In a world that is continually energized by electricity, the elements that contribute to efficient power generation are often overlooked. The generator collector ring is one such pivotal component whose role is paramount yet seldom highlighted. This article aims to dissect the intricacies of the generator collector ring, exploring its function, significance, and maintenance for readers ranging from engineering aficionados to industry professionals.

Introduction to Generator Collector Rings

In the realm of power generation, every component plays a pivotal role in ensuring the seamless conversion, transmission, and distribution of electrical energy. Among these, the generator collector ring may not be the most prominent in terms of visibility, but its function is essential to the integrity and efficiency of the entire system. These rings are specialized types of electrical slip rings used primarily for transferring power and electrical signals from a stationary to a rotating structure, hence forming an integral part of the power generation apparatus.

A generator collector ring is essentially a rotating metal ring that is connected to the spinning rotor of a generator. As the rotor turns, it needs to maintain an electrical connection with the stationary part of the generator to transfer the electricity it’s generating effectively. This is where the collector ring comes in – it provides a continuous conductive path through its rotational interface with the help of stationary brushes that glide on the ring’s surface, transferring the generated power to the external circuits.

Focusing on the generator collector ring is not just about an individual component; it’s also about appreciating the nuanced balance of a power-generating system’s architecture. As the link between motion and the transfer of electrical power, the collector ring bears the responsibility for unremitting electrical continuity. Any failure or inefficiency at this juncture can lead to major disruptions in power delivery or quality, which could, in turn, affect the reliability of the electricity supply on which modern society is so dependent.

Moreover, the heavy demand for continuous electricity and the increased load on power systems have put additional pressure on the performance and endurance of generator collector rings. Therefore, understanding their design, operation, and the challenges associated with them is crucial, not just for the engineers and technicians directly involved in their maintenance but also for decision-makers in industries where power generation reliability is non-negotiable.

It’s this component’s silent, yet vital contribution to the production and maintenance of electric power—and any risk to its functionality that could reverberate through the entire power system—that warrants the in-depth focus and exploration provided in this introduction to the generator collector ring.

How Does a Generator Collector Ring Work?

Delving into the generator collector ring’s functionality requires an understanding of the broader context of a generator’s operation. In essence, electric generators work based on the concept of electromagnetic induction, wherein the movement of rectangular coils of wire within a magnetic field generates electric power.

In an electrical generator, the rotor (the rotating assembly) is affixed with a winding, called the rotor winding. This winding is the actual location where the electricity gets generated by the aforementioned principle of electromagnetic induction. The electrical signal, or power, generated within the rotor must be effectively relayed to the stator (the stationary part), which is connected to the electrical grid or the machine being powered.

This is where the collector ring comes into play. The rotor winding is connected to the generator collector ring—a conductive circle, typically made of copper or another conductive alloy. As the generator rotor revolves, so do these rings. The challenge, however, is to transfer the electrical power from the constantly spinning collector ring to the stationary stator.

The answer to this challenge lies in brushes—carbon-based conductors—that are linearly pressed against the spinning collector ring, creating a constantly moving point of contact. By bridging the moving and stationary parts of the generator, these brushes, in collaboration with the collector ring, allow for the continuous transfer of electric power from the moving rotor to the stationary stator.

In other words, the collector ring and brushes collectively form the rotating electrical interface that allows countless rotations while maintaining a steady power flow. This functionality gives the generator the capacity to generate power continuously for extended periods, making it a vital linchpin within the broader mechanism of the generator.

Despite the brushes and collector ring’s interaction being highly efficient, it invariably results in friction and wear-and-tear, introducing the need for their regular maintenance and possible replacement over time. This reality is a significant consideration in the overall maintenance and management of the generator.

In summary, generator collector rings serve a pivotal role in orchestrating the transmission of power from the rotor to the external circuit within a generator. They ensure this transfer happens smoothly regardless of the generator’s rotational speed, facilitating the reliability and durability we associate with modern electrical power sources.

Different Types of Generator Collector Rings

Generator collector rings, while seemingly straightforward in their role, can vary significantly in design and application based on the specific requirements of the generator they’re paired with. Their diversity is a reflection of the myriad ways generators are used across different industries and settings. This variety ensures that electrical power generation can be efficiently and effectively tailored to meet specific operational needs.

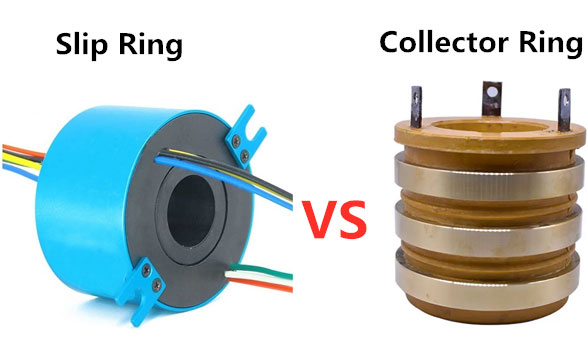

Slip Rings

Traditionally the most common type of collector rings, slip rings are utilized in AC (Alternating Current) generators to provide a continuous power output. They allow for the transmission of power and data across a rotating interface from the generator rotor to the stationary parts of the system, including the brushes. Slip rings are often made from durable, conductive materials capable of withstanding the wear that comes from constant friction. They are widely used in applications requiring a constant and uninterrupted transmission of power, such as in wind turbines and various industrial machinery.

Split Rings

Commonly found in DC (Direct Current) generators, split rings—also known as commutators—operate on a principle similar to that of slip rings but are specialized for converting AC to DC within the generator itself. Unlike the continuous circular design of slip rings, split rings are segmented, which allows for the reversal of current direction, a necessary process for generating DC power. This distinct functionality makes them invaluable in applications where DC power is preferred or required, including some types of motors and older-generation plants.

Phase Collector Rings

Specific to synchronous machines, phase collector rings are used primarily in settings where the machine operates both as a motor and a generator. These rings are crucial in providing an external excitation voltage to the rotor winding, which is necessary for the machine to generate power. Phase collector rings are characterized by their ability to handle high current densities and are commonly found in large, industrial power generation settings. For example, they play critical roles in hydroelectric and thermal power plants where high efficiency and reliability are paramount.

Each type of collector ring is designed with its unique set of advantages to cater to specific generator and operational needs. Whether it’s handling high voltage levels in industrial settings, managing the conversion of AC to DC, or providing stable and continuous power transmission, there’s a collector ring built for the challenge. Understanding these distinctions is fundamental to ensuring the optimal selection and maintenance of these critical components in power generation systems, ensuring they continue to meet the ever-evolving demands of global energy consumption.

The Importance of Generator Collector Rings in Power Generation

The generator collector ring occupies a role of unsung importance in the pantheon of power generation components. It serves as a bridge between motion and electrical continuity, enabling the transference of power from a generator’s spinning rotor to the fixed stator, which then passes the energy into the grid or to a specific load. Fundamentally, without collector rings, the generator cannot fulfill its primary purpose of providing a stable and usable source of electricity.

The Role in Power Transmission

Collector rings reside at the heart of power transmission within a generator system. This seemingly simple interface bears the full onus for the delivery of generated power to its intended destination without interruption. They allow the circuit between the rotor and the stator to be completed, thereby accommodating continuous electricity flow. This is no small task; the power generated often involves significant voltage and current levels, which the collector rings need to handle efficiently.

The operational integrity of these rings directly impacts the quality of the electricity being supplied. A poorly functioning collector ring could be the genesis of power fluctuations, interruptions, or surges. Power quality is a critical characteristic of electrical supply, particularly with the increased sensitivity of modern electronic devices, where even minuscule irregularities can result in failures or reductions in lifespan.

Real-world Significance

Consider the example of a hospital where uninterrupted power is not just necessary for lights and computers but is critical for life-saving equipment. Generator collector rings ensure that backup generators provide immediate and reliable power in the event of a grid failure.

In another instance, take the realm of manufacturing, especially in plants using complex robotics and machinery that require constant and precise power. Any fluctuation due to collector ring failure could result in costly production halts or even catastrophic damage to the production apparatus.

Finally, in renewable energy systems such as wind turbines, the collector ring must withstand fluctuating speeds and harsh environments while enabling the flow of power generated from the windy expanses. In these situations, the collector ring’s functionality is paramount to ensuring the reliable integration of renewable sources into the power grid, facilitating a transition to greener forms of energy.

In these and countless other scenarios, the collector ring stands as a gatekeeper, a custodian of continuity, ensuring that from massive power plants to the delicate components within digital devices, the flow of electrical power remains steady and secure. Its critical nature, therefore, is not just in its primary function but also in its status as a guarantor of sustainable and reliable power for an electricity-dependent world.

Generator Collector Ring Common Problems and Solutions

Generator collector rings are the linchpins of the power generation process, yet they are susceptible to a range of issues arising from their operational environment and the nature of their function. Identifying these problems and addressing them through diligent maintenance and troubleshooting is essential to ensure the longevity and reliability of power generation systems.

Common Problems

Wear and Tear: Due to the mechanical contact between the brushes and the rings, wear is inevitable. Over time, this wear can lead to decreased performance, increased resistance, and ultimately, power loss or fluctuations.

The buildup of Debris: Dust, dirt, and other airborne particles can accumulate on the surface of collector rings. This buildup can interfere with the electrical contact between the rings and brushes, leading to inefficient power transmission.

Corrosion: Collector rings are often subjected to harsh environments, which can result in corrosion. Corroded rings can increase electrical resistance and reduce the efficiency of power transfer.

Overheating: Slippage between brushes and rings, or excessive current loads, can lead to overheating. This not only damages the rings and brushes but can also degrade the power quality.

Troubleshooting Tips

Wear and Tear: Regularly inspect the collector rings and brushes for wear. When wear is detected, the brushes can be replaced, and the rings can be resurfaced or replaced if needed.

The buildup of Debris: Implement a cleaning schedule based on the operational environment. Brushes that are designed to be self-cleaning can help reduce debris on the collector rings. Sometimes, simply wiping the rings with a clean, dry cloth can suffice for mild debris.

Corrosion: Applying protective coatings can help prevent corrosion. In environments where corrosion is a significant issue, the use of more corrosion-resistant materials like special alloys or composites might be necessary.

Overheating: Ensuring proper alignment and pressure between the brushes and rings will minimize slippage and reduce the risk of overheating. Additionally, monitoring the current load to prevent overloading of the generator’s output capacity is crucial.

Regular Maintenance Practices

Inspection Schedule: Establish and adhere to a regular inspection and maintenance schedule for collector rings. This should be adjusted based on the operating conditions and load demands of the generator.

Lubrication: Some collector rings require lubrication to maintain optimal performance. Use the correct type of lubricant as per the manufacturer’s specifications.

Documentation: Keep detailed records of maintenance activities to predict wear patterns and replace parts before they fail.

Environmental Controls: In settings where dust, moisture, or chemical exposure is a problem, implementing environmental controls or enclosures can greatly extend the life of collector rings.

By understanding and addressing the common problems associated with collector rings, technicians can ensure these vital components remain in good working order. This is fundamental not just for the generator’s lifecycle but for the integrity and stability of the wider power system. Regular, proactive maintenance not only prevents failures but also reinforces the overall efficiency and responsiveness of power generation systems to meet the demands of a power-hungry world.

Latest Developments and Innovations in Generator Collector Ring Technology

As power generation requirements become increasingly complex and demanding, advancements in generator collector ring technology are crucial to ensure the scalability and reliability of electrical systems. Innovations range from new materials to design overhauls, all aiming to boost efficiency, reduce the need for maintenance, and adapt to diverse operational settings.

Material Advances

A key area of development is in the materials used to construct collector rings. There’s a growing emphasis on more advanced, durable materials that can better resist wear, withstand high voltages, and minimize frictional losses. Special alloys and advanced composites offer increased lifespan and lower maintenance, especially in harsh environments.

Design Innovations

Design improvements have also marked recent advancements. For instance, companies are experimenting with flexible collector rings that can adapt to different operating conditions and physical constraints. This could be particularly useful in applications such as wind turbines, where the operating environment calls for a more robust yet adaptable design.

Brushless Systems

One significant trend in collector ring systems is the shift toward brushless designs. This plays out in technologies such as Permanent Magnet Generators, where the power is transmitted via magnetic fields rather than through physical contact. This eliminates the wear and tear associated with traditional brushes and reduces maintenance requirements, thereby increasing overall system reliability.

Digital Monitoring and Maintenance

Lastly, the advent and integration of digital solutions, such as predictive maintenance, big data analysis, and Internet of Things (IoT) devices, are driving advancements in generator ring technology. These can provide real-time diagnostics and analytics, enabling early detection, and mitigation of issues before they become major problems. They offer a way to monitor the wear and tear on collector rings accurately and plan maintenance more effectively, thus improving performance and longevity while reducing costs and downtime.

As the world continues to innovate and evolve, so too must generator collector rings to accommodate varying environmental concerns, higher power demands, and the need for ever-greater efficiency and reliability. These recent advancements and trends are testimony to the adaptability and resilience of this critical technology, poised to meet the future needs of power generation systems worldwide.

Selection Criteria for Generator Collector Rings

Selecting the appropriate collector ring for a generator is paramount, as it directly influences the performance, efficiency, and reliability of the power generation system. Given the diverse array of generator applications—from small-scale renewable energy systems to large industrial power plants—the criteria for choosing the right collector ring vary significantly. Here are some guidelines that can help in selecting the most suitable collector ring for different scenarios or applications.

Understanding the Application

- Power Capacity and Voltage Requirements: The capacity and operating voltage of the generator significantly influence the choice of collector ring. High-power applications require robust collector rings designed to handle higher currents and voltages without degradation.

- Operational Environment: The environmental conditions in which the generator will operate dictate the material and design of the collector ring. For instance, generator systems exposed to harsh conditions such as maritime or industrial environments may need collector rings with corrosion-resistant materials and protective coatings.

- Rotational Speed: The speed at which the generator operates can impact the wear and tear on collector rings. High-speed applications may necessitate the use of specially designed rings and brushes that can withstand the increased friction and heat.

Material Compatibility

- Conductivity: The material of the collector ring should possess excellent electrical conductivity to minimize power losses during transmission.

- Durability: Materials that offer high resistance to wear and corrosion ensure that the collector ring maintains its performance over time, especially in applications where maintenance access is challenging.

- Compatibility with Brushes: The material of the collector ring should be selected to match the brushes’ material to reduce wear and increase the overall lifespan of the system.

Design and Configuration

- Single vs. Multi-Ring Systems: Depending on the complexity and requirements of the electrical system, the design could vary from a single ring for simpler setups to multiple rings for systems requiring higher levels of redundancy and reliability.

- Cooling Mechanisms: For high-power applications, the collector ring design may need to incorporate cooling systems to prevent overheating and ensure consistent performance.

Maintenance and Accessibility

- Ease of Maintenance: Collector rings designed for easy access and replacement of worn components, like brushes, can significantly reduce downtime and maintenance costs.

- Monitoring and Diagnostic Features: Advanced collector rings equipped with sensors and monitoring systems enable predictive maintenance, helping to avoid unexpected failures.

Regulatory and Standard Compliance

- Safety and Standards: Ensure the collector ring meets all relevant safety standards and regulations for the region and industry it will operate. This includes standards related to electrical safety, emissions, and environmental impact.

In summary, the selection of generator collector rings should be a thoughtful process that considers the specific demands and conditions of the application. By evaluating the criteria above, including the operational environment, power requirements, material durability, and design features, one can identify the most appropriate collector ring to ensure optimal performance and reliability of the power generation system.

How to Safely Handle and Maintain a Generator Collector Ring

Proper handling and maintenance of a generator collector ring are crucial to ensuring not just the component’s longevity and optimal performance but also the safety of those working with it. The collector ring, being an integral part of the generator’s electrical output system, demands specific safety measures, adherence to best practices, and a consistent maintenance routine. Here are key guidelines for safely managing this essential component.

Safety Measures

- Lockout/Tagout Procedures: Before any inspection or maintenance begins, it’s imperative to implement lockout/tagout procedures to ensure the generator is not accidentally started during work. This protects maintenance personnel from electric shock or injury.

- Wear Appropriate Personal Protective Equipment (PPE): Handling collector rings requires wearing the right PPE, including gloves, safety glasses, and other gear that protects against electric shock and physical injury.

- Avoid Direct Contact with Energized Parts: Ensure that the generator system is completely powered down and de-energized before touching any parts of the collector ring.

Best Practices

- Regular Inspections: Conduct regular visual inspections of the collector ring and associated components for signs of wear, damage, or contamination. Early detection of issues can prevent more significant problems down the line.

- Proper Cleaning Techniques: Use the correct cleaning solvents and methods to remove dirt, grime, and oxidation from the collector ring without causing damage. Avoid abrasive materials that might scratch the ring’s surface.

- Correct Installation and Alignment: When installing or replacing collector rings, ensure proper alignment and correct fit to avoid unnecessary stress or wear on the component. Misalignment can lead to premature failure.

Routine Maintenance Tips

- Scheduled Cleaning: Implement a regular cleaning schedule based on the operating environment and manufacturer’s recommendations. Cleaner collector rings result in better electrical contact and longer component lifespan.

- Brush Inspection and Replacement: Check the condition of the brushes regularly. Look for uneven wear or damage, and replace them as per the recommendation of the manufacturer or when they reach their minimum size.

- Lubrication When Applicable: While not all collector rings require lubrication, those that do should be lubricated according to the manufacturer’s guidelines using the appropriate type of lubricant.

- Environmental Monitoring: Keep an eye on the environmental conditions where the generator operates. Excessive humidity, dust, or corrosive agents can all impact the condition and functionality of the collector ring. Implementing environmental controls where necessary can be beneficial.

- Electrical Testing: Periodically perform electrical tests on the collector ring system to ensure it is operating within specifications. Tests might include resistance measurements and checks for insulation integrity.

Documentation and Record-Keeping

- Maintain Detailed Records: Keeping detailed records of all inspections, maintenance activities, and replacements helps forecast future needs and identify recurring problems that may require more comprehensive solutions.

Adhering to these safety measures, best practices, and maintenance tips cannot just prevent premature wear and potential failures but also ensure a safer working environment. A well-maintained collector ring is key to the reliable and efficient operation of generator systems, reflecting positively on the operational costs and overall lifespan of the power generation unit.

Conclusion

In recapping the article’s salient points, this conclusion will not only summarize the technical details discussed but also reinforce the unsung importance of the generator collector ring to the reader. With a newfound appreciation for this component, the hope is to fortify the attention and respect it deserves in the power generation narrative.

FAQs about Generator Collector Rings

Q1: What is a generator collector ring and how does it work?

A1: A collector ring, also known as a slip ring, is a component used in generators to transfer electrical current from a rotating part of the machine (rotor) to a stationary part (stator) or vice versa. It consists of a conductive ring that is connected to the rotating shaft and brushes that maintain contact with this ring, allowing for the continuous transfer of power while the shaft is in motion.

Q2: Why are collector rings important in generators?

A2: Collector rings are essential for the proper functioning of AC generators (alternators) and certain types of DC generators. They enable the transmission of electricity from the moving parts of the generator to the stationary external circuitry without using direct wired connections, which would be impractical due to the rotation.

Q3: What materials are used to make collector rings, and why?

A3: Collector rings are usually made from conductive materials such as copper, brass, or bronze, often with silver or gold plating to enhance conductivity and reduce wear. These materials are chosen for their excellent electrical conductivity, durability, and resistance to corrosion and wear.

Q4: How often should collector rings be inspected or maintained?

A4: The frequency of inspection and maintenance depends on the operating environment and workload of the generator. However, a general recommendation is to inspect the collector rings and their brushes every 3 to 6 months. In environments with high dust, moisture, or corrosive agents, more frequent inspections may be necessary.

Q5: What are common signs of collector ring wear or failure?

A5: Common signs include unusual noise, sparking at the contact points, irregular wear patterns on the rings or brushes, and a significant decrease in electrical output efficiency. Any of these signs could indicate that the collector ring or its components require maintenance or replacement.

Q6: Can collector rings be repaired, or do they need to be replaced when damaged?

A6: Minor wear and damage can often be repaired by resurfacing the ring to a smooth, clean finish. However, if there’s significant physical damage or deep scoring, replacement of the ring might be the only viable option to ensure the generator’s effectiveness and safety.

Q7: Are there any safety precautions to take when working with collector rings?

A7: Yes, safety is paramount. Ensure the generator is shut down and follow lockout/tagout procedures before performing any maintenance or inspection. Wear appropriate personal protective equipment (PPE), such as gloves and eye protection, to guard against electrical shock and physical injury.

Q8: How can I prolong the life of my generator’s collector rings?

A8: Regular maintenance, including cleaning, inspection, and timely replacement of worn parts, is key. Ensuring that the generator operates within its designed parameters and that the collector ring and brushes are correctly aligned can also significantly extend their lifespan.

Q9: Is it possible to improve the efficiency of a generator by upgrading its collector rings?

A9: Yes, upgrading to collector rings made from better conductive materials or those with enhanced designs for reduced friction and wear can improve the efficiency of power transfer, potentially enhancing the generator’s overall performance.