Slip rings play an irreplaceable role in various sectors, acting as the foundation for stable and efficient electricity and signal transfer in systems with rotational motion. They function by creating an electrical connection between stationary and rotating systems, such as electric generators, radar antennas, revolving doors, and wind turbines, just to name a few. Reliable and high-performance slip rings are critical in enabling these systems to operate effectively and without interruption, regardless of continuous or intermittent rotational movement.

Given the importance of slip rings in diverse industries, it’s critical to choose a dependable supplier for optimal functioning and performance. In light of this, two market-leading manufacturers emerged: Hangzhou Grand Technology and BGB Slip Ring. Both have carved a niche for themselves in the slip ring production industry, gaining acclaim globally and contributing greatly to technological advancements in various sectors.

Hangzhou Grand Technology, hailing from China, and BGB Slip Ring, originating from the UK, have a broad portfolio of successful, high-quality slip ring solutions that cater to a multitude of applications. While both manufacturers offer efficient slip ring solutions, their features, customization capabilities, and implementation can differ significantly depending on particular industrial needs and working conditions.

Across user forums and industrial sectors, concerns frequently arise regarding the selection between Hangzhou Grand Technology and BGB Slip Ring. The questions often focus on their respective attributes, features, quality standards, suitability for different environmental conditions, life-cycle costs, and after-sales support. Given this, it is essential to delve deep and compare the products and services offered by both these manufacturers to help potential customers make more informed decisions.

In the threads to follow in this article, we dive into the characteristics, capabilities, strengths, and potential downsides of Hangzhou Grand Technology and BGB Slip Ring’s offerings. The aim is to give a comprehensive picture of these two leading manufacturers, their respective positions in the slip ring industry, and the key considerations to be aware of before choosing a slip ring for your applications.

Introduction to Hangzhou Grand Technology

Brief History and Origins

Hangzhou Grand Technology originated in 2011 in the thriving city of Hangzhou, located in Eastern China. Over the past two decades, it has grown into a leading manufacturer of robust and high-performance slip rings. The company has local and global recognition for its commitment to reliable products and customer-orientated approach.

Company Overview

As a frontrunner in the slip ring manufacturing industry, Hangzhou Grand Technology operates under an ethos of technical excellence and client-driven customization. Their dedicated team consists of experienced engineers who work closely with each client to understand their requirements and offer tailor-made solutions. Emphasizing quality and performance, Hangzhou Grand Technology has built its reputation around delivering reliable and practical slip ring solutions equipped with the latest advancements in the industry.

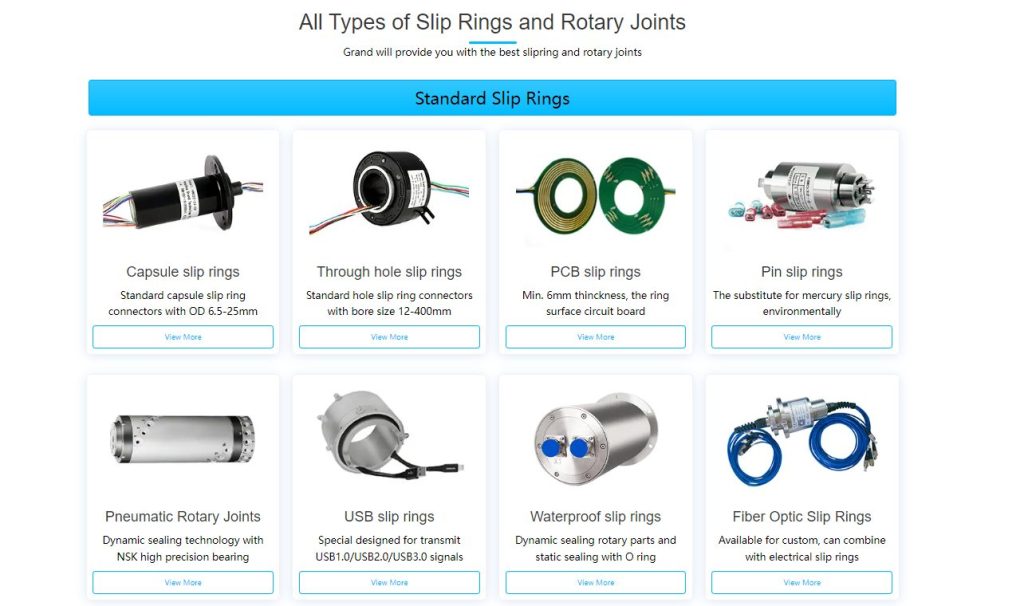

Slip Ring Product Range

The company boasts a comprehensive array of slip rings suited for multiple industries and applications. The product range encompasses capsule slip rings, designed for compact spaces and critical operations, through-hole slip rings for high load capacity and rotational speed, and pancake slip rings, which provide effective solutions for systems with limited axial space. Furthermore, they also produce wind turbine slip rings for renewable energy applications and Ethernet slip rings that accommodate high-speed data transmission.

Unique Features of Slip Rings from Hangzhou Grand Technology

Hangzhou Grand Technology slip rings come with several standout features. These include advanced sealing options that protect the slip ring from dust and moisture, thus ensuring operational longevity and consistent performance in various working environments. Additionally, the company offers high-performance contact materials to provide reliable and durable electrical connections, even under high-speed rotations and variable loads.

Technological Advancements and Innovations

Innovation is at the core of Hangzhou Grand Technology’s philosophy. The company is actively engaged in research and development initiatives to keep its product offerings at the forefront of market trends. They consistently innovate in design, contact materials, and manufacturing techniques to improve performance, reliability, and lifespan. The company’s pursuit of technological advancements fosters continuous improvement in its products, keeping it competitive in a fast-paced industry.

Introduction to BGB Slip Ring

Brief History and Origins

BGB was established in 1976 in the United Kingdom. Initially, the company focused on manufacturing slip rings exclusively for wind turbines but swiftly grew its portfolio to serve a wide range of industries. Over the last four decades, BGB Slip Ring has firmly cemented its position as a global leader in the slip ring manufacturing industry.

Company Overview

BGB Slip Ring’s operations are rooted in a profound dedication to quality, innovation, and superior engineering. With a strong commitment to upholding its high standards in the slip ring industry, the company prides itself on producing top-tier slip rings designed to meet diverse industry needs. BGB places heavy emphasis on research and development, which is reflected in the innovative design and cutting-edge functionality of its products.

Slip Ring Product Range

BGB Slip Ring has an extensive lineup of slip rings to suit a variety of applications. These include capsule slip rings for compact systems, through-bore slip rings for high-speed and high-load applications, and pancake slip rings where only limited height is available. The product range also embraces Fiber Optic Rotary Joints (FORJs), which transmit optical signals or data in systems that have a rotating interface.

Unique Features of Slip Rings from BGB Slip Ring

BGB’s slip rings come with several noteworthy features that set them apart. The company utilizes precious metals in its contacts, ensuring minimal friction, prolonged life expectancy, and exceptional transfer of signals and currents. Additionally, the rings are designed and engineered with greater emphasis on quality and longevity, with rigorous checks and testing implemented in the production process to maintain exemplary levels of quality.

Technological Advancements and Innovations

BGB Slip Ring’s commitment to continual innovation is starkly evident in its product line. The company invests heavily in R&D to refine existing products and bring innovative new solutions to the market. Technological advancements are sought out in harmonization with the evolving needs of consumers, leading to constant improvement of ring design, utilization of new materials, and enhancement of production methods. This focus on innovation ensures that BGB Slip Ring stays ahead of industry trends and continuously serves customers with the best possible solutions for their applications.

Key Differences between Hangzhou Grand Technology vs. BGB Slip Ring

Product Design

While both Hangzhou Grand Technology and BGB Slip Ring offer a range of diverse slip ring designs to suit various industrial applications, BGB often employs a more modular design approach. This allows for greater adaptability within different systems and industries whereas Hangzhou Grand Technology often focuses more on solid build quality.

Manufacturing Processes

Both manufacturers engage in robust manufacturing processes to ensure optimal performance and reliability of their products. However, Hangzhou Grand Technology tends to emphasize automated mass production to meet high demand while BGB Slip Ring focuses on a blend of automation and manual crafting to ensure rigorous quality checks during production.

Materials Used

Typically, Hangzhou Grand Technology employs advanced materials and conventional metals for their contact points, but BGB Slip Ring incorporates precious metals in their contact materials. This results in less abrasion and improved longevity.

Customization Capabilities

Both companies are well-known for their ability to customize offerings as per client requirements. While Hangzhou Grand Technology crafts specific solutions around the client’s needs using adept engineering, BGB Slip Ring often goes one step further in offering bespoke modifications including unique configurations and sizes.

System Compatibility and Integration

BGB Slip Rings are often considered more adaptable due to their modular nature, allowing for easier integration with other devices or components. However, Hangzhou Grand Technology slip rings often come as integrated units, offering robust performance across diverse applications.

Environmental Adaptability

Hangzhou Grand Technology slip rings often incorporate advanced sealing methods to protect against moisture, dust,t, etc., enabling them to operate consistently under tough environmental conditions. Comparably, BGB offers robust slip rings designed to operate efficiently under a wide range of environmental conditions.

Product Certifications and Compliance

Both manufacturers involve rigorous testing and adhere to the relevant safety and quality standards per the industry benchmarks. They have well-established compliance policies in place to ensure high-quality standards and customer satisfaction.

Availability of Components and Spare Parts

Both manufacturers ensure the availability of spare parts to minimize downtime in case of repairs and maintenance. However, the global distribution network of BGB Slip Ring further aids in faster availability and delivery.

Maintenance Requirements

BGB’s use of precious metals in their slip rings often leads to less wear-and-tear, potentially increasing life expectancy and reducing service intervals. Hangzhou Grand Technology’s slip rings are designed for durability and performance but may require regular checks for optimal operation.

Warranty Terms and After-sales Service

BGB Slip Ring invests substantially in after-sales service, offering comprehensive warranty terms and customer service channels. However, Hangzhou Grand Technology also maintains a solid reputation for customer support and offers robust warranties, but the exact terms may vary depending on the specific product and application.

It’s crucial to analyze these differences from the perspectives of particular industrial needs and conditions before selecting a more suitable slip ring supplier.

Key Similarities between Hangzhou Grand Technology vs. BGB Slip Ring

Commitment to Innovation and Research

Both Hangzhou Grand Technology and BGB Slip Ring have established a strong reputation for their commitment to research and innovation. They continuously invest in R&D to stay abreast of industry developments and drive technological advancements in their product offerings.

Industries Served

Given the versatility of their product range, both manufacturers cater to a wide range of industries. This includes renewable energy, defense, manufacturing, telecommunication, and numerous others, underlining their adaptability to varying industry-specific requirements.

Integration with Other Systems

Regardless of differences in their product design approach, both Hangzhou Grand Technology and BGB are well-recognized for offering slip rings that integrate seamlessly with a wide variety of systems. Their solutions are designed to ensure compatibility with other components, thus facilitating smooth and efficient operations.

Customization Capabilities

At the heart of both Hangzhou Grand Technology’s and BGB’s operations lies a customer-centric outlook. They both provide bespoke solutions tailored to match specific client needs, reflecting their focus on delivering tailor-made, effective solutions beyond just off-the-shelf products.

Focus on Customer Service

Customer service is a key pillar for both Hangzhou Grand Technology and BGB Slip Ring. Both companies strive to provide excellent pre-sales consultation, comprehensive after-sales service, and responsive customer support. They are committed to ensuring customer satisfaction, not only through top-tier products but also through high standards of service.

Despite these similarities, the respective advantages offered by Hangzhou Grand Technology and BGB Slip Ring can vary based on the specific needs of the application or sector. Balancing these considerations will be vital for making the most appropriate selection.

Detailed Comparison: Hangzhou Grand Technology vs. BGB Slip Ring

In this section, we’ll present an in-depth comparison between Hangzhou Grand Technology and BGB Slip Ring, focusing on their respective reputations and levels of customer satisfaction.

Hangzhou Grand Technology vs. BGB Slip Ring: Company Reputation and Customer Satisfaction

Both Hangzhou Grand Technology and BGB Slip Ring hold a reputable position within the slip ring manufacturing industry, built over years of dedication to quality, customer service, and innovative product offerings.

Hangzhou Grand Technology

Hangzhou Grand Technology, a relatively younger player in the market, has quickly gained considerable renown for its quality products and competitive pricing. This has been bolstered by their commitment to innovation and the continuous expansion of their product range, which has contributed significantly to positive customer sentiment. Moreover, Hangzhou Grand Technology’s dedication to customer service, inclusive of strong after-sales support and dedicated consultation, paves the way for high levels of customer satisfaction.

BGB Slip Ring

On the other hand, BGB Slip Ring built its reputation over four decades of service in this niche sector. Their commitment to quality, underpinned by the use of precious metal contacts for all their slip rings, is perceived highly among their customers. BGB’s collaborative approach towards understanding their customer’s needs and delivering customized solutions further drives customer satisfaction. Furthermore, BGB’s customer service ethos, shaped around exemplary after-sales service and accessible customer support, solidifies its strong rapport with customers.

In summary, both Hangzhou Grand Technology and BGB Slip Ring have built a strong reputation within the industry and maintain high levels of customer satisfaction. While Hangzhou Grand Technology demonstrates strength in delivering quality products at competitive prices combined with a strong focus on innovation, BGB Slip Ring excels in quality, customization, and sustainability of solutions, supported by its extensive industry experience. Customer preference between the two would likely vary based on specific need parameters, such as cost-effectiveness, product longevity, custom requirements, and support expectations.

Hangzhou Grand Technology vs. BGB Slip Ring: Slip Ring Design and Engineering Capabilities

Hangzhou Grand Technology

With a broad range of slip rings in its portfolio, Hangzhou Grand Technology showcases its well-rounded expertise in slip ring design and engineering. They offer products with advanced designs, including compact slip rings, miniature slip rings, capsule slip rings, and pancake slip rings.

Hangzhou Grand Technology’s design approach leverages automated design and production processes, aligned with their commitment to delivering high-quality, cost-effectively mass-produced slip rings. Their engineering strength is further reinforced by their ability to customize offerings based on specific client requirements, demonstrating their depth in engineering and design capabilities.

BGB Slip Ring

BGB Slip Ring, in comparison, impresses with its extensive industry experience and finely honed design capabilities. Their design expertise extends to standard and specialized slip rings, incorporating features like fiber optic rotary joints, hydraulic rotary joints, and integrated systems. BGB Slip Ring is recognized for leveraging a blend of manual crafting and automation, ensuring that each product undergoes stringent quality checks for optimal performance and longevity. BGB Slip Ring’s standout strength lies in its modular design approach and use of precious metals, manifesting its robust design and engineering capabilities in slip ring manufacturing.

In essence, both Hangzhou Grand Technology and BGB Slip Ring prove their expertise in slip ring design and engineering through their comprehensive product lines, and their dedication to improving product performance, reliability, and longevity. While Hangzhou Grand Technology shines with its more cost-effective, automated solutions, BGB Slip Ring positions itself with a stronger emphasis on quality and highly customized solutions, catered through its modular design approach and use of select materials. This comparison demonstrates how the two companies align their design and engineering capabilities with their respective strategic directions.

Hangzhou Grand Technology vs. BGB Slip Ring: Electrical Performance Characteristics

Hangzhou Grand Technology

Hangzhou Grand Technology’s slip rings reflect their dedication to producing high-quality, reliable products designed to ensure optimal electrical performance. Their slip rings are characterized by low electrical noise, long service life, and stable performance, thanks to advanced design features engineered to cater to various industrial needs. These include features such as an efficient contact system, high-quality materials for conductive elements, and robust insulation and encapsulation to prevent outside interference. Hangzhou Grand Technology’s strength in electrical performance characteristics is also evident in its capability to deliver both high and low currents through its diverse product range.

BGB Slip Ring

BGB Slip Ring, in contrast, is renowned for using precious metals in their contact materials to create products with exceptional electrical performance. Due to the use of these materials, BGB Slip Ring’s products often exhibit reduced electrical noise, lower contact resistance, and increased signal transmission quality compared to conventional metal contacts. Additionally, the modular design of BGB Slip Rings allows for improved customization and integration, with consideration for clients’ specific electrical performance criteria, such as the number of circuits, current capacity, and voltage requirements.

In summary, both Hangzhou Grand Technology and BGB Slip Ring take pride in delivering high-performance slip rings characterized by their ability to transmit signals and power efficiently, with minimal signal interference and low noise. While Hangzhou Grand Technology emphasizes the quality and reliability of a wide product range, BGB Slip Ring further differentiates itself through its use of precious metals and modular designs that cater to a diverse set of electrical performance expectations. Ultimately, the suitability of either company’s solutions will depend on specific project requirements and performance criteria.

Hangzhou Grand Technology vs. BGB Slip Ring: Mechanical Performance Characteristics

Hangzhou Grand Technology

Hangzhou Grand Technology focuses on constructing slip rings that excel in terms of durability, reliability, and efficiency. Their products are engineered to perform exceptionally well under various operational conditions, including different RPMs, operating temperatures, and lifecycle requirements. One of their strong advantages lies in their miniature and compact slip rings. These designs are particularly well-suited for space-restricted applications without compromising mechanical performance. The use of advanced materials and rigorous construction practices result in slip rings with low friction, minimizing wear and tear, thus ensuring a long operational life.

BGB Slip Ring

BGB Slip Ring, with decades of industry experience, produces slip rings with a focus on robustness and unmatched mechanical performance. Their use of high-quality materials and superior crafting techniques ensures smooth operation even under more challenging conditions, including higher speeds, extreme temperatures, and corrosive environments. BGB’s mechanical performance is further enhanced through its modular and integrated design approach, allowing for efficient customization to better suit complex application requirements.

In conclusion, both Hangzhou Grand Technology and BGB Slip Ring deliver reliable mechanical performance, underlined by robust design and construction methods. Hangzhou Grand Technology offers strength in compact slip rings that deliver reliable, efficient performance in space-constrained applications. BGB Slip Ring sets itself apart with its approach to robust construction, modular design, and reliability under extreme conditions. Users’ choice between the two would pivot on their specific mechanical requirements in terms of operational conditions and lifecycle expectations.

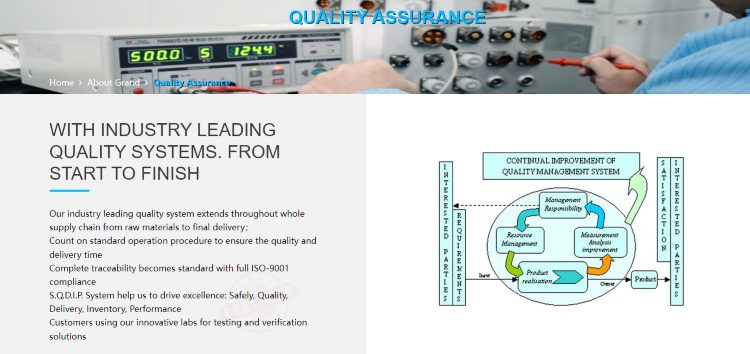

Hangzhou Grand Technology vs. BGB Slip Ring: Manufacturing Processes and Quality Control

Hangzhou Grand Technology

Hangzhou Grand Technology leverages cutting-edge technology and automated systems in its manufacturing processes, reflecting its commitment to improving production efficiency while maintaining a high level of quality. By utilizing both manual and automated assembly lines, the company ensures a balance between cost and quality control. Hangzhou Grand Technology is certified to ISO 9001 quality management systems, evidencing its adherence to stringent manufacturing standards. Furthermore, the company employs rigorous quality control methods, including regular quality inspections and strict testing procedures, to guarantee product reliability and performance.

BGB Slip Ring

BGB Slip Ring, on the other hand, combines expertise acquired over four decades with a blend of manual crafting and automation in their manufacturing processes. This synthesis of traditional craftsmanship and modern technology has allowed BGB to develop slip rings that meet high-quality and reliability standards. Quality control at BGB Slip Ring is exemplified by its adherence to the ISO 9001, ISO 14001, and OHSAS 18001 certifications as well as the AS 9100 aerospace standard. This showcases the company’s rigorous quality control efforts across all aspects of manufacturing, including state-of-the-art inspection and testing methodologies.

In summary, both Hangzhou Grand Technology and BGB Slip Ring are dedicated to ensuring the production of high-quality, reliable slip rings through their advanced manufacturing processes and quality control measures. While Hangzhou Grand Technology focuses on combining efficient automation with rigorous testing procedures, BGB Slip Ring emphasizes traditional craftsmanship paired with modern technology and exacting quality standards as dictated by its multiple certifications. Each company’s approach to manufacturing and quality control allows them to excel in their respective market positioning—competitive pricing and reliable performance for Hangzhou Grand Technology, and high-quality, custom solutions for BGB Slip Ring.

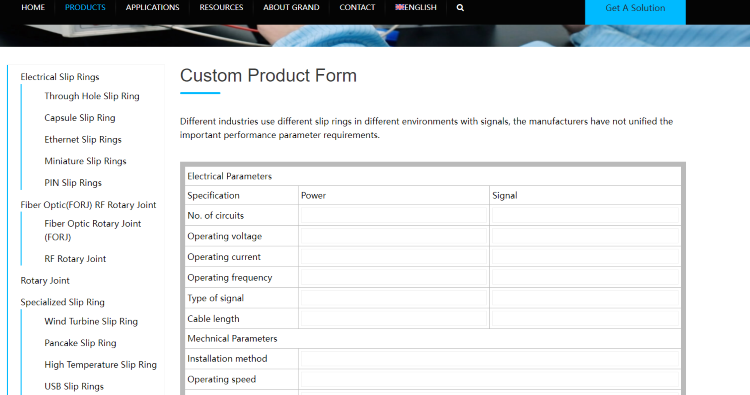

Hangzhou Grand Technology vs. BGB Slip Ring: Customization Capabilities

Hangzhou Grand Technology

Hangzhou Grand Technology demonstrates its ability to cater to client-specific needs by offering a wide range of customizable slip rings. By understanding their customers’ unique requirements, they provide tailored solutions in their slip rings’ design, size, materials selection, and additional features such as integrated systems. Hangzhou Grand Technology’s flexibility in customization is essential in adapting its products to fit various industries, such as robotics, wind power, medical equipment, and marine technology. This adaptability demonstrates their engineering capacity and commitment to meeting client expectations.

BGB Slip Ring

BGB Slip Ring showcases a deep understanding of customization in the slip ring industry. They capitalize on their modular design approach, which enables the development of unique slip ring assemblies by integrating mechanical, electrical, and data communication components per the customers’ requirements. This modular system facilitates adaptability to client’s needs and ensures the perfect fit for a broad range of specialized applications. BGB’s customization capabilities extend to handling complex requirements, such as high-performance data transmission, high current and voltage capacities, and unique environmental conditions.

In conclusion, both Hangzhou Grand Technology and BGB Slip Ring exhibit strong customization capabilities, proving their commitment to meeting clients’ needs in diverse industries and applications. Hangzhou Grand Technology emphasizes flexibility in design, size, and features, adjusting its product range to suit various applications. BGB Slip Ring’s distinct advantage lies in its modular design strategy, which allows it to create highly tailored solutions through the integration of mechanical, electrical, and data communication components. Ultimately, the choice between the two companies would hinge on a project’s specific requirements and the desired level of customization.

Hangzhou Grand Technology vs. BGB Slip Ring: Product Durability and Reliability

Hangzhou Grand Technology

Hangzhou Grand Technology has built a reputation for producing durable and reliable slip rings engineered to perform under various operational conditions. The company accentuates the use of high-quality materials in fabricating its products and combines them with advanced design principles to optimize lifespan and performance. Also, their attention to protective measures such as robust insulation and encapsulation not only improves product durability but also ensures consistent and stable performance across a wide range of applications.

BGB Slip Ring

BGB Slip Ring, with its extensive industry experience, is committed to delivering highly durable and reliable slip rings. Their use of precious metals in contact materials contributes significantly to product lifespan and dependable performance. BGB’s slip rings are designed to withstand rigorous use, including high rotation speeds, and extreme environmental conditions, significantly enhancing their durability. Their commitment to quality and adherence to industry standards reinforces the reliability of their products, making them a trusted choice for various industries.

In summary, both Hangzhou Grand Technology and BGB Slip Ring emphasize product durability and reliability, which are critical to ensuring optimal performance in various applications. Hangzhou Grand Technology prioritizes advanced design elements and robust protective measures to enhance product lifespan, while BGB Slip Ring emphasizes the use of quality materials and compliance with industry standards to ensure reliable performance. Depending on the specific applications and operational conditions, users can select either provider based on their particular durability and reliability requirements.

Hangzhou Grand Technology vs. BGB Slip Ring: Technical Support and After-sales Services

Hangzhou Grand Technology

Hangzhou Grand Technology is highly committed to providing excellent technical support and after-sales services. Their wide-ranging technical support includes comprehensive pre-sales consulting, problem diagnostics, and tailor-made solutions, facilitated by their team of experienced engineers. State-of-the-art online tools and direct communications channels are utilized to ensure swift and effective support. Furthermore, their after-sales services, including warranties and troubleshooting assistance, demonstrate their promise to customer satisfaction even after the point of sale.

BGB Slip Ring

BGB Slip Ring stands out with its robust technical support and after-sales services, which have been established based on its deep understanding of the industry and customer needs. A team of highly experienced technicians offers 24/7 support with installation, maintenance, and troubleshooting, helping customers maximize their return on investment. Furthermore, BGB offers impressive warranty terms and quick response times to malfunction reports, forming the cornerstone of their after-sales services. Regular maintenance and product upgrade services are also in place to ensure the product’s optimal use throughout its lifespan.

In conclusion, both Hangzhou Grand Technology and BGB Slip Ring take pride in providing top-notch technical support and after-sales services. While Hangzhou Grand Technology leverages advanced communication channels and a dedicated team of engineers for their service delivery, BGB Slip Ring stands out with its round-the-clock support, impressive warranty terms, and proactive maintenance services. Customers’ choices between the two will mainly depend on their preferences concerning service delivery, warranty terms, and the nature of their business operations.

Hangzhou Grand Technology vs. BGB Slip Ring: Product Range and Availability

Hangzhou Grand Technology

Hangzhou Grand Technology offers an extensive range of slip ring products, ensuring they cater to various industry needs. Their portfolio includes capsule slip rings, through-hole slip rings, ethernet slip rings, and even customized slip rings with specific characteristics tailored to the client’s requirements. Equipped with a technologically advanced manufacturing facility, Hangzhou Grand Technology can maintain high production rates, ensuring product availability even in the case of bulk orders or short notice requirements.

BGB Slip Ring

BGB Slip Ring also boasts an impressive product range, showcasing its years of industry expertise. From traditional slip rings to fiber optic rotary joints, hybrid slip rings, and even underwater slip rings, BGB’s diverse portfolio is engineered to meet requirements from various demanding applications. Their robust manufacturing processes and sufficient inventory levels enable BGB to promptly address customer needs, ensuring product availability promptly.

In conclusion, both Hangzhou Grand Technology and BGB Slip Ring exhibit a broad product range, reflecting their capability to cater to a multitude of industry requirements. Hangzhou Grand Technology offers an array of slip rings and ensures product availability through high production rates, while BGB Slip Ring distinguishes itself with a diverse assortment of specialized slip rings and efficiently managed inventories. The decision between the two companies will hinge on the specific types of slip rings required and the urgency of product availability needs.

Hangzhou Grand Technology vs. BGB Slip Ring: Cost-effectiveness and Value for Money

Hangzhou Grand Technology

Hangzhou Grand Technology takes into account the economic concerns of its clients by striving to provide cost-effective solutions without compromising on product quality. They focus on efficient manufacturing processes and bulk sourcing of high-quality materials, which helps them to keep production costs in check. As a result, customers get high-quality, durable, and reliable slip rings at competitive prices, making Hangzhou Grand Technology a valuable option for budget-conscious companies

BGB Slip Ring

BGB Slip Ring, on the other hand, values the concept of “value for money” and justifies its product pricing with a comprehensive package of benefits. Their high-grade materials, advanced design principles, rigorous testing procedures, and excellent after-sales services contribute to the overall value offered by their slip rings. While their upfront costs may seem higher compared to other manufacturers, the longevity, reliability, and reduced maintenance costs of their products validate the investment over the long term.

In conclusion, both Hangzhou Grand Technology and BGB Slip Ring offer cost-effectiveness and value-for-money options in the field of slip rings. Hangzhou Grand Technology appeals to budget-conscious companies with its efficient manufacturing process and competitive pricing, while BGB Slip Ring offers a comprehensive package that includes product durability, reliable performance, and top-notch after-sales services to provide excellent value for money. Potential customers should carefully consider their long-term needs and budget before choosing between these two robust options.

Conclusion

In summary, the BGB Slip Ring is often the go-to choice for cutting-edge technology, engineering excellence, and a higher standard of quality. However, the price of their products tends to be higher compared to Hangzhou Grand Technology. On the other hand, Hangzhou Grand Technology offers a more accessible range of slip ring solutions at competitive prices, making them ideal for budget-conscious clients who still require dependable performance.

When choosing between Hangzhou Grand Technology and BGB Slip Ring for slip ring applications, it is essential to understand your specific needs, budget constraints, and overall requirements. By evaluating the factors discussed in this article, you can make an informed decision and select the most suitable slip ring solution for your application.

See What We Can Do