In the heart of a world increasingly dominated by state-of-the-art electronics and high-speed communication, one device continues to play an integral role: the high-frequency slip ring. Although often unseen and unrecognized, this small but mighty component is the driving force of many of the appliances and technologies we rely on daily.

High-frequency slip rings are unique electromechanical devices that enable the transfer of electrical power and signal data from a stationary source to a rotating component, particularly under high-frequency conditions. This sophisticated capability is vital to ensuring continuous, uninterrupted communication across different parts of a system, eliminating the risk of tangling or damaging wires as rotation occurs.

From the high-definition imagery on your television screen to the precise data recorded by medical scanners, the high-frequency slip rings make their presence known across a vast array of digital technologies. They are pivotal in radar technology, telecommunications, security systems, and other advanced industrial applications. Their unparalleled ability to support high-speed data transmission makes them an essential component in all these industries.

Its widespread application underscores the importance of understanding high-frequency slip rings. The ability to comprehend their functionality can provide crucial insights to those involved in their manufacture, design, operation, and maintenance. It also empowers end users to make informed decisions about their specific applications, enhancing the performance efficiency, and longevity of their equipment.

As we navigate through this guide, we aim to unpack the complex world of high-frequency slip rings. We will understand their mechanics, their specialized applications, and why they hold so much relevance in our technologically driven society. This understanding will demystify the complexities, and inspire informed choices – shaping the experiences with modern-day technologies.

What Are High-Frequency Slip Rings?

To delve into the world of high-frequency slip rings, we must first understand the foundation upon which they stand: the slip ring itself.

- Definition of slip rings: At its core, a slip ring is an electromechanical device that allows the transfer of electrical power and signals between a stationary source and a rotating component. In its simplest form, it consists of conductive rings on the stationary side and brushes on the rotating side, enabling data and power to flow consistently, regardless of the relative position of these components.

- High-frequency slip rings: Building upon the standard slip ring, high-frequency slip rings are advanced electromechanical devices designed to handle and transmit high-frequency signals while aiding rotation in the system. They maintain a low noise level and signal loss, ensuring optimal signal integrity. Their intricate features, specifications, and working principles cater to applications where rapid and seamless data transmission is required. These slip rings primarily rely on advanced manufacturing techniques, carefully chosen materials, and precision engineering to ensure minimal wear, low insertion loss, and stable performance.

- Diverse applications and types of high-frequency slip rings: Owing to their unique features and capabilities, high-frequency slip rings find widespread use in an array of technologically advanced industries. Some common applications include satellite communication systems, medical imaging equipment, radar systems, wind turbines, and high-speed video systems. Additionally, there are various types of high-frequency slip rings that cater to different operational needs. These include high-density, coaxial, and hybrid slip rings, each tailored to the specifications required by industries dealing with high-speed data transmissions and specialized communication networks.

As we explore high-frequency slip rings, their underlying principles, and their specifications, one cannot help but appreciate the ambition and innovation that has gone into their development. These devices are not only powerful but also versatile, meeting the ever-increasing demand for high-speed phenomena in our modern, interconnected world.

How Do High-Frequency Slip Rings Work?

As we delve into the unique world of high-frequency slip rings, understanding their operating principle is essential. While seemingly complex, the functionality of these devices can be simplified into manageable concepts.

Operating Principle of High-Frequency Slip Rings

At their core, high-frequency slip rings work on the foundation of facilitating communication between moving parts. These devices consist of ‘rings,’ connected to the stationary part, and ‘brushes’ on the rotating part of the system. The brushes slide over the rings, creating an electrical connection. As a result, voltage or signal is transferred continuously between the stationary and rotating parts, even at high frequencies. The essence of a high-frequency slip ring’s operation lies in maintaining this connection without significant signal loss under high speed and frequency conditions.

- Role of frequency in data transmission: Frequency can be regarded as the ‘heartbeat’ of data transmission. It determines the rate at which information is sent across the system, with a higher frequency translating to faster transmission speeds. High-frequency slip rings have been developed to accommodate these higher rates efficiently, ensuring that rapid data transfer occurs smoothly and without distortion or loss in quality.

Key Components of High-Frequency Slip Rings

The efficiency and stability of a high-frequency slip ring lie in its crucial components. The rotating assembly includes brushes, typically composed of precious metals for enhanced conductivity and minimal wear. The stationary assembly houses the rings, which are often designed from materials chosen for their durability and high conductivity. Together, these components work in harmony, ensuring the slip ring’s ability to handle high-frequency signals seamlessly.

The key components of high-frequency slip rings are designed to facilitate the reliable transmission of high-frequency signals across a rotating interface. Here are the primary components:

Rotary and Stationary Contacts

- Conductive Rings: These are the circular conductive paths mounted on the rotating part of the slip ring. They are made from materials with high conductivity, such as gold or silver-plated copper, to ensure minimal resistance and signal loss.

- Brushes or Wipers: These are spring-loaded contacts that maintain physical contact with the conductive rings on the rotating part. In high-frequency slip rings, the brushes are often made from low-resistance materials like silver-graphite to minimize electrical noise.

Contactless Transmission Components

- Capacitive Couplers: In slip rings that use capacitive coupling, these components create a capacitive link between the rotating and stationary parts, allowing the high-frequency signal to be transmitted without physical contact.

- Inductive Couplers: These are used in inductively coupled slip rings, where the signal is transmitted via an electromagnetic field. This method is especially useful for high-frequency signals to avoid wear and tear from physical contact.

Dielectric Insulation

- Insulating Layers: These layers are placed between the conductive rings and other components to prevent electrical short circuits and to maintain the integrity of the signal path. The dielectric material must have high insulating properties and be capable of withstanding high frequencies without significant loss.

Signal Conditioning Circuitry

- Impedance Matching Components: These components ensure that the impedance of the slip ring matches the impedance of the connected devices, which is crucial for minimizing signal reflection and maintaining signal integrity.

- Filters and Amplifiers: These may be included to condition the signal as it passes through the slip ring, helping to reduce noise and ensure that the high-frequency signal is transmitted clearly.

Shielding and Grounding

- Electromagnetic Shielding: High-frequency slip rings often include shielding to protect the signal from external electromagnetic interference (EMI). This shielding can be a metal enclosure or a conductive coating around the signal paths.

- Grounding Mechanisms: Proper grounding is essential to prevent signal distortion and to protect the slip ring from potential electrical surges.

Housing and Mounting

- Outer Housing: The slip ring is typically encased in a protective housing that shields the internal components from environmental factors such as dust, moisture, and mechanical damage. The housing is usually made from durable materials like aluminum or stainless steel.

- Mounting Flanges: These are used to securely mount the slip ring to the rotating or stationary parts of the machinery. The mounting must be precise to maintain alignment and ensure consistent contact or coupling.

Signal Transmission Pathways

- High-Frequency Transmission Lines: These pathways are designed specifically to carry high-frequency signals with minimal loss. They may include coaxial cables or other types of transmission lines that are optimized for high-frequency use.

- Connectors: High-quality connectors are used to interface the slip ring with external circuits. These connectors are designed to minimize signal loss and are often gold-plated for better conductivity and reduced oxidation.

Rotational Bearings

- Precision Bearings: The slip ring uses high-quality bearings to ensure smooth and consistent rotation. The bearings are critical for maintaining the alignment of the contacts or couplers, which in turn is crucial for maintaining signal integrity.

These components work together to ensure that high-frequency signals are transmitted reliably across a rotating interface, making high-frequency slip rings essential for applications where both rotation and high-frequency signal transmission are required.

Importance of High-Frequency Slip Rings

High-frequency slip rings hold a unique position in a vast array of industrial applications, including telecommunications, medical equipment, and many others. Their significance often remains hidden, yet is crucial to realizing the full potential of these systems.

- High-frequency slip rings in industrial applications: When considering the various industries that rely on state-of-the-art systems, we find that many of them are intertwined with the need for rapid and seamless data transmission. Telecommunications, for instance, entails real-time transmission of voice and data over vast distances, making high-speed data transfer an essential aspect. Medical equipment such as MRI scanners and CT machines rely on high-frequency slip rings for precise data acquisition and imaging in a timely manner. Radar systems also employ high-frequency slip rings to maintain accuracy during continuous rotation, necessary for tracking and monitoring purposes. In all such applications, the use of high-frequency slip rings becomes vital to achieving uninterrupted, effective communication and optimal performance. In applications that require even more specialized conditions, such as satellite systems or deep-space explorations, high vacuum RF slip rings are used. These slip rings are designed to handle high-frequency signals while maintaining integrity in a vacuum environment, where traditional slip rings may struggle due to the absence of air and the challenges it poses for signal transmission. The high vacuum RF slip ring is thus indispensable in systems that require both high-frequency data transfer and stable performance in extreme conditions. In all such applications, the use of high-frequency slip rings—whether standard or specialized like the high vacuum RF slip ring—becomes vital to achieving uninterrupted, effective communication and optimal performance across various industries, ensuring that these critical systems operate smoothly under demanding conditions.

High-frequency slip rings play a crucial role in various advanced applications that require the transmission of high-frequency signals across rotating interfaces. Here are some of the key reasons why high-frequency slip rings are important:

1. Enabling Continuous Rotation with Signal Integrity:

- Uninterrupted Signal Transmission: High-frequency slip rings allow the transmission of high-frequency signals (such as data, video, or radio-frequency signals) between stationary and rotating parts of a system without interruption. This is essential in applications like radar systems and medical imaging devices, where continuous rotation is necessary.

- Maintaining Signal Quality: These slip rings are designed to minimize signal degradation, noise, and loss, ensuring that the transmitted signal retains its integrity, even at high frequencies. This is critical in systems where high signal fidelity is necessary for accurate performance.

2. Support for High-Speed Data Transmission:

- High Bandwidth Capacity: High-frequency slip rings can handle the transmission of large amounts of data at high speeds, which is important in modern communication systems, data acquisition systems, and Surveillance equipment.

- Efficiency in Data-Intensive Applications: For applications that require the transfer of high-resolution video, real-time data, or other high-bandwidth signals, high-frequency slip rings ensure that these signals are transmitted efficiently and without delay.

- Efficiency and stability in data transmission: The overarching goal of high-frequency slip rings is to facilitate reliable data transfer between stationary and rotating components. These slip rings are specifically engineered to enable faster data transmission without compromising on signal integrity. They minimize insertion loss, ensuring that signals can be accurately transmitted across various system components even in the presence of noise, interference, or mechanical stress. This increased efficiency and stability in data transmission leads to better system performance, faster operation, and ultimately, a more satisfying end-user experience.

3. Enhanced System Reliability and Longevity:

- Durability in Harsh Environments: High-frequency slip rings are often used in environments with high levels of vibration, temperature fluctuations, or exposure to moisture. Their robust design ensures that they can operate reliably under these conditions, reducing the risk of system failure.

- Reduced Maintenance Needs: The contactless transmission methods used in some high-frequency slip rings, such as capacitive or inductive coupling, reduce wear and tear on the components. This leads to longer operational life and less frequent maintenance, which is especially valuable in critical applications.

4. Versatility in Application:

- Wide Range of Uses: High-frequency slip rings are used in a variety of industries, including aerospace, defense, medical, robotics, and telecommunications. Their ability to transmit different types of signals (RF, microwave, video, etc.) across rotating joints makes them indispensable in these fields.

- Customization for Specific Needs: These slip rings can be customized to meet specific application requirements, such as different frequency ranges, signal types, and environmental conditions, making them versatile solutions for a wide range of engineering challenges.

5. Minimization of Electromagnetic Interference (EMI):

- Improved Signal Integrity: By incorporating advanced shielding and grounding techniques, high-frequency slip rings help to minimize electromagnetic interference, which can otherwise disrupt signal transmission. This is particularly important in environments where multiple electronic systems operate in close proximity.

- Enhanced Performance in Sensitive Applications: In applications like medical imaging or military radar, where even minor signal disturbances can have significant consequences, the ability of high-frequency slip rings to reduce EMI is crucial.

6. Facilitating Advanced Technologies:

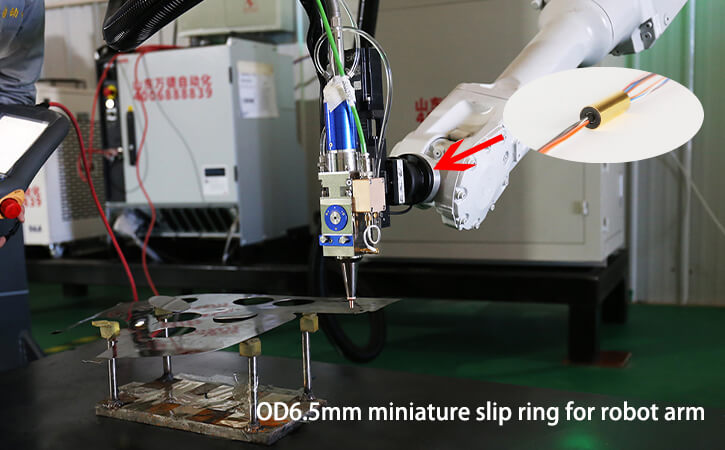

- Enabling Rotating Platforms: High-frequency slip rings are essential in technologies that require rotating platforms, such as antenna systems, gyroscopes, and robotic arms. They allow these systems to operate while maintaining a continuous flow of data or power.

- Support for Emerging Technologies: As technology advances, the demand for higher-frequency and higher-bandwidth signal transmission increases. High-frequency slip rings are crucial in supporting these emerging technologies, enabling new possibilities in fields like 5G communications, autonomous vehicles, and advanced manufacturing.

7. Contribution to Compact and Lightweight Designs:

- Space-Saving Solutions: High-frequency slip rings are often designed to be compact and lightweight, which is important in applications where space and weight are at a premium, such as in aerospace or portable medical devices.

- Integration into Complex Systems: Their ability to be integrated into compact and complex systems without compromising performance makes them valuable components in modern engineering.

High-frequency slip rings are vital for ensuring reliable, high-quality signal transmission in rotating systems, supporting the demands of modern technology in a wide array of applications.

By considering the importance of high-frequency slip rings, it becomes clear that the role they play within modern industrial applications is indispensable. The ability to enhance data transmission efficiency and stability underpins the success and functionality of many crucial systems that ultimately impact our daily lives.

High-Frequency Coaxial Slip Rings

High-frequency coaxial slip rings are specialized types of slip rings designed specifically for transmitting high-frequency signals through coaxial cables across a rotating interface. These slip rings are used in applications where maintaining signal integrity at high frequencies is critical. Here’s an overview of their key features, operating principles, and applications:

Key Features of High-Frequency Coaxial Slip Rings

- Coaxial Cable Integration:

- Signal Transmission: High-frequency coaxial slip rings are designed to transmit signals via coaxial cables, which consist of an inner conductor, an insulating layer, an outer conductor (shield), and an outer insulating layer. This structure helps maintain signal integrity by minimizing interference and loss.

- Impedance Matching: The slip rings are designed to match the characteristic impedance of the coaxial cables (typically 50 or 75 ohms) to prevent signal reflection and maintain signal quality.

- High-Frequency Capability:

- Frequency Range: These slip rings are capable of transmitting signals at very high frequencies, often in the GHz range, making them suitable for applications involving RF, microwave, or high-speed digital signals.

- Low Insertion Loss: High-frequency coaxial slip rings are engineered to minimize insertion loss, ensuring that the signal strength remains high as it passes through the slip ring.

- Precision Engineering:

- Mechanical Design: The mechanical components of the slip ring are precisely engineered to ensure consistent contact and alignment between the rotating and stationary parts, which is crucial for maintaining signal integrity at high frequencies.

- Low Crosstalk and Noise: The design minimizes crosstalk (unwanted transfer of signals between adjacent channels) and electromagnetic interference, ensuring that high-frequency signals are transmitted cleanly.

- Durability and Reliability:

- Materials: High-frequency coaxial slip rings use high-quality materials, such as gold-plated contacts and specialized dielectric insulators, to ensure durability and consistent performance over time.

- Shielding: Enhanced shielding is often included to protect against external electromagnetic interference (EMI) and to maintain signal integrity in environments with high levels of electrical noise.

Operating Principle

High-frequency coaxial slip rings operate by maintaining a continuous electrical connection between the rotating and stationary parts of the system through a coaxial structure. The central conductor carries the signal, while the outer conductor (shield) provides a return path and protects against EMI.

- Rotary Contact Mechanism:

- In traditional designs, rotary contacts are used, where brushes or other conductive elements maintain physical contact with the rotating coaxial rings. The precision of these contacts is crucial to minimize signal degradation.

- Contactless Transmission: Some advanced designs may use contactless methods like capacitive or inductive coupling, especially in very high-frequency applications where even slight contact resistance could degrade the signal.

- Signal Integrity:

- Consistent Impedance: Maintaining consistent impedance throughout the slip ring assembly is essential to avoid signal reflections and ensure that the high-frequency signals are transmitted accurately.

- Low Loss Pathways: The internal design of the slip ring ensures that the signal pathways have low resistance and capacitance, which helps maintain the integrity of the high-frequency signals.

Applications of High-Frequency Coaxial Slip Rings

- Radar Systems:

- Used in radar systems where the antenna rotates continuously while transmitting and receiving high-frequency signals. The slip ring allows the antenna to rotate without interrupting the signal path.

- Satellite Communications:

- Essential in satellite communication systems, where high-frequency signals need to be transmitted between stationary and rotating parts, such as in tracking antennas.

- Medical Imaging Equipment:

- Applied in medical devices like MRI and CT scanners, where high-frequency signals need to be transmitted from rotating imaging components to stationary receivers.

- Aerospace and Defense:

- Used in various aerospace and defense applications where high-frequency signal transmission is required in rotating assemblies, such as in gyroscopes or rotating radar antennas.

- High-Speed Data Transfer:

- Utilized in systems requiring high-speed data transfer, such as advanced robotics, autonomous vehicles, and high-resolution video transmission systems.

Advantages of High-Frequency Coaxial Slip Rings

- High Signal Integrity: Ensures that high-frequency signals are transmitted with minimal loss, reflection, or interference.

- Wide Frequency Range: Capable of handling a broad range of frequencies, making them versatile for different applications.

- Durable and Reliable: Engineered for longevity, with materials and designs that withstand the demands of continuous operation in challenging environments.

In summary, high-frequency coaxial slip rings are critical components in systems that require the reliable transmission of high-frequency signals across rotating interfaces, supporting the functionality of advanced technologies in various industries.

Purchasing Considerations for High-Frequency Slip Rings

The purchasing process for high-frequency slip rings is nuanced, requiring potential buyers to consider several factors that contribute to their decision-making. By being aware of these considerations, buyers can ensure the seamless integration of high-frequency slip rings into their respective applications.

Factors to consider during purchase: Some critical factors buyers must consider when purchasing high-frequency slip rings include:

- Type of application: The specific application will play a significant role in determining the requirements for the high-frequency slip ring, including operational environments, the necessary speed of data transmission, and system compatibility.

- Speed of data transmission: Matching the speed of data transmission to the needs of the application is vital, and buyers may be required to select slip rings capable of managing their specific data rates.

- Design: Slip rings can vary in terms of size, dimensions, and configuration. These factors have a bearing on their ability to fit into existing systems, as well as their ease of installation and maintenance.

- Material: Selecting the right materials for both the rings and brushes will ensure optimal performance, durability, and minimal wear.

- Cost: While cost should not be the primary driver, it plays a role in determining the overall financial investment, including the initial purchase as well as ongoing maintenance and replacement costs.

Common customizations and modifications available: The high-frequency slip ring market accommodates numerous customization options tailored to meet specific industrial requirements. Some common customizations and modifications include:

- Hybrid slip rings: Combining electrical power transmission with high-frequency signal transfer or integrating additional functionalities such as fiber-optic rotary joints, and hydraulic or pneumatic rotational interfaces.

- Custom designs: Adapting the slip ring size, dimensions, and configuration to fit into unique system architectures or specialized applications.

- Sealing and protective measures: Providing enhanced protection or sealing for harsh operational environments, including extreme temperatures, humidity, dust, or corrosive atmospheres.

- Certifications and standards: Meeting specific industry regulations or certifications, ensuring compatibility with defined safety and performance requirements.

In summary, when purchasing high-frequency slip rings, careful consideration of various factors such as application type, data transmission speed, design, material, and cost will ensure that the selected components meet the requirements of their intended use. Additionally, understanding the numerous customizations and modifications available can help buyers tailor their chosen slip rings to suit their unique needs, ultimately maximizing performance and value.

Installation and Maintenance of High-Frequency Slip Rings

Like any sophisticated machinery component, ensuring the proper installation and maintenance of high-frequency slip rings is a cornerstone of their operational success. How they’re handled can have a direct impact on their performance, reliability, and lifespan.

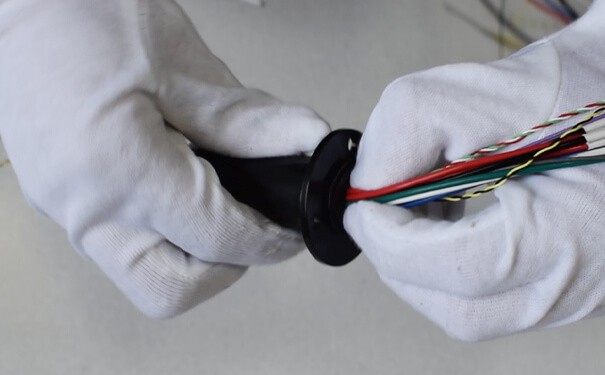

- Installation of high-frequency slip rings: To properly install high-frequency slip rings, certain steps are recommended. First, it’s crucial to read the manufacturer’s instructions thoroughly to learn about any specific requirements or precautions. The environment should be kept clean to avoid contamination during installation. The stationary and rotating parts should be appropriately aligned to minimize mechanical stress on the slip ring. Secure fastening methods must be used to ensure the stability of the slip ring during operation. Lastly, the connections should be double-checked to confirm proper transmission of power or signals.

- Routine maintenance: Regular maintenance of high-frequency slip rings can drastically enhance their performance and longevity. It may involve routine inspections to detect and rectify wear and tear early, cleaning to remove dirt or corrosion, keeping the device’s surroundings free of dust and debris, and lubrication (if required by the manufacturer). Regular testing should be conducted to identify any decrease in performance or signal transmission capability, allowing for early detection of potential issues and prompt corrective measures.

- Troubleshooting common issues: Several issues can arise with high-frequency slip rings, such as signal loss, noisy operation, or erratic rotation. When troubleshooting, identifying the root cause is first: check for loose connections, worn-out components, debris accumulation, or mechanical misalignments. Most of the time, issues can be resolved with simple adjustments, replacements, or cleaning, but in some cases, professional expertise may be required to avoid damaging the slip ring.

By taking these considerations into account, operators can ensure proper installation, carry out effective maintenance, and handle potential issues promptly, thus paving the way for steady, dependable operation of high-frequency slip rings. As with any critical component, the effort and precision put into caring for these devices play telling roles in their operational success.

The Future of High-Frequency Slip Rings

Navigating ever-changing technological landscapes, the future of high-frequency slip rings is brimming with constant research and development. Anticipating future trends is vital to understanding how these key components may evolve over time.

- Ongoing research and development: The world of high-frequency slip rings is a dynamic one. As our reliance on rapid and efficient data transmission keeps growing, so does the need for innovative and enhanced versions of these devices. Research and development are currently geared towards achieving higher rotational speeds, improving signal quality, delivering multidimensional capabilities, and increasing the lifespan of slip rings. Materials scientists, electrical engineers, and mechanical engineers are continuously working together to develop slip rings that are smaller, lighter, more robust, and capable of handling increasingly complex tasks.

- Future trends: Based on current advancements and market needs, several future trends can be predicted for high-frequency slip rings. One potential trend is the further integration of advanced materials and nanotechnology, which can lead to improved durability and performance under a broader range of conditions. Another is the emergence of more hybrid models, capitalizing on multifunctionality to enhance overall system efficiency. We may also see increased use of wireless technology to reduce mechanical wear and overcome limitations associated with physical connectors. Automation and intelligent systems may also become routine, with slip rings featuring monitoring capabilities for predictive maintenance and enhanced performance.

The future of high-frequency slip rings remains bright and full of promise. As we continue to push the boundaries of technology, these critical components will evolve, becoming even more effective in facilitating the high-speed, reliable, and efficient transfer of signals and power. It’s a fascinating journey the world is looking forward to witnessing.

Conclusion

Whether you’re new to the topic or are looking for in-depth knowledge, understanding high-frequency slip rings is paramount. They are vital components of modern technological operations and are set to hold continued significance in the future.

Want to know more about our products? Fill out the form to receive detailed specifications.

FAQs about High-Frequency Slip Rings

Tailoring responses to audience concerns, the FAQ section aims to provide clear, concise answers to common questions users often have about high-frequency slip rings. These FAQs are derived from extensive market research and customer interactions, enabling a deeper understanding of these devices.

Q: What is a high-frequency slip ring?

A: A high-frequency slip ring is a device that facilitates the transmission of high-frequency signals between stationary and rotating parts of a system. It serves as a pivotal component in many applications where high-speed data transmission is essential, such as telecommunications, radar systems, and medical equipment.

Q: What factors should I consider before purchasing a high-frequency slip ring?

A: Selecting a high-frequency slip ring requires consideration of factors such as the specific application, data transmission speed, cost, material, and design. Understanding your requirements and matching them with the capabilities of the slip ring will ensure optimal performance.

Q: What are some common customizations available?

A: The high-frequency slip ring market entertains numerous customization options. Some common customizations include hybrid slip rings which combine electrical power and high-frequency signal transfer, custom designs to fit unique system architectures, additional protective measures for harsh operational environments, and adherence to specific industry certifications and standards.

Q: How do I install and maintain a high-frequency slip ring?

A: Installation should adhere to the manufacturer’s guidelines and ensure clean, aligned, stable installation and correct connections. Regular maintenance includes routine inspections, cleaning, keeping surroundings free of dust and debris, lubrication (if required), and regular performance testing.

Q: What ongoing research and future trends can we expect in high-frequency slip rings?

A: Research in high-frequency slip rings is focused on improving signal quality, rotational speeds, multi-functionality, and durability. Future trends may see increased use of advanced materials and nanotechnology, the emergence of more hybrid models, wireless technology, and automation in slip rings.

These FAQs should help to clear up some of the common queries about high-frequency slip rings, providing more clarity toward understanding their significance, purchase considerations, installation, and future expectations. If further questions arise, customers should not hesitate to reach out for assistance and seek professional guidance.

See What We Can Do