In the dynamic, rapidly moving world of power transmission, high-quality, efficient peripherals like slip rings have become indispensable. They form the backbone of many industrial, commercial, and residential applications or systems that need to transmit power or signals across rotating interfaces. Two names frequently emerge on the radar when it comes to impressive track records of delivering top-notch slip rings – Hangzhou Grand Technology and Trolex Engineering.

Hangzhou Grand Technology, a Chinese technological titan, has steadily gained global recognition for its advanced, highly reliable slip rings. On the other hand, Trolex Engineering, a stalwart of British engineering, has accumulated a wealth of experience over the years, manufacturing durable slip rings that cater to challenging applications spanning various sectors.

To help you navigate the sea of information available and make the best choice for your specific needs, we offer this comprehensive comparison of slip rings from both Hangzhou Grand Technology and Trolex Engineering. From their design philosophy to their customer service, we delve deep into every notable aspect of their products.

As different sectors and applications demand different characteristics from slip rings, this comparison considers numerous factors. The factors include durability, performance under different environmental conditions, maintenance needs, technology used, warranty, customer service quality, and customer reviews.

This journey of comparison brings forth rich insights, outlining the key similarities and differences between the slip rings offered by these two remarkable companies. This in-depth comparison will enable informed decision-making, ensuring that you select the slip ring that best serves your unique demands and requirements.

Strap in, as we embark on this quest to uncover the multifaceted world of slip rings provided by Hangzhou Grand Technology and Trolex Engineering.

Introduction to Hangzhou Grand Technology

Brief Overview

Hangzhou Grand Technology, a leading light in the field of precise transmission products, was established in 2011. With its headquarters stationed in Hangzhou, China, this company quickly emerged as a force to reckon with, capturing attention on a rapidly globalizing stage.

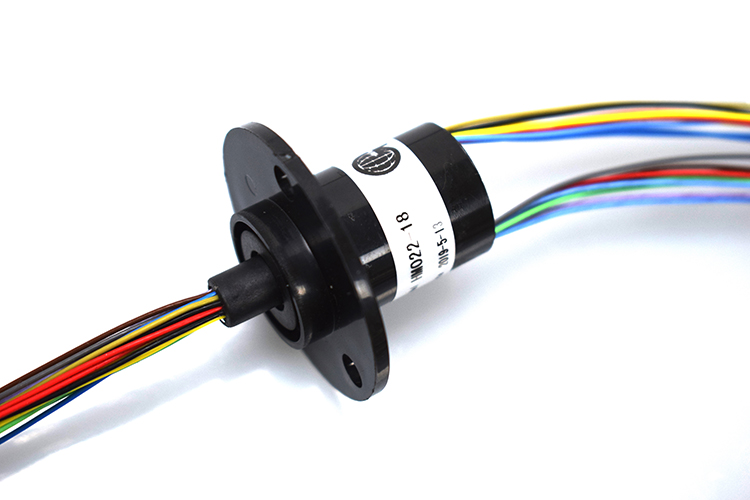

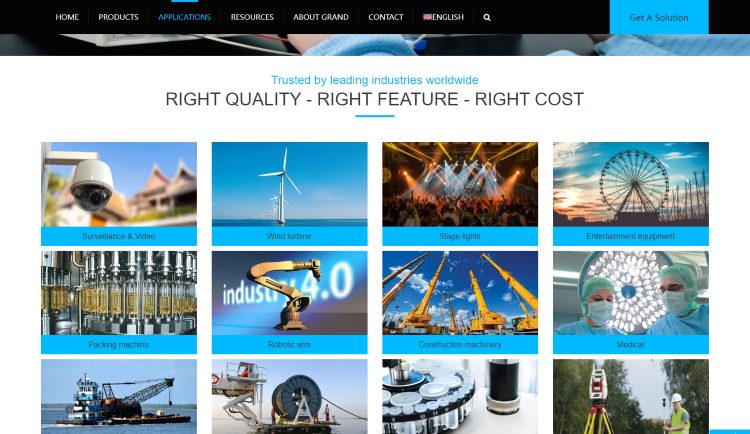

Hangzhou Grand Technology primarily specializes in manufacturing high-quality slip rings and rotary joints which have, over the years, become fundamental components in a myriad of applications. Their broad spectrum of offerings is designed to suit a range of industries, from wind energy and security to heavy equipment industries, showcasing their ability to cater to many different sectors’ specific requirements.

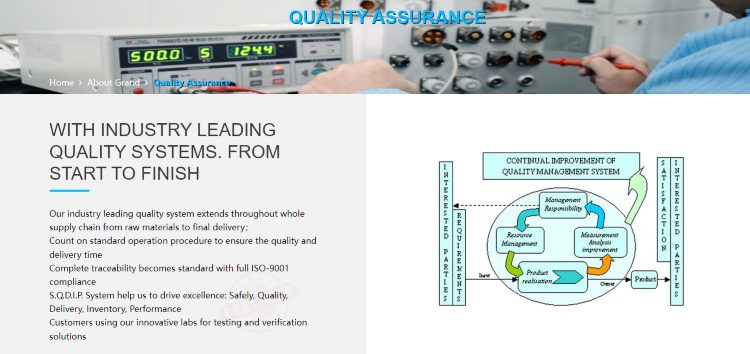

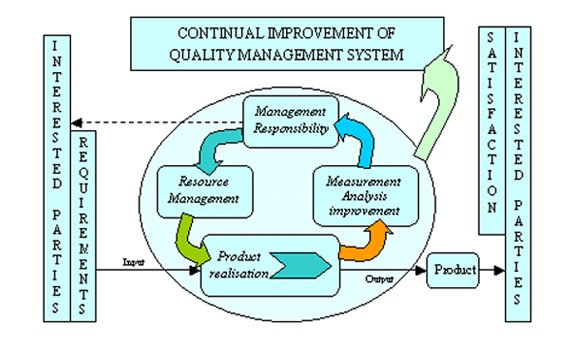

The mission at Hangzhou Grand Technology revolves around the goal of delivering superior, technologically advanced, and reliable products to their customers. Their values stem from a deep-rooted commitment to innovation, customer focus, and continuous improvement of their product line to meet evolving global market needs.

Spotlight on Hangzhou Grand Technology Slip Rings

Hangzhou Grand Technology’s slip rings form a pivotal part of its product portfolio. These slip rings are meticulously engineered to optimize their function, thereby ensuring optimal performance and durability. The company’s commitment to research and technological advancement enables them to design slip rings that can function in a vast variety of operational conditions, hence effectively serving their diverse clientele.

From aerospace, maritime applications, and heavy-duty industrial machinery to surveillance systems and renewable energy applications like wind turbines, Hangzhou Grand Technology’s slip rings are trusted by a wide array of clients. These slip rings’ versatile nature and the ability to customize them according to specific requirements add a unique value proposition for customers that most competitors generally struggle to match.

Hangzhou Grand Technology has continuously evolved over the years to meet changing industry needs. This has entailed developing slip rings with improved electrical and mechanical performance, streamlined design, low friction, long life, and low maintenance. These assets underscore the crucial role of slip rings in Hangzhou Grand Technology’s overall product offering.

Introduction to Trolex Engineering Slip Ring

Brief Overview

Founded over 60 years ago, Trolex Engineering has cemented its reputation as an epitome of British engineering excellence. Situated in the United Kingdom, this esteemed company has an extensive history of producing innovative and exceptional products that cater to various industry demands.

Trolex Engineering’s primary focus is on delivering reliable, highly precise engineered products and comprehensive solutions to suit challenging applications in diverse sectors, such as mining, industrial, and marine. The company’s dedication to meeting and exceeding customer expectations has earned them a loyal, ever-growing customer base.

The corporate culture at Trolex Engineering is driven by an unrelenting pursuit of quality, innovation, and a constant push to enhance the efficiency and performance of its products. Their overarching goal is to offer long-lasting solutions that add value to their customers’ operations and improve overall industry standards.

Spotlight on Trolex Engineering Slip Rings

Trolex Engineering slip rings hold a pivotal position in their product lineup. Their slip rings are meticulously designed to cater to highly demanding and specialized applications. Featuring robust builds and a keen focus on durability, these slip rings are purpose-built to withstand harsh industrial environments and challenging climatic conditions.

Trolex Engineering slip rings cater to an array of customers from various sectors, including mining, wind energy, marine and defense, petrochemical industries, and many more. Their slip rings are engineered to provide optimal electrical and mechanical performance – characteristics that have become synonymous with the company’s legacy of quality and excellence.

These slip rings’ importance lies not only in their high-quality design and manufacturing but also in Trolex Engineering’s ability to create tailor-made solutions for specialized, environment-specific use cases. This flexibility and customization capability significantly widens the company’s customer base and showcases its dedication to resolving industry challenges with bespoke solutions that exceed expectations.

In essence, Trolex Engineering’s slip rings embody the company’s unwavering commitment to innovation, durability, and precision, making them a noteworthy and indispensable product offering for their customers.

Key Differences between Hangzhou Grand Technology and Trolex Engineering Slip Ring

The unique characteristics of Hangzhou Grand Technology and Trolex Engineering slip rings reflect the distinct strategies of these two industry powerhouses. While their common goal is to provide high-quality, reliable slip rings for various applications, the path they take in meeting that goal offers key differences.

- Design Philosophy: Hangzhou Grand Technology tends to focus more on integrating state-of-the-art technology in their slip rings and ensuring customization, catering to a globally diverse market. On the other hand, Trolex Engineering prioritizes designing durable, robust slip rings equipped to withstand high-demand and challenging industrial environments.

- Price: Owing to different design complexities, targeted industries, and overall company pricing policies, their prices vary. Hangzhou Grand Technology’s value-for-money approach tends to appeal to a broader range of customers, while Trolex Engineering’s higher price point often correlates with specialized, heavy-duty industrial designs.

- Customer Support: Both companies strive to deliver excellent customer service, but the experience may differ due to location, response time, and the level of personalized attention.

- Warranty: The warranty terms and durations could vary, often serving as a key consideration point for potential customers. While both companies stand behind their products, the specifics of their warranty offerings may differ.

- Materials Used: Depending on the targeted application and environmental conditions, the selection of materials for the construction of their slip rings can differ. Trolex, for example, often favors more hard-wearing materials known for superior durability.

It’s important to remember that these differences don’t strictly indicate the superiority of one over the other. Rather, they underline their specializations, intended industries, and overall company philosophy. The choice between Hangzhou Grand Technology and Trolex Engineering’s slip rings will ultimately hinge on specific user requirements, budget, and operational conditions.

Key Similarities between Hangzhou Grand Technology and Trolex Engineering Slip Ring

Though Hangzhou Grand Technology and Trolex Engineering maintain their unique identities, their slip rings do exhibit several key similarities. This reflects their shared objective of delivering top-tier, reliable slip ring solutions. The following points highlight the overlap in their offerings:

- Industry Sectors Served: Both companies cater to various sectors such as marine, wind energy, aerospace, military, and heavy machinery. Their versatility enables them to provide specialized solutions to many different industries.

- Customization: Hangzhou Grand Technology and Trolex Engineering both offer slip rings that are customizable to their clients’ needs. This flexibility is particularly advantageous for customers with unique requirements and specific application parameters.

- Quality and Reliability: The slip rings provided by both companies are renowned for their exceptional quality and reliable performance. Irrespective of their design differences, the core of their appeal lies in the trust that customers place in the slip rings’ durability and efficiency.

- Commitment to Innovation: Both Hangzhou Grand Technology and Trolex Engineering place great emphasis on research, development, and continuous improvement. This enables them to refine existing products and develop new, cutting-edge slip ring solutions to stay ahead of the competition.

- Customer Focus: Understanding the importance of customer satisfaction, both companies strive to offer excellent customer service. Their dedicated approach can be observed through the emphasis on building strong, lasting relationships with their diverse clientele.

Despite their differences, these similarities showcase the common goals and elements that define the slip rings from Hangzhou Grand Technology and Trolex Engineering. Potential customers may weigh these overlapping characteristics against the contrasts outlined earlier. By doing so, a more informed decision can be made about which slip ring best meets individual requirements and preferences.

Detailed Comparison: Hangzhou Grand Technology vs. Trolex Engineering Slip Ring

Hangzhou Grand Technology vs. Trolex Engineering Slip Ring: Design

When comparing the slip rings from Hangzhou Grand Technology and Trolex Engineering, the design emerges as a key distinction. Each company’s design philosophy reflects its unique blend of innovation, industry needs, and customer expectations.

Hangzhou Grand Technology

Their slip ring design focuses on versatility and integrating advanced technology. Hangzhou Grand Technology refines its slip rings to optimize function, performance, and durability across a broad range of applications. The company’s slip rings are meticulously engineered, showcasing sleek, modern designs with high adaptability. They give much attention to creating slip rings that can function in numerous operational conditions — catering to their diverse, worldwide clientele.

Trolex Engineering

Trolex’s slip ring design philosophy is centered around enduring quality and robustness. With a strong focus on applications within demanding industrial settings, their slip rings are built From the ground up to withstand harsh conditions. From materials selection to the assembly process, each step is geared towards enhancing durability and long-term operational reliability. This results in muscular, heavy-duty slip ring designs, tailor-made for high-stress, challenging environments.

In essence, the differences in design approaches reflect how each company interprets and responds to the demands of the slip ring market. It allows Hangzhou Grand Technology and Trolex Engineering to serve a broad range of customers while staying true to their identities and core values.

Hangzhou Grand Technology vs. Trolex Engineering Slip Ring: Durability

Durability is a critical aspect when examining slip rings, given their role in connecting, transmitting, and enabling the functioning of various high-power, high-speed machinery. Both Hangzhou Grand Technology and Trolex Engineering duly prioritize this factor in their products. However, their understanding of durability within their operation parameters offers another interesting comparison.

Hangzhou Grand Technology

Durability in Hangzhou slip rings is achieved through a combination of advanced manufacturing processes, quality material selection, and precision engineering. A testament to the company’s dedication to quality, these slip rings are designed to offer consistent performance over an impressively extended lifespan. The result is a product built to withstand varied operational conditions while maintaining optimum performance levels.

Trolex Engineering

Durability is wired into Trolex Engineering’s DNA, and its slip rings are no exception. These hardy products are built to survive in especially demanding industrial environments. Given the company’s special focus on sectors such as mining, marine, and defense, their slip rings commonly face extreme weather conditions, mechanical stresses, and temperature variations. Consequently, Trolex slip rings are crafted with exceptional toughness in the design and materials used, thereby offering superior resistance against wear and tear.

In conclusion, while both Hangzhou Grand Technology and Trolex Engineering give significant weight to durability, their differing operational environment and industry focus result in unique durability characteristics for each. Prospective customers may consider these factors while opting for a suitable slip ring solution.

Hangzhou Grand Technology vs. Trolex Engineering Slip Ring: Price

Price can often factor significantly into purchasing decisions, and slip rings from Hangzhou Grand Technology and Trolex Engineering represent two different spectrums of the cost scale. Each company’s pricing strategy reflects its target market, brand positioning, and the intangible factor of value it brings along with its products.

Hangzhou Grand Technology

Slip rings from Hangzhou Grand Technology generally fall within a more economical range. By leveraging optimized manufacturing processes and cost-effective strategies, the company can pass on those savings to its customers. Despite the lower price point, there’s no compromise on quality; these slip rings offer high performance and durability. They attract customers seeking dependable solutions on a tight budget.

Trolex Engineering

On the other hand, the pricing of Trolex Engineering’s slip rings reflects the premium segment of the market. These slip rings, with their robust design and ability to weather harsh conditions, justify a higher price tag. Trolex Engineering’s slip rings cater predominantly to heavy industry sectors where the long-term reliability of the product offsets the initial investment.

Thus, the difference in prices of slip rings from Hangzhou Grand Technology and Trolex Engineering echoes their unique brand personas and the value proposition they offer to their respective customers. It’s worth noting that affordability or premium pricing shouldn’t be the sole metric driving the purchase—considering the match between the product’s features and the customer’s requirement is equally important.

Hangzhou Grand Technology vs. Trolex Engineering Slip Ring: Maintenance Needs

Maintenance plays an important part in the longevity and effective functioning of slip rings. A comparison of the maintenance needs for slip rings from Hangzhou Grand Technology and Trolex Engineering can offer a deeper understanding of the lifecycle management and operational efficiency of these crucial components.

Hangzhou Grand Technology

Hangzhou’s slip rings are engineered to minimize maintenance requirements. Their advanced design, use of innovative materials, and precise build quality contribute to a reduced frequency of maintenance intervals. Additionally, when maintenance is necessary, the tasks are generally straightforward to perform. This reduces downtime and contributes to the overall cost-effective operation promised by Hangzhou Grand Technology.

Trolex Engineering

Trolex, given their focus on durability and use in demanding environments, also designs their slip rings with low maintenance needs in mind. Their robust construction ensures the components can withstand tough conditions for prolonged periods. However, given the high-stress industrial environments they are often deployed in, preventative maintenance can be necessary to ensure their enduring performance. Trolex also offers comprehensive support to guide customers through any required upkeep procedures.

In summary, while both Hangzhou Grand Technology and Trolex Engineering have addressed the need for low maintenance in their slip rings, the nature of their most common environments and application requirements can lead to different maintenance practices. By recognizing these needs, end-users can ensure optimal operational longevity and reliability for their slip rings.

Hangzhou Grand Technology vs. Trolex Engineering Slip Ring: Performance in Different Environmental Conditions

Slip rings’ ability to function efficiently in various working conditions is a key consideration for customers, especially those in industries with unique environmental demands. Hangzhou Grand Technology and Trolex Engineering have both addressed this aspect in their slip rings, yet the range of conditions their products are tailored for can differ.

Hangzhou Grand Technology

Hangzhou Grand Technology’s slip ring offerings are adept at handling a diverse array of environmental conditions. With features such as temperature resistance, moisture protection, and shock/vibration resistance, they are designed to perform consistently in different settings. Their slip rings can cater to sectors like wind turbines, marine, and aerospace, among others. Though not specifically tailored for extremely harsh conditions, Hangzhou’s slip rings possess an inherent versatility that allows them to adapt to various industries and operating environments.

Trolex Engineering

Trolex Engineering specializes in producing slip rings meant to withstand the most demanding working conditions. Their slip rings are built to endure extreme temperature fluctuations, high mechanical stresses, and corrosive or abrasive substances. This durability has made them particularly suitable for rugged sectors such as mining, heavy machinery, and military equipment. Trolex Engineering’s slip rings are intentionally designed for maximum resilience in these unforgiving environments, ensuring optimal performance in even the harshest conditions.

In conclusion, the performance of Hangzhou Grand Technology’s slip rings in varying environmental conditions is marked by their adaptability, while Trolex Engineering’s slip rings are characterized by their exceptional toughness. Customers can evaluate the demands of their operating environments to decide which slip ring would best meet their needs based on these considerations.

Hangzhou Grand Technology vs. Trolex Engineering Slip Ring: Variety and Customization Options

The availability of different types of slip rings and customization options is a significant attribute when choosing among diverse industrial needs. Both Hangzhou Grand Technology and Trolex Engineering cover this aspect with different degrees of focus and offerings.

Hangzhou Grand Technology

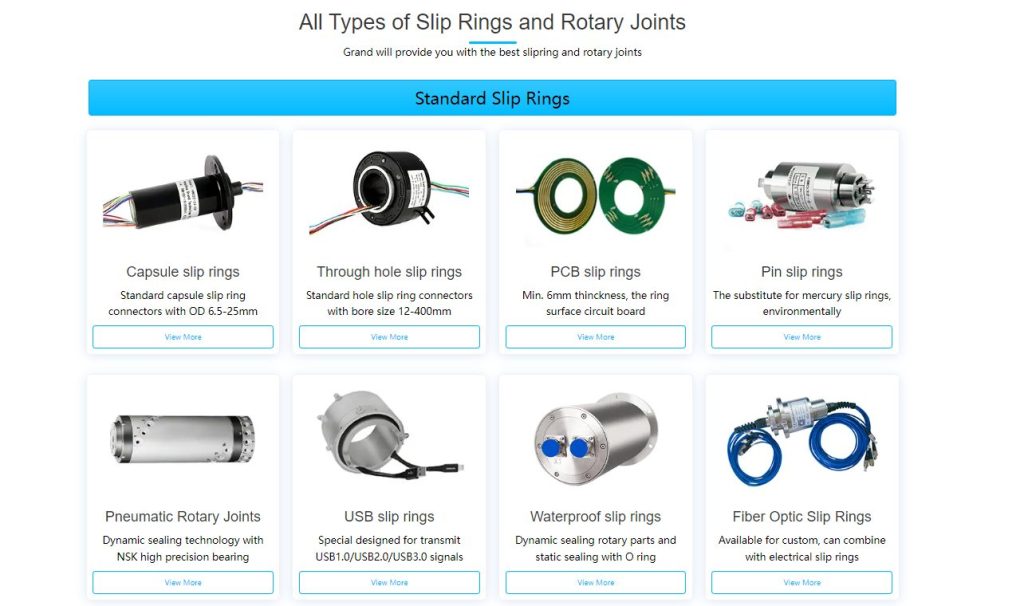

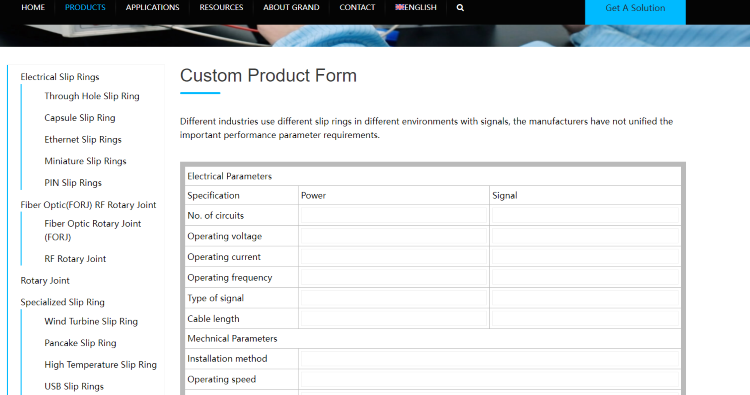

Hangzhou provides a broad variety of slip rings—capsule slip rings, through-bore slip rings, ethernet slip rings, and more, catering to a wide range of applications. Furthermore, Hangzhou Grand Technology emphasizes customization options for their clients, accommodating specific technical requirements based on factors such as size, ruggedness, speed, and more. This array of options and flexibility is an advantage in the diverse industries Hangzhou caters to.

Trolex Engineering

Trolex also provides a selection of slip ring types, though the range is more focused on heavy-duty applications requiring a higher degree of physical robustness. Trolex excels in the provision of bespoke solutions for customers in rigorous industries. This allows the company to craft slip rings that are tailor-made for their application, ensuring not only a fit for the machinery but also optimized performance and durability.

In a nutshell, both Hangzhou Grand Technology and Trolex Engineering represent diverse ends of the spectrum in terms of variety and customization options. Hangzhou serves a broader variety of applications, while Trolex specializes in custom solutions for exceptionally heavy-duty applications. Depending on a customer’s specific needs and industry type, one may find either Hangzhou or Trolex more suited to their requirements.

Hangzhou Grand Technology vs. Trolex Engineering Slip Ring: Customer Service

An important aspect of evaluating any product or company is the quality of its customer service. Excellent customer support can significantly enhance user experience, help resolve issues quickly, and ensure optimal usage of products. Hangzhou Grand Technology and Trolex Engineering, whilst they both place a high value on customer service, do so in their distinctive ways.

Hangzhou Grand Technology

Hangzhou Grand Technology is lauded for its responsive and comprehensive customer service. Their dedicated customer support team is trained to provide thorough assistance ranging from product selection and technical advice to installation support and after-sale services. Known for their prompt responses, they ensure queries and issues are addressed efficiently. This level of customer support, in addition to their high-quality products, has helped them maintain a high degree of customer satisfaction.

Trolex Engineering

Trolex Engineering takes customer service a step further by offering bespoke support services. Given the complex and rigorous applications of their slip rings, they prioritize offering expert support for installation, maintenance, and troubleshooting. Their team is skilled in dealing with the unique situations and challenges that come with heavy-duty, industrial applications. They also provide detailed guidance and assistance on their custom solutions, ensuring the customer can fully take advantage of their tailored products.

In conclusion, both Hangzhou Grand Technology and Trolex Engineering offer robust customer service platforms. Hangzhou Grand Technology emphasizes efficient, comprehensive support, while Trolex Engineering’s customer service is characterized by industry-specific expertise and in-depth support for their custom solutions. The customer’s preference will ultimately depend on their specific needs and what they value most in a customer service relationship.

Hangzhou Grand Technology vs. Trolex Engineering Slip Ring: Warranty

Warranty terms reflect a manufacturer’s confidence in the durability and performance of their products. It provides customers with peace of mind and assurances of product reliability, making it a pivotal factor when analyzing products like slip rings. Here we compare the warranty terms and services offered by Hangzhou Grand Technology and Trolex Engineering.

Hangzhou Grand Technology

Hangzhou Grand Technology backs its products with a strong warranty policy. They offer a standard one-year warranty on their slip rings, covering any manufacturing defects or performance issues in regular usage. During the warranty period, they offer repair or replacement services as needed. This aligns with the company’s commitment to quality and shows confidence in its manufacturing process. Their warranty also strengthens their value proposition of providing quality products at competitive prices.

Trolex Engineering

Trolex Engineering, aiming at high-stress industrial applications, extends a robust warranty on its products. Their standard warranty period is generally longer, given the premium nature of their offerings and the extreme conditions their products are designed to endure. They are committed to addressing any issues that might occur under normal operation, offering repair or replacement services. This bolstered warranty not only assures customers of the product’s long-term dependability but also underscores Trolex’s commitment to its products’ durability and quality.

To summarize, Hangzhou Grand Technology’s standard warranty period offers reasonable coverage for its products, while Trolex Engineering’s extended warranty services provide an additional layer of security, especially considering the harsh conditions their slip rings are commonly exposed to. When choosing a product, customers should consider not only the duration but also the extent and reliability of warranty services in balancing cost, performance, and durability.

Hangzhou Grand Technology vs. Trolex Engineering Slip Ring: Technology Used

The technology employed in the design and manufacture of slip rings is a significant factor in determining their performance, longevity, and applicability. Analyzing the technological aspects of Hangzhou Grand Technology and Trolex Engineering slip rings provides insights into their approach to product development and innovation.

Hangzhou Grand Technology

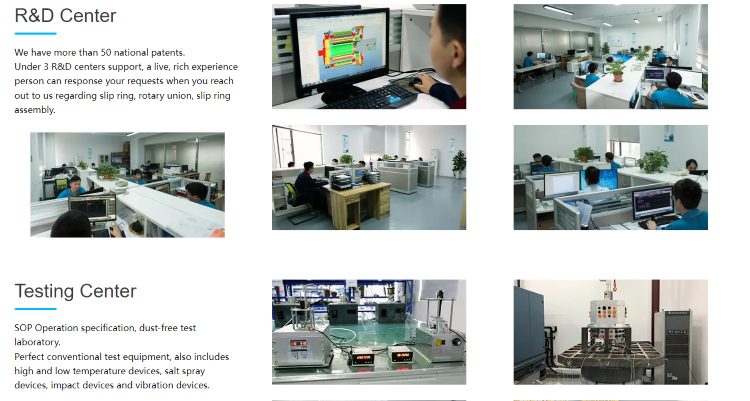

Hangzhou Grand Technology is known for its robust R&D capabilities and for integrating advanced technology into its products. The company utilizes cutting-edge materials and precision manufacturing techniques in its production process. Additionally, they have developed proprietary electrical contact technology to ensure outstanding transmission performance and long service life. Its slip rings also feature advanced design elements like low-torque operation, modular design, and multiple signal compatibility, indicating a diligent focus on innovation and usability.

Trolex Engineering

Trolex Engineering, catering mainly to high-stress industries, incorporates resilient and sturdy technologies into their slip rings. They deploy heavy-duty materials and advanced fabrication methods to ensure their products can withstand extreme conditions. Their slip rings are engineered with high-performance electrical contacts and materials to ensure optimal power and signal transmission over extended periods. Furthermore, they have developed specialist slip rings, such as those with ATEX certification for explosion-prone environments, underscoring their commitment to technological innovation with safety considerations.

In conclusion, while Hangzhou Grand Technology focuses on leveraging advanced technology to broaden product versatility and efficiency, Trolex Engineering concentrates on harnessing robust technologies to enhance durability and resilience in severe conditions. Therefore, depending on the particular technical requirements and working environments, customers can select the most suitable supplier based on these technological considerations.

Hangzhou Grand Technology vs. Trolex Engineering Slip Ring: Customer Reviews and Reliability

Customer reviews provide invaluable insights into a product’s performance, reliability, and the company’s customer service. Analyzing the feedback from users provides an understanding of the real-world performance of Hangzhou Grand Technology and Trolex Engineering slip rings.

Hangzhou Grand Technology

Hangzhou Grand Technology’s customer reviews highlight the company’s consistent product quality and robust customer service. Clients have frequently noted the reliable performance of their slip rings across various applications, praising their durability and efficiency. The company’s commitment to comprehensive customer service and ability to provide customizable solutions also receive appreciable mention in reviews. Overall, customers seem to consider Hangzhou Grand Technology a reliable provider of slip rings.

Trolex Engineering

Customer feedback for Trolex Engineering often emphasizes the exceptional durability and performance of their slip rings, especially under harsh operating conditions. Many clients in high-stress industries have favorably reviewed Trolex Engineering’s products for their endurance and consistent performance. Their cooperative customer service and commitment to solving complex problems are also commended. The overall consensus from customer reviews indicates that Trolex Engineering is a trusted and dependable source of slip rings for heavy-duty applications.

To conclude, both Hangzhou Grand Technology and Trolex Engineering have proven track records and are favorably reviewed by customers. Hangzhou Grand Technology receives praise for its dependable products and responsive customer service, while Trolex Engineering is esteemed for providing durable products suited to challenging environments and for being customer-oriented. These reviews contribute to the reliability and reputation of both companies, making them reliable choices for customers seeking quality slip rings.

Conclusion

In conclusion, both Hangzhou Grand Technology and Trolex Engineering are exceptional market choices for slip rings. However, making a decision depends on your specific needs, budget, and the application you need the slip ring for. Both provide excellent options, but your requirements will ultimately lead you to the right choice.

See What We Can Do