In today’s technologically driven world, electrical capsule slip rings play a vital role in various electromechanical systems. This article aims to provide a comprehensive understanding of these devices, focusing on their operation, specifications, applications, pros, cons, prominent manufacturers, and tips for maintenance and troubleshooting.

Introduction to Electrical Capsule Slip Rings

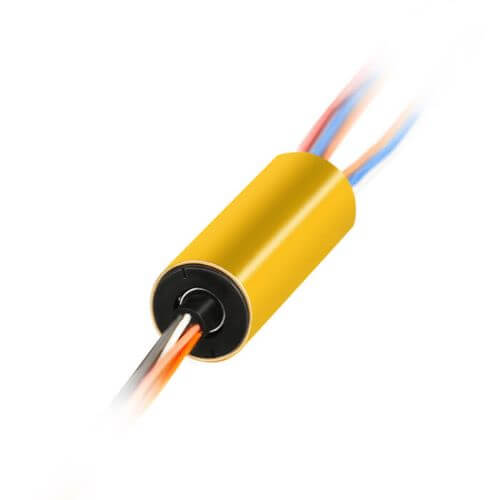

In our technologically advanced world, electrical capsule slip rings stand as a testament to ingenious engineering. They are subtle, usually overlooked, yet crucial components that form the backbone of various electrical and mechanical systems bridging the divide between moving parts and stationary sources.

Electrical capsule slip rings are essentially electromechanical devices. Their primary purpose is facilitating the transfer of power and electrical signals from a stationary point – often referred to as a stator – to a rotating structure named a rotor. This precise functionality forms the core of their operational foundation.

These devices often find their place in a staggering array of electromechanical systems, where they essentially act as a means to sustain constant interaction between stationary and moving parts without the need for obstructive cables that might limit rotation or cause potential tangles. They become the key to maintaining consistent, uninterrupted rotations. That[‘s the incredible beauty of their capabilities nestled within their humble structure.

This simple yet powerful mechanism of maintaining connections during full 360-degree rotations opens the doors to countless possibilities where electrical or signal transmission is required between the rotating and stationary parts. From medical equipment to wind turbines, and video systems to industrial machinery, they appear in an array of applications, shedding light on their ubiquitousness in the realm of mechanism.

Fully appreciating the workings and applications of these devices mandates delving deeper into their operational principles, types and specifications, advantages, maintenance requirements, and finally the critical considerations before opting for them. However, before wrapping up this introduction, it’s important to underscore again the tremendous impact they have on our technological environment – all while silently operating in the background.

Let’s now turn our attention to the interesting world of electrical capsule slip rings, their mechanics, and how they seamlessly integrate within various industrial, commercial, and residential technologies. By the end of this exploration, you’ll gain an in-depth understanding of these crucial devices, possibly viewing the world of electromechanics through a renewed and informed perspective.

Mechanism and Working Principle of Electrical Capsule Slip Rings

The magic of electrical capsule slip rings lies in their ability to create an electrical bridge between a stationary and a rotating part. But how, exactly, do they pull off this amazing feat? The answer lies in their unique design and working principle.

At its core, a capsule slip ring consists of two primary components – the metal rings and conductive brushes. These components form the two halves of a constantly moving relationship, working together in a seamless symphony to vanquish the physical limitations of rotational energy transmission.

Let’s break down their roles for a clearer picture. The metal rings are attached to the rotating shaft of the device. They’re designed to rotate synchronously with it. Various metals could be used for these rings, but to ensure the most efficient transmission of signals or electricity, good conductivity is a desirable trait – hence metals like copper, gold, or silver are often used.

This is where the brushes, made usually from precious metal composites, copper or graphite, come into play. They are in constant physical contact with the rotating metal rings and are anchored to the stationary part of the device. So, when the metal rings rotate, the brushes follow their curves, maintaining their touch at all times. This condition initiates the transfer of electrical signals or power from the stationary part, through the brushes to the spinning rings, and eventually, to the output device.

A key consideration in this configuration is the interface between the brush and the ring. Given the constant friction between them, it’s imperative to facilitate smooth, uninterrupted contact. Wear and tear must be minimized while ensuring high-quality transmission. This is where contact materials, predominantly precious metals, find their use due to their excellent conductivity, low friction, and corrosion resistance.

Lastly, while we often find single-ring, single-brush configurations, it is not uncommon for more complex devices to possess numerous brushes and rings. This multiplicity allows for the simultaneous transmission of multiple data signals or power pathways.

In essence, electrical capsule slip rings embody a fascinating mystery – serving as an unfailing bridge for rotating and stationary components. Their ability to transform a simple rotation into an opportunity for continuous electrical connectivity highlights their technical ingenuity, affirms their wide-ranging implications, and justifies the indispensability they hold within the realm of electromechanical systems.

Specifications and Types of Electrical Capsule Slip Rings

Electrical capsule slip rings come in various forms, each designed meticulously to cater to the diverse demands of their unique applications. Their designs and specifications vary across an array of identifying characteristics, ensuring a level of customization to fit a wide spectrum of application needs. It’s this flexibility and adaptability that sets them apart in the world of electromechanical components.

A crucial way of classifying capsule slip rings is by the number of circuits they contain. The number of electrical paths or channels a slip ring can support delineates its complexity and range of applications. Single-circuit slip rings are the simplest, supporting only one electrical channel, whereas multiple-circuit slip rings can support several electrical pathways, enabling concurrent transmission of multiple data signals or power across independent channels.

Another essential specification is the current rating. The current rating of a slip ring ultimately decides the maximum current it can carry safely. This characteristic is critical as devices with high power requirements would need a high-current slip ring, while low-power devices could do with a low-current variant.

Voltage rating, much like current rating, determines the maximum voltage that the slip ring can accommodate without reaching its electrical breakdown point. It’s important that the voltage rating aligns with the voltage of the power source it’s meant to connect with.

With rotational speed, the slip rings vary widely. Some variants are designed to operate at low speeds, while others can withstand high-speed operations. This specification defines the maximum speed at which the slip ring can function optimally without compromising its mechanical integrity or electrical performance.

Size, inevitably, is a key determining factor. The compact capsule slip rings are ideal for space-constrained applications, while larger units are desirable when there are limited spatial restrictions but substantial electrical requirements.

Temperature range and IP (Ingress Protection) Rating highlight their adaptability to different environments. The temperature range identifies the operating temperature limits of the slip ring, while IP ratings represent their resistance against dust and water ingress.

Overall, the assortment available in the electrical capsule slip rings tightly mirrors the multifariousness of their applications. Whether it’s in the medical field, the robotics industry, the defenses, or even in mundane household appliances, having an understanding of these specifics and identifying characteristics allows users to consciously choose the optimal slip ring variant for their peculiar needs.

Applications of Electrical Capsule Slip Rings

From the most unassuming personal gadgets to the largest and most complex industrial machinery, electrical capsule slip rings find applications that run the gamut of size, complexity, and industry. Their critical role in enabling smooth, uninterrupted rotation while maintaining electrical connectivity makes them indispensable in numerous fields. Here, we elucidate some of the countless applications of these unsung heroes in the empowering story of modern technology.

Perhaps one of the most prominent uses of electrical capsule slip rings is in the realm of imaging and surveillance systems. In CCTV cameras, for example, they allow the camera to pan a full 360 degrees, continuously transmitting power and data signals between the stationary and the rotating parts.

In the field of medicine, they feature extensively in medical imaging devices like MRI and CT scanners. Here, capsule slip rings facilitate the transmission of power and data between the stationary body of the scanner and the rotating imaging components, playing an instrumental role in creating high-resolution medical images.

The aeronautics and defense industries, too, benefit from the functionalities of capsule slip rings. Drones, missiles, and radar systems, for instance, rely on these components for unhindered transmission of data and power during continuous rotation, ensuring effective performance and precise control.

Industrial areas, such as robotics and automation, leverage the compact size and multiple pathways offered by capsule slip rings. These devices allow for smooth, unrestricted movement of robotic arms and conveyors, transferring power, control signals, and data in real-time.

In renewable energy applications, particularly wind turbines and solar panels, electrical capsule slip rings come to the forefront. They enable the turbines and panels to freely rotate with the wind or track the sun without the fear of damaging or tangling electrical cables, thereby ensuring efficient energy production.

Relatively smaller but equally significant applications include rotary sensors, test equipment, exhibit/display equipment, and even musical instruments such as electric guitars.

The ability of electrical capsule slip rings to accommodate diverse forms, sizes, and specifications is entirely responsible for the breadth and variety of their applications. Coupled with their unique mix of reliability, flexibility, and innovative functionality, these versatile devices serve as the pivot around which an enormous range of industrial and commercial operations revolve, testifying to their immense importance in our technology-driven world.

Advantages and Disadvantages of Electrical Capsule Slip Rings

Like any other mechanical or electrical component, electrical capsule slip rings come with their unique set of advantages and challenges. These factors can significantly influence the decision to choose slip rings for an application, and a comprehensive understanding of them aids in recognizing their fit for specific uses.

When it comes to advantages, the ability of electrical capsule slip rings to facilitate continuous 360-degree rotation without the interruption of power or signal supply stands as their primary benefit. They eliminate the need for tangling wires, which would otherwise restrict the movement of rotating bodies, paving the way for free and uninterrupted rotation-based operations.

Their range of types and specifications offer a high degree of customizability to fit an array of applications. From multiple circuits, differing current and voltage ratings, operational speeds, and size limitations, capsule slip rings cater to a wide spectrum of requirements within diverse industries.

Moreover, their operational reliability and durability provide long-lasting performance under various environmental conditions. Enhanced models come with sophisticated contact technology and high-quality materials that reduce wear and tear, increase service life, and maintain smooth electrical transmissions.

Despite these benefits, some considerations may present challenges. One such challenge is mechanical wear and tear. Regular contact between the brushes and rings during rotation can result in friction, leading to degradation over time. This issue necessitates periodic maintenance and possible replacements, contributing to operational costs.

Another downside might be the potential noise generation caused by brush and ring contact, especially at high rotational speeds. While this might not be a concern for most industrial applications, it may limit the use of capsule slip rings in environments where noise levels need to be kept to a minimum.

Lastly, electrical noise or signal interference can be a challenge in some applications. The configuration of the slip ring might introduce minor voltages that can interfere with the signal being transmitted, which can affect the signal quality.

These advantages and challenges portray an accurate picture of what electrical capsule slip rings bring to the table. Their pros and cons need to be evaluated against the requirements of the specific application in question, helping design and engineering teams make informed decisions, and ultimately aligning the features of the slip ring with the needs of the application.

Leading Manufacturers and Suppliers of Electrical Capsule Slip Rings

The global market for electrical capsule slip rings boasts a multitude of key players, each bringing a unique blend of technological prowess and varied product offerings. Below are some of the leading manufacturers who have distinguished themselves through the quality, innovation, and reliability of their products.

| No. | Manufacturer | Website |

|---|---|---|

| 1 | Hangzhou Grand Technology | https://www.grandslipring.com/ |

| 2 | Moog Inc. | https://www.moog.com/ |

| 3 | Stemmann-Technik | https://www.stemmann.com/en/home |

| 4 | Schleifring | https://www.schleifring.com/ |

Hangzhou Grand Technology

Hangzhou Grand Technology Co., Ltd. started as a special slip ring manufacturer in 2011. Grown into slip rings, rotary joints, and slip ring assembly experts of today with 6,000 square meter manufacture complex.

Obtained ISO9001, Rosh, CE, and GJB9001B certificates a number of slip rings, rotary joint patents, and proud of our products can meet military grade. Collaborated with universities, institutes, and renowned factories across Asia and Europe including Panasonic, SIEMENS, CSIC, SAMSUNG, HUAWEI, etc.

Moog Inc.

Moog is a leading supplier of high-performance slip rings for various industries, including aerospace. Among their offerings, Moog’s SR Series Slip Rings are designed for the demanding environments of helicopters, excelling in performance, reliability, and customization potential.

Stemmann-Technik

Stemmann-Technik, a part of the Conductix-Wampfler Group, offers a broad range of slip rings, including solutions for helicopters. Their Livietta Slip Ring Assemblies are designed explicitly for harsh and demanding environments in the aviation sector, providing reliable signal and power transmission.

Schleifring

Schleifring is a well-known manufacturer of electromechanical systems, including slip rings customized for various industries. Their Aircraft Slip Rings cater specifically to helicopters, offering robust performance, low wear, and high reliability to meet the challenges of aviation applications.

If you want to know more about other slip ring manufacturers, you can read Top 10 Slip Ring Manufacturers in China, Top 10 Slip Ring Manufacturers In the USA Market 2023, and Top 10 Slip Ring Industry Key Manufacturers 2023.

What sets these manufacturers apart is their commitment to quality, ongoing innovation, and flexibility in meeting unique customer requirements. Their focus on delivering reliable, efficient, and durable slip rings has made them the go-to choice for organizations around the world. By staying ahead in their R&D pursuits and responding swiftly to market trends, they continue to lead in an ever-evolving industry landscape.

Maintenance and Troubleshooting of Electrical Capsule Slip Rings

Maintaining and troubleshooting electrical capsule slip rings is vital to ensure their reliable performance and prolong their operational life. Understanding common problems, their causes, and corresponding solutions can go a long way in effectively managing these critical components.

One of the most common maintenance procedures for capsule slip rings involves inspection and cleaning of the contact surfaces. Regular inspection helps identify potential wear and tear while cleaning ensures the removal of dust and debris that could cause friction or degrade electrical conductivity.

When it comes to troubleshooting, below are some common problems encountered with capsule slip rings, along with their causes and solutions:

- Intermittent signals: This can be due to dirty or worn-out contacts, poor brush contact, or damaged wires. To resolve this, inspect the brushes and rings for wear, and clean or replace them if necessary. Check for any visible wire damages and make replacements if needed.

- Increased electrical noise: This is often caused by insufficient grounding, damaged bearings, or worn-out brushes. Ensure proper grounding of the slip ring. Inspect for bearing damages and replace if required. Also, check the brushes for signs of wear and replace them if they are worn out to reduce the contact noise.

- Overheating: Overheating can be due to excessive current, high rotational speed, or poor heat dissipation. Review the current and speed ratings of the slip ring to ensure they match the application. Increase heat dissipation by improving the cooling conditions or selecting a slip ring with a higher current rating.

- Failure to transmit signals: This can be a result of failed connections, damaged rings, or brushes. Check and repair any loose connections. Inspect the springs that hold the brushes to the rings – if they are too loose, they may require adjustment or replacement. Make sure to also verify the circuit continuity.

In all cases, referring to the slip ring’s manual and adhering to the manufacturer’s maintenance guidelines is crucial. If the issue persists despite your best efforts, reaching out to the manufacturer’s support team may be necessary. Remember, regular maintenance and prompt troubleshooting are integral to leveraging the operational effectiveness of electrical capsule slip rings in the long term.

Factors to Consider When Choosing Electrical Capsule Slip Rings

Selecting the right electrical capsule slip ring involves careful consideration of numerous factors. A well-thought-out choice can ensure high operational efficacy, longevity, and cost-effectiveness in the application’s context. The following factors serve as a guide when choosing a capsule slip ring:

- Specifications: The technical specifications top the list of considerations. These include the number of circuits, current and voltage ratings, maximum speed of operation, size specifications, and operational temperature range. The chosen slip ring should ideally align perfectly with the requirements of the application.

- Cost: The overall cost is a critical factor. While cheaper options might seem attractive, they might not provide the desired quality or longevity. Similarly, more expensive options might not necessarily equate to better performance. Therefore, it’s important to balance quality with cost-effectiveness.

- Manufacturer Reputation: The reputation and credibility of the manufacturer have a significant impact on the choice of slip rings. Manufacturers with a proven track record of delivering high-quality products that stand the test of time are typically preferred.

- Durability and Maintenance: Consider the durability of the slip ring and the frequency of required maintenance. Devices that can withstand tough conditions and require less frequent upkeep often prove beneficial in the long run.

- Aftersale Service: Strong aftersale service is a critical factor. Maintenance, replacement parts, and customer support, including technical assistance for installation or troubleshooting, are essential services that provide peace of mind and promote the longevity of the device.

- Customizability: The ability to customize the slip ring based on specific needs can be a key deciding factor. This includes alterations in circuits, different types of signals, unique sizes, or specific materials used.

- Regulatory Compliance: The selected slip ring must comply with all applicable industry regulations and safety standards.

By considering these factors, you can ensure the chosen electrical capsule slip ring fits your project’s requirements most accurately and can function optimally. Remember, your decision directly influences the performance of the slip ring and, by extension, the effectiveness of the whole setup it forms a part of.

Conclusion

Electrical capsule slip rings, with their compact design and multifaceted operational capabilities, play an essential role in sustaining various industrial operations. Understanding their working types, applications, and maintenance practices can lead to more informed decision-making, culminating in improved user experience and extended device longevity. Whether you are an end-user, a technician, or a hobbyist, this knowledge empowers you to choose the most fitting electrical capsule slip rings for your unique requirements.

See What We Can Do