In a world where creativity and innovation are increasingly celebrated, do-it-yourself (DIY) projects have emerged as a popular avenue for enthusiasts to showcase their skills. From woodworking to electronics, the DIY movement continues to gain momentum. Enter the realm of DIY electrical slip rings, where tech-savvy individuals are exploring the fascinating world of rotating electrical connectors. Discover how DIY enthusiasts are embarking on their own electrical slip ring projects, channeling their ingenuity to create seamless power and data transmission solutions.

The DIY community has always been driven by a thirst for knowledge and a desire to tinker with technology. With the advent of accessible information and readily available components, individuals are now venturing into the realm of electrical slip rings, once considered a domain reserved for specialized industries.

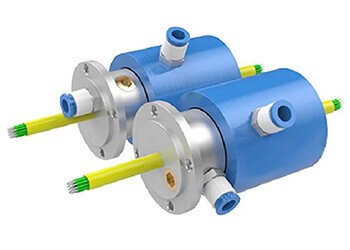

Electrical slip rings, also known as rotary electrical connectors, are devices that facilitate the transfer of power and signals between stationary and rotating components. These connectors are widely used in industries such as robotics, aerospace, and automation, where seamless connectivity is crucial. DIY enthusiasts have taken a keen interest in understanding and building their own electrical slip rings, seeking to unlock the possibilities of rotating interfaces in their own projects.

Embarking on a DIY electrical slip-ring project requires a blend of technical knowledge, creativity, and a willingness to experiment. Enthusiasts start by understanding the fundamental principles behind electrical slip rings, and studying the concepts of conductive rings, brushes, and contact surfaces. They dive into online resources, forums, and tutorials to learn about the intricacies of designing and constructing these connectors.

The journey begins with selecting suitable components and materials. DIYers often explore options such as conductive rings, brushes, bearings, and housings. They meticulously research and experiment with various combinations, aiming to strike a balance between functionality, cost, and ease of assembly.

The assembly process itself can be a challenging yet rewarding experience. DIYers carefully assemble the components, ensuring proper alignment, secure connections, and smooth rotation.

They may encounter hurdles along the way, such as optimizing contact surfaces, minimizing signal loss, or finding innovative solutions for specific project requirements. Persistence and resourcefulness play a significant role in overcoming these challenges.

One of the advantages of DIY electrical slip ring projects is the ability to customize the design to suit specific needs. DIYers can tailor their slip rings to accommodate different numbers of rings, handle specific voltages and signal types, or even incorporate additional features like fluid transmission. This flexibility allows for personalized creations that perfectly align with the intended project.

DIY electrical slip ring projects span a wide range of applications and industries. Robotics enthusiasts integrate homemade slip rings into their robotic arms, enabling seamless movement and enhanced functionality. Hobbyists exploring aerial drones utilize DIY slip rings to transmit power and control signals across rotating parts, unlocking new possibilities for aerial photography and videography. Creative inventors incorporate DIY slip rings into interactive art installations, combining technology and aesthetics in mesmerizing ways.

It is important to note that DIY electrical slip rings may not always match the performance and reliability of commercially available options. Professional-grade slip rings undergo rigorous testing and adhere to strict quality standards. However, for hobbyist projects and educational purposes, DIY electrical slip rings offer a unique opportunity to learn, experiment, and innovate.

The DIY electrical slip-ring movement has also fostered a vibrant community of like-minded individuals. Online platforms, forums, and social media groups provide spaces for DIY enthusiasts to share their experiences, exchange ideas, and seek guidance from experts. Collaborations, tutorials, and troubleshooting discussions abound, creating a supportive ecosystem that nurtures the growth of the DIY electrical slip-ring community.

As the DIY trend continues to gain momentum, the future looks promising for electrical slip-ring enthusiasts. Ongoing advancements in technology, combined with the DIY spirit, will lead to even more exciting and innovative projects. DIY electrical slip rings are empowering individuals to push the boundaries of creativity, while also gaining a deeper understanding of the intricacies of seamless power and data transmission.

In conclusion, DIY electrical slip-ring projects represent the epitome of hands-on ingenuity and curiosity. These projects allow enthusiasts to explore the fascinating world of rotating electrical connectors, unlocking new possibilities for seamless connectivity in their own creations. From robotics to art installations, the DIY electrical slip-ring movement showcases the power of innovation and collaboration within the DIY community. So, are you ready to unleash your inner engineer and embark on your own DIY electrical slip-ring adventure? The possibilities are limited only by your imagination.

See What We Can Do