Slip rings are fundamental to the successful operation of many modern machines and systems. They facilitate the transmission of electrical signals and power between stationary and rotating parts, making them crucial in various industries including wind energy, medical, automotive, and telecommunications. Two key players in the slip ring manufacturing arena are Hangzhou Grand Technology and IEC Corporation. Both companies are recognized globally for their commitment to quality, innovation, and customer satisfaction. Yet, their unique operational strategies, target markets, and product offerings reveal significant differences. It’s these contrasts and comparisons that place a valid and interesting discourse for professionals and consumers alike.

In this in-depth comparison, we take a closer look at both companies, paying particular attention to their respective histories, offerings, and overall positioning within the global market. Industry professionals, potential customers, and competitors will find this comparative study particularly insightful when looking to understand and navigate the ever-evolving slip ring landscape. With an understanding of slip ring technology’s importance in various sectors, the quality and reliability of said products cannot be understated. Thus, the relevance of comparing Hangzhou Grand Technology and IEC Corporation Slip Ring lies in the potential to shed light on the subtleties between their products, helping stakeholders make an informed decision when it comes to sourcing slip rings for diverse applications.

In essence, this article serves to compare and contrast these two global players on various facets, from their origins and market focus to their innovation strategies, manufacturing practices, and after-sales services. This analysis caters to a wide audience, including customers seeking the best slip ring solutions, industry players keen to understand competition, and potential investors. By bridging insights and information gaps, the comparison aims to enhance knowledge and catalyze intelligent decision-making in the vital area of slip ring application and procurement.

Introduction to Hangzhou Grand Technology

In the world of slip ring manufacturing, China-based Hangzhou Grand Technology is a name powerfully linked to impressive commitment and dynamism. Founded in early 2011, the company has steadily risen through the industry ranks, achieving a reputable standing as a reliable and innovative manufacturer. Its growth story is one characterized by a strong focus on technology, customer-centricity, and a deep intuition for market dynamics. The company’s leadership believes in maintaining a perfect balance between traditional manufacturing practices and evolving technological trends, allowing them to stay ahead in a competitive landscape.

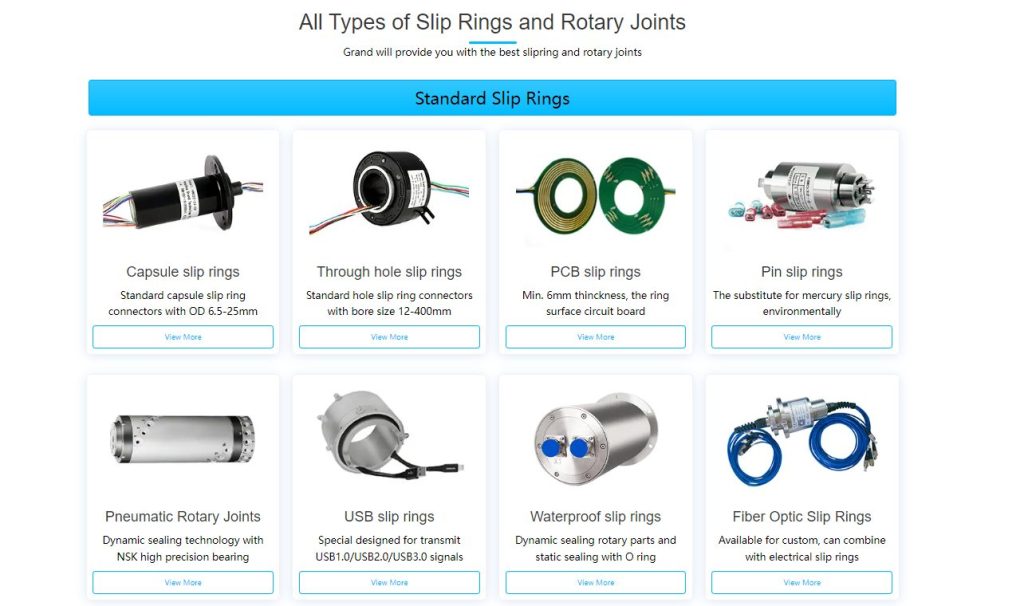

In terms of product offering, Hangzhou Grand Technology’s portfolio is comprehensive, inclusive, and innovative. They manufacture a wide array of slip rings, ranging from mini slip rings, capsule slip rings, through hole slip rings, to more complex and customized versions like the Ethernet slip rings and wind turbine slip rings. They are especially revered in the industry for their ability to tailor offerings according to client demands, presenting a blend of standard and custom solutions that accommodate various applications and industries.

Their products are known for their reliability, durability, and exceptional performance, salient features that have fueled Hangzhou Grand Technology’s reputation. This has, in turn, enabled them to penetrate multiple markets and industries around the globe. While their primary market is Asia, they have vigorously extended their reach beyond the continent. Today, some of the primary industries Hangzhou Grand Technology serves include telecommunications, medical imaging and devices, wind power, automotive, and security systems. This vast industry coverage marks its status as a prominent player, adeptly catering to diverse industry requirements with high-quality, cost-effective, and innovative slip ring solutions.

Introduction to IEC Corporation Slip Ring

IEC Corporation holds a distinctive place in the global slip ring industry. Established over five decades ago, substantial experience and global insights have ingrained the company with conscious industry reflexes and adeptness. Born out of a vision to build mechanically and electrically superior slip rings that push past conventional capabilities, they have continually demonstrated an unmatched commitment to innovation since their inception. Today, IEC Corporation stands as a testament to unyielding quality and steadfast dedication towards advancements in slip ring technology.

When it comes to product offerings, IEC Corporation treads the pathway of sophistication and specialization. They have a broad-ranging catalog featuring capsule slip rings, high-frequency/RF rotary joints, and pancake slip rings, among others. However, their standout attribute exists not only in the breadth of their offerings but also in their unique ecology of solutions. Each product is meticulously designed with attention to detail and a focus on high performance, durability, and minimal maintenance requirements.

This relatability to diverse needs has elevated them to be a supplier-of-choice in industries demanding the best. Over the years, their slip rings have been integrated into a wide array of systems, from medical and marine equipment to renewable energy production and defense technology. IEC Corporation’s key markets are spread across North America, Europe, and parts of Asia. Their slip ring solutions find applications in a variety of sectors, such as wind energy, defense, heavy industries, marine applications, and medical equipment, enabling them to cater to a broad and discerning customer base. Their global footprint is a testament to the undeniable versatility and immeasurable quality of their products, highlighting their place as a leading global supplier within the slip ring industry.

Key Differences between Hangzhou Grand Technology vs. IEC Corporation Slip Ring

Several distinctive differences between Hangzhou Grand Technology and IEC Corporation Slip Ring set them apart in the global slip ring industry.

The primary distinction lies in their market positioning and target audience. Hangzhou Grand Technology, with its aggressive and competitive pricing models and alignment towards customization, has positioned itself as a value champion in the industry, particularly appealing to price-sensitive markets that also cherish customizability and reliable performance. The primary market focus remains Asia, but its global outreach is expanding, suggestive of its growing ambitions.

IEC Corporation, on the other hand, primarily operates in the opulent markets of North America and Europe, focusing on customers who prioritize innovation, reliability, and high performance over just cost. Their global-centric approach ensures their products cater to a more extensive and diverse user base. Harmonizing with world-class quality standards, IEC Corporation has crafted its image as a premium provider of slip ring solutions, providing value in terms of longevity, robustness, and state-of-the-art technology.

Another crucial difference between the two companies lies in the breadth of their product offerings and customization options. Hangzhou Grand Technology emphasizes a wide product line, aiming to meet the versatile demands of different sectors with both standard and customized solutions. IEC Corporation, while maintaining a diverse product retinue, seems to lean more towards specializations with bespoke solutions fine-tuned for high-performance applications.

Lastly, pricing models and value propositions significantly vary between the two companies. Hangzhou Grand Technology leverages cost-effective manufacturing practices in Asia to offer competitively priced solutions, posing an attractive value proposition for cost-conscious customers who demand customization. Conversely, IEC Corporation’s value proposition sits with absolute quality and innovation, justifying a higher price tag necessitated by cutting-edge R&D investments and high-performance solutions. Their clientele appreciates the intricacies of their high-precision slip ring solutions, willingly accepting the premium for their exceptional quality and reliability.

In essence, the two companies cater to slightly different segments within the vast slip ring market, each offering unique selling propositions under different pricing models to meet their targeted customers’ varied needs. Such contrasts underscore how competition and diversity within the slip ring industry cater to the wide spectrum of industrial and consumer specifications.

Key Similarities between Hangzhou Grand Technology vs. IEC Corporation Slip Ring

Despite their visible differences, Hangzhou Grand Technology and IEC Corporation share several core similarities that underscore their place as popular and respected choices in the slip ring market.

One fundamental uniformity is their shared commitment to quality and reliability. Both companies place a high emphasis on producing slip rings that can withstand the test of time and usage. Stringent quality controls and proactive quality management measures are hallmarks of both corporations’ production processes. This fierce focus on quality has led both companies to achieve respective reputations for producing reliable and robust slip rings. Whether it’s the versatile requirements catered to by Hangzhou Grand Technology or the specialized demands met by IEC Corporation, quality is a non-negotiable theme.

The backbone of this quality commitment is underpinned by their notable industry experience and presence. Both Hangzhou Grand Technology and IEC Corporation have spent an extensive amount of time in the industry. Hangzhou Grand Technology, though younger than IEC Corporation, has swiftly grown and consolidated its place in the Asian and global markets. Meanwhile, the considerable years of operation of IEC Corporation have steeped the company in rich and varied industry experiences.

Finally, both companies have embarked on a mission of global reach, making their products available to a worldwide customer base. While their primary markets might differ, Hangzhou Grand Technology and IEC Corporation have ensured their innovative offerings span the globe, bringing their unique blend of quality and performance to customers near and far. Their global reach is closely tied to their provision of customer support — both companies offer reliable after-sales services underpinned by technical support, product maintenance, and customer inquiries.

In conclusion, despite differing market positions and product strategies, Hangzhou Grand Technology and IEC Corporation share a similar ethos in terms of quality, experience, and customer care, reflecting their shared dedication to excellence within the slip ring industry.

Detailed Comparison: Hangzhou Grand Technology vs. IEC Corporation Slip Ring

Hangzhou Grand Technology vs. IEC Corporation Slip Ring: Product Range and Customization Capabilities

The product ranges and customization capabilities of Hangzhou Grand Technology and IEC Corporation differ in nuanced ways, reflecting their unique market focus, customer requirements, and strategic directions.

Hangzhou Grand Technology

Hangzhou Grand Technology offers a wide-ranging product line that morphs with the manifold needs of the industries it serves. Their collection of slip rings encompasses miniature slip rings, capsule slip rings, through-bore slip rings, Ethernet slip rings, and wind turbine slip rings, to name a few. This vast product offering enables Hangzhou Grand Technology to cater to the diverse needs of various industries and applications.

However, the company shines brightest in its customization capability. Hangzhou Grand Technology is reputed for its ability to create and adapt existing products, addressing customer-specific requirements with a remarkable level of precision. Its strategic orientation towards customization provides a strong differentiator for the company, particularly in the highly price-competitive Asian market, where customers value bespoke solutions without sacrificing affordability.

IEC Corporation Slip Ring

On the other side, IEC Corporation likewise maintains an expansive product line, boasting offerings such as capsule slip rings, high frequency/RF rotary joints, and pancake slip rings, among others. While their offering covers a broad spectrum of slip rings, IEC Corporation’s focus is more on specialization and sophistication, attending to high-performance applications with consummate delicacy.

IEC Corporation offers customized solutions catering to unique industry-specific concerns while favoring artful, high-end slip ring designs for demanding applications. This focus has channeled the company’s expertise to furnish sectors such as defense, marine, and medical with specialized components, ensuring premium performance is met even for the most fastidious client.

Comparatively, both Hangzhou Grand Technology and IEC Corporation offer a diversified product range that can be tailored according to clients’ needs. However, these companies cater to different markets and customer expectations, resulting in distinct strategic positions in terms of customization. Hangzhou Grand Technology emphasizes affordability and adaptation for cost-sensitive markets, while IEC Corporation obliges discerning customers seeking specialized and sophisticated slip ring solutions for niche, high-performance applications.

Hangzhou Grand Technology vs. IEC Corporation Slip Ring: Quality Control and Certifications

Quality control and certifications form a fundamental aspect of the slip ring industry as they directly impact the safety, longevity, and performance of the products. Both Hangzhou Grand Technology and IEC Corporation appreciate this importance, instituting rigorous quality control measures alongside obtaining vital industry certifications.

Hangzhou Grand Technology

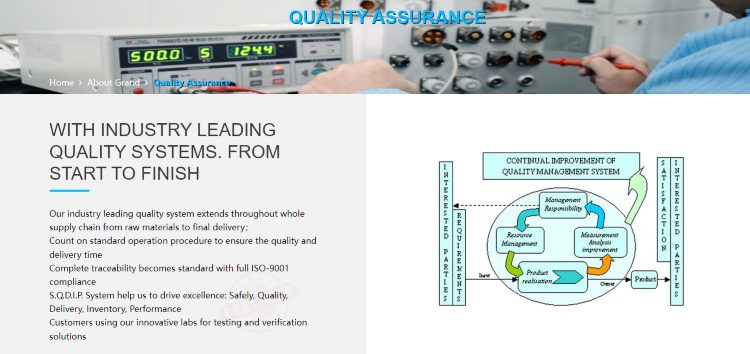

Hangzhou Grand Technology takes pride in its quality management systems, deploying advanced manufacturing and QC processes to ensure production consistency. It has established systematic and standardized production lines, accompanied by testing equipment like 3D measurement machines for precise inspection. Moreover, customer feedback is integral to their ongoing quality improvement efforts. Hangzhou Grand has earned multiple vital certifications, including ISO9001:2015, illustrating a commitment to international quality standards.

IEC Corporation Slip Ring

On the other hand, IEC Corporation, with its extended industry presence and targeting the highly regulated markets of North America and Europe, follows stringent quality controls based on decades of evolved practices and feedback. The company has robust QC measures in place, ranging from meticulous raw material sourcing and inspection, and precision-oriented production practices, to stringent post-production assessments. This rigor ensures its products are consistent in terms of premium quality and performance. In terms of certification, the IEC holds internationally recognized certifications, affirming their compliance with pivotal regulatory standards.

Comparatively, both Hangzhou Grand Technology and IEC Corporation demonstrate a commitment to maintaining high quality and safety standards. However, given the IEC’s operations in the more stringent regulatory environments of North America and Europe, its QC measures and certification needs are probably more extensive. Meanwhile, Hangzhou Grand Technology, while also committed to quality, primarily caters to the Asian markets’ quality and safety expectations, thus structuring its QC processes and certifications accordingly.

Hangzhou Grand Technology vs. IEC Corporation Slip Ring: Research and Development Initiatives

Progressive advancements in industrial technology underscore the need for active research and development initiatives within the sector. Both Hangzhou Grand Technology and IEC Corporation meet these evolving demands, though their R&D strategies differ based on their target markets and core competencies.

Hangzhou Grand Technology

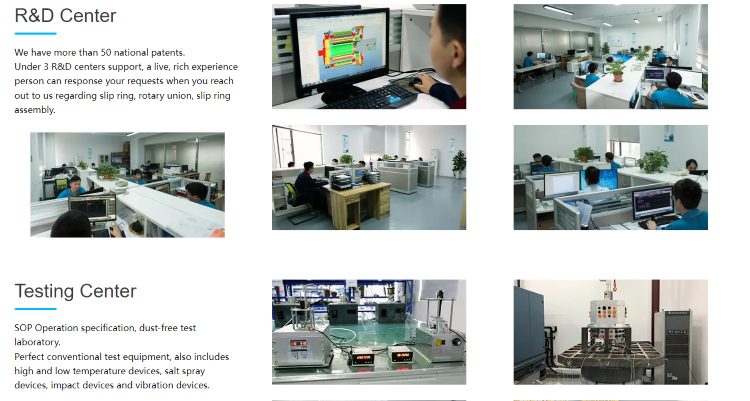

Hangzhou Grand Technology, in line with its strategic aim of versatility, affordability, and customizability, focuses its R&D initiatives on blending performance with cost-efficiency. This approach ensures their products maintain a competitive edge in the Asian market, which is often price-sensitive but also demanding due to rapid industrial growth. Hangzhou Grand Technology’s R&D efforts revolve around optimizing manufacturing processes to keep costs down, improving the performance-to-price ratio of their products, and innovating on design dynamics to accommodate diverse customization demands.

IEC Corporation Slip Ring

For IEC Corporation, the accent on R&D aligns with their emphasis on innovation and high-performance solutions. As a company operating primarily in the opulent markets of North America and Europe, where technological advances move at a rapid pace, IEC invests heavily in cutting-edge research that fuels the development of premium solutions. This strategy manifests in their products, characterized by sophisticated designs and robust performance that meets the needs of specialized, high-performance applications. Their R&D is also instrumental in advancing their specialization strategy by developing new high-end, niche slip rings.

In summary, both Hangzhou Grand Technology and IEC Corporation prioritize R&D within their operational framework, albeit with differing focus areas. Hangzhou Grand Technology aims at affordable performance, derived through manufacturing optimization and design customization. In contrast, IEC Corporation invests in innovations that deliver premium, high-performance slip ring solutions tailored for niche applications.

Hangzhou Grand Technology vs. IEC Corporation Slip Ring: Intellectual Property and Patents

Intellectual property and patents form an essential part of technology and product enhancements, especially in a dynamic and highly competitive industry like slip rings. Both Hangzhou Grand Technology and IEC Corporation have focused on this area, albeit following different paths that reflect their unique market positions and strategic orientations.

Hangzhou Grand Technology

Hangzhou Grand Technology, given its broad product range and step-up in customization capabilities, has accumulated a series of intellectual properties. These primarily revolve around their optimized designs and manufacturing processes that allow the company to provide cost-effective and bespoke solutions to their customers. Also, the company’s intellectual properties reflect its commitment to creating products that are adaptive to the varying customer requirements prevalent in the Asian market.

IEC Corporation Slip Ring

IEC Corporation, on the other hand, proliferates in high-end, specialized slip ring solutions. Consequently, its intellectual property portfolio reflects this directional focus. The company holds patents for specialized product designs and technological innovations that imbibe a higher degree of sophistication and reliability – aspects critical to the premium markets it operates in, such as the defense, medical, and marine sectors. IEC Corporation’s patents also echo its strong emphasis on continuous R&D, fostering high-performance, original solutions.

In essence, while both Hangzhou Grand Technology and IEC Corporation place value on intellectual property and patents, their focus areas differ. Hangzhou Grand’s patents underscore their efficient designs and tailored solutions for cost-sensitive markets, while IEC Corporation’s intellectual properties reflect their emphasis on building specialty, high-performance slip rings catering to niche yet demanding sectors.

Hangzhou Grand Technology vs. IEC Corporation Slip Ring: Manufacturing Capabilities and Production Efficiency

Manufacturing capabilities and production efficiency are integral to the slip ring industry as they dictate product availability, cost, and, in many ways, quality. Hangzhou Grand Technology and IEC Corporation, while both major players in this industry, have different manufacturing offerings reflecting their unique market orientations.

Hangzhou Grand Technology

Hangzhou Grand Technology’s manufacturing capabilities are set to accommodate a wide range of product variants while ensuring cost-effectiveness. This strategy is in sync with its orientation toward catering to a broad, price-sensitive market with differing needs. Their manufacturing setup operates on systematic and standardized production lines, allowing for quick scale-ups to meet customer demands. Also, continual refinement of these processes to boost efficiency is at the heart of Hangzhou Grand’s operations, ensuring their products remain cost-competitive.

IEC Corporation Slip Ring

On the contrary, IEC Corporation’s manufacturing realm focuses on specialized slip ring production, aligned with its market dominance in high-performance, niche applications. Their production framework is engineered for precision and consistency more than for scale. This focus manifests in their high-grade raw material sourcing, meticulous production processes, and rigorous quality control procedures. This setup allows IEC to ensure the production of high-end, reliable products in line with their market positioning.

To summarize, both Hangzhou Grand Technology and IEC Corporation exhibit robust manufacturing capabilities and production efficiency, tailored to their unique business strategies. While Hangzhou Grand Technology leans towards cost-effective large-scale manufacturing, IEC Corporation complicates a more specialized, precision-oriented production setup to meet its high-performance market’s requirements.

Hangzhou Grand Technology vs. IEC Corporation Slip Ring: Pricing Models and Affordability

In a competitive industry such as the slip ring manufacturing sector, pricing models and affordability play a critical role in a company’s market positioning and strategic orientation. Hangzhou Grand Technology and IEC Corporation, given their different target markets and product portfolios, present contrasting pricing strategies that correspond to their unique business models.

Hangzhou Grand Technology

Hangzhou Grand Technology built a business model targeting the broader and price-sensitive Asian market. The company’s focus on customization and cost-effectiveness significantly dictates its pricing models. The balanced blend of cost-effective manufacturing capabilities, and strategic sourcing of raw materials, coupled with efficiency-driven operational processes, allows Hangzhou Grand to maintain a competitive pricing strategy. Consequently, the company can attract a broader customer base that appreciates the interplay between affordability and functionality.

IEC Corporation Slip Ring

Alternatively, IEC Corporation caters to a different market segment, which primarily consists of North American and European companies requiring high-performance, niche slip ring solutions. Given their specialty in advanced, high-end products, and the high cost of rigorous R&D and quality control measures they uphold, IEC’s pricing model naturally tilts towards the premium side. Though perceived as less affordable compared to Hangzhou Grand, IEC’s pricing aligns well with its target customers’ willingness to pay for superior performance, reliability, and ongoing technological innovation.

In sum, Hangzhou Grand Technology and IEC Corporation adopt different pricing strategies, shaped by their unique market positioning, manufacturing strategies, and customer expectations. While Hangzhou Grand emphasizes affordability to appeal to its price-sensitive markets, IEC Corporation justifies premium pricing with high-end, specialized products that cater to a segment willing to pay for reliable and advanced slip ring solutions.

Hangzhou Grand Technology vs. IEC Corporation Slip Ring: Delivery Times and Logistics

Delivery and logistics form an essential part of the customer experience in the slip ring manufacturing industry. Meeting the client’s delivery expectations relies on efficient manufacturing capabilities, strong supply chain management, and reliable logistics partners. Both Hangzhou Grand Technology and IEC Corporation streamline their processes to ensure prompt and efficient delivery, although their delivery times differ based on their target markets and product complexities.

Hangzhou Grand Technology

Hangzhou Grand Technology, with its emphasis on serving a wide range of customers across the Asian market, has developed its logistical processes to ensure timely deliveries. This involves optimizing its standardized production lines, which allows the company to respond quickly to customer demands. It also maintains a comprehensive inventory of components to expedite production when required, further ensuring a quicker delivery time. Hangzhou Grand has forged strong partnerships with regional logistics providers to minimize transit times, delivering product orders cost-effectively and promptly.

IEC Corporation Slip Ring

Comparatively, IEC Corporation focuses on producing niche, high-performance slip rings for specialized applications in highly regulated markets, including North America and Europe. Given the complex nature of these products and the stringent quality control required, manufacturing lead times can be comparatively longer than those for standard slip rings. IEC Corporation prioritizes precision and reliability over speed when it comes to product development. However, once the products pass through meticulous quality checks, IEC works closely with reputable international logistics providers to ensure the fastest possible delivery times. Generally, IEC Corporation’s delivery times are compatible with their client’s expectations in the high-end slip ring market.

In conclusion, both Hangzhou Grand Technology and IEC Corporation place great importance on meeting their customers’ delivery expectations, even though their target markets and products have significantly different requirements. Hangzhou Grand capitalizes on efficient production and regional logistics partnerships to achieve rapid deliveries, while IEC Corporation focuses on maintaining the premium manufacturing standards high-end markets require, relying on international logistics partners to expedite product deliveries.

Hangzhou Grand Technology vs. IEC Corporation Slip Ring: Customer Support and After-sales Services

Extending beyond just the product offering, customer support, and after-sales services have a significant influence on customer satisfaction and loyalty in the slip ring industry. Hangzhou Grand Technology and IEC Corporation take distinctive approaches to this area of their operations, a reflection of their individual market focus and customer needs.

Hangzhou Grand Technology

Hangzhou Grand Technology, targeting a broad but price-sensitive market, has woven affordability into its after-sales services without compromising on quality. These services include technical support, limited warranty periods, and cost-effective repair or replacement policies. The company structures its customer support around addressing concerns, queries, and issues swiftly and effectively, often leveraging its regional network and constructing feedback mechanisms to understand and better cater to its customers’ needs.

IEC Corporation Slip Ring

IEC Corporation, with its foothold in the high-end segment, has constructed comprehensive customer support tailored to its clientele. It offers technical consultations, dedicated account management, and an extensive warranty period on its products. IEC Corporation’s after-sales services are characterized by their assurance of product longevity and performance, complementing the advanced and specialized nature of their slip ring solutions. IEC’s customer support team works closely with its clients, maintaining open lines of communication, and providing prompt and competent support to any issues or queries.

In summary, the customer support and after-sales service strategies of Hangzhou Grand Technology and IEC Corporation mirror their overall business approach and the specific needs of their respective markets. Hangzhou Grand combines affordability with efficient resolution to meet its customers’ needs, while IEC Corporation promises a comprehensive, top-tier level of support in line with its high-performance product offerings.

Hangzhou Grand Technology vs. IEC Corporation Slip Ring: Sustainability Practices

In today’s rapidly globalizing world, sustainability practices have a growing impact on a company’s brand image, customer relationships, and eventually, its bottom line. Both Hangzhou Grand Technology and IEC Corporation have adopted measures to address sustainability in their operations, reflecting an evolving industry mindset towards more responsible manufacturing and business practices.

Hangzhou Grand Technology

Hangzhou Grand Technology, dealing with a wide customer base across various Asian markets, requires a robust and scalable approach to sustainability. The company employs green manufacturing processes by adhering to protocols that minimize the use of harmful elements in the manufacturing process of their slip rings. They ensure waste is managed appropriately and invest in energy-efficient production models. Additionally, they leverage technology to reduce carbon output and environmental footprint.

IEC Corporation Slip Ring

IEC Corporation, well-known for precision products demanded by the high-end sector, pays due attention to sustainability in its operations. They abide by North American and European environmental regulations, incorporating various green initiatives into their production processes. Their sustainability practices are centered around reducing energy consumption, sourcing sustainable raw materials, and maintaining waste management protocols. Additionally, IEC Corporation utilizes advanced technology to ensure an environmentally friendly manufacturing process.

In conclusion, both Hangzhou Grand Technology and IEC Corporation demonstrate a notable commitment to sustainability, remarkable in their distinguished approaches. Hangzhou Grand focuses on green manufacturing and energy-efficient production, while IEC Corporation prioritizes regulatory adherence, energy conservation, and sustainable materials. This adherence to sustainability within the slip ring manufacturing industry illustrates the importance both companies place on environmental consciousness and future-oriented business practices.

Hangzhou Grand Technology vs. IEC Corporation Slip Ring: Supplier Relationships and Sourcing Practices

Supplier relationships and sourcing practices strongly influence the manufacturing landscape, ultimately playing a vital role in determining product quality, production costs, ability to meet deadlines, and overall business sustainability. As such, Hangzhou Grand Technology and IEC Corporation have distinctive approaches to managing supplier relationships and sourcing practices, reflecting their operating strategies and customer needs.

Hangzhou Grand Technology

Hangzhou Grand Technology, renowned for addressing mass-market needs across Asia, has formed reliable and long-lasting relationships with a wide array of regional and global suppliers. By leveraging economies of scale, Hangzhou Grand Technology strategizes its sourcing practices to acquire high-quality raw materials at affordable prices, allowing it to maintain competitive pricing for its customers. The company strongly values loyalty and collaboration with its suppliers, fostering relationships based on mutual growth and negotiated terms that benefit both parties.

IEC Corporation Slip Ring

On the other hand, IEC Corporation operates with a focus on premium and highly specialized slip rings catering to the high-end markets in North America and Europe. Its sourcing practices are centered on procuring superior-quality raw materials that meet or exceed specific technical criteria and stringent regulatory standards. Hence, IEC’s supplier relationships are characterized by stringent quality checks, technical collaborations, and transparent communication. Commitment to ethical sourcing is a fundamental aspect of IEC’s supplier management, aligning with its corporate ethos for high-quality and responsible operations.

In conclusion, the unique approaches Hangzhou Grand Technology and IEC Corporation adopt towards their supplier relationships and sourcing practices are in alignment with their overall business strategies and market positioning. While Hangzhou Grand emphasizes cost-effective sourcing and loyalty with suppliers, IEC Corporation prioritizes stringent quality standards and ethical sourcing practices, reflecting their focus on high-grade, specialized products.

Conclusion

Deciding between Hangzhou Grand Technology and IEC Corporation Slip Ring essentially depends on specific needs and specifications. Whether cost-effectiveness and customization strike your interest or innovative, specialized solutions capture your attention, both companies offer compelling propositions. As the detailed comparison illuminates, they each have unique strengths that cater to different industrial needs and applications.

See What We Can Do