There are various things to review before you install a through-hole slip ring. Each slip ring comes with unique specifications integrated to meet the equipment and operating environment requirements. As such, it is essential to compare existing offers carefully and identify models that suit your purpose. Are you looking for a through-hole slip ring installation? In this article, we cover the basic specifications that distinguish slip rings from other rotary joins, step-by-step installation for standard models as well as tips for installation and usage.

What are Slip Rings?

A slip ring is an electromechanical device whose design is designed to facilitate the transmission of signals from stationary components to rotating components. Slip rings are standard in electric motors, wind turbines, smart toys and video cameras, and military, mining, and monitoring equipment, among others. They are applicable in any device that requires the conductivity of power and data signals from fixed to rotating parts. Also known as electric rotary joints, slip rings work in specific equipment and feature properties optimized for the unique operating environment. There are also many types of slip rings, including through-hole, pancake and capsule, USB, FORJ, PCB, and miniature models.

What is a Through-hole Slip Ring?

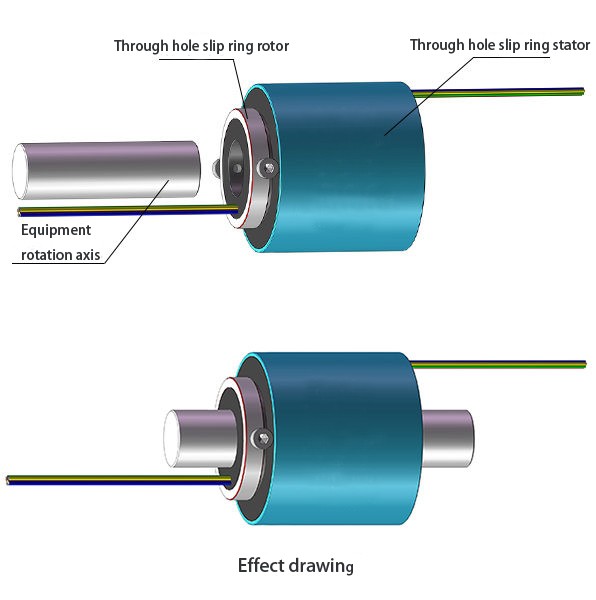

As the name suggests, a through-hole slip ring features a hollow space at the center of the design. They are also referred to as through bore slip rings. The space provides room for the channel wires and circuits. It connects the rotor (rotating component) to the stator (fixed part), allowing the center shaft to make infinite 360° rotations. However, not all modes can achieve 360° rotations, so it is essential to verify this before placing an order. All slip rings are application-specific, so you will find various customized models of through-hole slip rings. The features you choose will depend on your equipment (military, mining, turbines, smart toys) and operating environment (moisture and humidity, temperature, height, blast, outdoors).

Installing a Through-hole Slip Ring

The slip ring manufacturer will provide an installation guide for their model, so you should always follow the user manual for proper installation. Since through-hole slip rings can be installed in a wide variety of devices and used in different applications, there is no standard installation process. A standard through-hole slip ring features brushes, metal rings, housing, and other structures integrated into the design.

Most through-hole slip rings support up to 300 circuits with a 20A current capacity and 600VAC/VDC voltage. However, these specifications will vary depending on the application and equipment where the device is installed. Some through-hole slip ring models have dedicated shaft positions and installation spots for the mounting and installation supports. You can also ask the manufacturer to include dedicated locations for effortless installation. Technically, standard slip ring installation is accomplished in two ways as follows:

1. Installing on the Channel (Hole)

The first installation method involves fixing the through-bore slip ring on the channel or hole provided in the device. Here are the steps required to achieve this:

- Remove all dirt and moisture from the shaft to make sure it is clean and ready for installation

- Position the slip ring in the exact position you want to fix it on the shaft

- Adjust the slip ring accordingly and tighten it on the shaft using the four installation screws provided

- Make sure the slip ring is tightly fitted on the shaft before routing the cables and slip ring connections

- All wires should be in their proper position to prevent tangling or straining the connectors when the shaft is rotating

2. Installing on the Outer Flange

Some through-hole slip ring models require installing the device on the outer flange part. Here are the steps needed to achieve this installation process:

- Align the slip ring with the flange mounting hole and mounting base

- Install the flat washers and attach the slip ring by tightening all screws provided

- Route the wires and connections as shown in the user installation manual

Slip rings are designed for application in specific devices and operating environments. Some models will require fixing the rotary part for both the inner and outer rings. Others have a bore rotor that uses both fixed and rotating stators. As such, the installation will depend on your unique requirements.

Using a Through-hole Slip Ring

As application-specific electromechanical devices, most slip rings will come customized to the unique requirements specified when placing an order. You should include all the necessary specifications, so the manufacturer can create a precise design for your application. For instance, if the installation is outdoors, in blast areas, or exposed to high temperatures, the slip ring will require weatherproofing and insulation properties. Here are some insights for using a through-hole slip ring:

1. Make the Installation Clean

Once you have the exact through-hole slip ring you need for your application, make sure the installation process is clean and leaves no dirt, moisture, or particles. Slip rings are sensitive to weight and pulling, so you should ensure a safe distance between parts and adequate support for the housing. Make sure the finished installation is clean and all connectors are in their right position. The best conditions for through bore slip ring operation is low humidity with a temperature below 80° C.

2. Inspect the Installation for Wobbling and Looseness

You should inspect the slip ring frequently to ensure the screws and housing are tightly fitted. The installation will become loose over time, and when this happens, you should tighten them to prevent wobbling. Check the metal housing, screws, and other structural additions to ensure the installation is sturdy. It is also important to remove any extra weight from the slip ring, considering they are lightweight and very delicate.

3. Replace Parts When Necessary

Your slip ring will eventually get old and require replacement. As such, you should note down the projected lifespan and inspect your slip rings as recommended by the manufacturer. Maintenance and inspection can squeeze more life out of an electromechanical device. Nonetheless, friction, resistance, and general wear will take a toll on the graphite brushes and contact surfaces. You can replace worn-out parts to continue using the device.

Conclusion

Through-hole slip ring installation requires technical skill and experience, so it is best left to professionals. The priority should be to find the precise specifications for your slip ring, based on its application and equipment. Make sure you contact trustworthy vendors and installation technicians that can guarantee high-quality products and services.

See What We Can Do