In this in-depth guide, we’ll explore everything about industrial bus slip rings – from their fundamental principles and varieties to their maintenance and future technological advancements. We aim to create a more comprehensive understanding for better decision-making when selecting and using these components.

Introduction to Industrial Bus Slip Rings

An industrial bus slip ring is a critical device designed to enable the unobstructed transmission of power and electrical signals from a stationary structure to a rotating part. In essence, this sophisticated device is designed to endure rotational torques while preserving the consistent flow of power or signals, thus overcoming the constraints of a standard physical connection.

Going a step further, the concept of the industrial bus slip ring is based on the principle of electromechanical connection. This implements a “slip” mechanism to facilitate the flow of power or signals onto a perpetually rotating interface, hence the name ‘slip ring’.

The application of industrial bus slip rings is extensive, owing to their fundamental function of enabling rotation without compromising the integrity or continuity of the power or signal transmission. They are a cornerstone in many industrial settings, ranging from wind power generation, where the turbine blades constantly rotate, to medical scanning devices with rotating components, and various types of rotating platforms used in imaging industries.

Moreover, industrial bus slip rings play an indispensable role in maximizing productivity and promoting automation. They reduce the risk of broken connections and wear and tear associated with moving parts, thereby enhancing the overall reliability and efficiency of a wide array of industrial mechanisms.

In the face of growing industrialization and the ever-increasing demand for interactive and automated machinery, the industrial bus slip ring stands as a critical component, reliably bridging the gap between stationary controls and moving parts to ensure smooth and uninterrupted operations.

Working Principle of Industrial Bus Slip Ring

At the heart of any industrial bus slip ring lies a simple yet ingenious working principle. Designed for continuous rotation, a bus slip ring provides an electrically conductive bridge for power or signal transmission between stationary and rotating components. This functioning principle closely relates to the construction of the slip ring, which typically comprises a rotating ring and stationary brushes.

Starting on a detailed level, the rotating part of a slip ring is connected to the rotating structure, like the rotor of a motor or wind turbine, whereas the stationary part (the brush) attaches to the non-moving structure. The brush maintains an uninterrupted electrical connection with the rotating ring throughout its entire revolving movement.

The working principle shines in practice by successfully bypassing the usual twisting of wires that are directly attached to a rotating component, a situation that typically leads to wire breakages, signal disruption, or transmission losses. Instead, the bus slip ring allows for seamless and uninterrupted transmission of power or signals during rotation.

In terms of signal transmission, diverse forms of signals such as analog, digital, high-frequency, and even Ethernet or USB signals can be transmitted by specialized industrial bus slip rings. This highlights the flexibility and adaptability of bus slip rings in matching various industrial needs.

In a nutshell, the fundamental working principle of an industrial bus slip ring lies in the ‘slip’ mechanism. This mechanism allows for the transmission of power or signals consistently and efficiently across rotating parts. This process eliminates the operational concerns of disconnection or wear and tear that might arise from continuous rotation, thereby facilitating the seamless operation of myriad industrial machines and technologically advanced systems.

Types of Industrial Bus Slip Rings

Just as the needs of industries are diverse, so too are the types of industrial bus slip rings. Their designs and structures vary to suit different applications, ensuring their utility across a wide range of industrial platforms. Each type possesses specific functionalities, strengths, and potential weaknesses, making a thorough understanding of these types essential to optimal application.

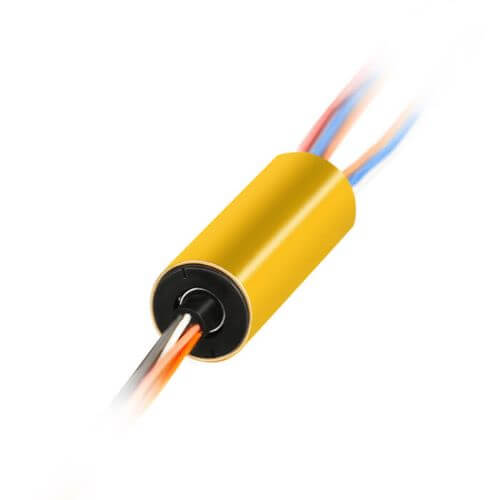

Capsule Slip Rings

Capsule slip rings are compact equipment ideally suited for data and signal transmission in confined spaces. They are typically designed with a small form factor, hence, the name “capsule”. These are commonly used for CCTV, robotics, and medical equipment where space is a constraint.

Despite their compact size, capsule slip rings can have multiple circuits for complex signal transmission. On the downside, they might face limitations concerning high current transmission due to size restrictions.

Through Bore Slip Rings

A through bore or hollow shaft slip ring is designed with a hole in the center. This design allows for the passage of additional equipment such as a shaft or cable through the center of the ring, saving space and increasing utility.

These slip rings are primarily used for heavy machinery, wind turbines, and rotary tables. The major strength of these slip rings is their ability to handle a blend of complex signals and high-current power transmission. However, they may not be suitable for applications where space conservation is paramount due to their larger size.

Pancake Slip Rings

Pancake slip rings follow a flat design as opposed to cylindrical designs found in most other slip ring types. They are ideal for installations with height restrictions but can accommodate larger diameters.

These slip rings are ideal for equipment with restrictive height constraints but allow for larger diameters. However, due to the design constraints, they usually have less number of circuits and could have higher mechanical wear and tear compared to other types.

Ethernet Slip Rings

As industries move towards digitization and IoT integration, ethernet slip rings secure their position as an essential component in modern industrial machinery. They are designed to provide stable, high-speed data transmission and support protocols such as Ethernet, Profibus, and Profinet.

With this advancement, data transmission efficiency and volume are substantially improved, paving the way for more accurate and real-time control and monitoring of industrial processes. However, these may require more specialist installation and maintenance due to their higher complexity.

In summary, the various types of industrial bus slip rings with their respective functionalities and strengths allow for vast applications in different industries. Understandably, each type comes with its own set of challenges, but the selection of the appropriate type according to the specific operational needs can eliminate potential limitations and optimize productivity.

Key Features of Industrial Bus Slip Rings

Understanding the key features of industrial bus slip rings is crucial in assessing their suitability for diverse applications. These features, ranging from rotation speed to supported signal types, are fundamental to a slip ring’s capacity to meet industrial requirements. Here are the main attributes to consider:

Rotation Speed

A critical parameter of a slip ring is its rotation speed, typically measured in RPM (revolutions per minute). High-speed slip rings are designed to maintain electrical contact stability even at high rotational speeds, a feature especially crucial in applications like wind turbines and motors. Conversely, other functions might require lower speeds. Therefore, the rotation speed requirement is primarily dictated by the specific industrial application.

Supported Signal Types

A versatile slip ring can accommodate various kinds of signals. The diversity ranges from analog and digital to high-frequency and ethernet signals. This flexibility in signal handling makes industrial bus slip rings suitable for applications that require data transmission, such as surveillance systems, robotics, or medical equipment.

Operating Temperature

Since slip rings are often integral parts of complex machines, they must be resilient and continue to function effectively under varying environmental conditions, including a wide range of operating temperatures. Some slip rings can endure extreme cold or heat, making them ideal for use in harsh climates or high-temperature industrial environments.

Life Expectancy

Another critical feature of a bus slip ring is its wear life or life expectancy. In essence, this parameter represents the slip ring’s durability and how long it can operate effectively without needing a replacement. A high wear life signifies fewer maintenance breaks and, therefore, higher productivity for businesses.

Insulation Resistance

Insulation resistance denotes the slip ring’s electrical safety and reliability by preventing stray currents from seeping into the device. An industrial-grade slip ring will boast high insulation resistance, ensuring safe and reliable operation even in demanding industrial settings.

Size and Design

The size and design of the slip ring are also crucial features. Specific applications may demand small, compact designs, while others could use larger models. The flexibility in size and design accommodates diverse industrial needs, ensuring that different applications can find a tailored fit.

In essence, these key features reflect the industrial bus slip ring’s adaptability to different industrial settings. Recognizing these characteristics and how they play into specific applications is essential to making an informed slip ring selection that optimizes operational efficiency.

Industrial Applications of Bus Slip Rings

The versatility of industrial bus slip rings facilitates their usage across a broad range of sectors. From power generation to medical equipment, these components have become indispensable in numerous industries, supporting various applications and improving efficiencies. Here are a few notable sectors:

Wind Power Generation

In this sector, bus slip rings are installed in the nacelle of wind turbines. They transmit the power and signals generated by the revolving blades to the stationary part of the turbine. This application allows for continuous power production even as the turbine freely rotates to align with the wind direction. Consequently, the slip rings enhance the efficiency and longevity of wind power operations.

Medical Devices

In sophisticated medical scanning devices, like CT scanners (Computed Tomography) and MRI (Magnetic Resonance Imaging) machines, slip rings are critical. These devices require the scanning apparatus to rotate smoothly around the patient while simultaneously transmitting high-quality data and images from the rotating scanner to the stationary computer system. Industrial bus slip rings facilitate this exchange, ensuring uninterrupted, real-time imaging.

Manufacturing Industry

In automation-dominated settings like automotive assembly lines, slip rings facilitate the rotation of robotic arms, conveyor belts, and turntables. They ensure smooth power transmission and communication signals in precise manufacturing processes. This reliable functionality boosts productivity and reduces downtime associated with regular cable replacements.

Defense Sector

Military devices, such as remotely operated vehicles (drones, submersibles) and radar antenna systems, are another domain where bus slip rings are put to use. They help in transmitting data and power signals during the sensors and system’s continuous rotation. They function to maintain reliable communication and real-time monitoring.

Communication Technology

Bus Slip rings find their usage in satellite communication systems as well. In satellite dishes, these components allow the antenna to rotate in multiple axes, contributing to the efficient tracking of satellites. They provide consistent signal transmission, enabling uninterrupted communication irrespective of the antenna movement.

Overall, the industrial applications of bus slip rings are expansive and vital. They play a pivotal role in numerous sectors, ensuring smooth, uninterrupted power, and signal transmission through rotating components. This adaptability and utility highlight the universal importance of bus slip rings in modern industries.

Installation and Maintenance of Industrial Bus Slip Ring

The performance and lifespan of an industrial bus slip ring significantly depend on proper installation and regular maintenance. Here is a straightforward guide to ensure correct installation and suggested maintenance practices:

Installation

- Understand the slip ring specifications: Before installation, familiarize yourself with the specifications, installation instructions, and any provided diagrams. This includes details such as operating temperature, voltage, current, etc.

- Prepare the mounting surface: The surface on which the slip ring will be mounted should be flat and clean to ensure a secure connection.

- Wire Connection: Connect the wires as per the instructions. Mismatches in wiring can not only degrade performance but might also damage the slip ring. Ensure that the wires’ orientation does not interfere with the rotation.

- Secure the slip ring: Once connected, the slip ring needs to be physically secured. Slip rings normally come with a flange or bracket to secure them to the mounting surface.

- Test the operation: Turn on the power and check the operation of the slip ring at a lower speed initially. Monitor the current and the voltage to ensure everything is operating as per the specifications.

Maintenance and Troubleshooting

While industrial bus slip rings are designed for long life and high reliability, routine maintenance can still extend their lifespan and performance. Here are some suggestions for regular maintenance and troubleshooting:

- Routine Inspection: Regularly inspect the slip ring for any visual signs of wear, such as debris around the brush or any changes in the connecting wires. If the inspection reveals any dust or debris, clean it carefully to avoid any obstruction in the rotation.

- Electrical Measurement: Periodically measure parameters like the voltage drop across the ring and brush and insulation resistance. Any significant or sudden change can serve as an early warning sign of potential issues.

- Temperature Monitoring: The slip ring’s temperature should be monitored. An increase in temperature can indicate a high current draw or possibly friction issues.

- Lubrication: If the slip ring design includes bearings, these should be lubricated as recommended by the manufacturer.

- Replacement of Brushes: Depending on usage, the brushes may need replacement after a certain period. The manufacturer’s guidelines should be referred to for specifics.

Maintaining a proactive approach toward the installation and maintenance of industrial bus slip rings can significantly enhance their lifespan and reliability. It can prevent sudden failures and contribute to improved efficiency and productivity for various industrial applications.

Choosing the Right Industrial Bus Slip Ring

Selecting the right industrial bus slip ring may seem challenging due to its wide variety and technical characteristics. However, a structured approach focused on several key factors can simplify the process, ensuring that the chosen slip ring is the best fit for the industrial requirements. Here are those factors:

Power and Signal Needs

When evaluating a slip ring, the first considerations should be power and signal transmission needs. Identify the type and number of signals that will be transferred (digital, analog, Ethernet, etc.), and count the power lines required, including their current ratings. The chosen slip ring should not only accommodate these needs but also provide some room for potential future expansion.

Size and Mechanical Constraints

Understanding mechanical constraints, such as available space, installation method, and desired rotation speed, is vital. Depending on these requirements, the slip ring could be a high-speed model, a miniature version, or a hollow shaft design for routing other components through its center.

Operational Environment

The operating environment often dictates the slip ring’s specifications. If the slip ring will be operating in harsh conditions, such as extreme temperatures, dust, or high humidity, the selected slip ring needs to be robust and capable of withstanding these conditions. For instance, certain slip rings are specifically designed to function efficiently in high-vibration environments or places with significant dust and debris.

Service Life and Maintenance

A longer service life and minimal maintenance requirements are always desirable in an industrial setting. Ascertain the chosen slip ring’s typical life expectancy and understand its maintenance requirements. In applications where service interruptions should be minimized, slip rings with high wear life and low maintenance requirements should be considered.

Financial Considerations

Lastly, consider the total cost of ownership, which includes the slip ring’s purchase price, installation cost, and running maintenance costs. It’s crucial to strike a balance between the cost and the required performance and durability of the slip ring.

To match these factors with various industrial requirements, it is important to thoroughly understand the operating conditions and requirements of the machinery where the slip ring will be applied. If necessary, seek assistance from the slip ring manufacturer or a qualified engineer.

Making an informed choice in selecting an industrial bus slip ring can significantly enhance the efficiency and productivity of the associated machinery. This process ultimately leads to improved overall operational effectiveness, reduced unplanned downtime, and potential cost savings in long-term maintenance and replacement.

Future Trends and Developments in Bus Slip Ring Technology

Modern technological trends aim to upgrade bus slip ring technology both in terms of resilience and operational diversity. Constant progression in materials and product manufacturing technology has allowed this essential industrial component to keep pace with changing needs and expectations. Here’s a closer look at recent advancements and potential future trends in bus slip ring technology:

Recent Advancements

Modern bus slip rings have seen significant improvements in their design and manufacturing techniques:

- Fiber Optic Slip Rings (FORJ): In the age of high-speed communication, Fiber Optic Rotary Joints (FORJ) offer a significant improvement. These advanced slip rings allow uninterrupted transmission of optical signals over a rotating interface, offering the benefit of a high data rate and negligible loss of signals.

- Improved Materials: Advancements in materials science, such as improved brush materials or coating technologies, have boosted slip rings’ performance and longevity. For instance, precious metals like gold are used for contacts, ensuring better signal quality and reducing the required maintenance.

- Soft Capsule Design: Modern slip rings often incorporate a soft-capsule design, which encloses each circuit to mitigate signal interference. This design helps in maintaining a steady performance and ensuring the long-term reliability of the slip ring.

Potential Future Trends

As industries continue to evolve, bus slip ring technology is poised to follow suit with several notable trends on the horizon:

- Miniaturization and Integration: As devices and equipment continue to shrink in size, the demand for smaller, integrated slip rings will increase. Miniaturized slip rings that do not compromise on functional diversity will likely become more prevalent.

- Smart Monitoring: With the rise of Industry 4.0, predictive maintenance and smart monitoring are becoming prevalent. Future slip rings might incorporate sensors and intelligence to monitor their health and predict failures, effectively reducing maintenance requirements and increasing operational efficiency.

- Greater Resilience: Future slip rings are expected to possess even higher durability to withstand harsher environments, such as extreme temperatures, heavy vibrations, or corrosive environments, making them suitable for a broader range of applications.

In conclusion, the future trajectory of bus slip ring technology seems set to make it an even more critical component in numerous industries. By keeping an eye on these trends and advancements, businesses can take full advantage of this essential technology, ensuring their operations remain agile and efficient in an ever-evolving industrial landscape.

Conclusion

As the world becomes more interconnected, industrial bus slip rings continue to play a pivotal role in various technologies. Understanding their fundamentals, functionalities and future trends can empower businesses to make more informed decisions, ultimately leading to enhanced productivity and performance.

FAQs About Industrial Bus Slip Rings

Bus slip rings are a vital part of many industrial operations, but their technical nature can raise several questions. Here are answers to some frequently asked questions about industrial bus slip rings:

Q: What is an industrial bus slip ring?

A: An industrial bus slip ring is an electromechanical device that allows the transmission of power and electrical signals from a stationary to a rotating structure. It can handle various signal and power types, making it a crucial component in many industrial applications, such as wind turbines or manufacturing robots.

Q: How does a bus slip ring work?

A: A bus slip ring works by maintaining electrical connections between stationary and rotating parts. The stationary part (stator) has brush contacts connected to an external power source. The rotating part (rotor) has conductive rings, which the brushes slide over, allowing continuous power and signal transmission as the part rotates.

Q: Why are bus slip rings necessary?

A: In many applications, traditional wiring is inadequate or inefficient due to the need for free rotation. Bus slip rings provide a solution to this by providing a constant electrical connection, enabling unrestricted rotation in equipment like wind turbines, CT scanners, or robotic assembly arms.

Q: How do I choose the right slip ring for my application?

A: Choosing a slip ring depends on factors like power and signal needs, size and mechanical constraints, operating environment, expected service life, and budget. Understanding these aspects thoroughly enables the selection of the slip ring that can best meet your requirements.

Q: What are the common maintenance needs for slip rings?

A: Routine inspection, electrical measurement, temperature monitoring, lubrication (for designs with bearings), and periodic brush replacement are standard maintenance practices for a slip ring. Regular maintenance helps to extend the lifespan of the device and reduces unexpected failures.

See What We Can Do