This article delves into the innovative realm of fiber brush slip rings, highlighting their technological advancements, remarkable benefits, and the vast applications they empower in industries reliant on rotational connectivity.

Introduction to Fiber Brush Slip Rings

Since the dawn of industrialization, technologies facilitating the transmission of power and electrical signals have exponentially evolved. Among these, slip ring technology has made an indelible mark across a multitude of industries. It has advanced and streamlined processes, enabling the exchange of power and electrical signals between stationary and dynamically moving components.

Slip rings, often referred to as rotary electrical interfaces or rotating electrical connectors, are crucial for systems to maintain steady electrical connections even during constant rotation. Initially, these slip rings were designed as metal brush contacts sliding against a rotating surface. However, the incessant demands of modern industries for higher performance, reliability, and maintenance efficiency necessitated innovation in this sphere.

The result was the advent of fiber brush slip rings. Developed as a cutting-edge alternative to traditional slip rings, they utilize a sophisticated approach to establish electrical contact. Rather than using metal brushes that often cause wear and tear, fiber brush slip rings employ high-density fiber brushes. These ensure persistent contact with the rotating surface, promoting seamless conductivity, reduced friction, and, therefore, less wear.

The significance of fiber brush slip rings cannot be underscored. With their inherent advantages, they transformed not only the way slip ring technology was perceived but also the myriad of applications it was integral to. Offering attributes such as low electrical noise, minimal maintenance, high-speed data transmission, and exceptional durability, fiber brush slip rings have carved a new path for rotational connectivity solutions.

This innovative technology promises to drive the future of industries ranging from renewable energy generation to medical imaging, security systems, and robotics. Now, as we delve further into the world of fiber brush slip rings, we will unveil the nuances of their operation, the key features and benefits, and the promise they hold for the future.

The Technology Behind Fiber Brush Slip Rings

In the quest for efficient and reliable rotational connectivity, fiber brush slip rings stand as a testament to engineering innovation. These devices operate on a remarkably straightforward principle, which belies their sophisticated functionality and design. At the heart of a fiber brush slip ring lies a bundle of conductive micro-fibers. These fibers are meticulously arranged to maintain constant electrical contact with a rotating metal ring. As the metal ring spins, the fibers flex and move, allowing for continuous conductivity without the friction and wear associated with traditional slip ring contacts.

This operation contrasts significantly with the mechanics of traditional slip rings. Traditional designs predominantly employ metal brushes that physically press against a rotating metal surface to form an electrical connection. Over time, this contact leads to wear and the generation of debris, necessitating frequent maintenance and potentially causing disruptions in electrical conductivity. Mercury-wetted slip rings offer an alternative by using a pool of liquid mercury to maintain conductivity. While reducing wear, they introduce environmental and health hazards, limiting their use in various applications.

The shift towards fiber brush technology in slip rings marks a noteworthy advancement for several reasons. Unlike their predecessors, fiber brush slip rings reduce electrical noise—a common issue in systems requiring the transfer of delicate signals. This is largely due to the more stable and consistent contact between the fiber brushes and the rotating surface. Additionally, the fibers’flexibility minimizes wear, dramatically extending the lifespan of the slip ring and reducing maintenance requirements.

Incorporating fiber optic technology further extends the prowess of slip rings. By integrating fiber optics, these slip rings facilitate the transmission of data at the speed of light, enabling them to support high-speed data transfer and communication needs of modern applications, surpassing the capabilities of purely electrical connections. This is particularly advantageous in environments where electromagnetic interference (EMI) could degrade signal quality, as fiber optic cables are immune to EMI, ensuring cleaner signal transmission.

The advantages of using fiber brush and fiber optic technologies in slip rings are thus manifold. They offer a leap in performance through reduced wear and tear, low electrical noise, and the capacity for high-speed data transmission. Moreover, the environmental and safety benefits of mercury-wetted variants further underscore their significance. The evolution towards fiber brush slip rings equipped with fiber optics represents a convergence of reliability, efficiency, and advanced capability, setting a new benchmark for rotational connectivity solutions across industries.

Fiber Brush Slip Rings: Key Features and Benefits

In a rapidly evolving technological landscape, fiber brush slip rings stand out for their state-of-the-art features and associated benefits. Extending beyond traditional slip rings’ limitations, they exemplify modern engineering prowess, providing solutions that meet diverse industry demands for rotational connectivity.

One of the prominent features of fiber brush slip rings is their ability to produce low electrical noise. In any electrical system, noise poses a significant challenge. It can distort signal clarity, leading to misinterpretation of data, affecting system operation, and even disrupting communication channels. However, the integrity of the fiber brush structure, with numerous individual fibers maintaining contact with the ring, mitigates this issue. This stable, multi-point contact ensures a smooth transmission pathway, significantly reducing electrical noise and enhancing the clarity of signal transmission, a valuable advantage in sensitive data transmission scenarios.

Another key feature is the minimal wear and tear that these slip rings experience. Traditional slip rings, mainly those using metal brushes, face considerable wear, primarily due to the abrasion between moving parts. This abrasion often leads to the creation of debris, which further hinders effective operation and necessitates regular cleaning and maintenance. By contrast, fiber brush slip rings, with their flexing fibers, undergo much less physical stress. This results not only in less wear and debris production but also in an extended service life for the slip ring – a boon for industries where downtime can have significant operational and financial implications.

The need for maintenance is another significant factor that determines the choice of rotational connectivity solution. Fiber brush slip rings, with minimal wear and almost no debris, provide a nearly maintenance-free operational advantage. This feature is not only cost-efficient but also brings practical benefits, especially in scenarios where accessing the slip ring for maintenance is challenging or labor-intensive.

One cannot overlook the high-speed data and signal transmission capabilities offered by fiber brush slip rings. Modern applications, especially in high-tech sectors like telecommunications, medical imaging, or aerospace, continue to demand faster data and signal transmission. Fiber brush slip rings, particularly those equipped with fiber optic capabilities, respond to these demands admirably. They can transmit large volumes of data at high speeds without interruption, ensuring that systems operate seamlessly and efficiently.

In conclusion, the key features of fiber brush slip rings – low electrical noise, minimal wear and tear, nearly maintenance-free operation, and high-speed data transmission – together orchestrate its multitude of benefits. These benefits pivot fiber brush slip rings into a position of strength in the realm of rotational connectivity solutions, promising greater operational efficiency, reliability, and longevity across diverse industries.

Applications of Fiber Brush Slip Rings

Fiber brush slip rings have carved a niche for themselves across various sectors, thanks to their advanced features accommodating a broad spectrum of applications. These devices have become integral to the functionality and efficiency of several key industries, from renewable energy to safety systems, healthcare, and the burgeoning field of robotics. Their unique design and operational benefits, such as low electrical noise, durability, and the capability for high-speed signal transmission, make them especially suited to these demanding applications.

In the renewable energy sector, wind turbines stand as a testament to the necessity and efficiency of fiber brush slip rings. Wind turbines operate in challenging environments, often experiencing vast temperature fluctuations and constant motion. The application of fiber brush slip rings within these systems ensures reliable energy transmission from the rotating blades to the stationary components. Their minimal maintenance requirements and resistance to wear significantly contribute to the turbines’ overall efficiency and longevity, making renewable energy production more viable and sustainable.

Security systems, particularly CCTV pan-tilt camera systems, rely heavily on the uninterrupted functionality provided by fiber brush slip rings. These cameras need to rotate continuously and smoothly to monitor large areas without losing power or signal integrity. Fiber brush slip rings facilitate this continuous rotation, ensuring that data and power are consistently transmitted to the camera system. This application highlights the slip rings’ capability to provide stable, low-noise electrical connections, crucial for maintaining the high-quality video feed required in security operations.

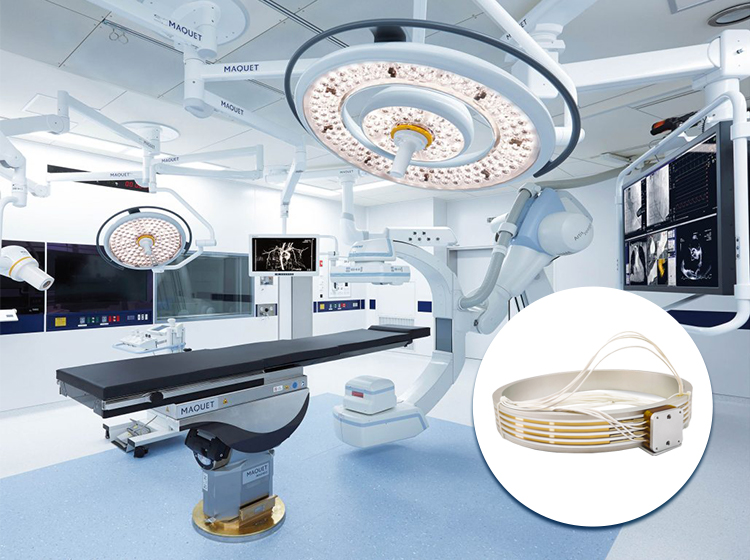

The healthcare industry benefits immensely from the integration of fiber brush slip rings in medical equipment, such as CT scanners. These sophisticated machines require the transfer of power and vast amounts of data between stationary and rotating parts. The precise and uninterrupted power and data flow enabled by fiber brush slip rings are paramount for capturing high-resolution images critical for accurate diagnoses. This application not only underscores the slip rings’ reliability and efficiency but also their role in advancing medical technology for better patient outcomes.

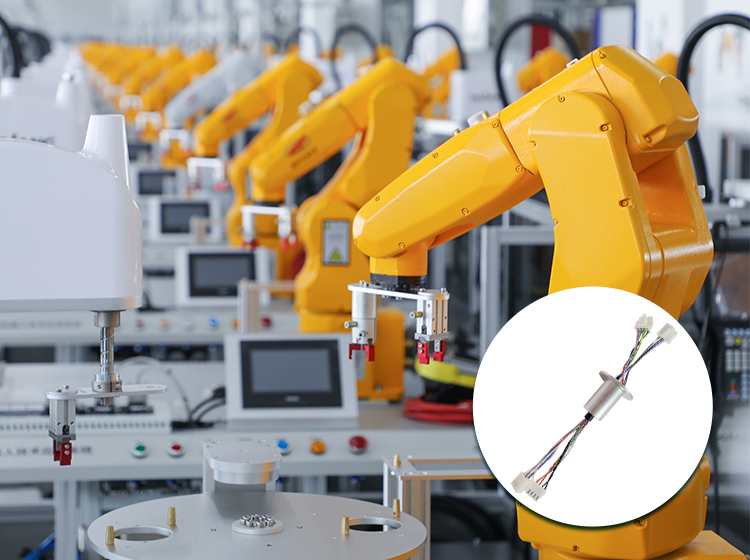

In the field of robotics and automation, the demand for seamless operation is paramount. Robotics systems, whether industrial robots or automated guided vehicles (AGVs), must perform complex tasks with high precision and reliability. Fiber brush slip rings contribute significantly to these systems by ensuring a consistent power supply and data exchange across moving parts, thus enabling robots to execute their programmed tasks accurately and efficiently. Their durability and high-speed data transmission capabilities make them indispensable in modern manufacturing and logistics operations, where downtime can have considerable economic impacts.

The diverse applications of fiber brush slip rings—from wind turbines and CCTV systems to CT scanners and robotics—illustrate their vital role in modern technology and industry. By providing reliable, efficient, and maintenance-free operation across various challenging environments, fiber brush slip rings help push the boundaries of what’s possible in these sectors, driving innovation and enhancing operational efficiencies.

Fiber Brush Slip Rings: User Concerns and Considerations

In the realm of rotational connectivity solutions, fiber brush slip rings have emerged as premier technologies, heralding a new era of efficiency and reliability. However, prospective users and industries considering these components for their applications must navigate a series of concerns and considerations to fully leverage their advantages. These encompass aspects such as reliability and durability under diverse conditions, seamless integration with existing systems, economic considerations vis-à-vis initial costs and long-term financial benefits, and the availability of customization to meet unique requirements.

Reliability and Durability stand at the forefront of user concerns. Prospective adopters seek assurance that fiber brush slip rings can withstand the rigors of their operational environment, maintaining performance stability over their lifespan. Unlike traditional slip rings, fiber brush variants are designed for enhanced durability, thanks to their minimal wear characteristics and resistance to environmental factors like dust, moisture, and temperature variations. Understanding how these devices perform under prolonged exposure to these conditions can reassure users of their reliability in critical applications, from wind turbines braving the elements to medical devices requiring consistent operation in temperature-controlled environments.

The issue of Compatibility and Integration with existing systems is another pivotal factor. The migration to or incorporation of fiber brush slip rings should ideally be seamless, without necessitating extensive overhauls of the current hardware setup. Users, therefore, assess how these slip rings can be adapted to existing mechanical and electrical interfaces. Given the broad spectrum of applications, from industrial machinery to sophisticated surveillance and medical equipment, the ease with which these devices can be integrated — considering factors like size, power requirements, and data transmission needs — plays a critical role in their adoption.

Cost Effectiveness emerges as a significant consideration, encompassing the initial expenditure versus the anticipated savings over time. While fiber brush slip rings may present a higher upfront cost compared to traditional slip rings, their value proposition lies in their reduced maintenance requirements, longer service life, and potential for lowering operational downtime. A detailed analysis comparing these long-term financial benefits against the initial investment can elucidate the economic viability for users, especially in industries where equipment longevity and reliability translate directly to productivity and profitability.

Lastly, the Customization Options available to users underscore the adaptability of fiber brush slip rings to specialized applications. The diversity of use cases — from aerospace to automated manufacturing lines — often necessitates unique specifications about dimensions, electrical capacities, or data transmission capabilities. The availability of bespoke configurations, tailored to meet specific operational parameters and environmental conditions, amplifies the appeal of fiber brush slip rings. It demonstrates the manufacturers’ commitment to addressing the nuanced needs of diverse industries, thereby enhancing user confidence in adopting these advanced rotational connectivity solutions.

In conclusion, delving into these user concerns and considerations reveals the multifaceted decision-making process behind selecting fiber brush slip rings. By thoroughly evaluating their reliability and durability, compatibility with existing systems, cost-effectiveness, and customization options, users can make informed choices that align with their operational requirements and strategic objectives. In doing so, they unlock the full potential of these innovative devices to drive efficiency, reliability, and advancement in their respective fields.

Fiber Brush Slip Rings: Installation and Maintenance

The transition to utilizing fiber brush slip rings in various applications involves a detailed process from installation to ongoing maintenance. By carefully navigating the installation steps and adhering to best practices for maintenance, users can optimize the performance and longevity of these critical components. While fiber brush slip rings are renowned for their low-maintenance design, understanding the nuances of their “minimal maintenance” can prevent potential operational issues and extend the service life of the device.

Installation of Fiber Brush Slip Rings

The installation process for fiber brush slip rings begins with a meticulous preparation stage, where the site and the equipment are readied. This involves ensuring the area is clean and free of dust and contaminants, and that all necessary tools and parts for the installation are at hand. The mounting of the slip ring ought to follow the manufacturer’s guide to the letter, with particular attention given to the alignment of the slip ring with the rotational axis of the machinery. Any misalignment can result in uneven wear and impaired performance, undermining the inherent durability of the component. Moreover, electrical connections should be carried out by qualified personnel, with insulation and grounding verified to prevent potential electrical issues.

Ensuring Optimal Performance and Longevity

To ensure optimal performance, regular inspections should be a part of standard operating procedures. These checks can help identify any abnormal wear or electrical anomalies before they escalate into significant issues. Lubrication is usually not necessary for fiber brush slip rings, but verifying this with the supplier is critical, as some specific environments or operational speeds might require special considerations. It’s also key to monitor the environmental conditions, such as temperature and humidity, under which the slip rings operate since extremes can affect performance. Keeping the surroundings clean, dry, and at a stable temperature can contribute greatly to the slip ring’s durability.

Debunking the Myth of Maintenance-Free Operation

Contrary to popular belief, “maintenance-free” does not equate to “no maintenance ever required.” It is more accurate to consider fiber brush slip rings as low maintenance rather than completely maintenance-free. They are engineered to minimize wear and operational issues but still necessitate regular checks to ensure proper functioning. Potential maintenance activities include visual inspections for physical damage, monitoring electrical resistance across the brush-ring interface, and confirming the secure fastening of the unit. Additionally, any unexpected noise or vibrations can be early indicators of issues that require immediate attention. Ensuring that any integrated sensors or monitoring systems are functional is also crucial for long-term maintenance.

In summary, the installation and maintenance of fiber brush slip rings demand attention to detail and adherence to recommended practices. A thorough installation ensures proper functionality from the start while adhering to tips for optimal performance and conducting minimal yet diligent maintenance can allay possible issues and misconceptions about these devices. Acknowledging that even the most advanced systems require some level of upkeep is essential in maintaining efficiency, performance, and longevity, thereby safeguarding the investment in fiber brush slip ring technology.

Future of Fiber Brush Slip Rings

The advent of fiber brush slip rings represented a significant leap forward in managing rotary connections, and looking to the future, the trajectory for these components is marked by potential technological enhancements and the exploration of new application domains. The strategic direction of research and development in this field is being shaped by user feedback, with concerted efforts to address current limitations and user concerns, ensuring that these critical components continue to evolve in step with the needs of advancing technologies.

Anticipated Technological Advancements and Potential New Applications

Anticipating technological advancements in fiber brush slip rings involves acknowledging the trajectory towards more compact, efficient, and higher-performance designs. For instance, the push for miniaturization in electronics could see slip rings becoming smaller while still delivering robust performance, allowing them to be integrated into a broader range of equipment, including those where space is at a premium. This miniaturization trend aligns with the proliferation of small-scale, sophisticated devices in medical robotics and aerospace engineering.

Additionally, potential new applications may arise from the expanding Internet of Things (IoT) ecosystem, where fiber brush slip rings could enable the continuous transmission of data and power in connected devices that require rotation. In the renewable energy sector, as wind turbines grow larger and more powerful, slip rings will need to adapt to handle higher power outputs and data monitoring needs, playing a crucial role in enhancing the efficiency of green energy solutions. Similarly, future developments in electric vehicles and autonomous systems could leverage this technology for reliable power and data transfer in rotational components.

Ongoing Research and Development Addressing Limitations and User Concerns

Addressing current limitations and user concerns, ongoing research and development activities are focused on refining the material science behind the brush and ring surfaces to extend wear life, reduce maintenance needs, and enhance electrical connectivity. Innovations in composite materials or nano-engineered coatings could result in surfaces that are self-lubricating and resistant to a wider array of environmental stressors, thus improving reliability and reducing the incidence of failure.

Electrical noise, a concern raised in signal-sensitive applications, is another front on which future development is poised to make a mark. Research into advanced signal filtration methods and noise-cancellation technologies can mitigate electromagnetic interference, thereby bolstering signal integrity in highly sensitive environments such as medical imaging and advanced communication systems.

The integration challenge is also being addressed, as R&D efforts strive to create more standardized interfaces and modular designs that simplify the installation process and enhance compatibility with various equipment types. Such advancements could democratize the use of fiber brush slip rings, enabling more industries to take advantage of their benefits with less customization required.

Moreover, smart slip rings equipped with sensors and IoT connectivity are likely to be developed, allowing for real-time monitoring of their status and performance. This predictive maintenance capability will be crucial in reducing downtime and ensuring the seamless operation of the systems in which they are installed.

In conclusion, the future of fiber brush slip rings is aligned with the trajectory of advancing industrial, medical, and communication technologies. As new needs emerge and existing demands evolve, so too will the design and functionality of slip rings. The commitment to continuous improvement in response to user feedback will ensure that fiber brush slip rings remain indispensable components at the forefront of technological innovation and application diversification.

Conclusion

Fiber brush slip rings represent a pivotal advancement in slip ring technology, offering unmatched benefits in terms of reliability, performance, and application versatility. Their adoption not only enhances current systems but also paves the way for innovation in industries seeking efficient rotational connectivity solutions.

FAQs about Fiber Brush Slip Rings

Q: How do fiber brush slip rings differ from traditional slip rings?

A: Fiber brush slip rings use fiber brushes instead of metal brushes, reducing electrical noise and wear, thus offering a longer lifespan and more reliable performance.

Q: Can fiber brush slip rings handle both power and data transmission?

A: Yes, they are highly capable of transmitting both power and data efficiently, making them ideal for a wide range of applications.

Q: What maintenance is required for fiber brush slip rings?

A: Although minimal, regular inspections and cleaning are recommended to ensure they remain in optimal condition.

Q: Are fiber brush slip rings more expensive than traditional slip rings?

A: While the initial cost can be higher, the long-term savings in maintenance and replacement costs, as well as their reliability, make them a cost-effective solution.

Q: What differentiates fiber brush slip rings from traditional slip rings?

A: Fiber brush slip rings utilize metal fibers in contact with the ring, as opposed to the solid metal brushes found in traditional designs. This distinction allows for more points of contact, reduces wear and boosts lifespan, and enhances transmission quality. In addition, fiber brush slip rings generally can handle a wider range of current loads and are more resistant to harsh environmental conditions.

Q: How long can I expect a fiber brush slip ring to last?

A: The service life of fiber brush slip rings can be extensive. Barring any unforeseen damage or extreme operating conditions, they can operate for tens of millions of revolutions, compared with traditional slip rings that might last only a few million revolutions. However, it’s important to note that the exact life expectancy will depend on operating conditions, including speed, load current, and environmental factors.

Q: Are fiber brush slip rings truly maintenance-free?

A: While fiber brush slip rings are often described as low maintenance or even maintenance-free, it would be accurate to say that they require minimal routine upkeep. Regular visual inspections are advised to catch any physical damage or abnormal behavior early. Other potential maintenance activities may include monitoring the electrical resistance across the brush-ring interface and confirming the slip ring unit’s secure fastening.

Q: Can a fiber brush slip ring handle both power and signal transmission?

A: Absolutely. The unique characteristic of fiber brush technology allows for the concurrent transmission of power and multiple types of signal, including Ethernet, video, and other data transmissions, in the same compact unit. This feature makes them particularly useful in applications requiring stable, uninterrupted data flow and power supply during rotation.

Q: Can a fiber brush slip ring be customized to suit my specific application?

A: Yes, most manufacturers of fiber brush slip rings offer customization options – these can range from alterations in dimensions and load capacity to specific requirements for data transmission capabilities or resistance to certain environmental conditions. This flexibility allows the slip rings to be adapted to a wide array of unique application requirements.

Q: If I replace a traditional slip ring with a fiber brush variant in my existing system, how complicated is the conversion process?

A: The conversion process is typically straightforward, especially if you’re working with a manufacturer that provides custom solutions. They can help design a fiber brush slip ring that fits within the existing mechanical envelope and interfaces with the current electrical setup. However, some modifications to your system might be necessary, depending on the specific requirements of your application and the slip ring’s design.

See What We Can Do