In an increasingly interconnected world, the demand for reliable and efficient rotary transmission solutions has become more crucial than ever. Slip rings play a vital role in transmitting electrical power and signals between rotating and stationary components in various industries. With numerous manufacturers on the market, users often find it difficult to choose the right slip ring provider. This article aims to provide a comprehensive comparative analysis of two prominent companies in the slip ring market: Hangzhou Grand Technology and UEA (United Equipment Accessories). By shedding light on their histories, key products, design innovations, market presence, and customer support, we seek to help users identify the most appropriate and high-quality slip ring based on their specific needs. In doing so, the article enhances the readers’ understanding of the critical factors to consider when making a well-informed decision in the multifaceted world of slip rings.

Company Overview: Hangzhou Grand Technology

Founded in 2011, Hangzhou Grand Technology has grown over 12 years from a small enterprise to a world-renowned name in the production of slip rings. Originally starting its operations in Hangzhou, China, the company has maintained steady and progressive growth, keeping the focus on innovation and the constant pursuit of excellence in its unique product offerings.

Hangzhou Grand Technology specializes in the design and manufacturing of high-quality slip rings for a diverse range of applications. Their commitment to exceeding customer expectations through advanced technologies has been the thrust behind their specialization. They have earned recognition both within China and globally for their meticulous attention to detail in creating products that fulfill industry-specific needs.

The company’s product portfolio comprises an impressive variety, with a special focus on their high power slip rings. These slip rings stand out from the competition due to their high power capacity, long-lasting durability, and wide-ranging applications. They are uniquely engineered to handle high voltage and currents while simultaneously transmitting data with minimal noise and interference, empowering industries such as heavy machinery, medical equipment, and renewable energy, among others.

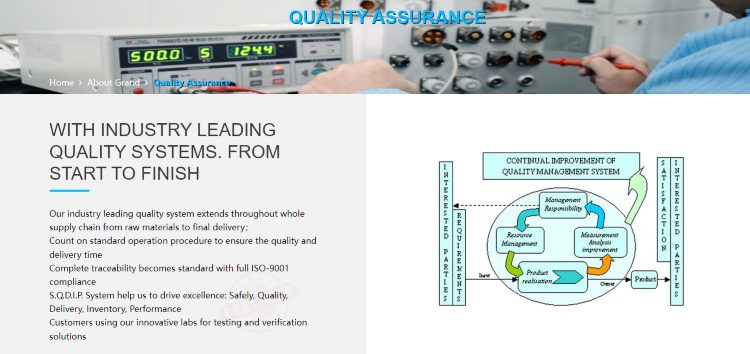

Hangzhou Grand Technology’s commitment to quality also extends to its adherence to industry standards and certifications. Recognized for its exceptional quality management processes, the company is ISO 9001:2015 certified. Their products comply with environmental directives such as RoHS and are CE certified, reassuring their customers of the high standards with which each product is created and tested. This dedication to quality control and environmental responsibility cements Hangzhou Grand Technology’s reputation as a trusted industry leader in the slip ring domain.

Company Overview: United Equipment Accessories (UEA) Slip Rings

Established in 1952, United Equipment Accessories (UEA) has created a notable legacy over several decades. The company, rooted in Iowa, United States, has been instrumental in supplying an extensive range of high-quality slip rings, successfully forging a reputation of trust and reliability among its customers.

UEA specializes in the design and manufacture of slip rings, cable reels, and rotary unions. Their specialization extends to offering unique, custom-engineered solutions to meet the diverse requirements of various fields encompassing renewable energy, construction, and utility sectors. They have established a strong reputation for their consultative approach, working closely with their clients to develop products that best suit their individual needs.

UEA is particularly recognized for its high-power slip rings. Distinguished by their superior power-carrying capacity, these slip rings can withstand extreme temperature ranges and offer exceptional durability. Designed to meet the robust demands of industries like wind energy, manufacturing, and defense, UEA’s high-power slip rings are appreciated for their precision engineering and reliable performance.

The company’s commitment to quality assurance is reflected in their certifications. UEA is certified following ISO 9001:2015, signifying its dedication to maintaining the highest production and management standards. Moreover, their products are designed to meet a variety of industry standards, including CE, RoHS, and UL, confirming the company’s adherence to global safety and environmental regulations.

In summation, UEA’s longevity, specialization, innovative products, and commitment to quality standards make it a stalwart in the manufacturing of slip rings, cable reels, and rotary unions, and a reliable choice for customers worldwide.

Key Differences between Hangzhou Grand Technology and UEA Slip Rings

Despite delivering high-quality slip rings, Hangzhou Grand Technology and UEA have unique differences that shape their appeal to diverse markets.

Product Portfolio

While both companies offer a range of slip ring solutions, UEA has broadened its product portfolio by incorporating cable reels and rotary unions. In contrast, Hangzhou Grand Technology, specializing exclusively in slip rings, demonstrates concentrated and focused expertise in this critical area.

Technology and Design

Hangzhou Grand Technology and UEA showcase differing design philosophies. Hangzhou Grand Technology aims to innovate with compact, modular slip ring assemblies that are efficient, space-saving, and sleek. On the other hand, UEA upholds traditional design elements by manufacturing split rings with independent brush block assemblies, providing robust and adaptable solutions for complex applications.

Core Market and Customer Base

Hangzhou Grand Technology primarily caters to the Asian market, with a large proportion of its customer base in China, due to its strategic geographical location. Conversely, UEA has firmly entrenched its roots in North America, catering largely to the United States and neighboring regions.

Pricing

Hangzhou Grand Technology typically offers more competitively priced products. Sourcing and manufacturing within China allow the company to keep production costs low, thereby providing more affordable solutions. UEA aligns its pricing model with the Western market, taking into account the premium quality components they use and the additional cost factors intrinsic to manufacturing within the United States.

Customization and After-Sale Services

Both companies provide customization options. However, while Hangzhou Grand Technology emphasizes customizable design and flexible modification, UEA often goes a step further through extensive after-sales support, comprehensive product updates, and active customer engagement, thus ensuring long-term service longevity and reliability.

Key Similarities between Hangzhou Grand Technology and UEA Slip Rings

Despite operating in different regions and employing distinctly unique designs, Hangzhou Grand Technology and UEA share commonalities that uphold their status as leading slip ring manufacturers.

Applications

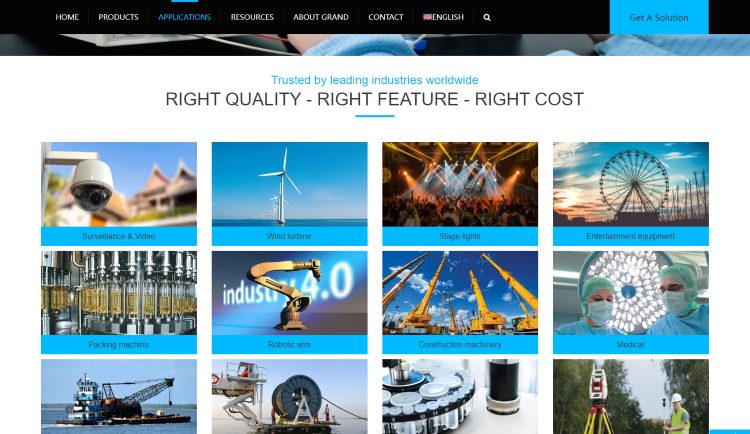

While differing in specific designs and components, both companies manufacture slip rings that serve a myriad of applications. These products are integral to industries such as wind energy, mining, defense, and telecommunications, ensuring the seamless transmission of power and signal across stationary and rotating interfaces in both industrial and marine environments.

Commitment towards Certifications and Industry Standards

Both Hangzhou Grand Technology and UEA harbor a commitment to industry standards and quality assurance. They proudly hold ISO 9001 certifications, displaying their dedication to maintaining production and management quality. This certification also reflects their focus on continual improvement of product quality and customer satisfaction.

Key Features

Shared key features are displayed in their slip rings, including high power handling capacity, temperature resistance, and long-lasting quality, testifying to their commitment to manufacturing robust and dependable products. Despite variations in design, these shared features affirm the reliability of both companies’ products in a range of demanding applications.

Innovation and Technology Advancement

Hangzhou Grand Technology and UEA both place a strong emphasis on innovation and technological advancement. They invest significantly in research and development, constantly seeking to introduce advanced technology into their products. This shared focus results in the production of state-of-the-art slip rings designed to meet the evolving needs of various industries.

Customer Service and Support

A vital element of their business models, both companies prioritize customer service. They strive to provide pre-sales consultation, prompt response to queries, efficient delivery, and continuous after-sales support. This unwavering dedication to customer service forms a foundation of trust and long-term relationships with their clients.

Detailed Comparison: Hangzhou Grand Technology vs. UEA Slip Rings

Hangzhou Grand Technology vs. UEA Slip Rings: Design and Construction

Hangzhou Grand Technology and UEA adopt different philosophies concerning the design and construction of their slip rings, balancing the requirements of space, cost, power transmission, and complexity of application to meet the multiplicity of their customers’ needs.

Hangzhou Grand Technology Slip Rings

Hangzhou Grand Technology focuses on compact and modular design in its slip ring construction. This philosophy has led the company to favor an integral structure for optimal space utilization and adaptability. Their products are known for their sleek and minimalist appearance, with internal elements engineered for noise and interference reduction during high-speed data transmission. The compact design is instrumental in a broad array of applications where space conservation is paramount. Furthermore, Hangzhou Grand Technology slip rings focus on the application of precious metals in the contact point to ensure long-term solid performance and durability of their products, enabling them to withstand years of high-current operation without degradation.

UEA(United Equipment Accessories) Slip Rings

UEA, on the other hand, adorns a more traditional approach to its slip ring design and construction. Their products often feature split ring constructions with independent brush block assemblies. This style of design offers a high level of flexibility and adaptability, especially when handling complex applications or accommodating custom orders. The UEA design philosophy prioritizes a robust, durable construction that can endure extreme conditions and heavy load requirements frequently encountered in fields like renewable energy, manufacturing, and the defense industry. Furthermore, UEA employs advanced materials and engineering in their slip rings to ensure long-life operation, reliability, and excellent power-signal performance.

In summary, both companies offer unique and effective solutions in their slip ring design and construction, but with differing focuses – Hangzhou Grand Technology emphasizes compact, efficient designs with precious metals to enhance longevity, while UEA prides itself on flexible, adaptable designs tailored to meet complex operational requisites.

Hangzhou Grand Technology vs. UEA Slip Rings: Variety and Range of Products

Both Hangzhou Grand Technology and UEA display a commitment to supplying customers with a diverse selection of slip ring products. However, their specific focus areas and supplementary offerings set them apart in their respective markets.

Hangzhou Grand Technology Slip Rings

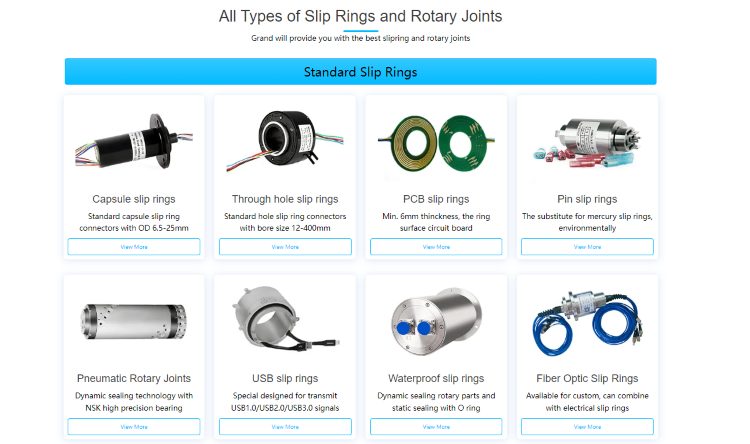

Hangzhou Grand Technology is dedicated exclusively to slip ring manufacturing and provides a wide spectrum of products catering to various industries. Their offerings include capsule slip rings, through-hole slip rings, miniature slip rings, and pancake slip rings – all designed to meet a range of requirements.

The company also actively seeks to create customized designs depending on the specific demands of its customers. Hangzhou Grand Technology’s product portfolio is further diversified by targeting niche application areas such as IP-protected slip rings and Ethernet-compatible designs to serve rapidly evolving industries.

UEA (United Equipment Accessories) Slip Rings

UEA, while offering a broad range of slip rings encompassing standard, high-current, high-speed, and fiber brush designs, has expanded its product lineup in unique ways. The company’s scope extends to the complementary markets of cable reels and rotary unions.

This extended product range offers customers the convenience and expertise of a one-stop shop to meet their varied needs. UEA’s ability to provide an integrated solution working in unison with its slip rings has bolstered its position within diverse customer segments.

Moreover, the company actively collaborates with clients to develop custom engineering solutions optimized for specific applications and regulatory standards. UEA’s investment in multiple product categories underlines its industry expertise and caters to a broader market reach.

In conclusion, Hangzhou Grand Technology and UEA both offer a wide variety of slip ring products, with differing strategies in their approach to supplementary offerings and catering to niche markets.

Hangzhou Grand Technology vs. UEA Slip Rings: Usage in Various Industries

Both Hangzhou Grand Technology and UEA provide slip ring solutions designed to address the challenges faced by different industries, supporting seamless power and data transmission across various applications. With an understanding of distinct industry requirements, the two companies have distinct strategies to cater to their diverse markets.

Hangzhou Grand Technology Slip Rings in Industries

Hangzhou Grand Technology’s slip ring products are employed across a wide array of industries, including but not limited to:

- Wind Energy – High-performance slip rings capable of handling the harsh conditions and the high vibration environments found in wind turbines.

- Robotics and Automation – Compact and modular slip rings facilitate seamless data and power transfer in complex robotic systems.

- Marine and Offshore – Weather- and corrosion-resistant slip rings for consistent performance in hostile maritime environments.

- Aerospace and Defense – Lightweight, compact, and durable slip rings enabling reliable power and data transmission in critical and high-stress applications.

Hangzhou Grand Technology consistently expands its product offerings, pursuing innovations that address the needs of other niche industries with unique requirements.

UEA (United Equipment Accessories) Slip Rings in Industries

UEA’s slip rings are utilized in a multitude of industries, offering tailored solutions to accommodate specific operational and environmental challenges. Some common industries leveraging UEA slip rings include:

- Renewable Energy – Robust slip rings for long-term reliability in wind turbines and solar tracking systems requiring continuous rotation.

- Construction and Resource Extraction – Heavy-duty slip rings capable of enduring high loads and rugged conditions in cranes, excavators, and drilling equipment.

- Medical and Life Sciences – Advanced slip ring technology for reliable power and signal transmission in medical equipment such as CT and MRI scanner systems.

With its expanded portfolio, including cable reels and rotary unions, UEA addresses extended industry needs while establishing its position in specialized segments.

In conclusion, both Hangzhou Grand Technology and UEA provide versatile slip ring solutions for an array of industries, tailoring their products to accommodate the unique challenges and requirements of each segment.

Hangzhou Grand Technology vs. UEA Slip Rings: Power Carrying Capacity

The power carrying capacity of a slip ring is key to its performance, enabling it to transmit electricity from a stationary to a rotating part. Both Hangzhou Grand Technology and UEA incorporate designs and materials to optimize this crucial characteristic.

Hangzhou Grand Technology’s Slip Rings Power Carrying Capacity

Hangzhou Grand Technology equips its slip rings with an impressive power-carrying capacity. Their products utilize precious metals and high-quality contact materials to enhance electrical conductivity and reduce resistance, ensuring efficient performance even at high currents. Depending on the model, these slip rings can carry power up to hundreds of amperes, suitable for applications ranging from small electronic devices to large industrial machinery.

A significant feature of Hangzhou Grand Technology is its capacity to customize the power-carrying ability of its slip rings as per specific requirements. Whether a client needs compact slip rings for low-energy devices or heavy-duty slip rings for high-energy applications, Hangzhou Grand Technology can provide a suitable solution tailor-made for their needs.

UEA (United Equipment Accessories) Slip Rings Power Carrying Capacity

UEA slip rings are at the forefront in terms of power-carrying capacity. The company has established a reputation for providing slip rings that can handle significant loads. With the use of durable contact materials and advanced manufacturing techniques, UEA slip rings can manage high power without compromising reliability or performance.

Particularly, UEA’s high-current slip rings are renowned for their superior power-carrying capacity. Capable of handling several hundred amperes and even reaching up to a thousand, these rugged slip rings are ideal for demanding applications in industries such as renewable energy and construction.

In summary, both Hangzhou Grand Technology and UEA excel in providing slip rings with high power-carrying capacities. However, their differentiations lie in the extent of customization toward power requirements (Hangzhou Grand Technology) and consideration towards heavy-duty applications (UEA).

Hangzhou Grand Technology vs. UEA Slip Rings: Durability and Lifespan

A deciding factor for many buyers when choosing between two slip ring manufacturers is the durability of the product and the lifespan it promises. Hangzhou Grand Technology and UEA have each established key strategies to ensure their products maximize these aspects.

Hangzhou Grand Technology Slip Rings’Durability and Lifespan

Hangzhou Grand Technology focuses on the longevity of its slip rings by investing in high-quality materials and ingenious design. The use of precious metals for contact materials, such as gold and silver, helps lower electrical resistance, minimize wear and tear in their slip rings, and ultimately extend the lifespan of the product. Furthermore, their lightweight and compact designs use fewer moving parts, minimizing the potential for mechanical failure.

Also worthy of note is Hangzhou Grand Technology’s streamlined modular design, which reduces maintenance requirements and, in many cases, enables easy part replacement, effectively increasing the product’s lifespan and utility over time.

UEA (United Equipment Accessories) Slip Rings’ Durability and Lifespan

In contrast, UEA emphasizes the durability of its product designs, suitable for use in demanding environments and high-load applications. Using high-grade contact materials and sturdy brushes, UEA slip rings are designed to withstand long-term functional stress without failure.

Particularly, the independent brush block assemblies used in their designs provide for reliable long-term operation and ensure the easy replacement of the brush block if wear and tear occur, effectively increasing the product’s lifespan. Additionally, the strategic use of advanced materials and engineering practices reduces the impact of wear and tear from repeated rotations, effectively prolonging the lifespan of the slip ring.

In conclusion, both Hangzhou Grand Technology and UEA design their slip rings to perform well over long periods, yet they emphasize different aspects: Hangzhou Grand Technology focuses on the use of quality materials and modular designs, while UEA prioritizes high-grade components and designs suitable for demanding environments.

Hangzhou Grand Technology vs. UEA Slip Rings: Infrastructure and Manufacturing Practices

Manufacturing infrastructure and practices are crucial for ensuring the production of high-quality slip rings. These aspects define not just the final product’s quality, but also its consistency and the company’s capacity to meet diverse customer needs. Both Hangzhou Grand Technology and UEA have implemented unique infrastructural setups and superior manufacturing norms.

Hangzhou Grand Technology’s Infrastructure and Manufacturing Practices

Hangzhou Grand Technology boasts an advanced manufacturing setup. They leverage state-of-the-art equipment and technology in their production processes, allowing them to meet precision requirements and maintain consistent high-quality outputs.

Their meticulous manufacturing practices encompass multiple quality control steps. Each slip ring undergoes thorough testing to ensure optimal performance. Hangzhou Grand Technology also places heavy emphasis on technological innovation and continually invests in research and development, allowing it to spearhead the development of new products and solutions.

These practices, coupled with a large, highly competent workforce and streamlined supply chain activities, allow Hangzhou Grand Technology to produce custom-made, high-quality slip rings efficiently and promptly.

UEA (United Equipment Accessories) Infrastructure and Manufacturing Practices

UEA prides itself on an expansive and versatile production infrastructure. Supporting their wide range of products, from slip rings to cable reels and rotary unions, UEA’s manufacturing facilities are designed for multi-product scenarios, enhancing their ability to fulfill various customer demands simultaneously.

UEA’s manufacturing practices underscore their commitment to quality. Their slip rings undergo rigorous testing at every stage of production, from raw material selection to final assembly. UEA’s focus on lean manufacturing and its employment of skilled professionals contribute to reducing waste, optimizing production times, and ensuring high standards of quality.

The integration of in-house engineering capabilities allows UEA to collaborate closely with clients to engineer customized solutions suited to specific applications.

In conclusion, Hangzhou Grand Technology and UEA are both committed to incorporating advanced infrastructure and manufacturing practices to deliver high-quality slip rings. However, they differ in their approach – Hangzhou values technological innovation and efficiency, while UEA places a high focus on versatility, collaboration, and lean manufacturing.

Hangzhou Grand Technology vs. UEA Slip Rings: Customization Abilities

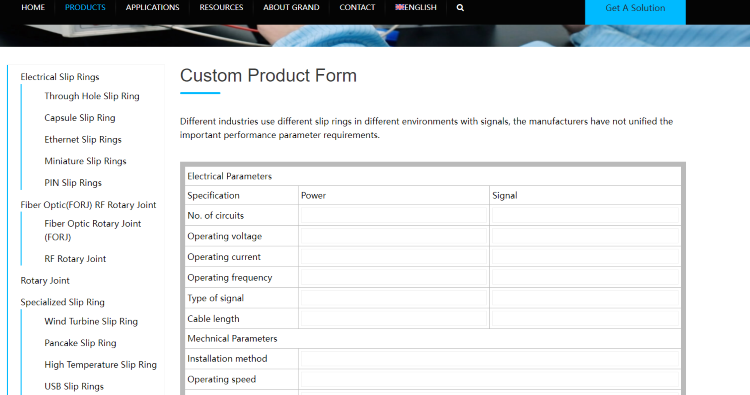

Given the diverse applications and environments in which slip rings are employed, the ability to customize products to meet specific needs is vital. Both Hangzhou Grand Technology and UEA have established their unique capabilities in providing customized slip ring solutions.

Hangzhou Grand Technology’s Customization Abilities

Hangzhou Grand Technology stands out for its remarkable customization abilities. Having harnessed its advanced manufacturing capabilities and technical know-how, the company is well-positioned to accommodate a variety of unique client applications.

From altering the power carrying capacity to modifying the design and materials, Hangzhou Grand Technology can personalize its slip rings to match the distinct requirements of each project. This flexibility allows them to provide solutions across different industry sectors, making their products suitable for diverse environments, be it a tiny drone or a large wind turbine.

Moreover, Hangzhou Grand Technology puts a large emphasis on customer collaboration. Their team works closely with clients right from the project conception phase, allowing them to better understand the client’s needs and develop a solution that fits seamlessly into their system.

UEA (United Equipment Accessories) Customization Abilities

UEA also showcases strong customization capabilities, setting them apart within the industry. With its broad product range, from slip rings to rotary unions to cable reels, UEA delivers versatility, complementing its superior designing, engineering, and manufacturing skills.

UEA’s team collaborates with clients to create tailor-made solutions, whether that involves a modification to an existing product or designing a new one from scratch. Furthermore, UEA’s in-house engineering team continuously works to refine designs according to customer feedback, ensuring they meet the evolving needs of the marketplace.

Their comprehensive approach allows them to address complicated customer challenges in varied sectors, from renewable energy systems to heavy-duty construction machinery.

To conclude, both Hangzhou Grand Technology and UEA are well-recognized for their customization abilities. However, they differ in approach – Hangzhou Grand Technology banks on its technology and process flexibility, while UEA leverages its broad product range and iterative design refinement process.

Hangzhou Grand Technology vs. UEA Slip Rings: Cost Competitiveness

Cost competitiveness is a crucial factor when selecting a slip ring supplier, as it directly impacts the project’s budget and overall profitability. Hangzhou Grand Technology and UEA have distinct strategies to keep their pricing as cost-competitive as possible while maintaining high-quality products.

Hangzhou Grand Technology’s Cost Competitiveness

Hangzhou Grand Technology has prioritized cost competitiveness throughout its product range. Capitalizing on efficient manufacturing and supply chain practices, the company can keep production costs low, consequently reflecting on its product prices. Their ability to streamline processes and create customized solutions also contributes to reducing costs by minimizing waste and rework.

Furthermore, Hangzhou Grand Technology’s location in China provides an additional advantage in cost competitiveness. Being situated in a country with relatively lower production expenses, they can produce high-quality slip rings at competitive prices without compromising on quality. This makes them a formidable contender, especially when targeting cost-sensitive markets or budget-limited projects.

UEA (United Equipment Accessories) Cost Competitiveness

UEA, on the other hand, focuses on providing premium products built with high-quality components and innovative designs. Owing to their dedication to advanced engineering and production practices, UEA’s slip rings come at a relatively higher price point than their low-cost competitors. However, their cost competitiveness is achieved through a different metric – value for money.

UEA aims to offer exceptional quality and durability in their products, which justifies the price differential. In addition, their strong emphasis on customization allows them to create tailored solutions that maximize efficiency and lifespan, thereby making them a cost-effective choice in the long run.

In essence, UEA provides excellent cost competitiveness when considering the long-term cost savings achieved through their high-quality, durable, and highly efficient slip rings, which require minimal maintenance and reduced downtime.

In conclusion, both Hangzhou Grand Technology and UEA possess unique strategies when it comes to cost competitiveness. Hangzhou Grand Technology leverages its efficient manufacturing, supply chain practices, and lower production costs to offer competitive prices. In contrast, UEA focuses on delivering superior quality and long-term value, which effectively establishes its cost competitiveness through long-term cost savings for customers seeking high-performing, reliable slip rings for demanding applications.

Hangzhou Grand Technology vs. UEA Slip Rings: After-Sale Services and Support

After-sales services and support play a critical role in shaping a customer’s experience and loyalty to a brand. Both Hangzhou Grand Technology and UEA acknowledge this fact, implementing substantial programs to provide robust support to their clients post-purchase.

Hangzhou Grand Technology’s After-Sale Services and Support

Hangzhou Grand Technology takes a comprehensive approach to after-sales services and support. Realizing that customer satisfaction doesn’t end at product delivery, the company maintains a responsive service team to assist clients with any post-purchase inquiries or technical issues.

Their services extend to providing detailed user manuals, maintenance guides, and technical support to ensure optimal usage of their slip rings. Additionally, they offer a robust warranty system that covers the repair or replacement of damaged components, subject to the warranty’s terms and conditions.

Furthermore, Hangzhou Grand Technology’s customer-centric approach drives them to regularly obtain feedback from their clients, using it to enhance both their products and services.

UEA (United Equipment Accessories) After-Sale Services and Support

In contrast, UEA extends its commitment to quality beyond product production into its after-sales services. They demonstrate robust support systems, designed to provide prompt and effective solutions to their clients’ post-purchase matters.

Their team of expert technicians provides unrivaled technical support, and troubleshooting issues, and offers guidance on maintenance practices to prolong product lifespan. UEA also assures a solid warranty plan for their products, covering repairs or replacements of any malfunctioning parts.

Moreover, capitalizing on its strong emphasis on customer collaboration, UEA maintains strong communications post-purchase, ensuring that its solutions continue to fulfill evolving customer needs.

To sum up, both Hangzhou Grand Technology and UEA understand the importance of after-sales services in creating a successful customer relationship. While Hangzhou Grand Technology aims for comprehensive and efficient support, UEA distinguishes itself with extensive technical support and the continuation of its customer-centric approach post-sale.

Hangzhou Grand Technology vs. UEA Slip Rings: Sustainability Practices

In the evolving business landscape, sustainability practices have become an essential benchmark for evaluating companies. Both Hangzhou Grand Technology and UEA recognize this and have taken significant measures to incorporate sustainability into their business operations.

Hangzhou Grand Technology’s Sustainability Practices

Hangzhou Grand Technology’s commitment to sustainability is evident in both its product design and manufacturing processes. They actively apply eco-efficient techniques during manufacturing, such as recycling programs, energy-saving initiatives, and waste-reduction strategies. This not only diminishes their environmental footprint but also improves their overall efficiency.

Moreover, Hangzhou Grand Technology ensures that its products meet relevant environmental standards, demonstrating its commitment to delivering environmentally friendly products. They endeavor to design durable products with longer lifespans, reducing the need for regular replacement and the resulting electronic waste.

UEA (United Equipment Accessories) Sustainability Practices

UEA places high importance on sustainability, integrating it into every aspect of their business: from design and manufacturing to distribution. The company employs a lean manufacturing process, which effectively minimizes waste and optimizes resource use. Additionally, they seek to use eco-friendly materials where possible, without undermining their product quality and durability.

Want to know about slip ring lead times? Contact us.

Beyond their manufacturing operations, UEA also commits to environmental stewardship in their facilities, implementing energy efficiency measures and waste management strategies. UEA’s community outreach and investment in local initiatives further indicate its commitment to sustainability and to being a responsible corporate citizen.

In summary, while both Hangzhou Grand Technology and UEA show a strong commitment to sustainable practices in their operations, their approaches are distinct. Hangzhou Grand Technology focuses on eco-efficiency in manufacturing and creating environmentally friendly products, while UEA embeds sustainability in every facet of its business, from lean manufacturing to community investment.

Conclusion

While Hangzhou Grand Technology and UEA are prime examples of high-quality slip ring manufacturers, users must compare their specific requirements with each company’s offerings. Factors like pricing, design, customization potential, durability, and customer support significantly differentiate the two, ultimately helping users make informed decisions.

See What We Can Do