This article aims to provide readers with an in-depth understanding of electrical separate slip rings, their functionality, types, applications, maintenance, and important factors users should consider when selecting the right slip ring for their specific needs.

Introduction to Electrical Separate Slip Rings

Electrical Separate Slip Rings are electromechanical devices that facilitate the continuous transmission of electrical power and signals from a stationary structure to a rotating one without tangled wires. This rotating electrical interface, recognized for its versatility, is expansively utilized in systems that require data and power transmission while in continuous rotation.

Consisting of a rotating part (rotor) connected to the moving mechanism and a stationary part (stator) connected to the power source, they function through brushes that maintain an electrical connection between the stator and rotor. The rotational movement can be in any direction – clock or counter-clock – and the power and signals are transmitted smoothly without any interruptions or disconnections, making the mechanism efficient and reliable.

They hold immense importance in various fields due to the critical role they play in performance optimization. Ranging from industrial equipment, wind turbines, and radar platforms to medical imaging devices and even amusement rides, the need for fluid power and signal transfer makes slip rings a necessity. This is especially true for complex systems where constant rotation is coupled with a requirement for data and power.

Their wide-ranging applications, durability, and ability to enhance efficient functionality make Electrical Separate Slip Rings pivotal components in the technologies that form the backbone of several industries. They are key to ensuring seamless, uninterrupted operations, making them an integral part of modern machinery and electronic devices.

Basics of Electrical Separate Slip Rings

Working Principle of Electrical Separate Slip Rings

At the core of Electrical Separate Slip Rings lies a simple yet effective concept of uninterrupted power and data transmission between a static and rotating assembly. When an electrical circuit requires a constant flow of data or power during rotation, slip rings come into play. They can simultaneously transmit numerous signals, both analog and digital, and varying voltage power.

The working principle is based on electrical contact between stationary brushes and rotating rings. As the rotor (attached to the rotating mechanism) moves, the electrical current from the stator (tethered to the stationary power source) is transmitted to the brushes. These brushes then glide over the spinning slip rings, facilitating power and signal transmission from the fixed component to the rotating one. This constant electrical connection ensures non-stop, two-way transmission without any disconnections or interference, regardless of the rotational direction or speed.

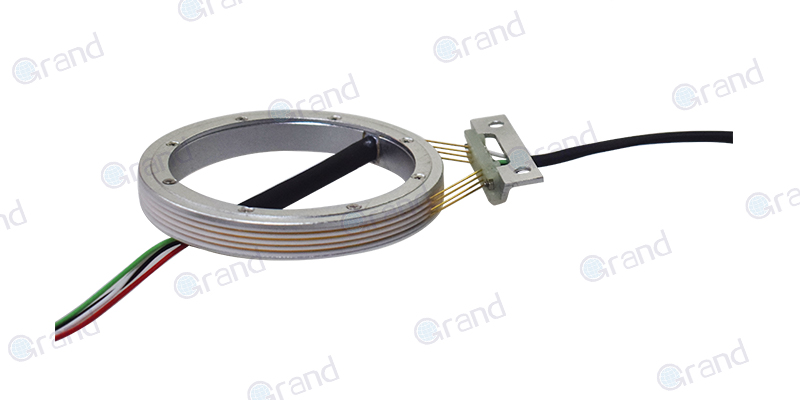

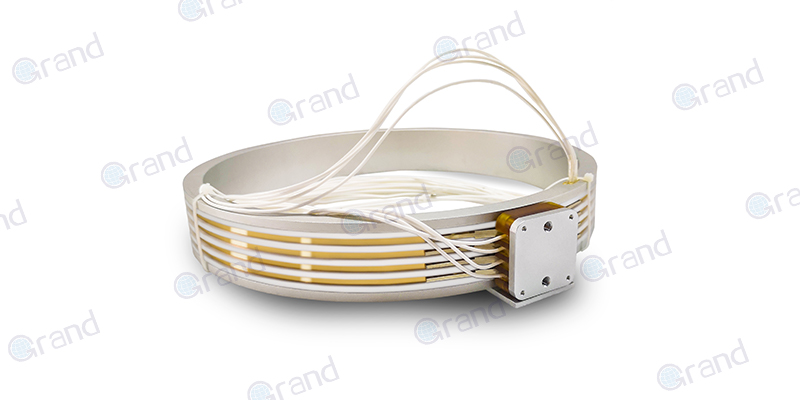

Physical Structure and Operation

The physical design of an Electrical Separate Slip Ring is crucial to its efficient operation. The basic structure predominantly consists of three parts:

- Stator: This is the stationary part connected to the main power source. It consists of electrical brushes made of materials like precious metals or carbon-metal composites. The brushes conduct electricity from the power source.

- Rotor: The rotating part of the slip ring attached to the moving assembly. It comprises rings made from conductive materials that maintain electrical contact with the brushes as they rotate.

- Housing: This component encapsulates the two aforementioned parts, protecting them from external elements and preventing electrical interference.

As the rotor spins, the brushes slide over the rotating rings while maintaining electrical contact. This method of “brush-to-ring” contact allows the continual transmission of power and electrical signals from the static part to the rotating section, hence allowing the free rotation and optimal functioning of various applications that rely on Electrical Separate Slip Rings.

Types of Electrical Separate Slip Rings

High-Speed Separate Slip Rings

High-Speed Separate Slip Rings cater to applications that necessitate swift rotational speeds while still effectively transmitting power and signals. These slip rings are custom-engineered to minimize noise and resistance that could arise from high-speed operations, ensuring optimal performance. They are often found in applications such as turbines, centrifuges, or high-speed video surveillance systems.

High-Frequency Separate Slip Rings

High-Frequency Separate Slip Rings specialize in the transfer of high-frequency signals. They are designed with advanced materials and shielding techniques to reduce signal attenuation and disruption during transmission, thereby preserving signal quality. These slip rings are well-suited for medical imaging equipment, satellite communication systems, and certain military applications where sustaining high-frequency signal integrity is paramount.

Miniature Separate Slip Rings

Miniature Separate Slip Rings are small-scale ring and brush assemblies. Their compact size and light weight make them perfect for any application where space limitations and weight constraints are prevalent. Despite their reduced size, these slip rings do not compromise performance, ensuring reliable power and data transmission. They are frequently used in robotics, miniature motors, wearable devices, and medical devices.

Fiber Optic Rotary Joint (FORJ) Separate Slip Rings

Fiber Optic Rotary Joint (FORJ) Separate Slip Rings utilize fiber optics technology for data transmission. These slip rings transfer high-bandwidth data or complex signals with virtually no loss or reduction in signal quality. FORJ slip rings are ideal for telemetry systems, long-range communication equipment, high-definition video transmission, and radar systems where high-speed and high-capacity data transfer is required over rotating interfaces. The use of fiber optics also makes them immune to electrical interferences, enhancing their reliability in critical applications.

Applications of Electrical Separate Slip Rings

Electrical separate slip rings, due to their versatile capability to enable continuous power and signal transmission during rotation, find vital applications across a multitude of industries and environments.

Industries and Environments

- Robotics: Electrical separate slip rings are crucial in the robotics industry, where effective power transmission and signal communication to rotating parts are required. They enable the smooth operation of robotic arms, ensuring that data and electricity flow seamlessly.

- Aerospace: In the aerospace industry, slip rings enable the transmission of data and power in complex satellite systems, space probes, and aircraft equipment. They handle high-frequency signals and withstand rigorous environments.

- Wind Turbine Generators: Wind turbines need slip rings to transmit power and data generated from the rotating turbine to the static grid. High-speed slip rings are particularly beneficial due to the fast rotational speeds of the turbines.

- Medical Equipment: In medical imaging systems like MRI and CT scanners, slip rings transmit power and data, facilitating necessary rotational movements while sending data to stationary computers for image production and analysis.

- Automation Systems: In automated manufacturing lines, slip rings are necessary for the conveyance of electricity and data signals in parts that require constant rotation.

- Marine and Military Applications: High-frequency slip rings are necessary for radar antennas systems, sonar equipment, and other communication systems, functioning effectively even in harsh marine and military environments.

Specific Use-cases Across Different Industries

- Robotics: Slip rings enable uninterrupted electrical power and signal transmission to robotic components, leading to efficient autonomous operations. For instance, in assembly lines, robotic arms use slip rings to maintain constant rotation while receiving instructions for precise movements and tasks.

- Medical: In CT scanners, slip rings allow for the smooth, continuous rotation of the X-ray tube around the patient, transmitting signals to stationary computers for image production.

- Renewable Energy: Wind turbine generators rely on slip rings to transmit generated power from the rotating blades to the stationary grid. Here, the slip ring endures high rotational speeds and demanding weather conditions.

- Aerospace: In satellite systems, slip rings facilitate the rotational movement of solar panels or antennas and ensure constant data transfer between rotating and stationary parts, enabling effective communication and power generation.

- Defense: In modern tanks, slip rings are utilized in the turret system to allow full-range rotational capabilities of the turret while maintaining vital communication and control signals between the stationary hull and the rotating turret.

Through these integral roles across different sectors, electrical separate slip rings contribute remarkably to the functioning of modern machinery, enhancing their efficiency and operational capabilities.

Comparison between Electrical Separate Slip Rings and Capsule Slip Rings

Feature Comparison

- Size and Form Factor: Electrical separate slip rings are characterized by their modular and separable structure, wherein the different components like brushes, rings, and housing can be individually customized or replaced. Capsule slip rings, on the other hand, are recognized for their compact, pre-assembled, and enclosed design.

- Flexibility and Customization: Separate slip rings offer higher flexibility in their design and can be modified as per the requirements of different applications. In contrast, capsule slip rings come with a predefined set of specifications and are less adaptable to customization.

- Maintenance and Replacement: As their name suggests, electrical separate slip rings can be disassembled and individual parts can be replaced or maintained with relative ease. Capsule slip rings typically require the replacement of the entire unit if one part fails, as accessing the internal components is more challenging.

- Load Capacity: Electrical separate slip rings can accommodate higher current and voltage loads due to their adaptable design and larger size, making them apt for heavy-duty applications. Capsule slip rings tend to have a lower load capacity, making them suitable for lightweight applications.

- Cost: Separate slip rings may cost more initially, given their customizable nature and ability to handle heavier loads. In the long run, separate slip rings can prove more cost-effective due to manageable maintenance and part replacement. Capsule slip rings might be cheaper initially, but replacing the entire unit upon failure can be expensive over time.

Applicability Scenarios

- Electrical Separate Slip Rings: These slip rings are ideal for applications that require various combinations of power, voltage, or signal transmission, high rotational speeds, or heavy-duty operation. Examples of suitable industries include wind turbines, robotics, satellite systems, and industrial equipment that need customization and adaptability in power and data transmission capabilities.

- Capsule Slip Rings: With their compact design and smaller form factor, capsule slip rings are suitable for lightweight applications where space is limited and customization is not a priority. These slip rings find use in smaller-scale devices, such as surveillance cameras, small motors, medical devices, and consumer electronics.

Depending on the desired applicability scenario, it is essential to understand the specific requirements and constraints of the equipment to make the right choice between electrical separate slip rings and capsule slip rings.

Key Advantages and Limitations of Electrical Separate Slip Rings

Key Functional Benefits

- Uninterrupted Transmission: Electrical separate slip rings provide continuous power and data transmission between stationary and rotating components, enabling uninterrupted operation in rotating systems or assemblies.

- Customizable: Their modular nature allows for customization according to different application requirements. For instance, they can be designed to cater to different power capacities, transmission speeds, or form factors based on application needs.

- Higher Load Capacity: These slip rings can handle higher current and voltage loads, making them suitable for heavy-duty applications.

- Maintenance-friendly: The separable structure of these slip rings allows individual components to be replaced or maintained, which extends their operational life and lowers long-term replacement costs.

Possible Limitations and How They Impact Various Applications

- Abrasion and Wear: The constant friction between the brushes and the rotating rings can lead to wear and tear over time. This might affect the efficiency of data and power transmission and require regular maintenance or replacement of brushes.

- Noise and Signal Loss: In some applications, especially those involving high speeds or high-frequency signals, separate slip rings may generate electrical noise that can interfere with signal transmission. Though designs have evolved to minimize this issue, it remains a potential limitation.

- Size Limitations: Separate slip rings tend to be larger due to their separable construction, which might not be suitable for applications with strict size constraints. However, some models can be made to be quite compact, countering this limitation.

- Cost Considerations: The initial cost of these slip rings might be higher than other types due to their increased complexity and customizable features. However, the long-term savings offered by their maintainability could offset this initial cost.

Despite these limitations, the extensive benefits of electrical separate slip rings make them the ideal choice for countless applications requiring continual power and signal transmission between stationary and rotating assemblies.

Leading Manufacturers and Suppliers of Electrical Separate Slip Rings

| No. | Manufacturer | Website |

|---|---|---|

| 1 | Hangzhou Grand Technology | https://www.grandslipring.com/ |

| 2 | Moog Inc. | https://www.moog.com/ |

| 3 | Stemmann-Technik | https://www.stemmann.com/en/home |

| 4 | Schleifring | https://www.schleifring.com/ |

Hangzhou Grand Technology

Hangzhou Grand Technology Co., Ltd. started as a special slip ring manufacturer in 2011. Grown into slip rings, rotary joints, and slip ring assembly experts of today with 6,000 square meter manufacture complex.

Obtained ISO9001, Rosh, CE, and GJB9001B certificates a number of slip rings, rotary joint patents, and proud of our products can meet military grade. Collaborated with universities, institutes, and renowned factories across Asia and Europe including Panasonic, SIEMENS, CSIC, SAMSUNG, HUAWEI, etc.

Moog Inc.

Moog is a leading supplier of high-performance slip rings for various industries, including aerospace. Among their offerings, Moog’s SR Series Slip Rings are designed for the demanding environments of helicopters, excelling in performance, reliability, and customization potential.

Stemmann-Technik

Stemmann-Technik, a part of the Conductix-Wampfler Group, offers a broad range of slip rings, including solutions for helicopters. Their Livietta Slip Ring Assemblies are designed explicitly for harsh and demanding environments in the aviation sector, providing reliable signal and power transmission.

Schleifring

Schleifring is a well-known manufacturer of electromechanical systems, including slip rings customized for various industries. Their Aircraft Slip Rings cater specifically to helicopters, offering robust performance, low wear, and high reliability to meet the challenges of aviation applications.

If you want to know more about other slip ring manufacturers, you can read Top 10 Slip Ring Manufacturers in China, Top 10 Slip Ring Manufacturers In the USA Market 2023, and Top 10 Slip Ring Industry Key Manufacturers 2023.

Maintenance and Troubleshooting of Electrical Separate Slip Rings

Common Problems, Their Causes, and Solutions

- Unstable Signals or Power Loss: This may be caused by wear and tear on the brushes or rings due to constant friction. Solution: Regular maintenance or replacement of brushes and cleaning of rings can minimize this issue.

- Overheating: This could occur due to high current or voltage loads, inadequate cooling, or over-speeding. Solution: Appropriate load balancing, provision for heat dissipation, and operating within speed limits can help prevent overheating.

- Excessive Noise or Vibrations: These could result from misalignment, worn-out parts, or inadequate lubrication. Solution: Regular inspections should be conducted to ensure proper alignment and functioning of parts. Replacing worn-out components and applying suitable lubricants can also curtail noise or vibrations.

General Maintenance Advice

- Regular Inspection: Frequent checks should be performed to verify the condition of brushes, rings, wiring, and housing, and to ensure optimal performance.

- Keep Clean: Keeping the slip ring clean from dust, grease, moisture, and oxidation can prevent damage and prolong its lifespan. The use of appropriate cleaning methods, like dry wiping or the use of specified cleaning solutions, can keep the slip ring in good condition.

- Lubrication: Applying suitable lubricants to the brushes and rings can reduce friction, therefore decreasing wear and tear and enhancing the slip ring’s operational lifespan.

- Correct Usage: Ensuring that the slip ring operates within its specified load and speed capacities can prevent overloads or excessive heating, which could lead to malfunctioning or damage.

While electrical separate slip rings are designed for longevity, regular maintenance is pivotal in achieving their maximum operational lifespan and performance. In the face of any issues, proper troubleshooting can address challenges promptly and effectively.

Factors to Consider When Choosing Electrical Separate Slip Rings

Crucial Considerations

- Specifications: Assess the application’s requirements in terms of current and voltage capacity, number of circuits, transmission speed, and any other relevant specifications to ensure that the chosen slip ring performs optimally.

- Cost: Consider both the initial cost of the slip rings and the long-term maintenance and replacement costs to make informed decisions based on budget constraints and value for money.

- Manufacturer Reputation: Selecting a reputable manufacturer can be pivotal in ensuring product quality, reliability, and longevity.

- After-sales Service: Choose a manufacturer that offers robust customer support, technical assistance, and warranty services, which are crucial in maintaining the slip ring’s operational efficiency.

How Each Factor Bridges the Gap Between User Needs and Product Features

- Specifications: By carefully assessing the specifications required for a specific application, users can select a slip ring model that aligns with their needs and ensures seamless transmission of power and signals.

- Cost: Evaluating the cost aspect helps to identify a slip ring that not only meets the user’s budgetary constraints but also offers long-term value through reduced maintenance and replacement costs.

- Manufacturer Reputation: A reliable manufacturer can provide consistent quality, advanced technology, and a proven track record of customer satisfaction, ensuring a superior slip ring that caters to user needs.

- After-sales Service: Excellent after-sales support assists users in maintaining their slip rings, prolonging their lifespan, and addressing any potential issues. This bridges the gap between user requirements and product performance, sustaining smooth operations in the long run.

Considering these factors when choosing electrical separate slip rings guarantees a compatible selection that enables users to achieve their desired operational performance and enjoy seamless power and signal transmission.

Conclusion

Electrical separate slip rings play an essential role in various industries. Understanding their basics, types, applications, maintenance, and selection factors ensures you make an educated decision that meets your project’s requirements and provides long-term performance, efficiency, and cost-effectiveness.

See What We Can Do