In electrical engineering, the electrical collector ring holds a vital place. Serving as an interface between a stationary and rotating part, it enables the transfer of electrical signals and power. This article offers insight into understanding electrical collector rings, discussing their role, design, types, key performance factors, applications, selection criteria, future trends, and more.

Introduction to the Electrical Collector Ring

The role of an electrical collector ring, commonly referred to as a slip ring, is fundamental in a plethora of electrical devices and systems. In essence, an electrical collector ring is an electromechanical device that allows the transmission of power and electrical signals from a stationary part to a rotating structure. This pivotal functionality allows systems to perform unrestricted, continuous, or intermittent rotation, which finds application in many trains, cranes, and renewable energy systems.

The electrical collector ring’s architecture is designed to enable smooth and stable transfer of power regardless of the rotation. These devices ensure continuity of operation in electrical systems, leading to their significant presence in several industrial, commercial, and even domestic applications.

Their vast spanning presence underlines their importance in our day-to-day lives. They occur in different shapes and forms in wind turbines, where they enable the transfer of power and data round the clock to rotating parts, or even in MRI machines, where they facilitate the accurate capture of comprehensive internal body images.

One of the most apparent indications of the electrical collector ring’s importance lies in resolving the problem of tangled wires in situations requiring a 360-degree rotation. Imagine a rotating restaurant with tangled power cords – that is precisely the kind of situation the electrical collector ring exists to avoid.

In the progressively tech-driven world we live in, the role of electrical collector rings continues to expand. Their functionality underpins several devices we consider commonplace, while also laying the foundation for several more applications that we are yet to deem as daily staples. In this progression, understanding the functionality and application areas of electrical collector rings becomes increasingly vital. This comprehensive exploration into electrical collector rings aims to enhance that understanding, paving the way to appreciate the engineering marvel hidden in plain sight.

Basic Principles and Design of Electrical Collector Rings

Electrical collector rings function based on a rather straightforward yet ingenious principle. They are designed to provide a continuous electrical connection between stationary and rotating systems, thus enabling the transfer of power or data signals irrespective of the rotating system’s motion.

At the backbone of a collector ring, two main components are integral to its operation: the rotating part, known as the rotor, and the stationary part, or stator.

The rotor is connected to the rotating structure of the system, be it the blade of a wind turbine or the theatrical turntable in a stage production. This connection might be through a shaft or directly to the structure, depending on the specific design. The rotor typically contains conductive circles or rings, which rotate in unison with the attached structure.

Conversely, the stator remains stationary, connected to the static part of the system. It is close to the rotor but never in physical contact. The stator carries brush contacts, which are designed from soft conducting materials that maintain an electrical connection with the rotating rings of the rotor. The brushes can slide or lightly press on the rings, ensuring electricity flow while mitigating any substantive friction that could affect the overall performance of the system.

Together, the brush contacts on the stator and the rings on the rotor create a closed loop for power or signal transmission. As the rotor turns, the stator’s brush contacts maintain consistent contact with different points on the rotor’s surface, ensuring uninterrupted electrical conduction. This ingeniously simple mechanism forms the basis for the operation of all collector rings, enabling their use in a wide range of applications.

The overall design of electrical collector rings, while seemingly simplistic, represents a fine balance of engineering principles. Considerations for friction, conductivity, durability, and system requirements each play a critical role in shaping the electrical collector ring’s design, reflecting the reason behind its critical role in facilitating smooth, efficient operations of countless rotating systems.

Types of Electrical Collector Rings

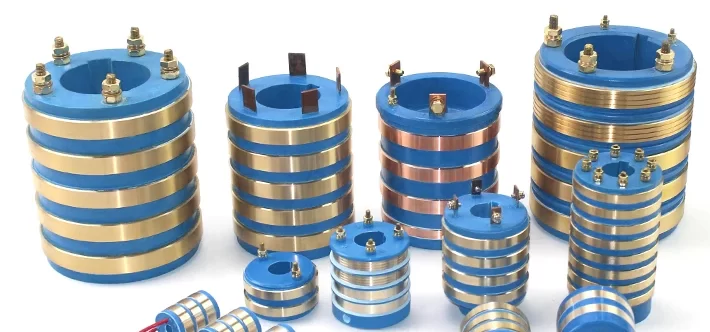

The diverse applications of electrical collector rings have led to their evolution into various types. Each type caters to different requirements and specifications, driven by the application, environmental factors, and system constraints. Some of the key variations include single and multi-channel, mono-metal and bi-metal, and solid and split rings.

Single and Multi-Channel Electrical Collector Rings:

Single-channel collector rings are designed to carry either power or signal but not both simultaneously. They are most commonly found in applications where the rotation is minimal (less than 360 degrees turn), or only one type of transmission (either power or signal) is required. On the other hand, multi-channel collector rings can carry multiple signals or power and signals simultaneously. This makes them extremely versatile for more complex applications, where multiple data streams or power and data need to be transmitted concurrently.

Mono-Metal and Bi-Metal Electrical Collector Rings:

The selection of the conductive material for the rings significantly impacts their performance and longevity. Mono-metal rings are fabricated from a single metal type, like copper or precious metals, which defines their electrical properties. Bi-metal rings, however, utilize two different metals in their construction often used to balance conductivity and durability by exploiting the advantageous properties of both metals.

Solid and Split Rings:

Solid rings are continuous and provide a seamless track for the brush contacts. They are typically used in applications requiring uninterrupted signal transmission. Conversely, split rings have a break in the ring form, with the brushes placed on either side of the split. As the split ring rotates, each brush comes into contact with a different part of the ring, essentially acting as a switch that alternates current direction, commonly used in applications like the commutator in a DC motor.

In essence, the electrical collector ring space has developed to offer multiple customizable designs, capable of serving a variety of applications, each with its unique set of requirements. Their diversity reinforces their widespread applicability and furthers their influence in the world of electrical and electronic systems.

Key Factors That Affect the Performance of Electrical Collector Rings

The performance of an electrical collector ring is influenced by several factors. The device’s overall capability can be directly tied to these factors, each unifying to determine the efficiency, durability, and suitability of a given collector ring for a specific application.

Voltage Rating:

A collector ring’s voltage rating is one of its most critical specifications. It denotes the maximum voltage the ring can handle without a risk of electrical breakdown. A high voltage rating indicates the ability of a collector ring to safely transmit higher electrical power levels. Hence, the chosen collector ring should suit the voltage requirements of the particular application.

Current Rating:

Like voltage rating, the current rating represents the maximum current that the collector ring can carry continuously without overheating or damage. It is predominantly determined by the ring and brush materials and their dimensions. For high-current applications, collector rings with larger cross-sectional areas and those constructed from highly conductive materials are favored.

Rotation Speed:

Rotation speed refers to how fast the rotor can turn while maintaining effective power or signal transfer. Since increased rotational speed might elevate friction and wear on the brushes, it impacts the overall performance and longevity of the collector ring. Devices designed for high-speed operations often come with special design considerations to reduce friction.

Size:

The size of the collector ring is usually dictated by the application’s constraints. For example, smaller collector rings might be required for compact equipment, and larger rings might be needed for heavy-duty industrial applications. Understanding the size constraints is essential to ensure the collector ring’s compatibility with the overall system design.

Temperature Range:

Collector rings must operate in various environments, each with its unique temperature spectrum. Collector rings exposed to extreme temperatures, either hot or cold, need to be constructed with materials that can endure such conditions without compromising their performance. Therefore, the operating temperature range should be considered when selecting an appropriate ring for a specific application.

In essence, understanding these key factors creates a thorough perspective on the practical aspects that affect the performance of electrical collector rings. By acknowledging these factors, we ensure the best-fitting collector ring selection for the sustained performance of various systems.

Applications of Electrical Collector Rings

Given their fundamental role in enabling continuous rotation in electronic systems, electrical collector rings find ubiquitous usage across various industries and applications. Here, we shall provide an overview of some salient domains that extensively rely on these devices.

Generators and Motors:

Collector rings find widespread use in AC generators and motors, where they facilitate the transmission of alternating currents between the rotor and the stator. In DC motors, split collector rings or commutators are used to change the current direction, keeping the motor’s rotation direction constant.

Wind Turbines:

In wind turbines, collector rings possess the twofold role of transferring power generated by the rotating blades to the stationary grid and sending sensor data from the moving parts to stationary control systems. They ensure round-the-clock operation, thus maximizing power generation and system efficiency.

Cranes and Rotating Machinery:

Collector rings are heavily used in cranes, especially revolving cranes, where the cabin needs to rotate 360 degrees. They ensure continuous power supply to the rotating cabin, preventing wire tangling. Other rotating machinery in industries like packaging, material handling, and cable spinning also employ collector rings for the same purpose.

Industrial Catering Equipment:

Rotating restaurants and food display turntables use collector rings to maintain the power supply while rotating. This enables fluid, consistent movement and upholds system functionality.

Medical Imaging Equipment:

In advanced imaging systems like CT scanners and MRI machines, collector rings serve to transmit power and data signals while the imaging components spin around the patient. This results in high-resolution, thorough imaging without any interruption in data.

Defense and Aerospace:

In radar systems, collector rings allow the antenna to rotate continuously, providing 360-degree coverage. Similarly, in the aerospace industry, collector rings find use in onboard systems of spacecraft and satellites where certain components require continuous rotation.

In essence, electrical collector rings serve as unseen companions across numerous industries, reinforcing operations without asserting conspicuous presence. From everyday machinery to advanced defense systems, their significant role goes to show how sometimes, the smallest components can facilitate the most significant strides in technology.

What to Look for When Purchasing an Electrical Collector Ring

Choosing the right electrical collector ring is a process that requires due diligence, paying attention to specific factors that are fundamentally tied to the overall performance, durability, and effectiveness of the device in a given application.

Material Quality:

The performance and lifespan of a collector ring can largely be determined by the quality of its materials, specifically, the rings and brushes. High-grade metals like copper, brass, or precious metals are typically preferred for the rings due to their superior conductivity, and carbon or graphite for brushes due to their endurance. Moreover, for harsh environmental conditions, the durability and resistance of chosen materials against factors like corrosion, high temperature, or extreme cold should also be considered.

Performance Specifications:

Next, the collector ring must meet the performance specifications necessary for the application. These specifications may include the voltage and current ratings, the maximum allowable rotational speed, and the temperature range. Ensuring these parameters align with the application’s requirements will dramatically improve the efficiency and reliability of the system.

Manufacturer Reputation:

The quality of a collector ring is often a direct reflection of its manufacturer. A manufacturer with a solid reputation for quality and reliability is more likely to produce collector rings that offer superior performance. Reviews, references, and industry certifications can provide insight into a manufacturer’s reputation in the market.

Customization for Specific Applications:

Every application comes with its unique set of requirements. Therefore, the selected collector ring should either meet these requirements out of the box or have the capacity for customization. Manufacturers that offer customization services can adapt the collector ring’s design to specific needs, which could include size, the number of channels, or specific materials for unusual operating conditions.

After-Sales Service and Support:

Post-purchase services like technical support, warranty, and maintenance services constitute an equally important selection criterion. A well-rounded after-sales service ensures that the collector ring continues to function optimally throughout its service life and any problems are quickly resolved.

In summary, the quality of an electrical collector ring is a synergy of multiple factors, including material quality, performance specifications, manufacturer reputation, customization options, and after-sales service. By examining these criteria, one can significantly enhance the odds of acquiring a high-quality, reliable, and long-lasting collector ring that optimally serves its intended application.

Maintenance and Lifespan of Electrical Collector Rings

Ensuring the longevity and efficiency of electrical collector rings goes far beyond the selection and installation process. Regular and appropriate maintenance is crucial in promoting the durability and performance capability of these devices.

Frequent Inspections:

The first step towards maintaining the health of any system is regular inspections. Regular visual check-ups of the collector ring for any visible damage, significant wear, or the presence of debris could preempt potential problems. Also, monitoring for unusual noise or abrasion can provide early signals of wear that need further investigation.

Cleaning Procedures:

Cleaning plays a critical role in maintaining collector rings. Debris or dust can accumulate on the surface of the rings, leading to irregular contact and wear of the brushes. Cleaning using methods recommended by the manufacturer at appropriate intervals can dramatically increase the lifespan of the collector ring.

Lubrication:

For several collector ring systems, especially those dealing with high-speed applications or ones that operate under challenging environmental conditions, adequate lubrication is a necessity. However, one must ensure the use of compatible lubrication as suggested by the manufacturer, as incorrect lubrication could lead to increased friction or even material degradation.

Brush Replacement:

Brushes, being in regular contact with the ring, are subject to wear and hence, need periodic replacement. Observing and maintaining the correct brush pressure is also essential to prevent undue wear on both the ring and the brush. Utilizing high-quality brush replacements that coincide with the specifications of the original part ensures maintaining the performance standards.

Preventive Maintenance and Scheduled Overhaul:

Having a comprehensive preventive maintenance routine that includes all of the above practices at regular intervals can dramatically enhance the service life of a collector ring. In addition, scheduling complete overhauls after a certain operation period encourages the identification of potential issues that might have been missed during regular maintenance.

In conclusion, the lifespan of electrical collector rings is intricately linked to the thoroughness of their maintenance routines. By following the prescribed best practices, it is possible to significantly prolong the usability, maintain peak system performance, and foster overall system durability.

Future Trends in Electrical Collector Ring Technology

With the rise of technology, the field of electrical collector rings is due for several transformative changes. Innovations spurred by digitization and internet-of-things (IoT) technology have begun to redefine design norms, leading to more advanced and versatile collector ring technologies.

Miniaturization:

As electronic devices shrink in size, the demand for smaller, more compact collector rings will likely grow. Miniaturization would require innovative design approaches that ensure effective power transmission while decreasing space requirements.

IoT Enabled Collector Rings:

The IoT revolution is poised to make its mark on collector rings as well. IoT-enabled collector rings could monitor and transmit data about their own performance and upkeep needs in real-time, enabling preventive maintenance and reducing operational downtime.

Smart Materials:

The advent of smart materials can dramatically improve the longevity and performance of collector rings. For instance, self-lubricating materials can reduce maintenance needs, and materials with improved conductivity can ensure lower power losses.

Improved Integration:

Future collector rings could be designed for better, more integrated fits within overall system designs. This is especially relevant in complex machinery, where collector rings’ seamless integration would simplify manufacturing processes and improve system efficiency.

Adoption of Renewable Power Sources:

As industries lean towards renewable energy options, legislation is pushing for the adoption of wind and solar energy. Collector rings, critical to the functionality of wind turbines, are set to see an uptick in demand and development with eco-friendly energy generation technologies.

In summary, the future of electrical collector rings is set to witness a paradigm shift in design, performance, and application scope. As these trends become more prominent, we can expect increasingly efficient, reliable, convenient, and sustainable collector ring solutions.

Conclusion

In conclusion, understanding electrical collector rings is essential to appreciate their role in numerous applications we encounter in our daily lives. By staying aware of their working principle, selection criteria, and maintenance, we ensure their prolonged and efficient performance.