In this comprehensive guide on “How Does a Slip Ring Work?”, we delve into the intricacies of slip rings, demystifying its complex mechanisms and highlighting its indispensable role in various industries. This multi-chaptered journey takes the readers through the fundamentals of slip ring’s structural mechanics, the relevant electrical concepts, its varied types and their workings, application across industries, troubleshooting, future innovations, maintenance, and answers to frequently asked questions. Ultimately, the article emphasizes the vital necessity of understanding slip rings to appreciate their impact on modern technology and inspire further exploration within the realm of electrical engineering and component design.

Introduction to “How Does a Slip Ring Work?”

Welcome to the intriguing world of electrical engineering, where we explore the driving force behind today’s technologies and auspicious innovations. Together, let’s delve into the workings of an essential yet often overlooked component- the slip ring. Our journey will guide us through the fascinating realms of mechanical design, electrical principles, and their unison that creates an impressive technology, impacting robotics, renewable energy, and beyond.

Slip rings, also known as rotary electrical interfaces, electrical rotary joints, or collectors, are devices specially designed to transfer power, data, or signals from a stationary part to a rotating part in a system. They are instrumental in devices we interact with daily as well as the machinery propelling industry 4.0.

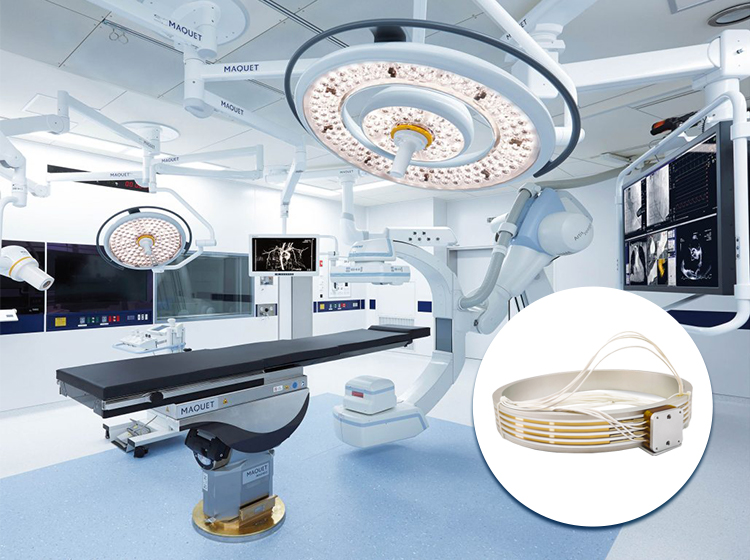

From the MRI scanning machines in hospitals to the wind turbines towering in renewable energy farms or the satellites orbiting our planet – slip rings play a key role in ensuring these complex machines function seamlessly.

As our journey unfolds, we will be unmasking the structure and the design principles of slip rings, looking closely at different types, their versatile applications across diverse industry sectors, and how they uniquely cater to each industry’s specific needs. We will explore common challenges that come with operating slip rings, how to troubleshoot these issues, and methods to extend their life span and ensure optimal performance.

Our voyage won’t stop there; we will dive into the future, peering at the oncoming developments and how changing demands are shaping new-gen slip rings. We will also address those curious questions that often linger unasked yet unanswered.

Each chapter serves as a building block, providing you with an integral understanding of “how does a slip ring work?” By the end of this adventure, you’ll comprehend not just the mechanics but the significance of this component, perfecting your knack for troubleshooting, maintenance, and even foreseeing future trends.

So let’s turn the page and start exploring the whimsical world of slip rings, understanding the catalysts behind technological revolutions, one spin at a time.

The Basic Mechanics of How Does A Slip Ring Works

In this chapter, we take a fascinating dive into the heart of how a slip ring functions, unraveling the core components that make up its sophisticated design. Imagine, if you will, a bustling city at night — buildings, streets, and cars illuminated by an intricate network of electricity. Just as power lines deliver electricity to light up this city, slip rings provide a continuous flow of power and data, ensuring that systems rotate smoothly, without losing their connection to vital resources.

What Is the Slip Ring Structure

At its most fundamental, a slip ring consists of three primary parts: the brush, the ring, and the housing. Each component plays a crucial role in maintaining a seamless electrical connection between stationary and rotating parts of a system.

- The Brush: Acts much like an artist’s brush, but instead of painting, it ‘paints’ electrical current across a rotating surface. Made from conductive materials like graphite or precious metals, the brush maintains contact with the slip ring’s surface as it rotates, ensuring a steady transfer of power and signals.

- The Ring: This is the ‘canvas’ on which the brush works. The ring rotates, carrying with it whatever device or component needs to turn — from wind turbine blades to medical equipment. It’s coated in conductive materials, designed to effectively transfer electrical signals from the brush.

3.The Housing: Protective and sturdy, the housing encases the ring and brush assembly. It safeguards the components from environmental factors, debris, and ensures the system operates smoothly without interference.

How It All Comes Together

When in motion, the brush and ring form an uninterrupted loop for electrical currents to flow. This system allows for power and data signals to be transmitted across rotating parts without the need for tangled wires or complex systems, which would otherwise inhibit movement or suffer from wear and tear.

Visual Explorations

[Note: Ideal diagram here would depict a cross-section of a slip ring, highlighting the brush, ring, and housing, labeling each part and showing the direction of electrical current.]

Imagine a wind turbine; its blades need to rotate freely to catch the wind, yet they also need power for sensors and controls that collect data on wind speed and direction. Here, the slip ring is pivotal, ensuring these rotating blades stay connected to the body of the turbine, which is stationary.

Real-World Application: The Mars Rover

Let’s propel our understanding into space with the Mars Rover example. Tasked with roaming the Martian landscape, the rover demands a slew of devices – from cameras to scientific instruments – to rotate in multiple directions. The slip ring within ensures that, despite the harsh Martian environment and the constant motion, power and data are consistently delivered, enabling the rover to send invaluable information back to Earth.

This chapter set the stage, revealing the slip ring’s basic mechanics and components. Understanding this foundation will prepare us for the more intricate exploration of electrical principles and the diverse types of slip rings that cater to various industry needs.

As we move forward, remember the slip ring’s role is much like that of our city’s power lines – unseen yet essential, keeping the lights on and machines working, no matter how or where they rotate.

The Electrical Principles Behind How Does A Slip Ring Works

Taking off from where we left in the previous chapter, we now journey into the electrical principles that underpin the operation of a slip ring. Think of these principles as the rules that govern the flow of traffic in our electrified city analogy. Just as traffic laws maintain the smooth, safe, and productive movement of vehicles, electrical principles such as resistance, conductivity, and insulation ensure the efficient transmission of power and signals across the rotating interface of a slip ring.

The Fundamentals: Resistance, Conductivity, and Insulation

To understand how slip rings work, we have to get familiar with these three key principles:

- Resistance: This is akin to the friction or obstacles faced by vehicles on a road. In an electrical system, resistance is the opposition to the flow of electricity. It’s crucial to minimize resistance in a slip ring to ensure efficient energy transmission and prevent excessive heat production which could damage the system.

- Conductivity: If resistance is about the obstacles, conductivity relates to how wide and clear the roads are for the traffic. In other words, conductivity refers to the ability of a material to permit the flow of electricity, with metals like copper and silver, which we find in slip rings, having high conductivity enabling smooth energy transfer.

- Insulation: Think of insulation as the traffic barriers that protect pedestrians from vehicles. In a slip ring, insulation is the material that isolates the conductive parts, preventing unwanted current leakage or short circuits, thereby avoiding damage and ensuring safe operation.

Applying These Principles to Slip Ring Design

With an understanding of these core principles, let’s discuss how they intertwine in designing an efficient slip ring:

- Managing Resistance: Slip ring designers pay meticulous attention to minimizing resistance. They achieve this by carefully choosing materials for the brush and the ring that will result in low contact resistance. This, in turn, ensures a smooth, efficient power transfer.

- Promoting Conductivity: Selecting materials with high conductivity is pivotal in slip ring design. Metals like gold, silver, or copper often lace the contact interface to facilitate efficient electricity flow even while rotating.

- Implementing Insulation: Designers wisely place insulation materials between conductive paths (ring circuits) in a slip ring. This keeps the transmission routes separate, preventing errors and complications that could halt the flow of power or data.

Making Sense of Electrical Principles in Real-World Applications

A practical reflection of these principles can be found in wind turbines. A wind turbine’s massive blade assembly must rotate to harness the wind energy, all while staying electrically connected to the stationary parts of the turbine. This connection enables the transfer of power and signals needed for sensors, controls, and other electrically dependent components.

For this assembly to rotate smoothly without overheating or short-circuits, the slip ring’s design must strike a balance between minimizing resistance, ensuring high conductivity, and applying insulation effectively.

Through these principles, we can see how each attribute of a slip ring focuses on maintaining a seamless, efficient flow of power and signals across a rotating interface. These principles are foundation blocks, guiding the design and operation of slip rings, ultimately enabling the impressive array of applications we see in the next chapter.

Remembering our electrified city, the rules of the road help guide the electricity’s journey, making sure it arrives safely and efficiently whatever its destination might be.

Types of Slip Rings and the Mechanics Behind Each of How Does A Slip Ring Works

Embarking further into our journey of understanding slip rings, we now explore the diverse types that have evolved to meet specific needs across various industries. The slip ring universe is vast, with designs ranging from compact pancake styles to intricate wireless systems – each tailored for distinct applications. This chapter will identify and dissect these variations, revealing how their unique designs facilitate seamless operation in their respective realms.

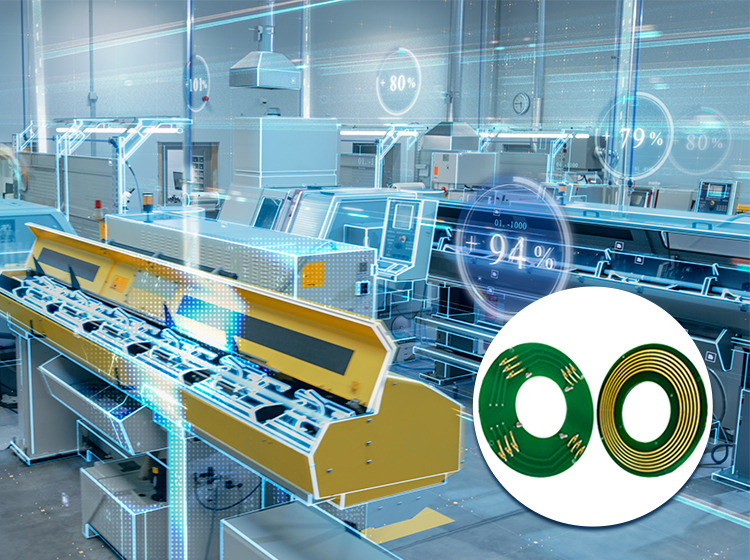

Pancake Slip Rings: A Slim Profile for Limited Spaces

Pancake slip rings are characterized by their flat, disc-like shape, which stands in contrast to the more cylindrical form of traditional slip rings. This design offers a critical advantage: a compact footprint that fits easily into spaces where length is limited but diameter is not as constrained.

- How They Work: Pancake slip rings stack multiple conductive rings closely together, with each ring assigned to a separate circuit. Brushes glide over the top surface of these rings, maintaining electrical connectivity as the device rotates. The flat, pancake-like shape reduces axial length but increases diameter.

- Applications: Useful in security cameras and medical machinery where space along the axis of rotation is limited, but the equipment requires a reliable electrical connection to rotate continuously.

Through-Bore Slip Rings: Central Openings for Versatility

Through-bore slip rings are named for their hollow center, allowing them to accommodate a shaft or pipe through the middle. This central opening offers vast possibilities for applications where you need to pass fluids, light, or mechanical components through the center of a rotating assembly.

- How They Work: In these slip rings, electrical contacts (rings) and brushes are located around the central hole. This design allows for power and data signals to be transferred to the rotating part that encases the stationary core or vice versa.

- Applications: They are widely used in wind turbines, robotics, and cable reels, where a physical through-way is beneficial for the system’s mechanical or optical components.

Wireless Slip Rings: Eliminating Physical Contact

Wireless slip rings, also known as “contactless slip rings,” use electromagnetic fields to transfer power and data across a rotating interface without direct physical contact, overcoming limitations of wear and tear associated with traditional slip rings.

- How They Work: These systems typically involve a transmitter and a receiver. The transmitter converts electrical signals into a magnetic or electromagnetic field, which is then captured by the receiver on the rotating part and converted back into electrical signals or power.

- Applications: Ideal for environments requiring clean operations free from physical wear, such as in food processing machinery or high-speed applications where traditional brushes may not keep up.

Mercury Slip Rings: Conductivity at its Best

Mercury slip rings use liquid mercury as a conductive medium for transferring electrical signals and power. Their design allows for extremely low electrical resistance and can handle high currents very efficiently.

- How They Work: Inside a mercury slip ring, a pool of liquid mercury makes contact with the rotating and stationary components. As the device turns, the mercury maintains continuous electrical connectivity due to its fluid nature.

- Applications: Used in high-speed and high-current applications, including industrial machinery and rotating stages, where traditional brushes might degrade quickly.

Servo Encoder Slip Rings: Precision in Motion

Servo encoder slip ring are specialized components designed to provide continuous transmission of power, data, and feedback signals in rotating systems. These slip rings incorporate encoder technology to ensure precise positioning and motion control, making them ideal for applications that require high accuracy.

How They Work: Inside a servo encoder slip ring, electrical contacts transmit signals between the stationary and rotating parts. The embedded encoder system tracks the rotational position, providing real-time feedback to control systems. This enables precise control of motion, speed, and positioning during rotation.

Applications: Servo encoder slip rings are widely used in robotic systems, CNC machines, and other high-precision equipment, where accurate motion feedback is essential for seamless operation and efficiency.

PIN Slip Rings: Reliable Power and Data Transmission

PIN slip rings are specialized components designed to provide uninterrupted transmission of power, data, and signals between stationary and rotating parts. These slip rings use a pin-based connection to ensure stable and reliable performance, making them ideal for applications where consistent power and signal transfer are essential.

How They Work: Inside a PIN slip ring, pins make electrical contact with the corresponding brushes or rings, transmitting signals or power between the rotating and stationary components. This connection allows for smooth and continuous operation in systems where rotation is involved, providing a reliable flow of electricity or data without interruption.

Applications: PIN slip rings are commonly used in various industries, including robotics, rotating equipment, and defense systems. They are particularly useful in applications where compactness and reliability are crucial, ensuring efficient operation in environments with limited space or high rotation speeds.

Specialized Slip Rings: Custom Solutions for Unique Applications

Specialized slip ring are tailored components designed to meet the specific needs of various industries and applications. These slip rings are engineered with unique features, such as custom materials, configurations, and size options, to provide optimal performance in environments that require specialized solutions. Whether it’s for high-speed rotation, extreme temperatures, or hazardous conditions, specialized slip rings ensure seamless transmission of power, data, and signals.

How They Work: Specialized slip rings function similarly to standard slip rings, transmitting power or signals between rotating and stationary parts. However, they are customized with specific materials, designs, or technologies to cater to particular operational requirements. This customization can include enhanced insulation for high-voltage applications, sealed designs for dust and moisture protection, or higher resistance to wear and tear, depending on the needs of the system.

Applications: Specialized slip rings are widely used in industries such as aerospace, marine, military, and industrial automation. They are ideal for applications that demand custom solutions, including harsh environments, high-precision equipment, and unique machinery. These slip rings help ensure reliable operation in challenging conditions, making them indispensable in systems where standard slip rings might not be sufficient.

CAN Bus Slip Rings: Ensuring Seamless Data Transmission in Rotating Systems

CAN Bus slip rings are specialized components designed to provide continuous transmission of power and data in systems that utilize the Controller Area Network (CAN) bus protocol. These slip rings ensure reliable data transfer between rotating and stationary parts, making them indispensable in applications that require high-speed communication, such as industrial automation, robotics, and automotive systems.

How They Work:

CAN Bus slip ring operate by allowing electrical contact between rotating and stationary parts of a system while maintaining the integrity of the CAN bus communication protocol. The slip ring enables seamless transmission of data signals from sensors, controllers, and other networked components, ensuring accurate and real-time communication in dynamic and rotating environments. This is crucial for systems that rely on continuous, uninterrupted data flow, such as vehicle telemetry systems or manufacturing robots.

Applications:

CAN Bus slip rings are widely used in industries that require high-performance, real-time data transfer in rotating systems. Some of the key applications include:

- Automotive: Used in vehicle systems for continuous communication between rotating parts like steering wheels and stationary electronics.

- Industrial Automation: Essential in robotics and automated manufacturing lines, where real-time data transfer is critical for control systems and sensor integration.

- Aerospace: Used in aircraft systems for continuous communication between rotating components and the central control system.

- Medical Equipment: Employed in rotating medical devices, such as MRI machines or robotic surgery tools, where data integrity is vital.

By maintaining seamless communication even in the most dynamic conditions, CAN Bus slip rings ensure that the systems relying on them can function efficiently and reliably.

Conclusion: Matching Slip Rings to Needs

It’s clear that the world of slip rings is nuanced, with each type serving a distinct purpose informed by its design and mode of operation. From the compact spaces accommodated by pancake slip rings to the innovative contactless transmission of wireless slip rings, understanding these differences is crucial when selecting the appropriate slip ring for a given application.

As technology advances and demands grow, the evolution of slip rings will continue, shaped by the ingenious integration of electrical principles and mechanical design. Next, we will look into the future possibilities and the emerging technologies in the realm of slip rings.

How Does A Slip Ring Works: Energize Various Industries

As we delve deeper into the world of slip rings, it becomes evident that these devices are not just components but pivotal elements that energize numerous industries, enabling some of the most groundbreaking advancements in technology and services. This chapter illuminates the indispensable role slip rings play across various sectors, from harnessing the power of the wind to capturing detailed medical images, facilitating precise robotic movements, and beyond.

Wind Turbines: Harnessing Renewable Energy

In the quest for sustainable energy, wind turbines stand tall—literally and metaphorically. Slip rings breathe life into these giants, allowing them to capture wind energy efficiently.

- Case Study: Consider a wind farm situated off the coastal belt, where wind speeds are consistently high. The slip rings installed in each turbine enable the nacelle (housing the generating components) to rotate freely, optimizing the angle of the blades and maximizing energy capture. This fluid movement is critical for the turbine’s yaw mechanism, ensuring that the blades are always positioned to capture maximum wind, thereby increasing the efficiency and longevity of the turbines.

Medical Imaging: Revolutionizing Diagnoses

Medical imaging devices, such as CT scanners and MRI machines, rely on slip rings to produce life-saving diagnostic images.

- Example: CT Scanners use slip rings to provide continuous power and data transfer while the scanning ring rotates around the patient. This capability enables the creation of detailed cross-sectional images of the body, allowing for early detection of diseases and conditions. The precision and reliability of slip rings in these machines directly impact the quality of images produced, making slip rings an unsung hero in medical diagnostics.

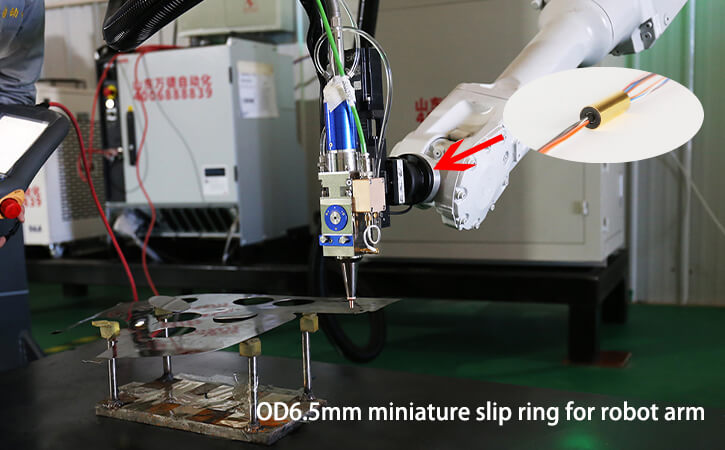

Robotics: Ensuring Smooth Operation and Precision

Robotics is a field that demands both precision and durability, and slip rings play a critical role in meeting these requirements.

- Case Study: In automotive manufacturing, robots equipped with slip rings perform tasks ranging from welding to assembly. The slip rings allow these robots to have 360-degree uninterrupted movement, ensuring that tasks are performed with high precision and efficiency. For example, a robotic arm in an assembly line that continuously turns to weld car parts must maintain a constant electrical connection for both power and control signals. Slip rings make this possible, significantly reducing downtime and improving productivity.

Entertainment Industry: Bringing Creativity to Life

Slip rings also find applications in the entertainment industry, particularly in theatrical productions and amusement park rides, where they help create mesmerizing effects and ensure safety.

- Example: Consider a modern amusement park ride that features rotating parts for 3D effects. Slip rings are used to transfer power and data to the rotating sections, ensuring seamless operation. This not only enhances the rider’s experience but also ensures that safety systems, which rely on continuous power and communication lines, function without interruption.

Surveillance Systems: Keeping a Vigilant Eye

In the realm of security, slip rings enable surveillance cameras to rotate continuously, providing 360-degree coverage without tangling wires.

- Case Study: Airport security employs high-definition PTZ (Pan-Tilt-Zoom) cameras to monitor large areas efficiently. These cameras use slip rings to ensure they can rotate endlessly and zoom into specific areas without losing power or data connectivity. This application of slip rings is critical for maintaining continuous surveillance and ensuring public safety.

Across various sectors, slip rings prove to be unsung heroes, facilitating advancements and ensuring the smooth operation of critical systems. Their adaptability to different environments and requirements makes them invaluable. As industries evolve and face new challenges, the versatility and reliability of slip rings will continue to play a key role in driving innovation and efficiency. Looking ahead, the next chapter will delve into the future of slip rings, exploring advancements and potential new applications in an ever-changing technological landscape.

How Does A Slip Ring Works: Demystifying Slip Ring Malfunctions

Exploring the realms of how slip rings function brings us face-to-face with the inevitable: malfunctions. Despite their robust design and essential role in various industries, slip rings are not immune to issues. This chapter delves into common complications that might hinder a slip ring’s performance, such as wear and tear, contamination, and electrical noise. Through real-world examples and preventive strategies, we aim to equip you with knowledge and techniques to diagnose and troubleshoot slip ring problems efficiently.

Understanding the Symptoms: Common Slip Ring Issues

Slip rings can exhibit several symptoms indicating issues, from erratic signal transmission to complete operational failure. Here, we uncover the prevalent problems and their primary causes.

- Wear and Tear: All mechanical devices are subject to wear over time, and slip rings are no exception. Excessive wear can result from improper installation, inadequate maintenance, or simply the end of a component’s lifecycle.

- Contamination: Dust, debris, and even moisture can infiltrate a slip ring assembly, leading to poor electrical contact and corrosion. In environments prone to contamination, such as industrial sites or outdoor installations, this issue is particularly common.

- Electrical Noise: Electrical noise in slip rings can lead to signal interference, disrupting the transmission of power and data. This issue often arises from poor grounding or electromagnetic interference from nearby equipment.

Case Study: The Wind Turbine Anomaly

Imagine a wind turbine that begins to experience fluctuating power outputs. Technicians identify wear and contamination as the culprits. Over time, exposure to the elements has allowed dust and moisture to penetrate the slip ring assembly, accelerating wear and causing irregular contact resistance. This case highlights the importance of regular maintenance and the need for protective measures in harsh environments.

Diagnostic Techniques: Finding the Root Cause

Isolating the issue in a malfunctioning slip ring requires a systematic approach:

- Visual Inspection: Often, the first step is a simple visual check for obvious signs of wear, contamination, or damage.

- Electrical Testing: Measuring resistance, continuity, and insulation can offer insights into the electrical integrity of the slip rings and identify potential faults.

- Environment Assessment: Evaluating the operating environment helps determine if external factors, such as excessive vibration or contamination, are contributing to the problem.

Troubleshooting Steps: Addressing the Issue

Once the diagnosis is clear, strategic steps can ensure swift resolution and prevent recurrence:

- Cleaning: For contaminated slip rings, thorough cleaning may restore functionality. However, it’s crucial to follow manufacturer recommendations to avoid damage.

- Replacement of Worn Parts: Severely worn components require replacement. Opting for higher quality or more durable materials can extend the lifespan of new parts.

- Mitigating Electrical Noise: Improving grounding methods and shielding can reduce electrical noise. In some cases, rerouting cables or altering the installation layout minimizes interference.

Preventive Measures: A Stitch in Time

Adopting preventive strategies can markedly reduce the occurrence of slip ring issues:

- Regular Maintenance: Scheduled inspections and maintenance can catch minor issues before they escalate, extending the operational life of slip rings.

- Environmental Protection: For installations in challenging environments, protective measures such as seals or enclosures can guard against contamination and moisture.

Encountering slip ring malfunctions can be daunting, but with a deeper understanding of their workings, common issues, and troubleshooting methods, you’re better equipped to address problems effectively. This chapter has shed light on not only identifying and resolving slip ring malfunctions but also on preventative strategies to ensure their longevity and reliable performance. As we continue to explore the slip ring’s pivotal role in technology and industry, remember that knowledge is power—empowering you to keep the wheels of innovation turning smoothly.

How Does A Slip Ring Works: Innovations and Future Trends

In the world of engineering and technology, slip rings are essential, quietly enabling rotational power transmission and data communication. But the narrative of the slip ring is not complete; it continues to evolve. This chapter highlights the horizon of slip ring technology advancements – focusing on upcoming materials, designs, and notable trends. As we prepare to embrace high-speed data transmission and a new generation of devices, we’ll explore how these developments could reshape the role and function of slip rings.

Emerging Technologies: Redefining the Shelf Life of Slip Rings

The journey towards the future of slip rings is paved with numerous advancements that show promise in enhancing the integrity and performance of these devices.

- Advanced Material Science: The adoption of new materials with superior wear resistance, improved electrical properties, and increased resilience to environmental factors could dramatically enhance slip ring longevity and efficiency. For instance, graphene—a single layer of carbon atoms with impressive conductivity and durability—represents a significant leap forward.

- Intelligent Designs: Innovations in slip ring designs, such as compact, modular units that simplify installation and maintenance, or customizable assemblies that cater to tailored requirements, reflect the industry’s drive towards agility and streamlined operations.

The Increased Demand for High-speed Data Transmission: A Transformative Trend

The proliferation of the Internet of Things (IoT) devices, advanced robotics, and high-bandwidth systems requires faster and more reliable data transmission than ever.

- Performance Under Pressure: The escalating demand for high-speed transmission pushes slip ring technology to keep pace. Already, mercury slip rings and fiber optic rotary joints are helping meet this challenge, facilitating high-speed and noise-free data communication.

- The Implication for Slip Rings: The advent of high-speed data transmission has instigated the development of slip rings that can ensure optimal signal integrity, minimal loss, and noise reduction—without compromising on their core function of power transfer.

Case Study: Autonomous Vehicles and Advanced Robotics

Consider the rapid evolution of autonomous vehicles. These complex systems demand seamless data communication alongside power supply—both of which are enabled by advanced slip rings.

Navigating the Future: Balancing Tradition with Innovation

As we confront innovation, it’s essential to strike a balance, blending the traditional functionality of slip rings with novel enhancements:

- Adopting New Technologies: This involves embracing groundbreaking materials, designs, and integrating them into existing systems while maintaining the core functions of the slip ring.

- Future-proofing with Trends: Staying abreast of shifting trends like high-speed data transmission can lead to more robust, future-ready slip ring systems.

Conclusion: A Journey, Not a Destination

Slip ring technology, like all technological domains, is a continual journey, gathering pace with every step. The industry faces many dynamic future challenges responding to emerging technologies and trends, such as high-speed data transmission. However, it’s through these challenges that we witness the most profound innovation. By attempting to forecast these advancements, we position ourselves on the front lines of technology—prepared and excited for the future of slip rings.

How Does A Slip Ring Works: The Maintenance and Longevity

In this chapter, we explore the stewardship of slip rings — an essential factor contributing to their effectiveness and longevity. Proper maintenance practices are the linchpins that not only prop up the slip ring’s lifecycle but also optimize its functionality. Intricate care routines, scheduled cleanings, and keen observations of wear are the order of the day for these electromechanical marvels. With detailed examples and a step-by-step guide, we will provide a comprehensive look at maintaining slip rings, helping to ensure they continue to do their vital work accurately and reliably.

Proactive Preservation: Maintenance as a Priority

A carefully crafted maintenance regime is the best defense against premature wear and unforeseen issues that could compromise a slip ring’s operation.

- Regular Maintenance Schedules: Timetabled inspections at set intervals–be it monthly, quarterly, or yearly depending on usage and environmental conditions–should form the backbone of the maintenance plan.

- Cleaning Protocols: Slip rings require cleaning with a sense of precision; this includes gentle wiping with approved solvents and soft cloths to avoid abrasive damage.

- Detailed Records: Keeping a logbook with detailed records of each maintenance session aides in predicting wear patterns and scheduling component replacements.

Case Study: The Robotic Arm’s Tale

Consider a robotic arm in an automotive assembly line incorporating slip rings for fluid 360-degree movement. Scheduled downtimes for maintenance resulted in a 25% reduction in unexpected operational halts compared to before the schedule was implemented, showcasing the effectiveness of proactive maintenance.

Wear and Tear: Recognizing the Red Flags

Understanding the signs of wear and knowing the criticality of each is central to preemptive maintenance.

- Visual Indicators: Discoloration, scoring, and unusual debris build-up can point to problems that need immediate attention.

- Aural Cues: Any change in the operating sounds of a slip ring, such as grinding or squeaking, could be the first audible alarm of an issue.

Practical Tips: Enhancing Slip Ring Performance

Useful advice that can be immediately applied can go a long way in effectively maintaining slip rings:

- Lubrication: Specific slip ring designs may require lubrication for optimal performance; ensure you use the correct type as per manufacturer specifications.

- Environmental Safeguards: Implementing protective measures against dust, moisture, and corrosive elements can help preserve slip ring integrity over time.

This chapter underlines the significance of astute maintenance in extending the life of slip rings. With practical advice, proactive strategies, and an emphasis on the consequences of negligence, it underscores maintenance as less of a chore and more of an investment — an investment in sustained performance, reliability, and ultimately, the uninterrupted operation of the machinery and systems that slip rings empower. Looking after these critical components conscientiously means more than preventing failure; it means ensuring the advancement of the technology they support.

The Integral Influence of Slip Rings on Technological Progression

Throughout this comprehensive guide, we’ve delved into what slip rings are, how they operate, and why they are a critical component in modern machinery and technology. Slip rings’ importance cannot be understated; they are the silent heroes in an array of mechanical systems, enabling rotations without the hindrance of tangled wires, thus facilitating endless possibilities in motion and power transmission.

The Essential Role of Slip Rings

Slip rings exist ubiquitously within countless devices and systems critical to modern industry and technology. They are integral in wind turbines, medical machinery like MRI scanners, and within the automotive industry, among many others. Without slip rings, the functionality and efficiency of these machines would drop significantly, highlighting the importance of understanding their operation.

Slip Rings: The Backbone of Rotational Systems

Consider the slip ring’s role in robotics. Without them, the dexterity and movement that define modern robotics would be severely limited. They provide the freedom for uninterrupted 360-degree movement while maintaining an electrical connection for signals and power—essentially allowing for a continuous transfer of information and energy, which powers innovation in automation.

Encouraging Further Exploration

Understanding how slip rings function opens a gateway to innovation in the field of electrical engineering and component design. By grasping the basics and complexities of slip rings, we can expand our knowledge and curiosity to innovate and improve the technology that relies on these components.

Be the Spark of Innovation

Encourage budding engineers and technophiles to explore the possibilities within this fundamental piece of equipment. Moving beyond the “how” and “why,” think of the “what next.” The evolution of slip rings from simple mechanical devices to advanced data and power conduits presents a challenge for creative minds to push the boundaries of what’s possible.

Remaining Questions and Misconceptions

Despite the depth explored in this guide, questions will linger. It’s natural—technology is constantly evolving, after all. An open call to readers: when faced with a misconception or an unanswered question, view it not as a roadblock but as an invitation. An invitation to seek knowledge, to experiment, and eventually, to innovate.

A Stepping Stone to Future Intricacies

This journey through the workings of slip rings serves as a foundational stone in understanding their impact on modern technology. They are not merely components; they represent the seamless fusion of motion and energy—a testament to human ingenuity. As our exploration concludes, remember that this is not an endpoint but rather an encouragement to continue learning, exploring, and contributing to the field of electrical engineering and beyond. Slip rings, while small in size, are monumental in their contribution to technological advancement, and your understanding of them could be the catalyst for the next technological breakthrough.

Have questions about our slip rings? Contact us today using the form below.