Introduction

Modern technology is like an exponential growth curve, with each new invention setting a foundation for further discoveries. Not surprisingly, this trend has led to the advent of various tools and machinery that influence our day-to-day life and industrial operations. Landmark instruments that have truly revolutionized how we operate in certain sectors are the unsung heroes of our technological landscape. One such instrumental machinery part is the Hydraulic Swivel Joint. This mechanism, though invisible to the naked eye in most equipment, serves an indispensable function. Its innate attribute of effectuating the smooth rotation and fluid transfer in machinery and heavy-duty equipment is pretty much the foundation of functions in sectors ranging from logistics and manufacturing to oil and gas operations. This comprehensive guide intends to shed light on all the dimensions – from theoretical and technical aspects of hydraulic swivel joints, their applications, benefits, and specifications, to some insights into maintaining them.

What Are Hydraulic Swivel Joints?

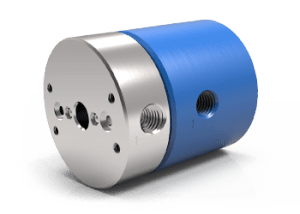

Hydraulic swivel joints, also known as rotating joints or unions, are mechanical devices that allow uninterrupted fluid transfer under high pressure while facilitating rotation. Imagine the ability to rotate a device, a part, a sub-system, an entire equipment, or even a pipeline, all while simultaneously facilitating the unhindered flow of a fluid. That’s exactly what these joints enable.

At the core of any hydraulic swivel joint, there exist two components, namely the input component and the output component. The function of the input is to uphold the reception of fluid, while the output component models this received fluid to a pathway creating rotation. Maintaining a secure connection between these facets irrespective of the ongoing rotational mechanism is one of the fundamental aspects of the functionality of these joints.

The device is designed in a manner that during the rotational process, the fluid, typically a hydraulic fluid under pressure, is delivered through precision fit parts that hold and rotate against each other. This mechanism ensures that the fluid stays within the joint even during continuous rotation and more importantly, there is no turbulence caused which could otherwise affect the performance of the mechanism.

Their design efficiency warrants fluid transfer in an endless rotation without loss of pressure, which is integral to the workings of various types of heavy-duty equipment. The strength and adaptability of hydraulic swivel joints cater to a plethora of environmental conditions, making it an unavoidable element in a large number of industrial and commercial applications. Fundamentally, their ultimate purpose in machinery and systems is to ensure a fluid— subject to intense pressure— flows uninterruptedly while delivering a steady and continuous rotation.

Materials Used in Hydraulic Swivel Joints

The materials used in constructing hydraulic swivel joints are meticulously selected based on the type of application, environmental conditions, and the nature of the hydraulic fluid used in the operations. The fact that these joints are often subjected to intense mechanical stress and a range of environmental conditions necessitates the usage of robust and resistant materials.

Commonly, three primary materials are used in the manufacturing of hydraulic swivel joints, carbon steel, stainless steel, and brass.

Carbon Steel: A commonly used material due to its excellent durability and high resistance to wear and tear. Carbon steel swivel joints are typically used in heavy-duty applications where the joints are subjected to intense pressures and usage.

Stainless Steel: Exhibiting superior resistance to corrosion and chemical damages, stainless steel is another preferred choice for hydraulic swivel joints. The material offers high strength and durability, making it an ideal choice for applications involving corrosive fluids or exposure to harsh environmental conditions.

Brass: Appreciated for its natural corrosion resistance, brass hydraulic swivel joints are generally utilized in applications where lower pressures are involved, or there’s a requirement for superior resistance against corrosive or saline environments.

To ensure the sealing function of these joints is not compromised during rotation, they integrate seals crafted from materials like Viton, Nitrile, or PTFE (Polytetrafluoroethylene). Each type of seal material is designed to cater to certain operational prerequisites, such as resistance to specific pressure ranges, temperatures, and chemical compatibility. For instance, Viton seals withstand high temperatures and chemicals while Nitrile seals possess excellent resistance against oil and other hydrocarbons. PTFE seals provide an exemplary performance for a wide range of temperature, pressure, and chemical criteria.

Overall, discerning the materials involved in the construction of hydraulic swivel joints helps in choosing the right joint type for particular operational conditions, attributing to a seamless performance and prolonged lifespan of the joint.

Hydraulic Swivel Joints Features

Hydraulic swivel joints have numerous notable features, which contribute to their versatility and widespread usage across multiple industries. These features not only encompass performance aspects but also encapsulate the specific design fundamentals ensuring optimized functionality in diverse applications. Here is a detailed analysis of these features:

Durability

Constructed with robust materials, like carbon steel or stainless steel, hydraulic swivel joints can withstand the prolonged rigors of intensive usage. The tenacious build ensures high levels of wear resistance, making them ideal for applications that encounter frequent or continuous movement, supporting long-lasting performance.

Flexibility

The joint facilitates smooth unidirectional or bidirectional rotation while maintaining fluid transfer. These rotating abilities grant versatility in motion to various equipment, helping prevent eventual stress failure, twists, or line ruptures.

Pressure Resistance

Hydraulic swivel joints are designed to endure high pressure— a necessity for many hydraulic systems. As pressure intensifies, the joint’s strength remains unaffected, providing secure and reliable operation throughout its operation. This high-pressure resistance feature maintains the efficiency of both the joint itself and the equipment it is integrated with.

Compact Design

The joints are often crafted with space-saving and ergonomic designs, making them easier to integrate into existing machinery and systems without impacting the overall dimensions or hindering other operational elements.

Ease of Maintenance

Maintaining hydraulic swivel joints is relatively straightforward, due in part to their design and material choice. With proper care, timely inspections, and replacements of worn components like seals, these joints can provide consistent performance over time.

Compatibility

Hydraulic swivel joints are catered to a multitude of hydraulic fluids, including oil, water, steam, and gas. This compatibility factor broadens their application scope, rendering them vital in numerous industries.

These remarkable features of hydraulic swivel joints equip them to withstand varied operating environments and seamlessly integrate into diverse machinery types, which highlights their indispensability in numerous sectors.

Hydraulic Swivel Joints Technical Specifications

The performance and applicability of hydraulic swivel joints can be gauged through their technical specifications. Here’s a more detailed look at these:

Working Pressure

Hydraulic swivel joints are designed to handle a vast gamut of pressure, with some models capable of functioning at pressures up to 6000 PSI (pound-force per square inch). This high-pressure handling capability is crucial in several heavy-duty applications like excavators, cranes, and drilling equipment. The ability to sustain heightened pressure indicates the extent and intensity of operations the joint can support, which is predominantly a determinant of the joint’s durability and its compatibility with machinery types.

Ambient Operating Temperatures

Hydraulic swivel joints can endure a wide spectrum of temperatures, usually operating efficiently in ambient conditions ranging from -40 degrees Celsius to 200 degrees Celsius. This broad operational temperature range implies that these joints can function flawlessly in extreme cold and hot environments. Thus, whether it’s used in heavy machinery operating in frigid zones or steering systems of vehicles under scorching conditions, the joint can continually function unaffected, maintaining the fluid flow and rotational mechanism.

Sizes

Hydraulic swivel joints come in a diversity of sizes, from as small as 1/8 inch to as large as 10 inches. The corresponding size selection is influenced by the volume and speed of fluid that needs to be transferred, in addition to the operating pressure. Smaller-sized joints usually find their place in lesser-intensity operations, whereas larger ones are preferred for heavy-duty and industrial-scale applications. The size often correlates with the pressure-handling capacity and determines the flow rate of the fluid the joint can support.

Medium Compatibility

Hydraulic swivel joints are highly versatile due to their potential to transfer a wide variety of mediums. They are compatible with a variety of hydraulic fluids including oil, steam, water, and even gases. This feature plays a pivotal role in determining the type of machinery or equipment the joint can be integrated into. For instance, a joint that can transfer steam might be apt for systems involved in heating processes, while one facilitating oil transfer can find its place in automotive or industrial machinery.

Understanding the technical specifications of hydraulic swivel joints can help potential users choose the correct joint that matches the requirements of their application perfectly and optimizes the performance of the system it is installed.

What Are Hydraulic Swivel Joints Used For?

Hydraulic swivel joints find application in a wide range of industries due to their ability to enable motion and flexibility while also delivering a controlled flow of fluid under high pressure. Below are some of their common applications:

Maritime Industry

Swivel joints are pivotal in operations involving the loading and offloading of liquid cargo in maritime applications. These can transfer fluids (like oil or liquefied natural gas) between the dock and the ship, enabling continuous flow even as the ship moves with tides and currents.

Manufacturing Industry

In the manufacturing sector, these joints find use in many machines, such as hydraulic presses, injection molding machines, forging machines, etc. They facilitate fluid flow for operations and enable part movement where needed.

Agriculture

They’re an integral part of irrigation systems and agricultural machinery. In sprinklers, for example, swivel joints enable continuous water flow while letting the sprinkler rotate, providing even water distribution.

Oil and Gas Industry

They’re critical in drilling operations, allowing the drill to rotate while pumping drilling fluid. Also, in both oil and gas extraction and refining operations, they facilitate critical fluid transfer.

Automotive Industry

In vehicles, hydraulic swivel joints are used in components like power steering systems, allowing smooth fluid flow while facilitating the rotation of steering components.

Construction

Construction machinery like cranes and excavators often use hydraulic swivel joints. These allow the equipment arm to rotate and move while maintaining the flow of hydraulic fluid necessary for operations.

Wind Energy

In wind turbines, these joints enable the rotor to rotate according to wind direction, while allowing transmission of hydraulic fluids for other functions such as blade pitch control.

Hydraulic swivel joints’ immense versatility and critical functionality make them a fundamental component in machinery and systems of numerous industries.

Types of Hydraulic Swivel Joints and Their Respective Benefits

Hydraulic swivel joints are distinguished into several types based on their design, structure, and functional attributes. Each variant carries specific benefits, making them suitable for use within different applications. Below are some of the common types of hydraulic swivel joints and their corresponding advantages:

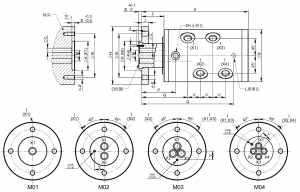

MH Series Hydraulic Rotary Joints

◆ Supported by double high-precision maintenance-free bearing for high stability

◆ High-quality imported sealing parts for prolonged service life

◆ Stainless steel rotor with special treatment to provide good durability

◆ Housing material available in aluminum, stainless steel, or brass

◆ Special leakage reflux design to avoid exterior contamination

◆ Customization available for different applications

Description

| Technical Ratings | |||

|---|---|---|---|

| Max. Speed | Max. Pressure | Temperature | Media |

| 300r/min | 30 Mpa | -30℃~+80℃ | Oil, Air or Similar |

Notes

- Operations under extreme ratings should be avoided. Maximal working speed is in reverse proportion to working pressure and is also influenced by the media lubricity and the heat dissipation ability of the sealing components. When the rotation speed is lower than 10RPM, the maximal pressure can be up to 30Mpa.

- Inner leakage is allowed between each passage. Please pay attention to the compatibility of different working media to avoid cross-contamination.

- The working fluid or hydraulic media should be filtered before being used. The filtration precision should be no lower than 10um.

- Drainage hole is accompanied for observation and collection of escaping media.

- For other applications, please consult AIKE SEALING beforehand.

By understanding the various types of hydraulic swivel joints and their benefits, users can choose the right swivel joint that aligns seamlessly with their operational requirements, ensuring efficient and durable performance.

The Benefits of Hydraulic Swivel Joints

Hydraulic swivel joints, with their versatile features and operational flexibility, provide numerous benefits. Here we’ll delve deeper into four key advantages:

Enhanced Equipment Life

Swivel joints allow for smooth rotation of connected parts and help in alleviating stress generated due to the movement. By preventing the torque buildup and reducing the wear and tear arising from movement, they can significantly enhance the lifetime of the equipment they are part of. This increased equipment life can lead to long-term cost savings and better operational efficiency.

Greater Flexibility

Swivel joints offer rotational flexibility, which is crucial in many applications. They allow for bidirectional or unidirectional rotation, depending upon the requirements, without affecting the fluid transfer. This flexibility provides optimal motion capabilities for equipment, ensuring a more adaptable and versatile operational range.

Prevention of Leakage

A well-constructed hydraulic swivel joint assists in preventing leakages of hydraulic fluid. The sealing mechanisms in these joints ensure the fluids within the hydraulic system stay contained, leading to better performance, safer operation, and lesser environmental impact. Furthermore, it helps maintain pressure within the system for efficient operation.

Broad Range of Applications

With their ability to withstand high pressures, a wide array of temperatures, and compatibility with a variety of hydraulic fluids, these swivel joints have a broad range of applications. They find use in numerous industries, from manufacturing and oil drilling to maritime and agriculture, opening possibilities for cohesive operational continuity in different machines and environments.

In a nutshell, hydraulic swivel joints play a major role in maintaining system integrity, enhancing operational lifespan, and promoting efficient performance across a multitude of applications and industries. Their usage underpins the grounding success of different operations, underscoring their importance in myriad equipment and machinery that rely on hydraulic systems.

How to Choose Hydraulic Swivel Joints?

Choosing the right hydraulic swivel joint requires careful consideration of several factors to ensure compatibility with the system or equipment it will be used with. Here’s an expanded look at three critical points to consider:

Working Pressure

The working pressure of a hydraulic swivel joint is a vital factor to account for when choosing a joint. It refers to the maximum pressure the swivel joint can handle over a sustained period. The choice of a swivel joint should be guided by the machine’s operational pressure. A swivel joint with a higher working pressure than what is necessary for application can be a waste of resources. Conversely, if the joint’s working pressure is lower than the application’s need, it could result in premature failure and potential risks. Therefore, the working pressure requirement is imperative in decision-making to ensure operational safety and cost-effectiveness.

Operating Temperature Range

The operating temperature range of a hydraulic swivel joint is another factor to consider. This refers to the range of temperatures within which the joint can function efficiently. Depending upon the working conditions and environment where the equipment will be used, the appropriate joint should be selected. For heavy machinery operating in high-temperature areas, a joint withstanding higher temperatures would be more suitable. On the other hand, equipment used in colder climates or refrigerated spaces would require a swivel joint that can efficiently function at low temperatures.

Size of the Joint

The size of the hydraulic swivel joint can greatly influence its compatibility with a system or machine. This criterion is usually dictated by the machinery’s design and the intensity of operations it needs to undertake. The size of the joint can impact the flow rate of the fluid it can support, hence, it becomes essential to assess the required fluid flow rate for an application. Smaller-sized joints are generally applied in systems demanding lesser intensity operations, while larger ones are preferred for heavy-duty applications.

Understanding these key points ensures that the selected hydraulic swivel joint is ideal for the intended use and provides optimal performance. The right choice can lead to increased efficiency, longer equipment lifespan, and reduced maintenance costs.

What Are the Alternatives to Hydraulic Swivel Joints?

While hydraulic swivel joints play a significant role in numerous applications, there are alternatives that can substitute for their functions under specific conditions. Here are some alternatives to hydraulic swivel joints:

Rotary Unions

Rotary unions, sometimes also known as rotating unions or rotary couplings, serve a purpose similar to swivel joints. They allow the flow of fluid from a stationary input to a rotating part. These can be used with diverse types of fluids, including steam, water, thermal oil, air, or coolant. While the principle is similar, the key difference lies in complexity, size, and application. Rotary unions are generally used in more complex, high-speed, and high-pressure applications such as printing and industrial machinery.

Flexible Hoses

If rotational movement is not a necessity but flexibility and fluid transport are required, then flexible hoses might serve as an alternative. These hoses can transport hydraulic fluid between different parts of a system allowing for bend and some movement, however, they lack the 360-degree rotary function of a swivel joint.

Elbow Fittings

In systems where changing the direction of the fluid’s path is needed without the flexibility or rotation offered by a swivel joint, elbow fittings can be used. They provide a fixed solution for altering the flow direction without worrying about any movement in the connected parts.

Ball and Socket Joints

In certain applications where freedom of movement is more crucial than fluid transmission, ball and socket joints can be utilized. These joints allow for a greater range of motion, providing flexibility without the capability of transferring fluid or withstanding high pressure.

Note that while these alternatives can substitute for certain functions of a hydraulic swivel joint, their suitability largely depends on the specific requirements of the application. It’s also important to understand that these alternatives might not fully replicate all features of a hydraulic swivel joint and hence, a thorough evaluation of application needs is vital before making a choice.

What Are the Causes of Hydraulic Swivel Joints’ Failure?

Hydraulic swivel joints, like any mechanical component, can experience failure due to a variety of reasons. Here’s an expanded look at some common causes of hydraulic swivel joint failure:

Excessive Pressure: If the swivel joint is subjected to pressure that exceeds its designed working pressure, it can lead to system failure. The seals and other internal components may become damaged due to the overload, resulting in leakage or total malfunction of the joint.

Operating Temperature Extremes: Operating the swivel joint outside its specified temperature range can cause the seals and other components to degrade or fail. For instance, high temperatures may cause seals to harden, while low temperatures may lead to material brittleness. Both instances can result in leaks or joint failure.

Misalignment: Improper installation or misalignment of the swivel joint can lead to excessive stress on its components. This increased stress can deteriorate seals, bearings, or even the joint body, causing failure of the swivel joint over time.

Contamination: Hydraulic fluids can sometimes carry contaminants, either in the form of debris, water, or chemicals. These contaminants can cause abrasion or corrosion of the internal components of the swivel joint, leading to premature wear and failure.

Poor Maintenance: Lack of proper inspection, maintenance, and cleaning can accelerate the wear and tear of swivel joint components. Inadequate maintenance may also increase the risk of contamination and corrosion, reducing the overall service life and leading to joint failure.

Inappropriate Material Choices: Using a swivel joint made of materials that are not suitable for the application, in terms of chemical compatibility, pressure, or temperature, can result in the joint’s deterioration or failure. Always ensure that the materials used in the swivel joint are compatible with the application requirements and environmental conditions.

Manufacturing Defects: While not common, manufacturing defects such as machining flaws, improper assembly, or poor material quality can contribute to premature swivel joint failure. It is essential to source swivel joints from reliable manufacturers with stringent quality control measures in place.

Understanding these potential causes of failure helps in choosing the right swivel joint for an application, ensuring correct installation procedures, and implementing proper maintenance practices, which significantly reduces the chances of failure and improves the operational life of the swivel joint.

Maintenance and Cleaning of Hydraulic Swivel Joints

Routine maintenance and cleaning are crucial for the longevity and optimal functioning of hydraulic swivel joints. Here’s an expanded overview of how to maintain and clean these important components:

Regular Inspections: Regularly inspecting the hydraulic swivel joints is the first step toward efficient maintenance. Check for any signs of wear, visible damages, or leakage that can indicate potential issues. Make sure the joint is operating within its specified ranges—pressure, temperature, and rotational speed.

Seal Maintenance: The seals in a hydraulic swivel joint are vulnerable to wear and tear over time. Regularly inspect the condition of these seals and replace them if any sign of wear out or damage is evident. Always use replacement seals recommended by the manufacturer to ensure compatibility and proper functioning.

Preventing Contamination: Always operate the hydraulic system with clean hydraulic fluid that’s free from debris or pollutants. Contaminated fluid can degrade the internal components of the swivel joint. Periodically changing the hydraulic fluid according to the manufacturer’s guidelines is a good practice to limit contamination.

Lubrication: Periodic lubrication is crucial for the smooth operation of swivel joints. Lubricating the joint reduces the friction between its moving parts, minimizing wear and tear that may occur over time. It is necessary to follow the manufacturer’s guidelines for lubrication frequencies and lubricant type to avoid any adverse effects.

Cleaning: Regularly clean the outer surface of the hydraulic swivel joint to remove any built-up dust, debris, or grime. Make sure to follow the manufacturer’s recommendations, ensuring that you don’t damage any critical parts while cleaning.

System Alignment: Regularly inspect the system alignment to reduce undue stress on the swivel joint. Any misalignment detected should be promptly corrected to prevent premature wear or joint failure.

Routine Joint Replacement: Over time, even with meticulous maintenance, hydraulic swivel joints may wear out simply due to continuous operation. Depending on the operational intensity, it might be useful to replace the swivel joints after a set period per your preventive maintenance program.

Implementing these measures can considerably extend the life expectancy of hydraulic swivel joints and enhance the reliability and productivity of the systems they serve. However, remember that the manufacturer’s guidelines should always be consulted and strictly followed for maintenance procedures and frequencies.

Conclusion

Hydraulic swivel joints play a critical role in various types of machinery and equipment by facilitating fluid transmission while allowing for rotational movement. However, selecting the right hydraulic swivel joint requires careful consideration of characteristics like working pressure, temperature range, and joint size.

While there exist alternatives to hydraulic swivel joints, such as rotary unions, flexible hoses, and ball and socket joints, their suitability depends greatly on the specific application and operational requirements. Hence, make informed decisions considering the specific industrial necessities and environmental conditions.

Understanding and addressing common causes of hydraulic swivel joint failures such as excessive pressure, temperature extremes, misalignment, contamination, poor maintenance, inappropriate material choices, and manufacturing defects can help prevent premature failure and system downtime.

Finally, maintaining the longevity and efficiency of these components depends heavily on routine maintenance practices. Regular inspections, seal maintenance, contamination prevention, lubrication, cleaning, system alignment checks, and preventive joint replacements are significant factors in ensuring the swivel joints’ optimal functioning and extended service life.

Ultimately, a considerable understanding of these points leads to better choices, operational safety, increased system efficiency, and significant savings in terms of time and money in the long run.

Frequently Asked Questions About Hydraulic Swivel Joints

Q: What is the lifespan of a hydraulic swivel joint?

A: The lifespan varies depending on the usage, environmental conditions, cleaning, and maintenance practices. Regular maintenance and use within specified guidelines can ensure long-lasting performance.

Q: Can I use any hydraulic fluid with my swivel joint?

A: No. The type of hydraulic fluid used depends on the material of the joint. Please read the manufacturer’s guidelines or seek professional advice to ensure compatibility.

Q: What should I do if my swivel joint leaks?

A: Initially, try tightening the joint. If the leak persists, you may need to replace the seals or the entire joint. Always consult with a professional if uncertain.

Q: Can the hydraulic swivel joint handle high temperatures?

A: A majority of joints can handle substantial temperatures. However, always check the manufacturer’s rating to avoid surpassing the recommended temperature, which could result in a failure.