This article offers a detailed exploration of Fiber Optic Rotary Joints (FORJ), their design, applications, and their significance in the realm of fiber optic systems.

Introduction to FORJ (Fiber Optic Rotary Joints)

Fiber Optic Rotary Joint, commonly known as FORJs, are a class of devices engineered to be the backbone of rotational freedom in the world of fiber optics. In essence, these intricate components form a nexus within fiber optic systems, allowing for the unimpeded flow of light-based signals while part of the system undergoes spinning or rotational motion. This capability is pivotal for a wide array of technologies that rely on both data transmission and mechanical rotation.

The primary allure of FORJs lies in their ability to facilitate the concurrent rotation of a platform with mounted equipment – such as surveillance cameras, radar antennas, or medical scanning devices – alongside the maintenance of a steady, high-bandwidth data link. This is essential because, in the absence of FORJs, data integrity could be compromised by the physical movement of cables, which would result in signal loss or even complete signal failure.

FORJs serve as the invisible yet invaluable cogs in fiber optic machinery, seamlessly merging mechanical flexibility with optical precision. Without FORJs, many of the dynamic and rotational systems we rely on would be tethered — restricted in movement or incapable of delivering the real-time data that modern applications demand. They address a unique challenge in the realm of optical communications: the translation of static fiber optic connection benefits, known for their high-speed and bandwidth capabilities, into environments where motion could otherwise introduce signal disruptions.

More than just facilitating motion, FORJs play an indispensable role in ensuring system longevity and reliability. Rotation, especially when frequent or at high speeds, can induce significant wear and tear on standard optical fibers. FORJs circumvent this issue by decoupling the mechanical movements from the optical path, preserving the fibers and thereby enhancing the overall lifespan of the system.

The importance of FORJs can be more fully appreciated when considering the broad range of applications they enhance: from the vast expanse of space, where FORJs aid communication with satellites, to the depths of our oceans, assisting in the operation of underwater remotely operated vehicles. They are also critical in the medical field, enabling complex imaging equipment to rotate around patients, and in renewable energy, where they contribute to the functioning of wind turbines by enabling the rotating blade’s communication with the static base.

In summary, the role of FORJs goes beyond mere accessory components; they are integral to the synergy between motion and communication, ensuring that as our technological systems move and evolve, our capacity to communicate data remains as swift and stable as if they were standing still.

Understanding Fiber Optic Rotary Joints

Fiber Optic Rotary Joints (FORJs) stand as a critical component within the intricate world of fiber optic communications, ensuring an uninterrupted flow of optical signals between the stationary and rotating parts of a system. These specialized devices bridge the gap between dynamic movement and static data infrastructure, enabling continuous high-speed, high-fidelity data transmission even in the face of mechanical rotation. The purpose they serve is foundational to the integration of fiber optics into an array of applications that require both rotational capability and the preservation of signal integrity.

At its core, the working principle of a FORJ revolves around the meticulous management of light paths within its structure to maintain a constant, loss-minimized optical link between rotating interfaces. Imagine a beam of light, representative of data, being transmitted through a fiber optic cable. As this cable enters the FORJ, the light encounters a series of precisely aligned optical elements – lenses and prisms, or sometimes direct fiber-to-fiber couplings, depending on the design. These elements are arranged in such a way that they can route the light through the rotary joint, from the stationary to the rotating part, and onto another fiber optic cable, without significant loss or distortion of the signal.

This is no small feat. The physics of light transmission through optical fibers requires that light enters and exits at specific angles to ensure total internal reflection within the fiber, a condition necessary for the light to propagate efficiently. The FORJ must precisely align its internal components to match these angles, despite the relative motion between the connected parts. This alignment challenge is met with a variety of engineering solutions that allow FORJs to accommodate different types of rotation, speeds, and fiber configurations.

The rotation of the FORJ itself introduces another layer of complexity: maintaining signal integrity during continuous or repeated movement. Achieving this requires not only precise initial alignment but also robust design strategies to counteract the potential for wear, degradation, or misalignment over time. Innovations in material science, precision engineering, and optical design have made it possible to construct FORJs that can withstand extensive operational demands while delivering reliable performance.

In essence, the basic working principle of FORJs lies in their ability to optically “negotiate” between stationary and rotating systems, ensuring that the light-based data signals are transferred with minimal interruption. This delicate balance of movement and optical performance characterizes the FORJ’s unique role in modern technology, ensuring that, whether in the depths of the sea, the vast expanse of space, or the precise environment of a medical facility, rotational motion, and data integrity go hand in hand.

The Design and Construction of FORJs

At their core, the design and construction of Fiber Optic Rotary Joints (FORJs) revolve around the principles of precision optics, ruggedness, and durability. Given the critical role they serve in the domain of fiber optic systems, their design demands both finesse and robustness. Their primary responsibility is to facilitate a seamless light path, ensuring uninterrupted data transmission, even as they facilitate rotation between joined parts.

Typically, FORJs comprise several key elements. A main body, generally made of robust materials like stainless steel or aluminum, provides the rigidity and endurance needed to withstand various operational conditions. This body houses the crucial optical components, which may consist of accurately aligned optical fibers, lenses, collimators, or prisms, depending upon the complexity and specificity of the application.

The optical components within a FORJ are meticulously aligned, be it through butt-coupling, lens coupling, or even wavelength multiplexing in the case of multi-channel FORJs. Each alignment strategy is designed around two fundamental niches: maximizing signal transmission and safeguarding against signal loss during rotation. Such precise alignments are no mean feat, considering that even marginal misalignments could result in drastic signal losses.

Moreover, materials chosen for the optical subsystem range from standard optical glasses to advanced proprietary materials that ensure minimal insertion loss – the loss of signal power resulting from inserting a component in the optical path. These materials also need to withstand the potential for wear and operational stresses over time.

FORJs often feature mechanical bearings to facilitate smooth and precise rotation while minimizing any impact on the optical path. Bearing choice is influenced by a multitude of factors including the expected rotation speed, load capacity, and desired service life.

Components are often sealed within the FORJ body to shield them from environmental conditions. This includes protection from dust, water ingress, and in some specialized cases, more aggressive threats such as chemicals, pressure extremes, and substantial temperature variations.

The design of FORJs is heavily influenced by the ultimate functionality they aim to provide. Indeed, every design choice from material selection to component placement contributes to facilitating an uninterrupted, stable optical link between a rotating interface and the stationary part of a system.

A high-quality FORJ exhibits a harmonious blend of robust construction and fine-tuned optics that can withstand a diverse range of operational demands while transmitting data signals with minimal interruption. In short, the design and construction of FORJs are a testament to meticulous engineering at the interface of optics, materials, and mechanics. Through their design, FORJs help forge the link between static high-speed data transmission and the dynamic world of rotational devices, proving once again that in technology, it is often the hidden components that render the most significant impacts.

Types of FORJ

Fiber Optic Rotary Joints (FORJs) are inherently diverse, formulated to cater to a spectrum of applications, from simple point-to-point communication setups to complex networked systems requiring multiple data channels. The distinctions among FORJs—such as single-channel, multi-channel, and multi-mode configurations—steer their functionality to align with the intricacies and requirements of various applications.

Single-channel FORJs

Single-channel FORJs are the simplest form of fiber optic rotary joint, designed to support a singular optical path between the rotating and stationary system components. The pragmatic design of these FORJs makes them a cost-effective solution for applications that require one-way data streams or uni-directional communication. Due to their simplicity, single-channel FORJs tend to have lower insertion loss and are easier to maintain, making them suitable for a broad range of industrial uses where only one data channel is necessary. Applications include closed-circuit television (CCTV) systems on rotatable platforms, basic wind turbine signal communication, and some types of rotary sensors.

Multi-channel FORJs

Multi-channel FORJs allow several discrete light paths, or channels, to pass through a single rotary joint, enabling multiple independent data transmissions concurrently. This simultaneous multi-faceted communication capacity makes them incredibly valuable for complex and high-data-volume applications such as radar systems, where each channel can be dedicated to distinct signals like control signals, sensor data, and video feeds. Additionally, they are instrumental in broadcasting equipment where numerous signals, including audio, video, and control commands, must be transmitted without interference. The design challenge for multi-channel FORJs is to mitigate cross-talk — the optical signal interference between adjacent channels. This is typically achieved through precise optical isolation techniques.

Multi-mode FORJs

Multi-mode FORJs differ not in the number of channels they provide but in the type of optical fiber, they accommodate. Multi-mode fibers have larger core diameters compared to single-mode fibers, which allows them to carry multiple modes or light rays. These FORJs are favorable in applications requiring the transfer of substantial bandwidth over shorter distances, often seen in theater stage equipment or industrial robotics. The advantage of multi-mode FORJs is that they are generally more tolerant to misalignments and handling damages than single-mode counterparts. However, due to modal dispersion where different modes travel at different speeds, they have a limited bandwidth-distance product, restricting their usage to applications that don’t require long-distance communication.

Each type of FORJ is designed with targeted environments and functionalities in mind. While single-channel FORJs cater to more straightforward, singular data link applications, multi-channel variations accommodate the need for multiple data streams without intersystem interference. Multi-mode FORJs provide versatile options for high bandwidth requirements over shorter distances. Together, these variations of FORJs ensure that across industries and technologies, rotational motion can be harmoniously synchronized with the uncompromised flow of fiber-optic data transmission.

Applications of FORJ

Fiber Optic Rotary Joints (FORJs) are instrumental in a variety of fields, fulfilling the critical function of ensuring seamless data transmission between stationary and rotating structures. These sectors often involve sophisticated technology where data integrity is paramount, and operational precision is non-negotiable.

Telecommunications

In the realm of telecommunications, FORJs play a vital role in facilitating high-speed data transfer within communication networks requiring rotational interfaces. For example, they can be found in radio and television broadcast towers where antennas must rotate to ensure the best transmission and reception coverage. Here, FORJs allow continuous, high-bandwidth signal transmission despite the rotational motion, maintaining broadcast quality without interruption.

Space and Satellite Technology

The stakes are incredibly high in space and satellite technology, where equipment failure can mean mission failure. FORJs are employed in satellite communication systems, enabling antennas to rotate and maintain alignment with ground stations or with other satellites, ensuring a steady exchange of critical data from earth observation, GPS, and telecommunications satellites. The stellar durability and signal integrity FORJs supply are invaluable in the vacuum of space, where repairing or replacing components is often not an option.

Undersea Equipment

The undersea environment leverages FORJs in a diversity of applications from oil exploration to scientific research. Remotely Operated Vehicles (ROVs), crucial in deep-sea exploration and pipeline inspection, rely on FORJs for the delivery of real-time video and sensor data to operators on the surface. The rotary joints in these applications are designed to withstand tremendous pressures and corrosive conditions while ensuring that optical signals are not compromised.

Wind Turbines

Wind energy is a sector where FORJs are directly contributing to sustainable energy development. Within wind turbines, FORJs are utilized for the transmission of electrical control signals, data, and video across the rotating interface between the nacelle and the tower. This continuous flow of information is critical for efficient turbine operation, including pitch control for the blades and system monitoring, which is essential for maintaining high levels of safety and efficiency in power generation.

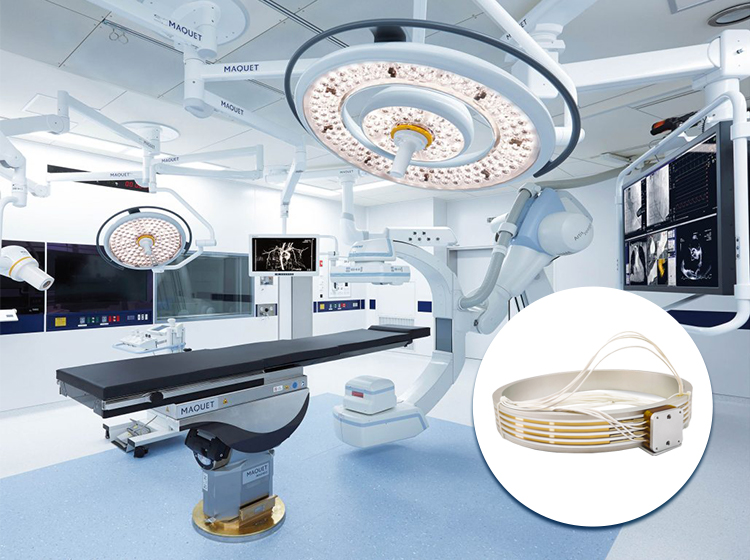

Medical Equipment

In the medical sphere, FORJs are seen in advanced imaging systems such as Computer Tomography (CT) scanners and Magnetic Resonance Imaging (MRI) machines. They enable the rotating scanner components to communicate seamlessly with the stationary data processing units, facilitating the continuous flow of high-resolution imaging data crucial for accurate diagnosis and treatment planning.

Industrial Automation

In industrial automation and robotic arms systems, FORJs provide the ability to transmit control and feedback data across rotating joints essential for precise, repetitive movements. This is particularly important in manufacturing processes where robots may be used for tasks such as assembly, painting, or welding, with FORJs embedded in the joints ensuring a constant connection for control signals and sensory feedback.

Aeronautics and Defense

In aeronautics, FORJs are utilized in onboard systems of helicopters and other aircraft where rotatable antennas or sensors require a constant connection to the aircraft’s communication systems. Meanwhile, in defense, they are used in turret systems, enabling the transfer of targeting and surveillance data as the turret rotates independently from the vehicle.

Through these various contexts, it’s evident that the integration of FORJs touches an eclectic array of crucial sectors, providing unified solutions to complex data transmission challenges. The invisible threads FORJs weave across industries are fundamental to maintaining the integrity and reliability of systems that society heavily relies on—from the depths of the oceans to the vast expanse of space, and from the life-saving functionalities in medical facilities to the energy-generating turbines in the heart of the green revolution.

Performance Parameters and Specifications of FORJ

The effectiveness and efficiency of Fiber Optic Rotary Joints (FORJs) are determined by a set of critical performance parameters and industry standards. These metrics not only gauge the capability of FORJs in diverse applications but also guide engineers in selecting the appropriate FORJ for a specific task. Key performance metrics include wavelength range, insertion loss, return loss, and rotational speed, each playing a pivotal role in FORJ’s functionality.

Wavelength Range

The wavelength range of a FORJ is a critical factor that determines the spectrum of light frequencies the device can efficiently transmit. This is particularly crucial for systems that operate over multiple wavelengths or require the flexibility to adapt to different fiber optic communication standards. Typically, FORJs need to support standard telecommunications wavelengths such as 850 nm for shorter distances (multi-mode fibers) and 1310 nm or 1550 nm for longer distances (single-mode fibers). Modern FORJs are designed to be adaptable, supporting a wide range of wavelengths to cater to diverse operational needs while maintaining high performance.

Insertion Loss

Insertion loss, often measured in decibels (dB), refers to the loss of signal power resulting from the incorporation of the FORJ in the optical path. Lower insertion loss is preferable as it translates to better signal integrity and, consequently, more reliable data transmission. Industry standards generally stipulate that insertion loss should be kept below a certain threshold, typically around 1-2 dB for single-channel FORJs. However, this value can vary based on the complexity of the FORJ, such as multi-channel units, which might exhibit slightly higher insertion losses due to their more complex internal structures.

Return Loss

Return loss measures the amount of light that is reflected to the source due to impedance mismatches within the FORJ, and it is also expressed in decibels (dB). A higher return loss value is desirable as it indicates lower reflection levels, contributing to superior signal quality. Industry standards for return loss are quite stringent, often demanding values above 45 dB for single-mode fibers, which are more susceptible to reflection-related issues. This parameter is critical in sensitive communication systems where even minimal reflections can cause data corruption or signal degradation.

Rotational Speed

Rotational speed, indicated in revolutions per minute (rpm), defines the maximum speed at which the FORJ can operate while maintaining its specified performance metrics. This parameter is especially relevant in applications involving high-speed rotations, such as in aerospace or industrial machinery. The rotational speed capacity of a FORJ must align with the operational requirements of the device it serves; hence, FORJs engineered for high-speed applications are often meticulously designed to minimize friction and wear, ensuring longevity and consistent performance. Industry standards for rotational speed can vary widely, tailored to the specific demands of different sectors, with some high-performance FORJs designed to withstand speeds of several thousand rpm.

These performance parameters are interconnected, often influencing each other. For instance, a design optimized for a high rotational speed might have slightly increased insertion loss due to the complexities involved in maintaining signal integrity at higher speeds. Manufacturers of FORJs are continually pushing the boundaries of technology to improve these metrics, striving to offer products that meet the rigorous demands of modern applications while adhering to, or surpassing, industry standards. This relentless pursuit of excellence ensures that FORJs remain pivotal components in the seamless operation of complex systems across various industries, from telecommunications to aerospace and beyond.

Installation and Maintenance of FORJ

Integrating a Fiber Optic Rotary Joint (FORJ) into a fiber optic system is a nuanced procedure that demands meticulous attention to detail to ensure optimal performance and longevity. Following a systematic installation process, along with adhering to prescribed maintenance routines, is paramount for the seamless operation of FORJs across various applications.

Installation Process

The installation of a FORJ typically follows a procedure aimed at preserving the integrity of the optical paths and ensuring compatibility with the rotational dynamics of the system. The steps include:

- Preparation: This phase involves gathering all necessary components, tools, and documentation. It’s crucial to ensure the compatibility of the FORJ with the fiber optic cables (in terms of type, wavelength, and connectors) and the mechanical interface with the rotating and stationary parts of the system.

- Inspection and Cleaning: Before installation, a thorough inspection of the FORJ, fiber optic connectors, and cables is essential to check for any defects or contaminants. The use of specialized equipment like fiber scopes can aid in inspecting the end faces of fiber connectors while cleaning should be performed with approved solvents and materials to avoid damage.

- Alignment and Connection: Carefully aligning the FORJ with the stationary and rotating parts of the system is crucial to avoid undue stress on the fibers. Once aligned, the optical connections are made, ensuring that connectors are securely fastened and the optical paths are free from bends that exceed the fiber’s minimum bend radius.

- Testing: After installation, testing the FORJ’s performance is vital to confirm that the insertion loss and return loss are within acceptable parameters and that there’s no disruption in data transmission. This can involve using light sources, power meters, and potentially an Optical Time-Domain Reflectometer (OTDR) for more comprehensive diagnostics.

Maintenance Procedures and Challenges

While FORJs are designed for durability, regular maintenance is crucial to uphold their performance and extend their lifespan. Typical maintenance procedures might include:

- Regular Inspections: Periodic visual inspections and performance tests (measuring insertion loss and return loss) can catch issues before they escalate into failures. This includes checking for any physical damage or signs of wear on the rotating components.

- Cleaning: The optical connectors and exposed parts of the FORJ should be regularly cleaned with appropriate tools and solutions to prevent signal quality degradation caused by dust and other contaminants.

- Lubrication: For mechanical components that require lubrication, using the correct lubricants as specified by the manufacturer is critical. Over-lubrication can attract dirt, while under-lubrication can lead to premature wear.

- Software Updates: For FORJs that are part of a larger system with software controls, ensuring that the software is regularly updated is vital for maintaining optimal performance and compatibility with the system.

The challenges in maintaining FORJs often stem from their operating environments. Systems exposed to harsh conditions, such as extreme temperatures, humidity, vibrations, and contaminative particulates, necessitate more frequent and rigorous maintenance routines. Accessibility can also pose a challenge, especially for FORJs installed in remote or confined spaces, making regular inspections and maintenance more difficult.

Despite these challenges, the meticulous installation and diligent maintenance of FORJs are indispensable for harnessing the full potential of these devices. By following best practices and manufacturer guidelines, the reliability and efficiency of fiber optic systems employing FORJs can be significantly enhanced, assuring continued high performance in applications that depend on them.

Request Technical Support for Fiber Optic Rotary Joints

FORJ Case Studies

Fiber Optic Rotary Joints (FORJs) have featured prominently in numerous successful projects and applications, demonstrating their versatility and problem-solving capacity. From enhancing communications to facilitating advanced scientific research, the use cases of FORJs are as varied as they are impactful. Here are a couple of case studies illustrating this:

Large-Scale Wind Farm Integration

Context: In a bid to bolster renewable energy capacities, a large-scale wind farm project situated offshore aimed to maximize its energy output through real-time monitoring and dynamic blade pitch adjustments. The project required robust data and control signal transmission between the moving turbines and the stationary control center.

Application: This is where FORJs were deployed as a pivotal solution. Specifically, multi-channel FORJs were integrated within the wind turbines to handle signal and power across the rotating interface between turbine blades and the nacelle. These FORJs facilitated the continuous flow of operational data, including wind speed, blade position, and power output, while also enabling real-time control signals for blade pitch adjustment based on wind conditions.

Outcome: The successful incorporation of FORJs substantially increased the wind farm’s efficiency. The resultant precision in blade orientation directly translated into higher energy capture and longer turbine life due to reduced mechanical stress. Not only did this installation exhibit FORJs’ integral role in sustainable energy initiatives, but it also underscored their reliability in harsh environmental conditions and their contribution to the intelligent operation of modern renewable energy infrastructure.

Advanced Robotic Surgery Systems

Context: In the medical field, robotic surgery systems have transformed the landscape of minimally invasive procedures. The high-stake environment of surgical robotics demands absolute precision and reliable transmission of high-resolution sensory data and real-time control commands.

Application: FORJs were incorporated into the rotational joints of a robotic surgery system, ensuring uninterrupted data communication from the various sensors and instruments on the rotating arm to the surgeon’s control console. This application demanded single-mode FORJs due to their low insertion loss and high return loss, ensuring the fidelity of high-bandwidth data streams required for precise instrument manipulation.

Outcome: The FORJs played a crucial role in the success of the robotic surgery system, offering surgeons the ability to perform complex procedures with enhanced precision and flexibility. The reliability and signal integrity provided by the FORJs also enhanced the safety and effectiveness of surgeries, improving patient outcomes and advancing the field of medical robotics.

Deep Sea Exploration ROVs

Context: Remote Operated Vehicles (ROVs) are essential tools in deep-sea exploration, underwater construction, and marine research. Reliable data transmission from the ROV to the surface vessel is critical, especially given the harsh and inaccessible operating environments.

Application: FORJs were integrated into the design of ROVs to manage the data and video signals transmitted across the rotating components involved in their operation. Given the extreme conditions and pressures, these FORJs were designed with high-strength materials and specialized sealing to withstand deep-sea challenges while maintaining high-quality data transmission.

Outcome: ROVs equipped with these specialized FORJs successfully facilitated a plethora of deep-sea missions, ranging from studying unexplored marine ecosystems to carrying out repair and maintenance of underwater infrastructure. The durability and performance of FORJs in such conditions have been instrumental in expanding the frontiers of marine science and industry.

These case studies showcase how FORJs have been crucial in adapting to and overcoming the unique challenges presented by diverse fields. They affirm the invaluable role of FORJs in enabling innovation, enhancing operational efficiencies, and contributing to technological advancements.

Concerns about FORJs and Their Solutions

When it comes to the incorporation of Fiber Optic Rotary Joints (FORJs) in intricate systems, users may have several concerns, primarily focusing on issues like durability, regular maintenance needs, and the overall cost of these components. Let’s delve into each of these concerns and explore the strategies and solutions that manufacturers implement to alleviate them.

Durability Concerns

Challenge: Users often worry about the lifespan of FORJs, especially when deployed in harsh environments, or applications involving high-speed rotations or continuous operation. Durability concerns encompass wear and tear on moving parts, resistance to environmental factors like moisture, dust, or extreme temperatures, and the risk of signal degradation over time.

Solution: To address these issues, manufacturers invest in research and development to produce FORJs crafted with robust materials like stainless steel or special alloys that resist corrosion and physical wear. Additionally, they incorporate advanced sealing technologies to prevent the ingress of contaminants. In terms of signal integrity, premium-grade optical components and precision-engineered coupling mechanisms are used to ensure minimal signal loss throughout prolonged use. Some manufacturers also offer custom solutions tailored to stringent environmental requirements or unique operational parameters, further enhancing the durability of the FORJs they provide.

Maintenance Challenges

Challenge: Maintenance is another significant concern for users—it must be easy, infrequent, and should not overly disrupt the system’s operation. Regular maintenance is essential to prevent system downtime, but excessive maintenance can be a burden in terms of time and cost.

Solution: To mitigate maintenance challenges, manufacturers have refined the design of FORJs to reduce the need for regular servicing. This includes the integration of contactless designs for specific models to decrease wear and the need for lubrication. When maintenance is required, user-friendly design elements are often added to facilitate quick and simple servicing. For instance, some FORJs come with modular designs allowing for the replacement of specific components without having to dismantle large portions of the system. Additionally, comprehensive maintenance kits and detailed guides are frequently provided to empower users to perform routine servicing efficiently.

Cost Concerns

Challenge: The cost of high-precision instruments like FORJs can be substantial. The initial outlay for the hardware, along with the expenses involved in installation and ongoing maintenance, constitute a significant financial consideration for businesses.

Solution: Manufacturers combat the concern of cost from multiple fronts. Cost efficiency is enhanced through the automation of production processes and the economies of scale achieved by larger production runs. These savings can then be passed on to the customer. In addition, by improving the durability and ease of maintenance—thereby reducing the total cost of ownership—manufacturers ensure that the FORJs represent a cost-effective solution over their operational lifespan. The advancement in fiber optic technology also enables manufacturers to develop cost-effective multi-channel FORJs that can handle several signals simultaneously, reducing the necessity for multiple single-channel FORJs and hence lowering the overall system cost.

Some manufacturers go one step further, offering customization services that ensure users only pay for features they need. By tailoring FORJ configurations to the precise requirements of a project, unnecessary costs associated with superfluous capabilities can be avoided.

Beyond these proactive measures, manufacturers maintain a dialogue with their customer base, often providing technical support and consultation to ensure that the solutions are not only technically viable but also financially justifiable. Through warranties and service agreements, they offer added assurance of the FORJ’s performance and viability over time, which helps alleviate upfront cost concerns by signaling the manufacturer’s commitment to product longevity and customer satisfaction.

In addressing these concerns, manufacturers not only enhance the appeal of their products but also contribute to advancing the broader field of fiber optic technology. By doing so, they not only shore up confidence in FORJs as a component but also bolster the reliability and efficacy of the numerous complex systems in which FORJs play an essential role.

Future of FORJ Technology

The sphere of Fiber Optic Rotary Joint (FORJ) technology, playing a pivotal role in various applications where uncompromised signal integrity during rotation is crucial, stands on the cusp of numerous potential advancements. Emerging trends and developmental trajectories are shaping the future of FORJ technology in significant ways.

Miniaturization and Smaller Designs

Trend: There’s an industry-wide push towards miniaturization, adhering to the demand for compact and lightweight systems, particularly in aerospace, medical devices, and consumer electronics. The challenge is to reduce size without compromising the FORJ’s capability to transmit signals effectively.

Future Perspective: Advancements in microfabrication and precision engineering predict the production of smaller, yet more powerful FORJs. We anticipate the development of micro-FORJs leveraging nanotechnology to fit advanced systems with spatial constraints, offering the same, if not enhanced, performance as their larger counterparts. This miniaturization trend, inspired by the progression in integrated circuits and MEMS technology, could lead to FORJs being integral in even the most compact rotational systems.

Enhanced Performance Metrics

Trend: The ever-increasing demand for high-speed data transfer and low-latency communication emphasizes the need for high-performance FORJ models with improved specifications, including lower insertion loss and higher channel counts.

Future Perspective: R&D efforts are expected to focus on augmenting these performance metrics by optimizing the optical paths, refining fiber alignment technologies, and employing advanced materials with better optical properties. Innovations in waveguide technology may also allow FORJs to support a broader range of wavelengths, thereby enhancing their utility for different applications. The goal is to push the boundaries of data throughput and signal fidelity while maintaining robustness in diverse operational settings.

Intelligent and Integrated Systems

Trend: Systems are becoming increasingly integrated and intelligent, with FORJs expected to be part of assemblies where they actively communicate with the system, calibrate themselves, and even predict maintenance needs.

Future Perspective: With the advent of the Internet of Things (IoT) and smart technology, FORJs might soon be equipped with sensors that allow them to monitor their own performance and the integrity of the optical signals they are transmitting. They could be integrated into smart networks that analyze real-time data to optimize performance, forecast maintenance, and provide insights into system health. This self-monitoring capability would not only elevate the reliability of the rotary joints but could also pave the way for autonomous operation in complex systems.

Environmental Stewardship and Material Innovation

Trend: A global emphasis on sustainability and environmental responsibility has put pressure on manufacturers to develop eco-friendlier components.

Future Perspective: Material innovations may lead to the use of more sustainable, less resource-intensive components that maintain or enhance the performance of FORJs. Biodegradable plastics, recycled materials, or components that require less energy-intensive production processes might be employed, contributing to the overall reduction of the environmental footprint of fiber optic technologies.

Customization and Modular Design

Trend: Diverse applications necessitate tailored solutions. A modular approach to FORJ design allows for the customization of systems for specific applications without the need for entirely bespoke designs.

Future Perspective: Going further in this direction, we might see FORJs becoming more adaptable and modular, enabling users to replace or upgrade certain aspects of the FORJ without the need to replace the entire unit. This modular concept not only extends the life of the FORJ but also allows for rapid adaptation to evolving technical requirements.

As FORJ technology progresses, it is clear that the focus will not solely be on enhancing the physical product but also on how it integrates into and communicates with larger systems. Through this integration, FORJs will continue to underpin innovations across industries, enabling advancements in everything from telecommunications to robotic surgery, and beyond.

Conclusion

Undoubtedly, FORJ technology underpins countless applications, ensuring reliable and seamless data transmission in rotation-intensive environments. With continuous advancements, FORJs will continue to shape the fiber optic landscape, prompting us to stay updated.

FAQs about FORJ

Q: What is the primary function of a FORJ?

A: A FORJ allows for uninterrupted data transmission even during physical rotation in a fiber-optic system.

Q: Are there different types of FORJs?

A: Yes, there are several types of FORJs, including single-channel, multi-channel, and multi-mode FORJs, each serving unique functions.

Q: What are common concerns about FORJs?

A: Users often express concerns related to the durability, maintenance, and cost of FORJs.

Q: What does the future hold for FORJ technology?

A: The future of FORJ technology will likely see advancements in size reductions, improved materials, and integrated models, among other areas.

Q: What exactly is a Fiber Optic Rotary Joint (FORJ)?

A: An FORJ is a specialized device that allows the uninterrupted passage of light signals through optical fibers across a rotating interface. Essentially, it enables optical communication between stationary and rotating parts without impeding the rotation of either component.

Q: How is data transmitted through a FORJ in high-rotation speed environments without getting twisted?

A: FORJs are meticulously engineered to maintain an optical connection between the rotating and stationary fibers. The rotation mechanism is typically built around precision bearings and an optical coupling that doesn’t rely on the physical contact of the fibers, thus preventing any twisting or tangling while allowing high-speed rotation.

Q: Can FORJs function effectively under extreme environmental conditions?

A: Yes, FORJs are designed with durability in mind and can be engineered to withstand harsh environments, including high pressure, extreme temperatures, and corrosive conditions. Advanced sealing technologies and the use of rugged materials ensure that they remain functional under such extreme conditions.

Q: What factors determine the number of channels in a FORJ, and can they be increased post-manufacture?

A: The number of channels in a FORJ is determined by the number of independent optical signals that need to be transmitted. It’s a design parameter and typically cannot be adjusted after manufacturing. However, modular design FORJs offer some level of adaptability to changes in system requirements.

Q: Are FORJs susceptible to electromagnetic interference (EMI)?

A: No, one of the main advantages of using FORJs is their high immunity to EMI. Since the signal is transmitted through light rather than electrical currents, FORJs are not affected by electromagnetic fields, making them ideal for use in environments with high EMI.

Q: How are FORJs maintained, and do they require specialized personnel?

A: Maintenance procedures vary by model, but generally, FORJs are designed for minimal maintenance. Simple cleaning and periodic inspections may be sufficient. Whenever maintenance is required, the process is usually straightforward, and with the proper training and manuals, it typically doesn’t require highly specialized personnel.

Q: Do FORJ products come with any form of warranty or post-purchase support?

A: Yes, most reputable manufacturers offer warranties that cover defects in material and workmanship for a specified period. In addition, many companies provide post-purchase support in the form of customer service, technical support, and availability of replacement parts.

Q: How does fiber type (single-mode vs. multi-mode) affect the performance of a FORJ?

A: Fiber type is an important consideration as it impacts the transmission range and bandwidth. Single-mode fibers are used for long-distance and high-bandwidth applications due to their lower attenuation and dispersion. Multi-mode fibers, with their larger core, are easier to align but are used for shorter distances due to higher attenuation and dispersion. The choice between single-mode and multi-mode FORJs depends on the specific requirements of the application.

Q: Can FORJs be customized for specific applications?

A: Yes, most FORJ manufacturers offer customization services for specific applications. Customization can range from unique channel counts, integration of electrical slip rings, special connectors, tailored dimensions, and specific materials for enhanced environmental resistance.

Q: What limitations should I be aware of when integrating a FORJ into my system?

A: When integrating a FORJ, considerations should include mechanical limitations such as rotational speed, torque, and dimensional constraints, as well as optical performance factors like wavelength compatibility, insertion loss, and channel crosstalk. It’s important to consult with the manufacturer to ensure the FORJ is compatible with the specific operational requirements and integration constraints of your system.

See What We Can Do