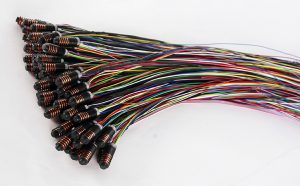

Across many industries, slip rings play an important role in commercial and industrial machines. Various industries are using them, from cranes to filling systems, to packaging machines to medical devices. The rotation of machinery can make it difficult to transmit electrical current, data, or signals through cables. By using slip rings, stationary and rotating components can be communicated by wireless power and data transmission.

Slip Ring Applications

From an industrial environment to a commercial one, electrical slip rings are used in a variety of sectors. There are many applications for it, including gas and oil plants, biomedical and pharmaceutical equipment, aerospace, agricultural machinery, and other rotating equipment.

Let’s take a look at a few slip rings’ daily life applications:

- An electric motor, alternator, and generator are all examples of electric machines that use slip rings.

- Among its uses are induction motors, computer numerical control machines, pallet machines, rotary sensors, capping machines, and packing machines.

- A slip ring device is an industrial component used for controlling, manufacturing, and packaging processes in the food and pharmaceutical industry.

- CT scanners, X-rays, and medical robots all use this material.

- The slip ring is used in military devices, magnetic driver’s radars, tanks, and other steering wheel devices.

- CCTV cameras utilize the slip ring to provide video surveillance.

Choosing the Right Slip Ring

Slip rings cannot be chosen in a straightforward manner. You can, however, choose a slip ring to fit your needs by following the following specific steps. The following are key things to consider when selecting an electromechanical slip ring for your application:

1. Analyze Your Needs

In order to determine the most appropriate slip rings for your application, it is necessary to outline the unique specs required for your product. Device type and specifications will be determined by the operating environment, machinery type, and ultimate application. To compare existing options, you should specify what you want beforehand. In this way, offers that don’t meet the minimum requirements will also be easier to ignore.

2. Look for a Reputable Provider of Slip Rings

Slip rings aren’t too common, which makes review processes easier. A vendor may have multiple models from the same brand, but there are a range of models and series. There are distinct features and quality advancements that distinguish each series from the rest. Stick with reputable brands to ensure that your slip rings are genuine.

3. Find Your Desired Model

It is the remaining part of the process to determine what slip rings are available from reputable vendors after you have determined the slip ring type and its specifications. To find the best solution for your application, examine the various slip ring models and options. In order to understand what slip ring you need, you will need to know how your system works. Just make sure you choose the right vendor.

See What We Can Do