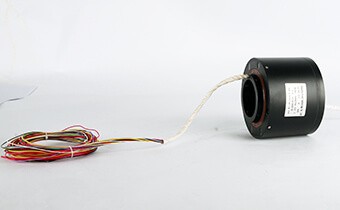

As a precision transmission device, an electrical slip ring has many advantages for rotating equipment. Without knowing its working principle or using the method, some problems may be caused, impacting the whole equipment. In view of this situation, Grand Technology’s after-sales department sorted out some common slip ring failure.

The following are several common situations. If you need more help, please directly contact us – the professional slip ring manufacturer.

Signal Interference

Signal interference is divided into external interference and internal interference. If the interference is too large, first judge the interference source and interference signal type. For internal interference, special wires shall be used to achieve internal and external shielding, and for external interference, the interference source shall be shifted or shielded. If the signal interference is not considered at the initial stage of design, and the exposed conductor cannot be shielded after use, its internal structure can only be redesigned.

Protection Level

The electrical slip ring shell is formed by a mold at one time, and the protection grade is only IP51. Some customers use it outdoors without adding external protection, which will inevitably be affected by dew, and dust, and even put it in water. It will cause water ingress inside the electrical slip ring and electrical short circuit failure. Or corrode the shell under the influence of salt spray.

Lack of Power Surge Protection

Grand technology will test the insulation performance of products with more than five times of high voltage for factory slip rings. Even so, under some working conditions, it will be instantly broken down and burned out. This phenomenon is particularly common in wind power slip rings.

Short Circuit

The short circuit of the old slip ring may be caused by the service life, burnout caused by overload, or wire jumping of the brush wire, which needs further detection. The short circuit of the new slip ring may be caused by poor internal insulation or broken wire skin. Such problems cannot be solved by the user. It is recommended to return to the factory directly for maintenance or replacement.

Inflexible Rotation

If the new slip ring does not rotate smoothly, please return it directly without additional reasons. The poor rotation of the installed electrical slip ring is usually caused by strong vibration in the service environment, resulting in the displacement of the internal assembly of the slip ring.

See What We Can Do