In an era where efficient power and data transmission are increasingly crucial for seamless and robust operations, hybrid slip rings have emerged as an innovative solution. These cutting-edge devices integrate electrical and signal transmission capabilities into a single unit, catering to the demands of various industries, from healthcare and manufacturing to aerospace and telecommunications.

Hybrid slip rings exemplify the rapid advancement in engineering and design, and their relevance in today’s technological landscape cannot be overstated. By simultaneously facilitating power and signal transmission within a single compact device, hybrid slip rings deliver significant benefits, including improved system performance, streamlined design, and cost-effectiveness. As complex systems continue to develop and become more interconnected, the incorporation of hybrid slip rings into such systems is poised to be a game-changer, propelling us further into an era driven by efficient and reliable technologies.

Understanding Hybrid Slip Rings

To appreciate the significance of hybrid slip rings, one must first understand their composition and functionality. Hybrid slip rings are sophisticated components that function as a bridge between stationary and rotating parts within a system, allowing for uninterrupted transmission of electrical power and signal. Their design is an amalgamation of traditional slip rings and rotary joint, resulting in a compact device that serves a dual purpose.

The operation of hybrid slip rings is based on the principles of electromagnetism and direct contact. The primary components of a hybrid slip ring include the rotor (which attaches to the rotating part of the system) and the stator (which remains stationary). As the rotor spins in sync with the system component, the stator maintains an electrical connection with the rotating body via brushes that make direct contact with the rotor. This persistent connection facilitates the transmission of power and data between otherwise disjointed system parts.

The integration of power and data transfer in a single unit is one of their unique selling points. Conventional systems often require separate devices for power and data transfer, which not only consumes more space but can also increase the complexity and potential point of failure in the system. Hybrid slip rings, however, simplify this by integrating both functionalities into one device, enhancing system design and operation.

This integration enables hybrid slip rings to accommodate a multitude of signals such as Ethernet, USB, HDMI, and even fiber optic along with the necessary power for system operation. Furthermore, they have the capacity to adapt to fast-paced technological advancements, making them a versatile component that can cater to future innovations.

Overall, understanding the operation and functionality of hybrid slip rings is key to realizing their potential contributions to various technological sectors. They symbolize progress in the field of power and data transmission, demonstrating how effective integration can refine system designs and facilitate efficient operations in the ever-evolving technological landscape.

Key Benefits and Advancements in Hybrid Slip Rings

The key benefits and latest advancements of hybrid slip rings extend their usefulness across numerous sectors, revolutionizing the way systems handle power and data transmission. Their impact is interwoven with technological advancements, ensuring they remain at the forefront of efficient and performance-driven system designs.

Key Benefits of Hybrid Slip Rings

- Versatile Signal Transmission:

- Supports the simultaneous transfer of power, data (Ethernet, USB, CANbus), and fiber optics.

- Facilitates the transmission of various media, including hydraulic and pneumatic connections, through the same interface.

- Compact and Space-Saving Design:

- Hybrid slip rings reduce the need for multiple rotating interfaces, which helps save space and simplify the mechanical setup.

- Ideal for applications where size and weight constraints are critical, such as drones and medical equipment.

- Enhanced Signal Quality:

- Maintains stable and high-quality transmission of signals, even in high-speed rotating environments.

- Prevents electrical noise and interference during data transfer, making it suitable for sensitive communications.

- Improved Durability and Reliability:

- Designed with corrosion-resistant and wear-resistant materials for long operational life.

- Suitable for harsh environments, withstanding extreme temperatures, dust, and moisture.

- Reduced Maintenance Needs:

- Many hybrid slip rings are engineered for minimal maintenance, reducing downtime and operational costs.

- Advanced contact technology (e.g., gold-on-gold) helps in achieving long-lasting performance.

- High-Speed and Multi-Channel Support:

- Capable of transmitting data at high speeds and supporting multiple channels for different signals.

- Useful in demanding applications such as robotics, where real-time communication is essential.

Recent Advancements in Hybrid Slip Rings

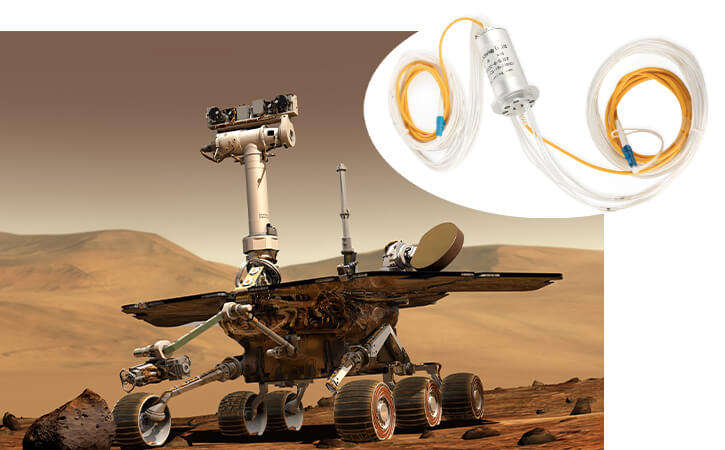

- Integration with Fiber Optic Technology:

- Modern hybrid slip rings now support high-speed data transfer through integrated fiber optics.

- This advancement makes them ideal for telecommunication, military applications, and smart systems requiring large data bandwidths.

- Wireless and Contactless Slip Ring Technology:

- Development of inductive coupling and capacitive technology has led to the emergence of contactless hybrid slip rings.

- Reduces wear and tear, enhancing lifespan and signal reliability, especially in applications with continuous rotation.

- Enhanced Miniaturization:

- Advances in materials and micro-engineering have led to smaller, lighter hybrid slip rings without compromising performance.

- This is essential for compact devices like surgical robots and autonomous drones.

- Smart Monitoring Capabilities:

- Some modern slip rings are integrated with sensors to monitor temperature, vibration, and rotational speed.

- Predictive maintenance features allow for early fault detection, preventing failures and downtime.

- Environmentally Friendly and Energy-Efficient Designs:

- New slip rings are designed to reduce energy losses during signal transmission, improving efficiency.

- Innovations in material science have made some slip rings more sustainable by using eco-friendly materials.

- Customization for Industry-Specific Applications:

- Hybrid slip rings are increasingly tailored for niche industries like wind turbines, space exploration, and medical equipment, meeting precise technical requirements.

- Customization includes specialized connectors, media channels (fluid/gas), and advanced shielding for electromagnetic interference (EMI).

Applications of Hybrid Slip Rings

- Robotics: Transmitting power, control signals, and data in high-speed robotic joints.

- Aerospace and Defense: Used in radars, antennas, and satellite communication systems requiring continuous rotation.

- Medical Equipment: Integration in CT scanners and surgical robots for seamless power and data transfer.

- Renewable Energy: Deployed in wind turbines to transfer power and data efficiently from rotating blades to the stationary grid interface.

Hybrid slip rings are becoming essential components in advanced machinery, offering precision, high-speed data transmission, and operational flexibility. Their continuous evolution ensures that they meet the increasing demands of modern technologies while addressing the challenges of efficiency, miniaturization, and durability.

Hybrid Slip Rings: Technical Specifications

When selecting or designing hybrid slip rings, understanding the technical specifications is crucial to ensure they meet the specific requirements of the intended application. Below is a breakdown of key technical parameters and their typical ranges or configurations:

Electrical Specifications

- Current Capacity:

- Power Circuits: 2A to 500A or more (depending on application)

- Signal Circuits: Typically 2A to 10A

- Voltage Rating:

- Low-voltage signal transmission: 24V to 48V DC

- Power transmission: 240V to 1000V AC/DC or higher

- Dielectric Strength:

- 500V to 5000V AC (depending on insulation and application)

- Ensures isolation between circuits and safe operation under high voltage.

- Electrical Noise (Contact Resistance Variation):

- <10 mΩ to 100 mΩ

- Low noise ensures reliable signal transmission for communication protocols like CANbus or Ethernet.

- Insulation Resistance:

- 100 MΩ @ 500V DC (common)

- High insulation resistance prevents leakage and cross-talk between channels.

Mechanical Specifications

- Rotational Speed:

- Standard: Up to 300 RPM (general industrial use)

- High-Speed Applications: 10,000 RPM or more (e.g., medical CT scanners, aerospace)

- Number of Channels:

- Power Channels: 1 to 12 (or higher for complex systems)

- Signal Channels: 5 to 50+ (for simultaneous data and control transmission)

- Contact Technology:

- Gold-on-Gold: Low wear, low contact resistance (ideal for data signals)

- Silver or Copper Alloy Brushes: High-current capacity and durability for power circuits.

- Life Span:

- 10 million to 100 million revolutions (depending on design and operating conditions)

- Torque Requirement:

- 0.01 Nm to 2.0 Nm

- Low torque ensures smooth operation, especially in robotic or medical applications.

- Housing Material:

- Aluminum, stainless steel, or engineering plastics

- Ensures durability and resistance to environmental conditions.

Environmental Specifications

- Operating Temperature:

- Standard: -20°C to +80°C

- Extended Range: -50°C to +150°C (for aerospace or harsh environments)

- IP Rating (Ingress Protection):

- IP54 (basic protection) to IP68 (fully sealed against dust and water)

- Higher IP ratings are required for outdoor applications, such as wind turbines.

- Shock and Vibration Resistance:

- Designed to withstand mechanical shocks and vibrations according to MIL-STD or IEC standards for critical environments.

Signal Transmission Capabilities

- Data Protocol Support:

- Ethernet (10/100/1000 Mbps)

- CANbus, Profibus, USB 2.0/3.0

- Fiber optics for high-speed data transmission (1 Gbps or more)

- Noise Immunity and EMI Shielding:

- EMI shielding is critical for preventing interference in environments with high electromagnetic activity (e.g., industrial automation, radar systems).

- Transmission Loss:

- Fiber-optic circuits: ≤0.5 dB loss per pass

- Electrical signals: Low insertion loss and consistent transmission quality over time.

Fluid or Pneumatic Channel Specifications (Optional)

- Fluid/Gas Channels:

- 1 to 8 channels integrated for hydraulic or pneumatic control

- Supports liquids, gases, or vacuum transmission.

- Pressure Handling:

- Up to 20 bar or more for hydraulic applications

- Essential for automated systems requiring air or liquid supply, such as robotics or industrial machines.

Summary Table of Typical Specifications

| Parameter | Range |

|---|---|

| Current Capacity | 2A – 500A |

| Voltage Rating | 24V – 1000V AC/DC |

| Rotational Speed | 300 – 10,000 RPM |

| Operating Temperature | -50°C to +150°C |

| IP Rating | IP54 – IP68 |

| Data Protocols | Ethernet, USB, CANbus, Fiber Optics |

| Insulation Resistance | 100 MΩ @ 500V DC |

| Contact Technology | Gold-on-Gold, Silver Brushes |

| Fiber Optic Loss | ≤0.5 dB per pass |

| Fluid Channel Pressure | Up to 20 bar |

| Life Span | 10 – 100 million revolutions |

These technical specifications are essential for ensuring optimal performance, reliability, and longevity of hybrid slip rings across different industries. The specific requirements will vary based on the application, such as high-speed robotics, harsh-environment machinery, or precision medical devices, requiring careful customization of the slip ring design.

Hybrid Slip Rings: Power and Data Transmission

Hybrid slip rings are advanced rotary interfaces designed to transmit both power and data signals simultaneously between stationary and rotating components. This dual capability makes them essential in applications like robotics, medical equipment, wind turbines, and defense systems, where both energy and real-time data communication are required. Below is a detailed look at the power and data transmission aspects of hybrid slip rings.

Power Transmission in Hybrid Slip Rings

The power transmission channels in hybrid slip rings are responsible for delivering electricity from a stationary source to rotating equipment.

Key Features of Power Transmission

- Current Capacity:

- Varies from 2A to 500A, depending on the application.

- Low-power circuits: Ideal for control systems (2A to 10A).

- High-power circuits: Used in industrial equipment and wind turbines (100A or more).

- Voltage Rating:

- Common voltage ranges: 24V to 1000V AC/DC.

- Low-voltage applications: Used for small motors, sensors, or LED lighting.

- High-voltage applications: Power-heavy equipment such as cranes or rotating machinery.

- Contact Technology:

- Gold-on-gold contacts: Low-resistance, ideal for precision power delivery in sensitive systems.

- Silver or copper alloy brushes: Suitable for high-current applications, providing durability and reduced arcing.

- Protection Against Noise and EMI:

- Shielded power circuits reduce electromagnetic interference (EMI), preventing disruptions in nearby data channels.

- Heat Management:

- Efficient thermal dissipation systems are required to prevent overheating during high-power transmission.

Data Transmission in Hybrid Slip Rings

Hybrid slip rings enable high-speed data transmission over rotating interfaces without signal degradation. This is crucial for systems requiring real-time communication, such as robotics, surveillance cameras, or industrial automation.

Data Protocols Supported

- Ethernet:

- 10/100/1000 Mbps (Gigabit Ethernet) for network communication.

- Used in IP cameras, IoT sensors, and control systems.

- USB:

- USB 2.0 and 3.0 for data transfer between connected devices.

- Ideal for sensors, control panels, and medical instruments.

- CANbus / Profibus / Modbus:

- Widely used in industrial control systems for machine-to-machine communication.

- Provides robust and interference-free communication.

- Fiber Optic Transmission:

- Supports high-bandwidth communication over long distances with minimal loss.

- Used in defense, telecommunications, and medical imaging equipment.

Key Features of Data Transmission

- Low Contact Resistance:

- Gold-plated contacts ensure minimal signal loss and stable transmission.

- Contactless or wireless solutions (e.g., inductive coupling) further reduce interference.

- Noise Immunity and EMI Shielding:

- Advanced shielding prevents cross-talk between power and data channels.

- Ensures smooth operation in environments with high electromagnetic interference.

- High-Speed Transmission:

- Capable of Gigabit data rates for modern applications requiring large data throughput.

- Real-Time Communication:

- Enables zero-latency transmission for applications like robotic arms and CNC machines.

- Signal Integrity:

- Fiber optics and advanced cabling help preserve signal quality over long rotational cycles.

- Transmission loss is minimized to ≤0.5 dB per pass for optical channels.

Power vs. Data Transmission Characteristics

| Parameter | Power Transmission | Data Transmission |

|---|---|---|

| Current Capacity | 2A – 500A | Not applicable |

| Voltage Rating | 24V – 1000V AC/DC | Signal-level voltages (5V – 24V) |

| Data Rate | Not applicable | 10 Mbps – 1 Gbps (Ethernet, USB, CANbus) |

| Contact Type | Silver, copper, or gold brushes | Gold-on-gold or contactless (inductive) |

| Noise Resistance | EMI shielding required | High immunity with shielding and isolation |

| Transmission Type | Continuous power delivery | Real-time, high-speed data transfer |

| Maintenance | Regular inspection for wear | Minimal maintenance, long lifespan |

| Application | Motors, wind turbines, industrial machines | Robotics, medical devices, IP cameras |

Hybrid slip rings play a critical role in modern applications requiring both power delivery and data communication over rotating interfaces. Their design and materials ensure long-lasting performance, stable transmission, and minimal maintenance. By overcoming challenges related to wear, friction, and EMI, hybrid slip rings enable the efficient operation of cutting-edge technologies across multiple industries.

Hybrid FORJ Slip Rings

A Hybrid FORJ Slip Ring is a specialized rotary interface that combines the functionality of electrical slip rings (for power and electrical signals) with a Fiber Optic Rotary Joint (FORJ), enabling the simultaneous transmission of power, electrical signals, and optical data between stationary and rotating parts. These components are essential for applications requiring high-speed data communication over long distances, especially where conventional electrical signals might not meet the necessary bandwidth and noise immunity requirements.

Key Features of Hybrid FORJ Slip Rings

- Simultaneous Transmission of Power and Optical Data

- Combines electrical circuits for power and control with fiber optics for high-bandwidth data transfer.

- Capable of handling both AC/DC power and multi-channel optical signals through a single, compact interface.

- High-Speed, Lossless Data Transfer

- Fiber optic channels can support Gigabit and Terabit speeds over long distances with minimal signal degradation.

- Optical signals are immune to electromagnetic interference (EMI), making them ideal for noisy environments.

- Compact and Modular Design

- Hybrid FORJ slip rings offer customizable configurations, including the number of optical and electrical channels to meet application-specific requirements.

- Available in hollow-shaft or through-bore designs to allow cables, fluids, or other components to pass through the center.

- Durability and Reliability

- FORJs use contactless optical transmission, reducing wear and extending operational life.

- Electrical slip ring components use gold-on-gold contacts or low-friction brushes for durability and minimal maintenance.

Technical Specifications

| Parameter | Optical Channels | Electrical Channels |

|---|---|---|

| Transmission Type | Single-mode / Multi-mode fiber | AC/DC power, control signals |

| Bandwidth | Up to 40 Gbps per optical channel | 10 Mbps – 1 Gbps (Ethernet, USB) |

| Channel Count | 1 – 12 optical channels | 1 – 50 electrical circuits |

| Current Capacity | Not applicable | 2A – 500A |

| Voltage Rating | Not applicable | 24V – 1000V AC/DC |

| Insertion Loss | ≤ 3 dB per optical pass | <10 mΩ (low contact resistance) |

| Rotational Speed | Up to 3000 RPM | Up to 10,000 RPM (for high-speed) |

| Operating Temperature | -40°C to +85°C | -50°C to +150°C |

| IP Rating | IP65 – IP68 (sealed models) | IP54 – IP68 |

Advantages of Hybrid FORJ Slip Rings

- High-Speed Data Transmission

- Optical channels support Gigabit and Terabit speeds, ensuring real-time communication for critical systems.

- Ideal for applications like radar systems and medical imaging equipment that require ultra-fast data transfer.

- EMI Immunity

- Fiber optics are inherently immune to electromagnetic interference (EMI), making hybrid FORJ slip rings reliable in electrically noisy environments (e.g., industrial automation).

- Reduced Wear and Maintenance

- The contactless nature of fiber optics minimizes wear compared to traditional electrical slip rings, ensuring a long lifespan.

- Electrical contacts use low-friction materials, further reducing maintenance requirements.

- Compact Design with Multiple Functions

- Reduces the need for separate components by integrating power, electrical, and optical communication channels into one device.

- Saves space and simplifies installation, especially in confined environments such as robots or drones.

Hybrid FORJ slip rings combine the benefits of fiber optic rotary joints (FORJ) and electrical slip rings to offer a powerful solution for applications requiring both power and high-speed data transmission. These devices are essential in industries such as aerospace, medical, industrial automation, and renewable energy, where reliability, bandwidth, and durability are critical. Their advanced designs offer high data rates, EMI immunity, reduced wear, and multi-channel capability, making them a preferred choice for cutting-edge technologies.

Applications of Hybrid Slip Rings

Given their versatile functionality and efficiency, hybrid slip rings find applications across a myriad of industries, serving as a testament to their undeniable significance in various system setups.

One of the substantial sectors employing hybrid slip rings is healthcare. In medical imaging equipment like CT scanners, MRI machines, and X-ray machines, hybrid slip rings effectively transfer power and image data signals from rotating gantries to stationary systems, thereby facilitating the production of high-resolution images essential for accurate diagnosis and treatments.

Hybrid slip rings also play a crucial role in the telecommunications industry. They are vital components in radar and satellite antennas, where they enable continuous rotation of antennas while maintaining consistent power supply and data transmission. This functionality ensures reliable tracking of signals and plays a vital role in maintaining communication links.

The aerospace and defense sectors too, are beneficiaries of hybrid slip rings. They form an integral part of navigation systems, surveillance systems, and targeting systems in various military equipment and aircraft. Their ability to withstand harsh environments and still provide reliable power and data transmission proves critical in these applications.

Manufacturing units and industrial automation systems depend heavily on hybrid slip rings. They enable the efficient operation of heavy equipment such as cranes, wind turbines, automated assembly lines, and robotics. The reduction of mechanical wear and tear due to the use of hybrid slip rings extends the lifespan of these systems, boosting productivity and decreasing maintenance costs.

Real-world examples of hybrid slip ring applications are numerous. For instance, in the wind energy sector, they have significantly improved the performance of wind turbines. By facilitating the seamless transfer of power and data from the rotating blades to the stationary base, hybrid slip rings allow wind turbines to operate effectively irrespective of the blade rotation speed.

Another example can be seen in the field of broadcast media. In the elaborate setups of live events, cameras fitted with hybrid slip rings provide flawless video feeds, despite continuous 360-degree panning. This capability has dramatically improved the quality of live event broadcasts, taking viewer experience to the next level.

In conclusion, hybrid slip rings are an integral part of various industries, courtesy of their unrivaled ability to enhance system performance and efficiency. Their unique advantages and applications demonstrate their significance as catalysts for innovation and technological growth.

Things to Consider When Choosing Hybrid Slip Rings

As with any technology, selecting the appropriate hybrid slip ring requires careful consideration and a comprehensive understanding of the system requirements. Some key aspects to keep in mind include compatibility, ease of installation, maintenance needs, lifespan, size, and of course, cost.

- Compatibility: Hybrid slip rings are designed to transmit a variety of signals and work with different power levels. Hence, it is crucial to ensure that the chosen hybrid slip ring is compatible with your specific devices, systems, and operating conditions. Compatibility extends to the electrical properties of the hybrid slip ring, its operational speed range, and its ability to work in the environmental conditions pertaining to your system.

- Installation Process: Every device adds some level of complexity during the installation process. Therefore, evaluating the ease of installation of the hybrid slip ring within your system is important. Some hybrid slip rings come with features like plug-and-play compatibility, which can drastically simplify installation.

- Maintenance Requirements: While all hybrid slip rings aim to reduce overall system maintenance, their own maintenance needs can vary. Understanding these requirements can provide insight into potential downtime and cost implications. Opting for a hybrid slip ring with sealed units or contactless data transmission technology can help minimize maintenance needs.

- Lifespan: The lifespan of a hybrid slip ring is determined by factors such as the speed of operation, type of signals transmitted, and physical wear and tear. Therefore, the product’s lifespan matching the system’s expected or required lifespan should be a key consideration when making your selection.

- Size of the Unit: The size of the hybrid slip ring can significantly impact its compatibility with your device or system. Thorough consideration is required to ensure the chosen slip ring fits appropriately within the available space.

- Cost: Last but certainly not least, the cost of the hybrid slip ring unit and its related costs – like maintenance, replacement parts, potential downtime, etc., need to be taken into account. It is important to remember that while a cheaper solution might seem attractive upfront, it may not always be the most cost-effective choice in the long run, especially if it compromises quality, reliability, or service life.

Understanding these factors thoroughly before committing to a particular hybrid slip ring helps ensure you select the most fitting component for your requirements. Each system and application has its own unique needs; understanding the role and impact of a hybrid slip ring within that configuration is vital to making an informed decision. By reviewing the factors mentioned and aligning them with your system requirements, you can effectively choose a hybrid slip ring that enhances your system’s performance and efficiency.

Latest Advancements in Hybrid Slip Rings

Like every realm of technology, hybrid slip rings, too, continue to evolve, pioneering advancements that consistently enhance their performance, reduce size, and improve resistance to environmental elements.

One of the most significant improvements in hybrid slip ring technology is the development of Fiber Optic Rotary Joints (FORJ). These advancements allow hybrid slip rings to carry high-speed data transmission through the non-contact transmission of optical fiber signals, significantly enhancing their overall performance and reliability.

A transition towards more compact designs without compromising on functionality has been a pivotal advancement. Modern hybrid slip rings are designed to meet the increasing demand for miniaturization in various applications such as robotics, CCTV cameras, and medical equipment. These compact designs ensure less space occupancy without diminishing signal integrity and power transmission capabilities.

Developments in materials science have allowed hybrid slip rings to withstand increasingly hostile environments without degrading performance. The use of advanced engineering materials that can resist corrosion, high temperatures, and radiation boosts the durability of these devices. For example, the use of stainless steel, gold alloy brush contacts, and other city-grade materials has broadened the scope of hybrid slip ring usability, improving resistance to environmental elements.

Additionally, improvements in contactless transmission technology have notably enhanced the hybrid slip ring’s lifespan and efficiency. These modern contactless slip rings use magnetic fields or light instead of physical contact to transfer data and power. This reduced wear and tear extends the operational life of the hybrid slip rings, minimizes maintenance, and ensures consistent high-speed transmission, leading to improved performance.

Finally, the incorporation of smart features stands as a milestone in hybrid slip ring evolution. The integration of sensors and software for real-time performance monitoring ensures immediate fault detection and maintenance, which substantially increases system efficiency and longevity.

Overall, these advancements in hybrid slip ring technology contribute to enhancing the efficiency and performance of systems across varying domains. As the technology continues to progress, one can expect hybrid slip rings to further revolutionize power transmission and data communication. In doing so, they pave the way towards achieving higher operational standards across industries.

Case Studies in Hybrid Slip Rings

Hybrid slip rings are employed in a myriad of applications across different industries. Below are some case studies exhibiting their successful implementation, which demonstrate not just their utility but their essential role in facilitating operational efficiency.

1. Case Study in Medical Imaging – CT Scanner

One of the most prominent implementations of hybrid slip rings is within the medical industry, particularly in computerized tomography (CT) scanners. A medical device manufacturer faced challenges in transmitting power and data simultaneously from the rotating part of the scanner (the gantry) to the stationary area.

By integrating a custom hybrid slip ring into their CT scanner, they were able to streamline power and high-speed data transmission, resulting in better-quality images, improved diagnostic capabilities, and reduced scan time. The hybrid slip ring’s compact design also allowed it to fit neatly into the tight space, favoring the overall form factor of the scanner.

2. Case Study in Renewable Energy – Wind Turbine

A leading wind turbine manufacturer was grappling with the issue of transferring power and sensor data from the rotating blades to the stationary generator system. Traditional power and data transmission methods were costly and ineffective, adding unwanted complications to the task.

The solution came in the form of a high-performance hybrid slip ring. The slip ring was designed to handle high-power transmission for the turbine operations and simultaneously transmit crucial sensor data to the system controller. The installation markedly enhanced the operational efficiency of the wind turbine and contributed to significant energy output gain.

3. Case Study in Broadcasting – Live Event Camera Setup

In the field of broadcast media, a prominent production company was finding it challenging to capture smooth, 360-degree videos during live events. The problem laid in transmitting high-definition video signals from the constantly rotating camera to the control room without losing signal quality.

Integrating a hybrid slip ring into the camera’s pivoting system served as the optimal solution to this issue. The slip ring provided uninterrupted, high-resolution video transmission, irrespective of rotational movements. This implementation led to drastically improved video quality and significantly enhanced the viewing experience for live audiences.

These case studies illustrate that the integration of hybrid slip rings into different systems is instrumental in achieving operational efficiency and extending system performance. Looking at these scenarios, it is no surprise that hybrid slip rings are integral for diverse industries, and their potential uses continue to broaden with ongoing developments in their technology.

The Future of Hybrid Slip Rings

The landscape of hybrid slip ring technology is ever-evolving, and its future appears dazzling with exciting developments. As we move forward, there are several promising trends on the horizon that stand to redefine their deployment, particularly witnessed in their integration with IoT, AI, and sustainable practices.

Integration with IoT

As the Internet of Things (IoT) continues to expand its impact across various sectors, hybrid slip rings are not an exception. IoT integration could lead to hybrid slip rings becoming smarter and more holistic in their approach. Hybrid slip rings could understand and optimize system performance by collating and analyzing data from various parts of the system. This advancement would allow the devices to foresee possible problems, schedule maintenance, and improve efficiency on the go.

Advancements in AI

Hybrid slip rings integrated with AI technology will not just improve system efficiency but also the process of their design and manufacturing. AI can guide the production of hybrid slip rings tailored to the exact requirements of a system based on the collected data, significantly improving performance. On the application side, AI can drive real-time adaptations in the slip ring’s operation based on pattern recognition and predictive analysis, ensuring optimal performance and prolonged lifespan.

Sustainable Practices

With the global shift towards sustainable practices, the future of hybrid slip rings will invariably gravitate towards ‘greener’ solutions. This could manifest in multiple ways, be it the utilization of environmentally friendly materials in their production or the improvement of their energy efficiency, resulting in lesser power loss during transmission. Hybrid slip rings would aim at reducing the environmental footprint while boosting the efficiency of the system. Similarly, the demand for seawater corrosion-resistant rotary joints is increasing as industries look to reduce maintenance costs and extend the lifespan of equipment exposed to harsh environments. By using advanced corrosion-resistant materials, these rotary joints can operate effectively in marine and coastal conditions, contributing to more sustainable and durable systems that reduce the need for frequent replacements and repairs. Together, innovations in both hybrid slip rings and seawater corrosion-resistant rotary joints represent a significant step toward more eco-friendly and efficient industrial systems.

Furthermore, hybrid slip rings are expected to gain more traction in renewable energy applications, particularly in wind and solar energy systems. They would play a key role in improving the efficiency of these energy systems and contributing to a more sustainable future.

Looking for a quote? Our inquiry form will help us understand your Hybrid slip rings requirements.

In essence, the future of hybrid slip rings seems promising and electric with possibilities. They portray a potential conduit for fascinating technological breakthroughs, setting the stage for an exciting era of enhanced system performance and sustainability. Their integration into IoT, AI, and sustainable practices appears to be the inevitable next step, offering possibilities for innovative application and ensuring that hybrid slip rings maintain their relevance in the dynamic technological landscape of the future.

Conclusion

In conclusion, hybrid slip rings play a pivotal role in transforming power and data transmission. Their significance, coupled with the ongoing advancements and future trends, demonstrates their irreplaceable standing in the industry. As we continue to be awed by technological innovations, hybrid slip rings promise a future of seamless integration between power and data, propelling us further into an efficient era.

FAQs about Hybrid Slip Rings

Understanding hybrid slip rings often involves navigating through a series of questions and doubts. The most common queries relate to their reliability, adaptability, types and speeds of signals they can transmit, their suitability for diverse environments, and concerns about heat generation.

Q: Are hybrid slip rings reliable?

A: Hybrid slip rings are designed to provide high reliability. Their purpose is to offer consistent power and data transmission between rotating and stationary parts of a system, and this is what they excel in. They are built to withstand varying operational speeds and diverse environments, hence they present an optimal solution for uninterrupted system performance. However, like any device, the reliability of a hybrid slip ring greatly depends on appropriate usage, regular maintenance, and operation within the stipulated conditions.

Q: What types of signals can hybrid slip rings transmit?

A: Hybrid slip rings are versatile in their capabilities. They are designed to transmit a variety of signals including, but not limited to, Ethernet, USB, HDMI, RS232, RS485, CANbus, and even fiber optic signals. The type of signals a hybrid slip ring can transmit will, however, depend on its specific model and design.

Q: What is the typical speed of operation for hybrid slip rings?

A: The operational speed of hybrid slip rings can vary significantly based on their design and the system’s needs. Some hybrid slip rings are designed for low-speed operation in heavy machinery, while others are built for high-speed data transmission in radar and satellite systems. It is essential to match the speed capabilities of the hybrid slip ring with the operational speed requirements of your system for optimal performance.

Q: Can hybrid slip rings operate in diverse environments?

A: Absolutely. Hybrid slip rings are designed to cater to a wide range of environmental conditions. Whether it’s a high-temperature environment in industrial machinery, a high-humidity environment in marine applications, or low-temperature conditions in wind turbines, there are hybrid slip rings suitable for virtually all conditions. Always ensure to specify the operational environment when selecting a hybrid slip ring.

Q: Do hybrid slip rings generate heat?

A: Like all electronic devices, hybrid slip rings can generate heat during operation due to electrical resistance. However, heat generation is typically minimal and well managed through clever material choices and design techniques such as heat dissipation pathways. Nonetheless, it’s important to consider heat management when incorporating a hybrid slip ring into your system, particularly if it operates in a high-temperature environment.

See What We Can Do