In this in-depth article, we peer into the inner workings of AC motors to understand if they require brushes for their operation. This is not just a technical exploration but also a practical guide to help users weigh their options when it comes to maintenance, efficiency, and reliability in selecting the right type of motor for their needs.

Introduction: Do AC Motors Have Brushes

In the vast landscape of electrical machinery, alternating current (AC) motors stand as titans of industry and innovation, propelling a myriad of applications that range from the fans cooling our homes to the assembly lines manufacturing our cars. The ubiquity of AC motors stems from their ability to efficiently convert electrical energy into mechanical power, which is invaluable in both industrial and domestic settings. They can be found at the core of household appliances, powering HVAC systems, and even driving the pumps that circulate water in your home aquarium.

In the heart of many traditional motors, there is a component known as the brush. These brushes are not akin to what one might use on canvas or hair but are rather vital electrical contacts made of conductive materials. Their primary function is to maintain an electrical connection between static and moving parts of a motor—essentially, to transfer current. In the case of direct current (DC) motors, brushes slide against a spinning commutator, reversing the flow of electricity to sustain rotation.

One might then wonder, with the central role that brushes have played in the history of electric motors, do they also hold a position of importance within AC motors? To appreciate this inquiry fully, it’s essential to reflect on the mechanical differences between AC and DC motors and the design evolution that has influenced modern motor construction. This leads us to the guiding question of our discussion: Do AC motors have brushes, and if not, how do they operate without them?

As we embark on this exploration, we’ll unravel the intricacies of AC motor operations and the ingenuity behind their brushless design. We’ll delve into how the absence or presence of this small component can significantly influence the efficiency, maintenance, and suitability of a motor for specific tasks. Unearthing the answer isn’t just a question of yes or no—it’s about understanding the elegant dance between electricity and motion that powers our world.

Understanding AC Motors

To delve into the question about the presence of brushes in AC motors, we first need to understand what an AC motor is and how it operates. An alternating current (AC) motor is a type of electric motor that converts electrical energy into mechanical power through the use of an alternating current – hence its name. The ‘alternating’ aspect of the current refers to its periodic reversal in direction, which varies about time in a sinusoidal manner. This is in contrast to direct current (DC), which flows continuously in one direction.

At the heart of an AC motor lie its major components – the stator and the rotor. The stator, as the name suggests, remains static, housing the motor’s primary windings, which are coils of wire that carry the alternating current. This current, when flowing through these windings, produces a rotating magnetic field.

Nested within this stator is the rotor, which is designed to revolve. The rotor contains its windings called rotor windings. When the magnetic field produced by the stator coils interacts with these rotor windings, it induces a current that subsequently generates its magnetic field. The interaction between these two magnetic fields results in a torque that drives the rotor to spin, creating the motion that powers your device or machine.

Among the AC motors on the market, two types are especially common: induction motors and synchronous motors. Induction motors, also known as asynchronous motors, are popular for their simplicity and rugged design. They leverage the principle of electromagnetic induction, wherein the current in the rotor is induced by the magnetic field, rather than being directly supplied. This means they inherently run slightly slower than the frequency of the alternating current, hence the name ‘asynchronous.’

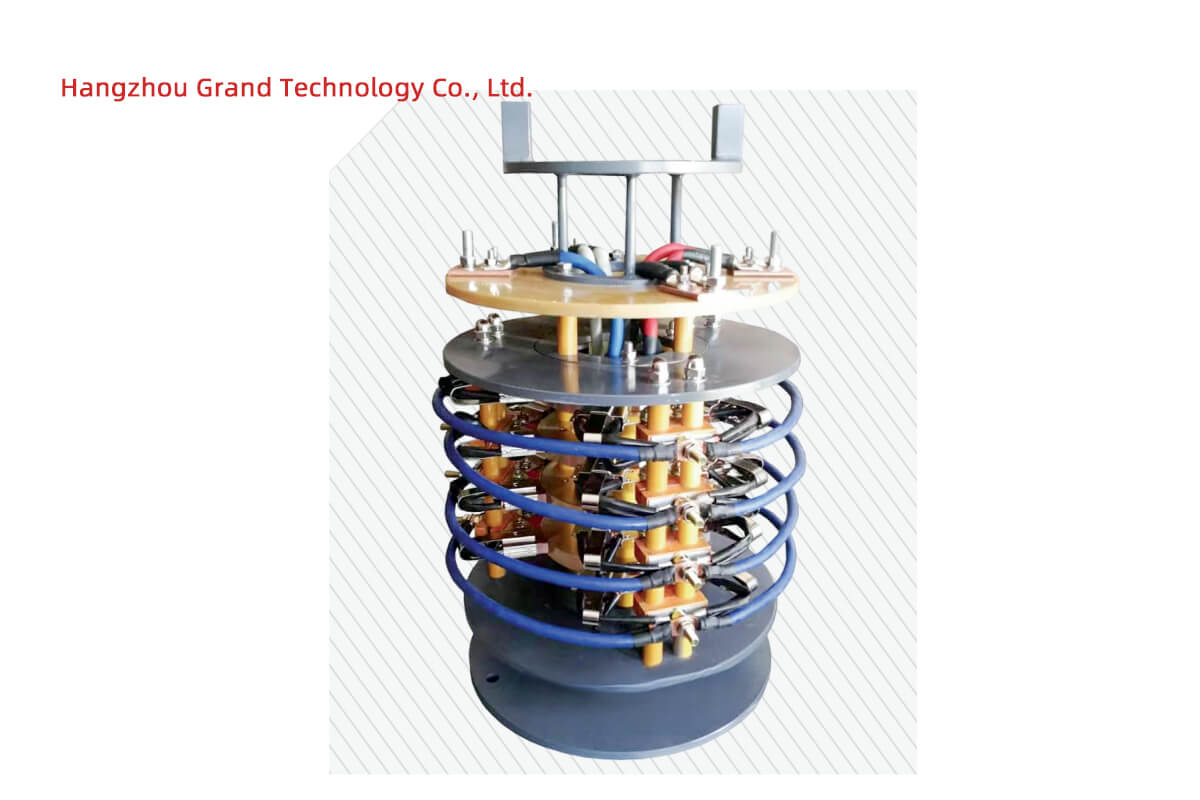

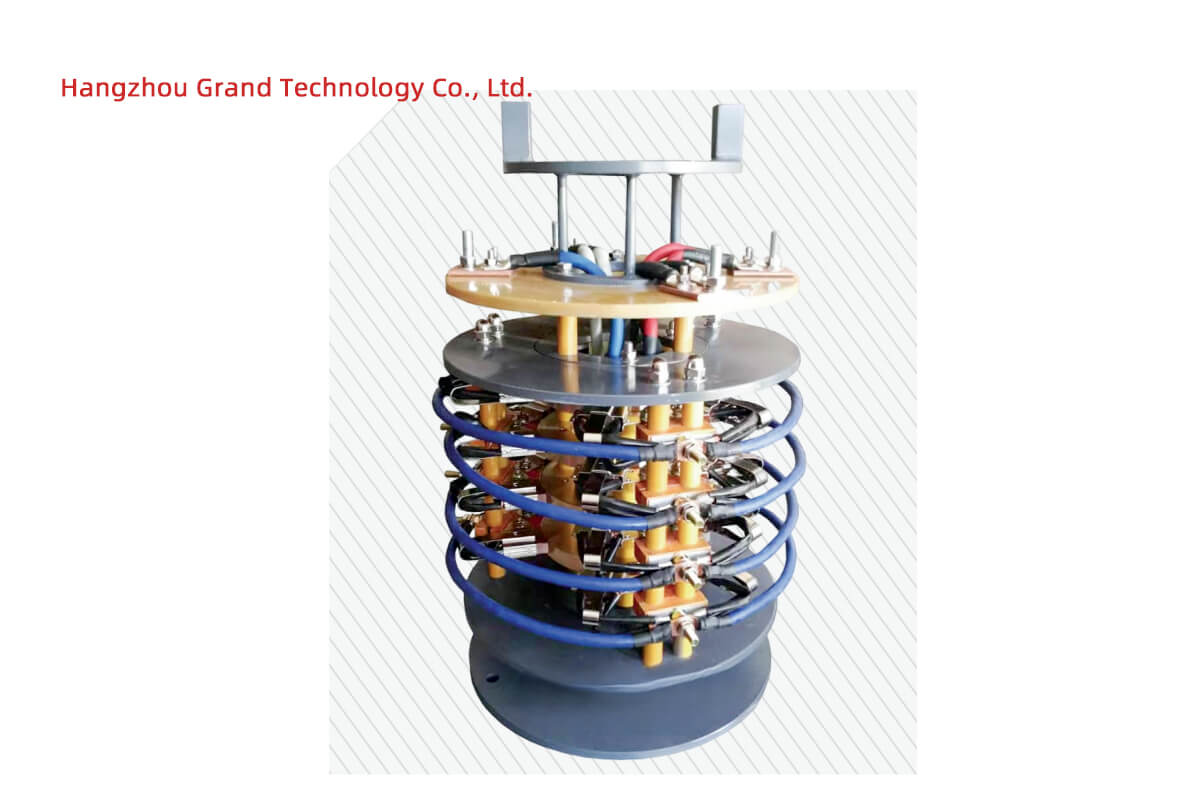

On the other hand, synchronous motors run at the same speed, or ‘in sync,’ with the AC frequency. Unlike induction motors, they require a direct supply of AC to the rotor, which can be achieved either through slip rings or a shaft-mounted rectifier assembly. This ability to maintain constant speed regardless of variations in load makes them ideally suited for applications where precision is essential, such as in clocks or audio turntables.

By fully understanding AC motors—their definition, components, and prevalent types—we lay the groundwork to better appreciate the nuanced role of brushes within these motoring giants.

Role and Function of Brushes in Motors

To understand the relevance of brushes in AC motors, we must first detail what role they play in electric motors in general. Brushes are fundamental to a process we term ‘commutation.’ To understand commutation, picture a basic motor that consists of a stator (stationary part) and a rotor (rotating part) which need to maintain an electrical connection to function correctly. While this seems straightforward on paper, in practice, we have a moving component and a static one, which could potentially break the electrical flow.

This is where brushes come into play. They act as the conduit for the electric current to flow from the static part to the rotating part of the motor, thus maintaining the required electrical connection. Brushes are most often made of carbon or graphite, materials with excellent conductivity and a low coefficient of friction, allowing them to maintain contact with the rotating parts without quick wear or heat generation.

Direct current (DC) motors present a prime example of motors heavily reliant on brushes. In a traditional DC motor, brushes press against the commutator – a rotating cylinder segmented to reverse the direction of the electric current between the rotor and the external circuit. Without brushes to commutate, or switch the current, the rotor would only hustle to and fro and never accomplish a full circular motion. The brushes ensure that the current maintains the appropriate direction to support continuous rotation.

Brushes also find application in some types of AC motors like the universal motor, a variant that can operate on either AC or DC. These motors are typically found in devices that require a smaller, high-power motor, such as portable power tools, blenders, vacuum cleaners, and hair dryers. The motor’s brushes are instrumental in these cases for promoting the motor’s rotational movement and enabling its compatibility with AC and DC power supplies.

However, brushes are not without their challenges. They are prone to mechanical wear over time due to the constant contact against the rotating commutator. This necessitates regular inspection and replacement – a consideration that can influence the choice between brushed and brushless motors. With the fundamental knowledge of the roles and responsibilities of brushes in motors, we can now explore just how significant these often underappreciated components are in AC motors.

AC Motors and Brushes

In the realm of AC motors, the usage of brushes represents an intriguing point of discussion. Contrary to what might be familiar with DC motors, the vast majority of AC motors are designed to operate without brushes. This distinction isn’t merely a matter of technological preference but hinges on the fundamental principles of how AC motors function and the advantages brought about by a brushless design.

Brushless Design in AC Motors

The hallmark of most AC motors, particularly induction and synchronous motors, is their brushless nature. This design choice is predicated on several key factors that enhance the motor’s performance, longevity, and reliability. In brushless AC motors, the need for physical contact to transfer electrical current between stationary and moving parts is eliminated. This eradication of brushes circumvents the mechanical wear and tear, friction losses, and heat generation typical of brushed counterparts. The absence of brushes means there’s less maintenance, fewer parts to replace, and, consequently, a longer service life for the motor.

Comparing Brushless and Brushed Designs

Comparing brushless AC motors with those that utilize brushes, such as universal motors, reveals stark differences in performance and maintenance needs. Brushless motors tend to run cooler and more efficiently, owing to their reduced internal friction and the absence of sparking from brushes. This efficiency not only translates to lower operational costs over time but also permits these motors to operate at higher speeds without the risk of overheating.

Maintenance is another area where brushless motors outshine their brushed counterparts. Brushless motors minimize the downtime and labor costs associated with the replacement of worn brushes. Additionally, without brushes, these motors emit less electromagnetic interference (EMI), making them ideal for precision applications where EMI could be a concern, such as in medical equipment or communication devices.

The Shift from Brushed to Brushless Motors

The transition from brushed to brushless AC motors in various applications marks a significant evolution in motor technology. This shift isn’t arbitrary but is driven by the increasing demand for more efficient, reliable, and low-maintenance motors across industries. In sectors like automotive, aerospace, and consumer electronics, where efficiency and durability are paramount, brushless motors have become the standard. The rise of electronic control technology has further facilitated this transition, allowing brushless motors to be precisely controlled for a vast range of speeds and torques, enhancing their applicability across a broad spectrum of uses.

In summary, the design choice of excluding brushes from most AC motors capitalizes on the intrinsic benefits of efficiency, reliability, and low maintenance. While brushed motors still find their niche in specific applications where their unique characteristics are required, the clear trend in AC motor design is a pivot toward adopting brushless technologies. This shift not only reflects advancements in motor construction but also aligns with the broader objectives of improved performance, sustainability, and cost-effectiveness in modern machinery and devices.

User Concerns and Common Questions

The presence or absence of brushes in AC motors can give rise to certain concerns for users. These concerns largely pivot around questions of maintenance, lifespan, efficiency, operational costs, noise levels, and reliability. Let’s delve deeper into each of these concerns, incorporating the previously discussed principles.

Maintenance Requirements if Brushes are Present

If you’re using AC motors equipped with brushes, such as universal motors, a fundamental user concern would be their higher maintenance needs. Remember, brushes endure constant physical contact with the rotating part of the motor. As wear-resistant as materials like graphite or carbon are, they still eventually wear out over time. Neglecting to replace worn brushes can lead to a decrease in performance and even motor failure. Therefore, motors with brushes demand regular inspection and potential replacement of brushes, adding to the overall maintenance bill.

Lifespan Comparison between Motors with Brushes and Brushless Motors

In terms of lifespan, brushless AC motors typically outlive their counterparts with brushes. The absence of brushes reduces the parts subjected to wear and tear, enhancing the motor’s longevity. This is particularly important in industries where extended application lifespan and uninterrupted performance are valued, such as manufacturing and processing facilities.

Efficiency Differences and Operational Costs

Efficiency and operational costs also draw concerns from users. Because brushless motors lack the friction and associated power losses present in brushed motors, they tend to be more efficient. This improved efficiency translates into lower energy consumption, which results in lower operational costs. Over the lifespan of a motor, these savings can be substantial, making an initially more expensive brushless motor a cost-effective solution in the long run.

Noise Levels and Reliability

Another concern often expressed by users is the noise level of the motor. Brushed motors produce more operational noise, in part due to the physical contact between the brushes and the commutator. Brushless AC motors, with their frictionless operation, tend to operate more quietly, which can be a significant advantage in noise-sensitive environments.

Reliability, as always, is a central concern for users. With fewer moving parts – and thus fewer potential points of failure – brushless AC motors tout higher reliability. The lack of wear-prone brushes and the associated risk of sparking lends these motors an additional layer of safety, which is paramount in industries such as mining or chemical processing, where safety can never be compromised.

In a nutshell, while AC motors with brushes still serve purposes in specific applications, the progression towards brushless designs seems to be an answer to user concerns about maintenance, lifespan, efficiency, costs, noise levels, and reliability. So, whether you’re a technician, a buyer, a maintenance engineer, or an end-user, having a well-rounded understanding of these attributes will enable you to make a wise decision regarding the selection and application of AC motors.

Alternatives to Brushed AC Motors

As we move further into the 21st century, the sphere of electric motors has seen a gradual but definitive shift away from the traditional brushed designs, particularly in the context of AC motors. The advent and refinement of brushless motor technology have revolutionized motor design, combining enhanced performance with maintenance-free operation.

Introduction to Brushless Motor Technology

Brushless motor technology signifies a remarkable deviation from the historical reliance on brushes. With brushless designs, the commutation of the motor—previously managed by brushes in direct physical contact with the rotor—is handled electronically. In AC motors, particularly, this translates into induction and synchronous motors, which operate on principles that inherently eliminate the need for brushes.

Advantages of Brushless AC Motors

The advantages of brushless AC motors are manifold. One of the most compelling is reduced maintenance. The absence of brushes negates the need for periodic replacement and mitigates common failure points within the motor. This not only saves time but also reduces the cost associated with motor upkeep.

In addition to requiring less maintenance, brushless AC motors often boast higher efficiency. The lack of friction from brushes means a lower energy dissipation as heat, leading to more energy being converted into rotational force. This efficiency carries with it the benefit of lower operational costs and, in ecologically conscious times, a reduced carbon footprint.

A longer life is another significant advantage. Without brushes to wear down, the lifespan of a brushless motor is extended, making it a more dependable long-term investment. This reliability is essential across the many industries where downtime can mean lost revenue and increased operating costs.

Future Trends and Recent Advancements

Recent advancements in AC motor technology continue to push the envelope. One of the key trends is the integration of modern electronics, enabling better control over motor operation. Variable frequency drives (VFDs) and advanced controllers can now precisely adjust motor speed and torque, providing unmatched efficiency and performance as per demand.

Synchronous reluctance motors, another emergent subset of brushless motors, are gaining popularity for their ability to offer even greater efficiencies, particularly under partial load conditions. This is an important consideration in industries where motors do not always need to run at full capacity.

Moreover, with the increasing feasibility of incorporating smart technologies, modern AC motors are beginning to come equipped with sensors that monitor performance and predict maintenance needs, heading toward a future where motors are not just components but interactive devices within an Internet of Things (IoT) ecosystem.

In the broader context of evolving motor technology, the trend is tilting towards systems that are more sustainable, cost-effective, and intelligent. While brushed motors still have their place, particularly in applications where cost or specific technical constraints are paramount, it is evident that brushless technology is leading the way into the future of AC motor design and application.

Conclusion

In the exploration of AC motors and their relationship with brushes, we can conclude that most modern AC motors are designed without brushes. The evolution away from brushes heralds benefits such as decreased maintenance and extended motor life, aiding in efficiency and reliability. When selecting the ideal motor, considering these nuances is essential for optimal performance and satisfaction.

FAQs about Do AC Motors Have Brushes

Q: Can any AC motor types have brushes?

A: Yes, some specialized AC motors, like universal motors, can have brushes, but they are not as common as brushless types.

Q: What determines whether an AC motor will have brushes?

A: The specific design and intended application of the motor will determine whether brushes are necessary. Most standard AC motors used today are brushless.

Q: Are brushless AC motors more expensive than those with brushes?

A: Initially, brushless motors can be more expensive due to more complex electronics. However, reduced maintenance and operational costs often offset the higher upfront cost over time.

Q: How do I maintain a brushless AC motor?

A: Brushless AC motors require minimal maintenance, mainly periodic inspections, cleaning, and ensuring cooling systems are functioning correctly.

Q: Do all AC motors lack brushes?

A: No, not all AC motors lack brushes. While the majority of AC motors, including induction and synchronous motors, operate without brushes, some AC motors, such as universal motors, retain the use of brushes.

Q: Are brushless AC motors more efficient than those with brushes?

A: Yes, in general, brushless AC motors are more efficient than their counterparts with brushes. This efficiency owes to there being less internal friction, less heat generation, and no losses due to mechanical wear.

Q: If an AC motor has brushes, will it require more maintenance?

A: Yes, an AC motor with brushes will typically require more maintenance. Brushes, because they maintain physical contact with the commutator, wear down over time and will require inspection and eventual replacement.

Q: What is the difference in lifespan between AC motors with brushes and those without?

A: On average, AC motors without brushes tend to have a longer lifespan than those with brushes. The absence of brushes eliminates one of the key components susceptible to wear and tear, thereby enhancing the motor’s durability and longevity.

Q: Are there ways to control brushless AC motors precisely?

A: Yes, modern electronic control technologies, such as variable frequency drives (VFDs) and advanced controllers, allow brushless motors to be controlled precisely for specific speeds and torques. This ability to fine-tune performance parameters optimizes efficiency across a vast array of applications.

See What We Can Do