Slip rings are critical electromechanical components used in a variety of commercial and industrial devices. Crane technology, filling systems, packaging machinery, and medical technology are all examples of where they can be found. Rotating components in equipment frequently hinders electrical power, data, or signals from being sent through wires. Wireless power and signal communication between stationary and rotating parts is made possible by slip rings.

This method of sending power, signals, and data is dependable, maintenance-free, and low-wear. Furthermore, pressurized air and gases can get carried across electrical cables. Because slip rings are so important, there are so many to choose from that finding the proper one might be intimidating. If you’re buying a slip ring for the first time, make sure it’s the right fit for your apparatus. Because you already have a match or an improvement, replacement slip rings are easy to come by.

Things to Consider

When looking for the optimal slip, there are several factors to consider.

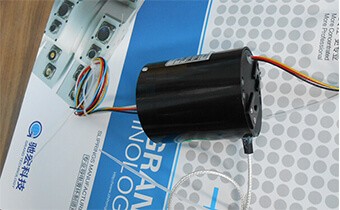

1. Type

Slip rings come in various styles, from the basic model with a shaft, bands, clamps, and brush assembly to advanced models composed of ultra-light materials. Through-hole (sometimes called through bore), pancake, and PCB slip rings are the most prevalent varieties of slip rings on the market. There are further distinctions like electric and fiber optic, USB, and micro slip rings. Each slip ring is unique, with a design tailored to a particular machine or purpose. In most circumstances, you’ll only be able to choose from a limited number of models. A pancake PCB slip ring, for example, maybe your only alternative if your application has vertical height limits. As a result, it’s critical to understand the many types of slip rings and pick the right one for your needs.

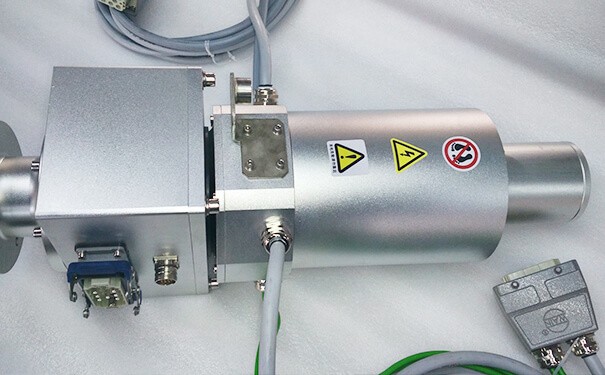

2. Specifications of the Application

Slip rings are application-specific, which means they’re made for a specific use and won’t work for anything else. Slip rings like wind turbine slip rings frequently have the size and operating environment requirements because each user is unique. Water resistance may be required, for example, in gadgets designed for outdoor use. Mining, cranes, high altitudes, and other severe situations, on the other hand, may necessitate unique features. When selecting slip rings, make sure the model is appropriate for your machinery and application. For popular slip ring motors and other machinery, there is a variety of standard slip rings available. However, you offer thorough directions to the vendor so that the slip ring can be modified to your specifications.

3. Mechanical Dimensions

The mechanical properties are critical to consider while selecting electromechanical devices that transport power and data. The following are some of the mechanical parameters to consider:

- The channel count

- RPM rate

- Materials for contact and housing

- Torque

- Temperature and relative humidity

- Maximum levels of protection

Each parameter is distinct and must be precisely measured for the unit to work reliably. For example, high-speed conductive rings may compromise the number of pathways in exchange for a higher current capacity and more coil rotations. Resistance and signal transmission is additionally affected by humidity, contact material, and operational temperature.

See What We Can Do