paced data communication systems.

- Insulation Resistance: High insulation resistance is a crucial feature ensuring the data slip ring’s capability to prevent leakage of electrical signals between circuits—a feature particularly pertinent in devices handling sensitive or high-powered signals.

- Durability: The longevity and durability of data slip rings are largely influenced by their construction materials. Premium data slip rings often use high-quality materials that are resistant to wear and corrosion, ensuring they can maintain reliable performance over long periods.

- Protocol Compatibility: Depending on their design, data slip rings can be compatible with a variety of data protocols such as Ethernet, USB, Canbus, and HDMI, which dictate their aptness for specific application settings.

- Environmental Resistance: Some slip rings are constructed to withstand harsh environmental conditions such as high temperatures, dust, humidity, and vibration. This makes them suitable for rugged or extreme environments like mining operations or marine applications.

- Size and Weight: Depending on the available space and weight restrictions an application may have, the physical size and weight of the data slip ring can be a critical factor in the selection process.

By understanding these key features and specifications, users can more effectively choose the most suitable data slip ring, ensuring optimal performance and efficiency in their specific operational contexts.

Applications of Data Slip Rings

Diverse in form and function, data slip rings find their use across an array of industries and applications. Their ability to transmit uninterrupted power and data even during continuous rotation makes them indispensable in many modern systems.

- Surveillance Systems: In surveillance systems, especially in pan-tilt cameras, data slip rings enable the rotation of cameras through 360 degrees without hampering the transmission of power and video signals. This allows for continuous monitoring and securing of larger areas with minimal hardware.

- Telecommunications: In the telecommunications industry, data slip rings play a key role in satellite communication systems. The need to maintain consistent communication, even as satellites rotate, necessitates the use of slip rings capable of handling high-bandwidth data transfer.

- Wind Energy Systems: Wind turbines, particularly in their nacelles, require the constant transmission of power and data signals between stationary and rotating components. Data slip rings in these systems assure efficient wind power harnessing without concerns of cable twisting or entangling.

- Automated Machinery: In the realm of industrial automation, robotic arms, and automated assembly lines often deploy data slip rings. They enable the smooth operation of these machines, facilitating the continuous transfer of power and signals for control and sensor feedback.

- Medical Imaging Equipment: Sophisticated imaging systems like CT scanners have a critical demand for high-quality, real-time data transfer between stationary parts and rotating gantries. Therefore, they extensively rely on data slip rings that support high data rates and ensure precise imaging results.

- Offshore/Marine: Data slip rings find utility in the marine industry for radar operation, rROVs (Remotely Operated Vehicles), and other sea-based applications where maintenance, accessibility, and resistance to corrosive environments are of utmost importance.

- Motion Simulators: In the aviation and entertainment industry, motion simulators make extensive use of slip rings to ensure continuous electrical connections while performing complex, multi-axis rotations.

The myriad of applications that data slip rings serve sheds light on their versatile nature and pivotal role in numerous services, systems, and sectors. By understanding these application areas, one can better appreciate the innovative function of data slip rings and their impact on enhancing operational efficiencies.

Data Slip Rings Selection Guide

Selecting the right data slip ring is paramount to the success of any application that requires it, as the device’s specifications directly impact performance and efficiency. The following guide outlines essential factors to consider when choosing a suitable data slip ring.

- Data Protocol Compatibility: The slip ring must be compatible with the data protocols being used in your system or application, such as Ethernet, USB, Canbus, HDMI, etc. Confirming this compatibility ensures seamless and efficient data transmission.

- Transmission Speed: Assess the data rate requirements of your application to select a slip ring with adequate data bandwidth capabilities. High-speed applications and those with large volumes of data transfer require slip rings with higher data rates (e.g., Fiber Optic Slip Rings for advanced communication systems).

- Operating Environment: Consider the environmental conditions in which the data slip ring will be used. For harsh or extreme environments, choose a slip ring designed with features like temperature resistance, dust sealing, humidity protection, and vibration resistance.

- Size and Weight: The physical dimensions and weight of the slip ring should be suitable for the space and weight restrictions of your specific application. Customized slip rings can be designed if required to fit the unique constraints.

- Cost: Establish a budget based on your project or operational needs and search for a data slip ring that provides the right balance of performance and affordability. Bear in mind that lower-cost options might sacrifice quality or durability.

- Manufacturer’s Reputation: Do thorough research on the manufacturer and their products. A reputable manufacturer with a proven track record of quality, reliability, and customer support is more likely to provide a superior data slip ring.

- Durability: Evaluate the durability of materials used in the slip ring construction, as well as the quality of manufacturing. High-durability slip rings are essential for long-term performance and minimal maintenance.

- Customization: Make sure the slip ring provides adequate customization options to meet your specific application requirements, such as the number of circuits, rotational speed, or even integration with other components like encoders, fluid rotary unions, or hydraulic units.

- Maintenance and Support: Check for ease of maintenance and the availability of replacement parts or support documentation, as this can significantly impact the overall operation of your slip-ring-backed system.

Taking these factors into consideration when selecting a data slip ring will help ensure the most appropriate device is chosen for its intended application. By doing so, users can be confident that their chosen slip ring will deliver optimal performance, minimize maintenance, and maximize their system’s efficiency.

Maintenance of Data Slip Rings

Proper and regular maintenance of data slip rings plays a vital role in ensuring their optimal performance and extending their service life. Adhering to appropriate maintenance and care practices can also prevent unexpected downtime and reduce cost implications linked to premature component failure. Here are key tips and strategies for maintaining data slip rings:

- Routine Inspections: Implement a schedule for regular inspections to check the physical state of the slip ring and its performance metrics. This includes visually inspecting the slip ring for any visible wear, corrosion, or damage. Additionally, specific performance aspects like data transmission quality or signal noise should be monitored to detect any potential degradation early.

- Cleaning: Over time, slip rings may accumulate dust, grime, or other particulates, which can interfere with their performance. Regularly clean the slip ring using approved cleaning solutions and techniques. Be sure to take into account the slip ring’s specificity; for instance, non-metallic slip rings usually require specialized cleaning solutions.

- Lubrication: Depending on the design and construction of the slip ring, periodic lubrication might be necessary, especially for mechanical contact-based slip rings. Use manufacturer-recommended lubricants and follow their guidelines to avoid any potential version to the slip ring’s contact surfaces.

- Preventive Maintenance: Establish a preventive maintenance schedule based on the manufacturer’s recommendations. This can range from replacing worn-out parts to complete refurbishments of the slip ring assembly. Such proactive interventions can extend the life of the device and prevent unexpected failures.

- Record Keeping: Maintaining a log of all maintenance activities can help track the slip ring’s performance and condition over time. Additionally, it aids in planning future maintenance activities and recognizing patterns of wear or need for component replacements.

- Training: Ensure the team handling the slip rings is adequately trained to perform the maintenance tasks. Understanding the correct care procedures can prevent inadvertent harm to the slip ring and improve adherence to set maintenance schedules.

- Spare Parts: Keep an inventory of essential spare parts provided by the manufacturer. In case of a sudden failure, immediate replacement can ensure that system downtime is minimized.

By following this maintenance guide, you can optimize the performance and lifespan of your data slip rings. Regular maintenance not only preserves your investment but also guarantees the effective and uninterrupted operation of the systems they serve.

Data Slip Rings Trusted Manufacturers

Numerous manufacturers in the industry offer an extensive range of data slip rings designed for various applications. While specific needs may dictate the selection of a particular data slip ring, the reputation and credibility of the manufacturer play a critical role. Here, we discuss some of the most trusted data slip ring manufacturers offering robust products, reliable performance, and customer support.

| No. | Manufacturer | Website |

|---|---|---|

| 1 | Hangzhou Grand Technology | https://www.grandslipring.com/ |

| 2 | Moog Inc. | https://www.moog.com/ |

| 3 | Stemmann-Technik | https://www.stemmann.com/en/home |

| 4 | Schleifring | https://www.schleifring.com/ |

Hangzhou Grand Technology

Hangzhou Grand Technology Co., Ltd. started as a special slip ring manufacturer in 2011. Grown into slip rings, rotary joints, and slip ring assembly experts of today with 6,000 square meter manufacture complex.

Obtained ISO9001, Rosh, CE, and GJB9001B certificates a number of slip rings, rotary joint patents, and proud of our products can meet military grade. Collaborated with universities, institutes, and renowned factories across Asia and Europe including Panasonic, SIEMENS, CSIC, SAMSUNG, HUAWEI, etc.

Moog Inc.

Moog is a leading supplier of high-performance slip rings for various industries, including aerospace. Among their offerings, Moog’s SR Series Slip Rings are designed for the demanding environments of helicopters, excelling in performance, reliability, and customization potential.

Stemmann-Technik

Stemmann-Technik, a part of the Conductix-Wampfler Group, offers a broad range of slip rings, including solutions for helicopters. Their Livietta Slip Ring Assemblies are designed explicitly for harsh and demanding environments in the aviation sector, providing reliable signal and power transmission.

Schleifring

Schleifring is a well-known manufacturer of electromechanical systems, including slip rings customized for various industries. Their Aircraft Slip Rings cater specifically to helicopters, offering robust performance, low wear, and high reliability to meet the challenges of aviation applications.

If you want to know more about other slip ring manufacturers, you can read Top 10 Slip Ring Manufacturers in China, Top 10 Slip Ring Manufacturers In the USA Market 2023, and Top 10 Slip Ring Industry Key Manufacturers 2023.

These trusted manufacturers provide premium data slip rings, alongside offering exceptional customer support and valuable expertise in engineering solutions for diverse needs. By partnering with such reputable manufacturers, users can ensure they acquire reliable products tailored to their specific operational contexts, enhancing the performance and efficiency of their respective systems.

Data Slip Rings Quality Standards and Certifications

Quality standards and certifications serve as validations and indications of the safety, performance, and reliability of products such as data slip rings. They ensure that these devices meet certain requirements driven by industry standards, regulatory bodies, or customer expectations. Here are some of the essential data slip ring quality standards and certifications, and their significance:

- ISO 9001: The ISO 9001 standard is related to quality management systems and is internationally recognized. Manufacturers who attain this certification have demonstrated consistent product quality and a continuous commitment to enhancing customer satisfaction through effective quality control measures and improvement initiatives.

- ISO 14001: This certification relates to environmental management systems. When a slip ring manufacturer has this certification, it signifies their commitment to minimizing their operation’s negative environmental impacts and their efforts in continuous environmental performance improvement.

- CE Marking: The CE mark indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area (EEA). For data slip ring manufacturers, this emblem signifies that the products meet the requirements of the relevant European health, safety, and environmental protection legislated directives.

- RoHS Compliance: The Restriction of Hazardous Substances (RoHS) directive controls the use of specific hazardous substances in electrical and electronic equipment. Compliance ensures that data slip rings are manufactured with minimal use of hazardous substances, promoting electronic consumer goods safety and environmental sustainability.

- UL Certification: A data slip ring with Underwriter Laboratories (UL) certification ensures that the slip ring has been tested and certified to meet specific safety standards. Users can, therefore, be confident about the safety and reliability of such products.

- IP Rating: Ingress Protection (IP) rating is essential for determining the degree of protection provided by the slip ring enclosure against intrusion from foreign bodies (dust, dirt) and moisture. High IP-rated slip rings are essential in applications where the equipment is exposed to harsh environmental conditions.

Conclusively, ensuring that your data slip ring conforms to these standards and certifications can guarantee both safety and product reliability. As a user, insisting on such standards also allows you to use these criteria in selecting a suitable and reliable data slip ring for your specific application, further assuring optimal longevity and performance.

The Importance of Data Slip Ring

Data Slip Rings Future Trends and Innovations

As technology continues to evolve rapidly, data slip rings will undoubtedly witness a range of advancements and trends shaping their future landscape. These improvements are geared towards enhancing performance, reducing maintenance, expanding application capabilities, or introducing new features to meet emerging needs. Here are some significant future trends and innovations predicted in the realm of data slip rings:

- Miniaturization: With the continued trend of downsizing in many technical fields, the demand for compact, high-performance slip rings is increasing. More advanced manufacturing and assembly processes will facilitate the development of smaller slip rings without compromising their data transmission capabilities or durability. Miniaturization allows slip rings to be integrated into tighter spaces, extending their applicability across a broader range of scenarios.

- IoT Enhancement: The rise of the Internet of Things (IoT) is heralding the need for more “intelligent” slip rings capable of transmitting much more than just power and simple data signals. Future slip rings could come equipped with sensors and smart features, enabling machine learning algorithms to predict maintenance needs, track performance metrics, monitor operational conditions, and potentially self-optimize data transmission depending on the exigencies of the application.

- Use of Advanced Smart Materials: Research is ongoing into the use of smart materials capable of modifying their properties based on changes in their environment. For slip rings, this could lead to increased durability, reduced wear, and better performance under varying conditions. Moreover, advanced materials could also contribute to signal noise reduction and improved data transmission rates.

- Advanced-Data Protocols: As communication standards evolve, future slip rings will need to support more advanced data protocols reliably. We can expect development in slip rings capable of handling increasingly complex and faster data streams, poised to support technologies such as 5G and beyond.

- Integration with renewable energy systems: With rising interest in renewable energy systems, the role of slip rings in wind turbines, solar trackers, and other renewable energy applications is likely to become more crucial. This will necessitate the development of robust high-power slip rings capable of withstanding harsh environments typical of many renewable energy installations, while still efficiently transmitting sophisticated sensor data.

- Increased Durability and Service Life: Advancements in manufacturing processes and material science are expected to result in slip rings with longer lifespans and improved durability. Predictive maintenance technologies could play a significant part in extending service life by identifying potential operational issues before they result in complete failure.

By staying aware of these future trends and innovations, users and developers can ensure that they’re ready to make the most of the exciting advancements in data slip ring technology, thereby enhancing the efficiency and effectiveness of their respective systems.

Conclusion

Data Slip Rings play a pivotal role in myriad industries. Keeping abreast of their working principles, applications, selection strategies, maintenance, and future trends will help users optimize their applications and remain at the forefront of technological advancements.

See What We Can Do