In the fast-evolving world of medical technology, precision and reliability are non-negotiable, as even the slightest error can compromise patient safety and diagnostic accuracy. Medical devices, from advanced imaging systems like CT and MRI scanners to robotic surgical arms, rely on seamless power and signal transmission to function effectively. This is where slip rings play a pivotal role, ensuring uninterrupted rotation and data transfer in critical applications. At Grand Slip Rings, we pride ourselves on being a leading manufacturer of high-performance slip rings and rotary joints, with a specialized focus on medical-grade solutions designed to meet the stringent demands of the healthcare industry. Our IP22-rated micro slip rings are engineered to deliver exceptional performance in compact, space-constrained environments, offering dust and water resistance to ensure durability in controlled medical settings. These micro slip rings are not only ultra-compact but also designed to minimize electrical noise, making them ideal for sensitive medical equipment. By addressing the critical needs of modern medical devices—such as reliability, precision, and compliance with sterilization standards—Grand Slip Rings empowers healthcare providers to deliver safer, more efficient patient care. Whether it’s enabling continuous rotation in imaging systems or ensuring precise signal transmission in robotic surgery, our IP22 micro slip rings are at the heart of innovation in medical technology.

What is a Medical IP22 Micro Slip Ring?

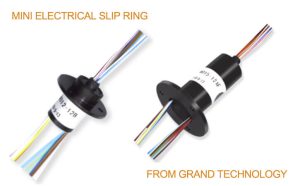

A Medical IP22 Micro Slip Ring is a specialized electrical component used in medical equipment to provide a continuous transfer of electrical power and signals between stationary and rotating parts. Slip rings are essential in rotating systems, enabling uninterrupted signal transmission for applications like medical imaging, robotic surgery, and diagnostic tools.

Definition of Slip Rings

Slip rings, also known as rotary electrical connectors, are electromechanical devices that facilitate the transfer of electrical signals and power between stationary and rotating parts. They are commonly used in rotating equipment like MRI machines, CT scanners, and robotic surgical instruments. Slip rings consist of a series of conductive rings and brushes that maintain contact as the assembly rotates, providing a seamless electrical connection.

These devices are critical in systems requiring continuous rotation and power transmission, where traditional wire connections would fail. They ensure smooth operation without the wear or risk of disconnecting that would otherwise occur in rotating systems.

IP22 Rating and Its Importance in Medical Environments

The IP22 rating is part of the Ingress Protection (IP) classification system, which is used to define how well an electrical device is protected against solids and liquids. This rating is particularly important in medical environments, where equipment must be safeguarded from dust and water to ensure reliability, patient safety, and long-term operation.

The IP rating consists of two digits. The first digit represents the level of protection against solid objects, while the second digit represents protection against liquids.

- First Digit (Protection against solid objects):

- For an IP22-rated device, the first digit is 2, which means the device is protected against solid objects larger than 12.5 mm (e.g., fingers, tools, or wires). This ensures that the device can withstand accidental contact or exposure to small items, preventing internal components from being damaged by foreign objects.

- Second Digit (Protection against liquids):

- The second digit for IP22 is 2, which means the device is protected against vertically falling water drops when the device is tilted up to 15 degrees. This level of water resistance helps to prevent minor water exposure, such as drips or splashes, which could otherwise affect the device’s performance or cause electrical short circuits.

Why IP22 is Crucial in Medical Environments

Protection from Dust:

- Medical environments, especially those in operating rooms, diagnostic areas, and laboratories, are often highly controlled to minimize contamination. While IP22 doesn’t offer full dust protection, the level 2 rating ensures that larger dust particles (greater than 12.5 mm) are blocked from entering the device, thus reducing the chances of equipment malfunction. Dust or other solid contaminants can cause wear or failure of internal components if not properly managed.

- While higher protection (like IP54 or IP65) is ideal for heavy dust exposure, IP22 provides an adequate level of dust protection for many medical applications where dust is not excessive, but cleanliness is still critical.

Protection from Water Exposure:

- In medical settings, equipment is often exposed to various levels of water or liquids, whether from accidental spills, cleaning procedures, or splashes. The IP22 rating ensures that the device can withstand small amounts of liquid, such as water droplets falling vertically. This is crucial in environments where equipment is often sterilized or cleaned, like MRI machines, surgical robots, or diagnostic tools.

- Although IP22 does not offer complete waterproofing, it is designed to withstand minor water exposure that may occur during everyday medical operations. This protection is especially valuable in areas where equipment might be subjected to cleaning or exposure to fluids in a controlled manner, preventing damage or electrical hazards.

Reliability and Safety in Medical Devices:

- Medical devices must meet stringent safety standards to protect both patients and healthcare professionals. Even small amounts of moisture or dust entering sensitive equipment can lead to electrical failures or malfunction, potentially leading to inaccurate readings, system shutdowns, or safety hazards. The IP22 rating ensures that devices can operate safely and reliably in such environments.

- Devices with IP22 protection are typically used in non-invasive procedures or applications where the equipment is not directly exposed to heavy liquid exposure, but where basic resistance to dust and water is necessary to maintain consistent performance.

Medical Equipment Vulnerability:

- Medical equipment like robotic surgery instruments, imaging devices (MRI/CT scans), patient monitoring systems, and infusion pumps all require high levels of reliability. These systems often operate continuously or in highly sensitive environments. Any disruption due to contaminants, such as dust or liquid entering the device, can cause system failures, potentially compromising patient care.

- IP22 is designed to mitigate this risk in applications where exposure to dust and light moisture is minimal but still present, making it ideal for use in most medical environments where strict hygiene and sterilization protocols are followed but direct exposure to large amounts of water is not common.

In a medical environment, where safety, accuracy, and equipment reliability are paramount, the IP22 rating plays a critical role in protecting devices from potential contamination by dust and water. While it may not offer the highest level of protection, it strikes an ideal balance for most medical equipment, ensuring operational integrity and safety in environments where exposure to contaminants is controlled but still present. The IP22-rated Medical Miniature Slip Rings, for example, are crucial in ensuring uninterrupted performance while minimizing the risk of damage from minor environmental factors in medical settings.

Key Features of Medical IP22 Micro Slip Rings

Ultra-Compact Size: Medical devices, especially those used in surgery and diagnostics, often operate in confined spaces where size is a crucial factor. The Medical IP22 Micro Slip Rings are designed to be ultra-compact, with diameters often less than 10mm. This small size allows them to fit seamlessly into small-scale medical systems like robotic arms, endoscopic equipment, or any device where space constraints are significant. Their compact design ensures that they don’t take up unnecessary space, helping manufacturers optimize the design and functionality of their devices.

Medical Compliance: Medical equipment must meet rigorous safety and performance standards, especially in terms of sterilization and cleanliness. Medical IP22 Micro Slip Rings comply with ISO 13485, an international standard for medical device quality management systems. This means that these slip rings are manufactured under strict quality controls, ensuring they meet the safety and reliability requirements necessary for medical applications.

Additionally, these slip rings are made from materials that can be sterilized using various methods such as autoclaving, ensuring they can be used in medical environments where contamination risks must be minimized.

Low Electrical Noise: One of the critical features of Medical IP22 Micro Slip Rings is their ability to minimize electrical noise. Medical imaging systems, sensors, and diagnostic tools rely on precise data transmission, where even the smallest electrical interference can lead to inaccurate results. These slip rings are designed to reduce electrical noise through the use of high-quality materials and advanced engineering techniques, ensuring clean and stable signal transmission for sensitive medical equipment.

This feature is essential for imaging devices like MRI machines and ultrasound systems, where signal integrity directly impacts image quality and diagnostic accuracy.

Grand Slip Rings’ Competitive Edge

Grand Slip Rings stands out in the market by offering distinct advantages in terms of size, price, and customization:

Size: Grand Slip Rings are known for their exceptionally small sizes, with diameters as small as 5.9 mm. This ultra-compact form factor allows integration into extremely confined spaces, where other slip rings may not be feasible. Whether it’s a surgical robot or diagnostic equipment, Grand Slip Rings offer flexible solutions for diverse medical applications.

Price: Despite offering high-quality, precise engineering, Grand Slip Rings maintain competitive pricing. This ensures that customers receive reliable, high-performance products at an affordable cost, making them an attractive choice for medical device manufacturers who need to keep their expenses within budget without sacrificing quality.

Customization: Grand Slip Rings offer tailored solutions for specific medical applications. Customers can request custom designs based on unique size, material, and performance requirements, ensuring a perfect fit for their devices. Whether the need is for a specific number of circuits, high power transmission, or low-noise applications, Grand Slip Rings can deliver bespoke solutions that meet the diverse demands of the medical industry.

The Medical IP22 Micro Slip Ring plays a vital role in ensuring reliable electrical transmission in medical equipment, offering compactness, medical compliance, and reduced electrical noise. With Grand Slip Rings, users can expect competitive advantages in size, cost, and customization, making them a preferred choice for manufacturers of medical equipment. The combination of ultra-compact design, regulatory compliance, and low-noise technology ensures these slip rings contribute significantly to the performance and safety of medical devices used in critical applications.

Applications in Medical Devices

The use of IP22 Medical Micro Slip Rings in medical devices plays a pivotal role in ensuring uninterrupted and precise operation in a variety of medical applications, ranging from diagnostic imaging to surgical robotics. Here’s a detailed breakdown of how these slip rings are applied in key medical devices:

CT/MRI Scanners: Enable Continuous Rotation for Imaging

CT (Computed Tomography) and MRI (Magnetic Resonance Imaging) scanners are essential diagnostic tools used in healthcare settings to provide detailed images of the body’s internal structures. These devices require the continuous rotation of the scanner’s imaging components to acquire high-resolution images from different angles. This is where IP22 Medical Micro Slip Rings play a vital role.

Continuous Rotation:

- CT and MRI scanners rely on rotating gantries to capture cross-sectional images of the body. Slip rings provide the necessary electrical connections between the rotating gantry and the stationary electronics, allowing for continuous rotation without interrupting the transmission of power or signals. These slip rings ensure that the gantry’s motor, detectors, and imaging systems receive constant power and data transmission during their rotation, maintaining the accuracy and consistency of the imaging process.

Signal Transmission:

- As these systems rotate, they must transmit electrical signals for data processing. The IP22-rated micro slip rings are particularly useful in this application, providing reliable signal transmission while preventing dust and water from contaminating the sensitive internal components. Given the sterile environment required in medical imaging, maintaining uninterrupted power and signal flow is crucial for achieving high-quality diagnostic images.

Robotic Surgical Arms: Ensure Precise Signal Transmission in Minimally Invasive Procedures

Robotic surgical systems are transforming the landscape of modern surgery, offering minimally invasive procedures with enhanced precision and control. These systems rely on multiple components that must operate in perfect synchronization. Medical Micro Slip Rings ensure seamless power and signal transmission between stationary and rotating parts, making them integral to the success of these devices.

Minimally Invasive Surgery:

- Robotic surgical arms are designed to make small incisions and carry out delicate operations with precision. The ability to rotate and move these arms without interruption is crucial. Slip rings, specifically the IP22-rated versions, help maintain the rotation and signal transmission between the robotic arm and its control system, ensuring that commands are executed accurately. These components are designed to withstand the movement and operational stresses of robotic systems, ensuring the arm’s functionality during surgeries.

Signal Transmission and Power Supply:

- The robotic arms must transmit power to the motors and handle various sensors that allow for real-time feedback during procedures. The slip rings provide a reliable conduit for power and data, ensuring the arm can respond to input from the surgeon in real-time. The low electrical noise characteristic of the slip rings is critical in these applications, as it ensures that the signal transmitted to the surgical tools remains stable, which is crucial for performing precise movements and operations.

Adaptability:

- Medical robotic arms need to function in a variety of environments, from sterile operating rooms to high-precision labs. The adaptability of IP22 slip rings ensures that the systems remain operational even in the face of environmental factors such as dust and moisture, making them ideal for use in sterile medical settings.

Portable Diagnostic Tools: Support Compact, Battery-Operated Devices

Portable diagnostic tools, such as handheld ultrasound machines, portable ECG monitors, and mobile diagnostic units, require compact components that can deliver high performance despite limited space and battery constraints. In these devices, medical micro slip rings are used to ensure reliable power and data transmission in compact, mobile formats.

Compact and Efficient:

- Many portable medical devices need to operate efficiently without a direct connection to mains power, instead relying on batteries or other mobile energy sources. The slip rings in these devices must be compact and lightweight to fit into the limited space available in portable diagnostic equipment. The ultra-compact size of the IP22 Medical Micro Slip Rings (often less than 10mm in diameter) is ideal for integration into these small devices.

Uninterrupted Power and Data Flow:

- Even though these devices are portable, they still require constant power to drive sensors and transmit data for processing. Slip rings ensure that the power supply remains uninterrupted, even when the device is in motion or being adjusted during a diagnostic procedure. Whether for hand-held ultrasound imaging or battery-powered ECG units, these slip rings provide a stable connection that supports critical device functions.

Medical Compliance:

- Portable diagnostic tools are often used in field settings, including emergency situations and remote locations. The IP22 rating ensures that these slip rings protect against light dust and moisture exposure, making them reliable even when working in less controlled environments.

Case Study: Grand Slip Ring’s Aerospace/Military Slip Rings and Their Adaptation to Medical Reliability

Grand Slip Rings, known for their aerospace and military-grade slip rings, offer a wealth of experience in building reliable, high-performance connectors that can be adapted to the medical field. Aerospace and military applications require slip rings to perform under extreme conditions, including vibration, temperature variations, and exposure to electromagnetic interference.

- Aerospace and Military Lessons:

- The lessons learned from these high-demand sectors are directly applicable to the medical field. Grand’s aerospace slip rings, for example, are designed to provide high reliability in environments where failure is not an option—much like medical environments where patient safety depends on the continuous operation of life-critical equipment.

- Features such as low electrical noise, customized solutions, and high durability in aerospace slip rings have been adapted for use in medical applications where sensitive equipment like MRI machines and robotic surgical systems require the same level of performance.

- Military-Grade Reliability:

- Grand Slip Rings’ military products are designed to function in environments subject to vibrations, electromagnetic interference, and extreme temperature fluctuations. This experience is valuable in medical applications where devices may be subject to physical movement (e.g., robotic arms) or where precise and stable signal transmission is critical for patient safety.

- Adapting for Medical Use:

- The ability to customize these slip rings for specific applications—whether it’s ultra-compact designs for portable diagnostic tools or specialized configurations for high-precision surgical robots—ensures that Grand Slip Rings provide unmatched reliability and adaptability in the medical sector. Grand’s experience in building high-performance, durable slip rings for industries that require precision under extreme conditions ensures that their products can meet the demanding needs of the healthcare sector.

The use of Medical IP22 Micro Slip Rings is crucial across a wide range of medical applications, from diagnostic imaging systems like CT and MRI scanners to robotic surgery tools and portable diagnostic devices. The reliability and adaptability of these slip rings ensure that power and signal transmission remain uninterrupted, even in the most challenging medical environments. By drawing on lessons from aerospace and military applications, companies like Grand Slip Rings provide highly customizable, reliable, and efficient solutions for the medical industry, ensuring safety, precision, and performance in life-saving devices.

Technical Specifications & Customization of Medical IP22 Micro Slip Rings

Medical IP22 Micro Slip Rings are engineered to deliver reliable power and signal transmission for a range of medical devices. Their compact size, high customization potential, and adherence to stringent medical standards make them crucial components in modern healthcare equipment. Below are the key technical specifications and customization options available for these slip rings.

Size: Micro Slip Ring Dimensions (6–12mm Through-Bore)

The size of micro slip rings is a critical factor, especially in medical applications where space is often limited. The typical range of through-bore diameters for these micro slip rings is between 6mm and 12mm, with some designs offering even smaller dimensions. These compact sizes are ideal for integration into small medical devices, such as robotic surgical arms, imaging systems, and portable diagnostic tools.

- 6–12mm Through-Bore:

- These slip rings are designed to fit into devices with stringent space limitations, allowing engineers to create smaller, more efficient medical systems. The through-bore refers to the central hole of the slip ring, through which components like wiring or tubing can pass, making it an essential feature for compact designs.

- Smallest Designs:

- Some medical micro slip rings may even feature diameters as small as 5.9mm, offering extreme space savings without compromising on signal or power integrity. Their small form factor is especially beneficial for portable and hand-held diagnostic tools.

These small and compact designs allow medical equipment manufacturers to incorporate slip rings into devices that require minimal internal space while maintaining the necessary functionality for continuous operation.

Size: 34mm Outer Diameter Micro Slip Ring

A 34mm outer diameter micro slip ring is a compact and efficient solution for transferring power and data between rotating and stationary parts of a system. With its small size, this slip ring is specifically designed for applications where space is limited, but reliable performance is still essential. The 34mm outer diameter makes it ideal for use in medical devices, such as imaging equipment, monitoring systems, and robotic surgical tools, where maintaining a small footprint without compromising functionality is crucial.

Despite its compact design, the 34mm outer diameter micro slip ring is capable of handling high-speed rotations and continuous data transmission. It ensures uninterrupted signal and power transfer, even in systems that require frequent rotation, such as rotating cameras, sensors, and actuators. This makes it suitable for applications like CT scanners, MRI machines, and other precision medical equipment that need reliable performance in tight spaces.

Additionally, the small size of the 34mm micro slip ring allows it to be integrated into a variety of other advanced technologies, including drones, wearables, and compact robotics. The slip ring facilitates power transfer and ensures smooth operation while keeping the overall device lightweight and compact. The materials and construction used in these slip rings ensure durability, reliability, and minimal wear, even in high-rotation and high-demand environments.

Overall, the 34mm outer diameter micro slip ring is an essential component for modern devices that require continuous, high-quality power and data transmission in compact spaces. Its versatility, reliability, and space-saving design make it an excellent choice for a wide range of industries and applications.

Circuit Ratings: Voltage/Current Capacity

The circuit ratings of Medical IP22 Micro Slip Rings play a crucial role in determining their suitability for specific applications, particularly in medical equipment where precision and reliability are paramount. The voltage and current capacity must align with the requirements of the device’s electrical system to ensure optimal performance and safety.

Voltage Capacity:

- Medical IP22 Micro Slip Rings typically handle voltages ranging from 12V to 480V depending on the application. For medical equipment such as imaging systems or surgical robots, higher voltage ratings may be required, while lower-voltage configurations are suitable for portable diagnostic devices or wearable sensors.

Current Capacity:

- The current capacity of these slip rings ranges from 1A to 50A, depending on the number of circuits and the specific design requirements. Slip rings designed for high-power medical devices like robotic surgical tools may require higher current ratings to support the motors and actuators, while low-current designs are used for signal transmission in imaging equipment.

Aligning with UEA Inc.’s Insights:

- Drawing insights from UEA Inc.’s circuit ratings blog, it’s essential to ensure that the circuit rating matches the device’s operating conditions. Overloading the slip ring with higher voltages or currents than it is rated for can lead to overheating, failure, or, in medical applications, compromised patient safety. As such, manufacturers should select the appropriate voltage and current rating for the medical device based on its power requirements and the slip ring’s specifications.

IP22 Protection: Suitability for Controlled Medical Environments

The IP22 rating provides critical protection for medical devices against dust and moisture. Medical environments, particularly operating rooms, diagnostic areas, and patient care units, are subject to controlled conditions to prevent contamination. The IP22 rating is designed to safeguard the internal components of medical devices, such as slip rings, from minor dust and water exposure.

Protection Against Dust:

- The IP22 rating ensures that the slip ring is protected against solid objects larger than 12.5 mm, such as dust particles, debris, or accidental contact with hands or tools. This level of dust protection helps maintain the integrity and long-term performance of the device, as dust buildup inside electrical components can cause malfunctions or system failures.

Protection Against Water:

- The IP22 rating also ensures that the device can withstand water exposure in the form of vertically falling water drops when tilted at up to 15 degrees. In medical environments, where sterilization or cleaning procedures can expose equipment to moisture, this protection is essential to prevent liquid from entering sensitive components, such as electrical circuits or signal transmission lines.

Suitability for Controlled Environments:

- While IP22 offers a basic level of protection, it is well-suited for environments where there is light exposure to dust and moisture but where stringent cleanliness and operational reliability are still maintained. In more demanding medical settings, higher IP ratings (such as IP54 or IP65) may be necessary, but IP22 remains a versatile and commonly used rating for medical equipment requiring moderate protection.

Custom Solutions: Grand Slip Rings’ Ability to Tailor Designs

One of the key advantages of Grand Slip Rings is their ability to offer custom solutions tailored to the specific needs of medical applications. This customization includes hybrid solutions, such as electrical + fiber optic rotary joints, that provide unparalleled versatility and performance in complex medical environments.

Hybrid Electrical + Fiber Optic(FORJ) RF Rotary Joint:

- Grand Slip Rings offer the ability to integrate both electrical and fiber optic circuits into a single rotary joint. This hybrid solution is essential for applications where high-speed data transmission (via fiber optics) is required alongside traditional electrical power and signal transmission.

- Medical Applications: For example, in MRI or CT scanners, where high-bandwidth data must be transferred quickly and without signal loss, the integration of fiber optics can ensure efficient communication between the rotating imaging components and the stationary electronics. Simultaneously, electrical signals are transmitted to power components like motors or detectors.

Customization for Specialized Applications:

- Grand Slip Rings are known for their ability to adapt designs based on customer specifications. Whether it’s a specific number of circuits, high voltage requirements, or unique environmental considerations (such as temperature or vibration resistance), Grand can tailor their slip rings to meet the precise needs of medical equipment manufacturers.

- For example, robust designs can be created for robotic surgical systems that require extreme precision and reliability under constant movement and vibration. Alternatively, ultra-compact designs can be tailored for portable diagnostic equipment, where size and weight are crucial factors.

Enhanced Performance and Reliability:

- Customization also allows for the use of specialized materials and coatings to enhance the slip ring’s performance. In medical applications where sterilization is critical, custom designs can be made using materials that can withstand autoclaving or chemical cleaning processes without degrading over time. Furthermore, custom designs can be engineered to reduce electrical noise, which is crucial in sensitive equipment like medical imaging systems and patient monitoring devices.

The IP22 Medical Micro Slip Rings offer a variety of technical specifications and customization options that make them ideal for use in modern medical devices. With compact sizes ranging from 6mm to 12mm, they fit into space-constrained applications while ensuring reliable power and signal transmission. Their voltage/current ratings align with the needs of various medical devices, and the IP22 protection ensures that they can function effectively in controlled medical environments. Additionally, Grand Slip Rings provide highly customizable solutions, including hybrid electrical and fiber optic rotary joints, which cater to the diverse and demanding needs of the medical industry. With these advanced features, medical equipment manufacturers can ensure their devices remain reliable, efficient, and capable of meeting the stringent requirements of the healthcare sector.

Replacement and Maintenance of Medical IP22 Micro Slip Rings

Medical equipment is integral to patient care, and ensuring its reliability and longevity is essential to avoid downtime and maintain high performance. Proper maintenance and timely replacement of components like Medical IP22 Micro Slip Rings are crucial to ensure that medical devices continue to function safely and efficiently.

Why Replace? Wear in High-Use Medical Equipment and Risks of Downtime

Medical devices, especially those used in high-demand settings like hospitals, surgical centers, and imaging facilities, endure continuous use. Over time, components like slip rings, which are subject to rotational movement, electrical contact, and external factors like moisture, dust, or physical strain, may experience wear. The reasons for replacing these slip rings are multifaceted:

Wear and Tear:

- Slip rings experience mechanical wear due to friction between the rotating ring and the brush contacts. Over time, this wear leads to decreased performance, such as signal interference, power fluctuations, and, eventually, complete failure. This can affect medical equipment that relies on continuous rotation and uninterrupted signal transmission, such as MRI machines, CT scanners, and robotic surgical arms.

Electrical Contact Degradation:

- As the slip rings age, the quality of the electrical contact may deteriorate, resulting in increased electrical noise or intermittent signal loss. In sensitive medical applications, such degradation can lead to inaccurate readings or malfunctioning of life-critical devices. Replacing the slip ring prevents these issues from compromising the device’s performance.

Risk of Downtime:

- Unplanned downtime due to slip ring failure can have significant consequences in medical environments. Equipment failure can delay diagnoses, surgeries, or treatment, which directly impacts patient care. Furthermore, downtime leads to increased maintenance costs and potential revenue loss for healthcare facilities. Timely replacement of worn slip rings minimizes the risk of unexpected failures and ensures continuous operation of medical equipment.

Grand Slip Rings’ Replacement Service

Grand Slip Rings offers a replacement service that ensures compatibility, fast turnaround times, and global support, helping medical facilities keep their equipment running smoothly.

Compatibility with Legacy Systems:

- Grand Slip Rings understands the importance of maintaining equipment compatibility with existing systems. If you need to replace a slip ring in legacy equipment, such as older Moog slip rings, Grand provides high-quality replacement solutions that ensure seamless integration with older models. This is particularly important in medical environments where the replacement slip ring must work flawlessly with legacy systems without requiring costly upgrades or modifications.

- Whether for imaging systems, diagnostic tools, or surgical robots, Grand’s replacement slip rings offer drop-in replacements for a wide range of systems, allowing healthcare providers to continue using their existing equipment without disruption.

Fast Turnaround and Global Support:

- Medical environments often require urgent replacement services to minimize downtime. Grand Slip Rings offers fast turnaround times, ensuring that replacement slip rings are delivered and installed quickly, reducing the downtime of critical equipment.

- Additionally, Grand provides global support. No matter where you’re located, Grand Slip Rings offers assistance with sourcing replacement parts and technical support. For example, searching for “Medical IP22 micro slip ring near me” will lead you to local distributors or service centers that can provide the parts and expertise needed to maintain your medical equipment’s performance.

- Whether in emergency medical environments or routine maintenance schedules, Grand Slip Rings’ fast and efficient service ensures that critical medical systems remain operational with minimal interruption.

Maintenance Tips: Extend Lifespan with Proper Care

Proper maintenance of Medical IP22 Micro Slip Rings can help extend their lifespan and reduce the frequency of replacements. Here are some key maintenance tips:

Regular Inspections:

- Periodically inspect slip rings for visible signs of wear, such as discoloration of the rings or brushes, dust buildup, or evidence of sparking or electrical arcing. Catching early signs of wear can prevent more severe damage that may cause system failure.

Cleaning:

- Dust and moisture are two of the most common threats to slip rings. Ensure that the slip rings are kept clean and free from debris. For medical environments, cleaning should be done with care to avoid contaminating sensitive components. Use soft cloths or brushes and appropriate cleaning solutions designed for electrical components.

- For medical imaging devices, ensure that the slip rings are regularly cleaned according to the manufacturer’s guidelines to prevent dust or moisture from interfering with the signal transmission.

Lubrication:

- Some slip rings require lubrication to reduce friction between the brushes and the rings. Over time, lubrication can dry out or become contaminated, so periodic checks and re-lubrication may be necessary. Ensure that you use the correct type of lubricant to avoid damaging the slip rings.

Avoid Overloading:

- Ensure that the slip rings are not subjected to voltages or currents beyond their rated capacity. Overloading can cause excessive wear on the electrical contacts and lead to failure. Refer to the manufacturer’s specifications for the proper voltage and current ratings to maintain optimal performance.

Environmental Control:

- Medical devices often operate in environments with varying levels of moisture and dust. While IP22-rated slip rings are designed to withstand light exposure to water and dust, it’s still essential to maintain environmental control where possible. This may involve reducing exposure to excessive moisture or contaminants, especially in high-risk areas such as operating rooms or diagnostic imaging rooms.

Testing and Calibration:

- Regularly test the slip rings for electrical integrity and performance. This includes checking for signal continuity, voltage stability, and ensuring that electrical noise remains within acceptable limits. Calibration of the slip ring’s performance can help identify any degradation in signal transmission before it affects device operation.

The replacement and maintenance of Medical IP22 Micro Slip Rings is vital to the performance, reliability, and longevity of medical equipment. Worn slip rings can lead to significant downtime and compromise patient care, making timely replacements essential. Grand Slip Rings’ replacement service ensures compatibility with legacy systems, fast turnaround, and global support, reducing downtime for medical facilities. Additionally, following proper maintenance tips, including regular inspections, cleaning, lubrication, and avoiding overloading, can significantly extend the lifespan of slip rings, ensuring the continuous, safe operation of critical medical equipment. By maintaining slip rings in optimal condition, healthcare providers can minimize the risk of equipment failure and ensure that devices remain ready for use when needed most.

Purchasing Options & Pricing for Medical IP22 Micro Slip Rings

When it comes to purchasing Medical IP22 Micro Slip Rings, healthcare providers and medical equipment manufacturers are looking for high-quality, reliable components at competitive prices. Below, we provide a transparent breakdown of cost considerations, where to buy, and bulk order discounts for hospitals and medical OEMs.

Price Range: Transparent Cost Breakdown

The price of Medical IP22 Micro Slip Rings varies based on several factors, including size, complexity, voltage and current ratings, and customization requirements. Here’s a general idea of what you can expect in terms of price range:

Standard Medical IP22 Micro Slip Rings:

- Basic Models: For basic, off-the-shelf Medical IP22 Micro Slip Rings, prices typically range from $100 to $500 per unit, depending on the size (6–12mm diameter), the number of circuits, and the material quality.

- Customization Fees: If you require customization (e.g., hybrid electrical + fiber optic, special coatings, or custom voltage and current ratings), prices can increase to $500 to $1,500 or more per unit based on the complexity of the design and performance requirements.

Where to Buy

- Direct from Grand Slip Rings (Custom Orders):

- Custom Orders: For highly specific or customized Medical IP22 Micro Slip Rings, it’s best to place an order directly with Grand Slip Rings. By working directly with the manufacturer, you can ensure that the slip rings meet your exact requirements, whether it’s for medical imaging equipment, robotic surgical systems, or portable diagnostic tools.

- Customizations Offered: These may include hybrid designs (electrical + fiber optic), specific voltage and current ratings, unique environmental protection features, and more. By purchasing directly from Grand, you ensure the highest level of customization and a direct line of communication for any additional needs or technical support.

- Distributors and Resellers:

- Grand Slip Rings has a network of authorized distributors and resellers globally. If you’re looking for a more convenient purchasing process or local support, you can find Grand Slip Rings available through these partners. Simply search for “Medical IP22 micro slip ring near me” to find authorized distributors or service centers that can supply standard or custom slip rings for medical applications.

Bulk Orders: Discounts for Hospitals/Medical OEMs

Bulk purchasing is an excellent option for hospitals, medical equipment manufacturers (OEMs), and healthcare providers who need large quantities of Medical IP22 Micro Slip Rings for their medical devices or machinery. Grand Slip Rings offers significant discounts for bulk orders, making it a cost-effective choice for those in the healthcare industry.

Discounts for Hospitals and Medical OEMs:

- Hospitals and medical OEMs that place bulk orders can expect volume discounts based on the quantity and frequency of their orders. Discounts typically start at 10–20% off the standard price for orders of 50 or more units and can increase for larger orders.

- Loyalty Programs: Grand Slip Rings may also offer loyalty programs for long-term customers, such as hospitals or large medical device manufacturers, providing additional savings for repeat orders or long-term contracts.

Cost Savings for Medical Equipment Manufacturers:

- For medical OEMs, placing bulk orders allows for significant cost reductions, which is crucial for keeping manufacturing costs down and remaining competitive in the market. These savings can be reinvested into other areas of product development or passed along to end-users, ultimately benefiting patients and healthcare providers.

Customization for Bulk Orders:

- Grand Slip Rings can also customize slip rings for bulk orders, ensuring that large quantities of medical devices all have the same high standards for performance and reliability. Custom features, such as hybrid designs or tailored circuit ratings, are available for bulk orders, ensuring that the entire batch meets the specific needs of the medical application.

Purchasing Medical IP22 Micro Slip Rings is a straightforward process, with options ranging from affordable standard models to highly customized solutions. Grand Slip Rings offers competitive pricing, with substantial savings over brands like Moog, making them a cost-effective option for medical equipment manufacturers and healthcare facilities. Whether purchasing directly from Grand for customized needs or through authorized distributors, you can expect reliable performance and global support. Additionally, bulk order discounts offer further savings for hospitals and medical OEMs, making Grand Slip Rings an attractive option for large-scale medical equipment projects.

Why Choose Grand Slip Rings?

Grand Slip Rings stands out in the market for its high-quality Medical IP22 Micro Slip Rings, offering healthcare providers and medical equipment manufacturers reliable, efficient, and customized solutions. Here are some reasons why Grand Slip Rings is a top choice in the medical sector:

Quality Assurance: Rigorous Testing for Medical Compliance

Ensuring that medical devices meet stringent safety, performance, and regulatory standards is essential in healthcare. Grand Slip Rings goes above and beyond to guarantee that every Medical IP22 Micro Slip Ring undergoes rigorous testing to ensure it meets medical compliance standards, including:

- ISO 13485 Compliance: Grand Slip Rings adheres to international quality management standards specifically designed for medical devices, ensuring that all slip rings meet the necessary requirements for medical applications.

- Electromagnetic Interference (EMI) Testing: Given the critical nature of medical devices, Grand Slip Rings undergo EMI testing to ensure that electrical noise is minimized and does not interfere with sensitive medical equipment like imaging systems, robotic surgical arms, or patient monitoring devices.

- Environmental Testing: Each slip ring is tested for environmental durability, including its ability to resist dust, moisture, and temperature fluctuations. This ensures consistent performance in real-world medical settings where equipment is exposed to various conditions.

- Sterilization Compatibility: The materials used in Grand Slip Rings are compatible with sterilization processes, ensuring that they meet the hygiene standards required for medical equipment.

Diverse Portfolio: Holistic Solutions for Medical Applications

Grand Slip Rings offers a diverse portfolio of related products designed to address a wide range of medical applications. Their range of slip rings and accessories provides holistic solutions that meet the varied needs of the healthcare industry, ensuring seamless integration across medical equipment.

- Ethernet slip rings are ideal for medical devices that require continuous, high-speed data transfer, such as imaging systems, diagnostic equipment, and robotic surgeries. These slip rings ensure reliable data transmission between rotating and stationary parts without data loss, making them crucial for applications like MRI machines and CT scanners.

Fiber Optic Rotary Joints (FORJs):

- Fiber Optic Rotary Joints (FORJs) are essential for applications that require high-bandwidth data transfer, such as medical imaging systems or telemedicine equipment. When paired with medical IP22 slip rings, these hybrid solutions provide a seamless combination of power and data transmission for high-speed medical applications, ensuring clear, fast communication between device components.

Custom Solutions:

- Grand Slip Rings can provide custom solutions based on your specific medical equipment requirements. Whether you need multi-circuit designs, hybrid power and data transmission, or specific material choices for sterilization and reliability, Grand Slip Rings offers tailored solutions to ensure optimal performance in critical medical applications.

Global Reach: Partnering with Leading Medical Device Manufacturers

Grand Slip Rings has established strong partnerships with leading medical device manufacturers across the globe. Their global reach allows them to support healthcare providers, OEMs, and equipment manufacturers with consistent quality, on-time delivery, and reliable customer service. Key benefits include:

- Worldwide Availability:

- Grand Slip Rings operates in multiple regions, ensuring that their products are available globally. This extensive network of distributors and service centers ensures that customers can access Grand Slip Rings products and services no matter where they are located.

- Collaboration with Top Medical Manufacturers:

- By partnering with top medical device manufacturers, Grand Slip Rings has refined its products to meet the highest standards in the industry, ensuring that their slip rings are optimized for medical use. These collaborations also allow Grand to stay at the forefront of innovation, offering the latest technologies in slip rings and related components.

Sustainability: Eco-Friendly Materials and Long-Term Durability

Grand Slip Rings is committed to sustainability, ensuring that their products not only perform well but also contribute to a more environmentally responsible industry.

- Eco-Friendly Materials:

- Grand Slip Rings uses eco-friendly materials that minimize environmental impact during manufacturing and disposal. These materials are chosen for their durability, recyclability, and ability to withstand harsh medical environments, reducing the need for frequent replacements.

- Long-Term Durability:

- Medical equipment must endure constant use and exposure to demanding environments. Grand Slip Rings are engineered for long-term durability, ensuring that they provide reliable performance throughout their service life. This contributes to reducing waste and the need for frequent replacements, supporting both cost savings and environmental sustainability.

Medical IP22 Micro Slip Rings play a critical role in advancing medical technology, ensuring reliable power and signal transmission in various applications, from robotic surgeries to diagnostic imaging. Grand Slip Rings stands at the forefront of providing these vital components with unmatched quality, durability, and customization. By choosing Grand Slip Rings, you are investing in a product that adheres to the highest standards of medical compliance, offers a diverse range of solutions, and is backed by global support and sustainability.

Ready to integrate high-performance Medical IP22 Micro Slip Rings into your medical devices? Request a quote for your custom designs today. Let us help you find the perfect solution for your needs, whether you’re working on robotic systems, imaging equipment, or portable diagnostic tools. Contact Grand Slip Rings now to get started!

FAQs about Medical IP22 Micro Slip Ring

Q: Which device uses slip rings?

A: Slip rings are used in a variety of devices where continuous rotation and uninterrupted electrical contact are required. These devices span across multiple industries, including medical, aerospace, industrial automation, and telecommunications. Some of the primary devices that utilize slip rings include:

CT and MRI Scanners: In medical imaging equipment, slip rings are used to transmit electrical signals and power between rotating and stationary parts, such as the rotating gantry in CT scanners or MRI machines. These machines require continuous rotation to capture images, and slip rings enable this motion by maintaining electrical connections without interrupting the power and signal flow.

Robotic Arms: In medical robotics, slip rings ensure smooth and uninterrupted communication between rotating arms and their control systems. This is crucial for precise movements in robotic surgeries, where continuous and reliable signal transmission is required for real-time adjustments.

Wind Turbines: Slip rings are also found in wind turbines, where they allow the transfer of power from the rotating blades to the stationary electrical systems.

Radar Systems: Slip rings are used in radar systems to maintain a continuous electrical connection between the rotating antenna and stationary power sources or receivers, ensuring reliable signal transmission over time.

Aerospace Applications: Aircraft use slip rings in various moving parts, such as control surfaces, to transmit power and data from rotating components without interruption.

In each of these applications, slip rings ensure that the rotating components continue to operate without disruption, allowing for reliable, continuous power and signal transmission essential to the function of these critical systems.

Q: What are the advantages of slip ring technology in CT?

A: Slip ring technology offers numerous advantages in CT (Computed Tomography) scanners, particularly in terms of maintaining uninterrupted electrical contact between the rotating and stationary parts of the system. The primary benefits of using slip rings in CT technology are as follows:

Continuous Rotation for Imaging: In a CT scanner, the rotating gantry that houses the X-ray tube and detectors requires continuous movement to capture multiple angles of the body. Slip rings enable this continuous rotation without the need for physical connections such as cables or wires, which would otherwise limit the rotation or cause disruptions in data transmission. This smooth, uninterrupted rotation is essential for obtaining clear, high-quality cross-sectional images of the body.

Improved Image Quality: By allowing uninterrupted data transmission, slip rings ensure that the CT scanner’s detectors continuously receive signals from the X-ray tube, contributing to higher image resolution and clarity. This is particularly critical in medical imaging, where the quality of the images directly impacts the accuracy of diagnoses and treatment planning.

Reduced Maintenance and Wear: Traditional CT scanners used brushes and cables to transmit signals, but these systems wore out quickly, causing more frequent maintenance and potential downtime. Slip rings eliminate the need for brushes, reducing mechanical wear and extending the lifespan of the scanner’s components. This leads to fewer interruptions in service and greater reliability of the CT machine.

Flexibility and Efficiency: Slip rings allow for more compact, efficient designs in CT scanners, which improves the overall functionality of the machine. They enable continuous data transfer between the rotating gantry and stationary systems, supporting faster and more efficient scans.

Enhanced Patient Throughput: The improved efficiency and reduced wear of slip ring technology allow for quicker imaging procedures, thus reducing patient wait times and enhancing throughput in busy medical facilities. This efficiency benefits both healthcare providers and patients, helping medical facilities handle a higher volume of scans in a shorter time frame.

Overall, the use of slip ring technology in CT scanners significantly enhances both the performance and reliability of the system, providing faster, more accurate imaging while reducing the risk of mechanical failure.

Q: What does a slip ring assembly do in a CT scan quizlet?

A: A slip ring assembly in a CT scan plays a crucial role in enabling the continuous rotation of the scanner’s gantry while maintaining uninterrupted electrical power and signal transmission between the stationary and rotating parts of the system. Here’s a breakdown of its function:

Enables Continuous Rotation: The primary function of a slip ring assembly in a CT scanner is to provide a means for the rotating gantry to maintain continuous motion without the need for traditional wiring. The slip rings allow the electrical connections to rotate along with the gantry while transmitting power and data to the stationary system.

Signal Transmission: The slip ring assembly transmits electrical signals from the rotating X-ray tube and detectors to the stationary computer system, where the data is processed to create cross-sectional images of the body. This continuous transmission is crucial for obtaining high-quality images.

Increased Efficiency and Reliability: By eliminating the need for brushes and cables, slip ring assemblies reduce mechanical wear and tear, ensuring that the CT scanner operates more efficiently and with less maintenance. This reliability is essential in busy healthcare settings where downtime can affect patient care.

In summary, the slip ring assembly in a CT scanner ensures that the rotating gantry can move freely while maintaining uninterrupted electrical connections, contributing to the efficiency, image quality, and reliability of the scanner.

Q: How do you check slip rings?

A: To check the condition of slip rings, several methods can be used to evaluate their performance and detect any potential issues:

Visual Inspection: Start by visually inspecting the slip rings for signs of wear, corrosion, or damage. Look for obvious physical defects such as broken or worn brushes, damaged rings, or any buildup of dust and debris that could interfere with the smooth operation of the slip rings.

Electrical Continuity Testing: You can check the electrical continuity of each circuit by using a multimeter to measure resistance between the rings and brushes. A good slip ring should have low resistance (or no resistance) between the conducting surfaces. High resistance can indicate poor electrical contact or damage.

Brush and Ring Wear: Regularly check the condition of the brushes that make contact with the rings. Worn brushes or rings can lead to inefficient signal transfer or mechanical failure. If the brushes are too short, they may need to be replaced.

Signal Quality Test: In applications like medical imaging or industrial equipment, checking the signal integrity transmitted through the slip rings is essential. Monitor the signal quality for any degradation, noise, or interruptions that could indicate issues with the slip ring’s electrical contacts.

Cleaning: Cleaning the slip rings is important to ensure that no dust or contaminants are interfering with the electrical contact. Use non-abrasive cloths or brushes to clean the surface of the slip rings and brushes.

By conducting regular checks and maintenance on slip rings, you can ensure that they continue to function reliably and prevent unnecessary downtime.

Q: How many slip rings were present in spiral CT?

A: In a spiral CT (also known as helical CT), the system typically uses a single slip ring assembly that provides continuous electrical power and signal transmission for the rotating gantry. The spiral or helical scanning technique allows the X-ray tube and detectors to rotate continuously while the patient moves through the scanner, acquiring slices of data that are then reconstructed into 3D images.

While modern CT scanners may use additional slip rings for more complex systems or hybrid designs (such as systems that combine both electrical and fiber-optic transmissions), the most basic spiral CT systems generally use a single slip ring to support this continuous rotation.

The slip ring assembly ensures that electrical connections are maintained without interruption as the X-ray tube and detectors rotate, enabling the continuous, smooth acquisition of data required for high-quality images.

Q: What is the difference between a split ring and a slip ring?

A: The main difference between a split ring and a slip ring lies in their design and function in electrical systems:

Split Ring: A split ring, often used in commutators, is a type of ring that is split into two or more segments. It is typically used in DC motors or other rotating electrical devices to reverse the direction of current flow. The split ring acts as a mechanical switch, periodically reversing the current as it rotates. Split rings are primarily used in low-voltage, low-current applications.

Slip Ring: A slip ring, on the other hand, is a continuous, unbroken ring used to provide continuous electrical contact between rotating and stationary parts of a system. Unlike split rings, slip rings are used in applications requiring uninterrupted transmission of power or signals, such as in medical imaging, wind turbines, and robotics. They allow for the seamless transfer of electrical power, data, or signals in rotating systems without interruption.

Q: How reliable are slip rings?

A: Slip rings are highly reliable components, especially when designed and manufactured for specific high-performance applications. The reliability of slip rings depends on several factors, including the materials used, design specifications, and operating conditions. Here’s why slip rings are considered reliable:

Durability: High-quality slip rings are designed to endure continuous rotation, electrical contact, and harsh environmental conditions. In industrial and medical settings, slip rings are built to withstand heavy use with minimal maintenance, providing many years of service life.

Low Maintenance: Slip rings that use advanced materials, such as gold or platinum, are highly resistant to wear, corrosion, and electrical noise, reducing the need for frequent maintenance or replacements.

Precision: In critical applications like medical imaging, slip rings ensure precise signal transmission with minimal interference. Their ability to maintain consistent contact under continuous rotation ensures reliable performance.

Customization: Slip rings can be customized for specific applications, allowing for solutions tailored to meet the exact demands of the environment. This customization further enhances their reliability and suitability for complex systems.

In summary, slip rings are very reliable, offering long-term performance and minimal maintenance when properly designed and maintained.

Q: What is the difference between a collector ring and a slip ring?

A: The collector ring and slip ring serve similar purposes in that they both facilitate the transmission of power or signals between stationary and rotating parts, but they differ in their design and function.

Collector Ring: A collector ring is part of a commutator system, often found in DC motors or other applications that require current reversal. The collector ring is typically segmented, with each section connected to a different brush. As the motor rotates, the brushes make contact with the collector rings, reversing the current flow in the armature windings to maintain continuous rotation.

Slip Ring: A slip ring is a continuous, unbroken ring used to transmit power or signals between rotating and stationary components. Slip rings are typically used in more advanced applications, including medical devices like CT scanners, industrial machines, and wind turbines, where uninterrupted electrical contact is required for continuous operation.

While both components transmit electrical signals, collector rings are typically used in systems that require current reversal, while slip rings provide continuous signal and power transmission without reversal.

Q: How do you clean slip rings?

A: Cleaning slip rings is an essential part of maintenance, as dust, debris, and other contaminants can interfere with their performance. To clean slip rings, follow these steps:

Turn off the Equipment: Always turn off the power to the device before cleaning the slip ring to prevent electrical shock or damage.

Use Non-Abrasive Materials: Use a soft, lint-free cloth or brush to gently wipe the surface of the slip rings and brushes. Avoid abrasive materials, as they can damage the slip rings or brushes.

Cleaning Solution: If necessary, use a mild cleaning solution (preferably designed for electrical components) to wipe away grease, dirt, or grime. Ensure that the cleaning solution is non-conductive and safe for electrical components.

Avoid Moisture: Make sure not to introduce excessive moisture into the slip ring assembly. Use a dry cloth to wipe away excess cleaning solution.

Inspect for Damage: After cleaning, inspect the slip rings and brushes for signs of wear, corrosion, or other damage that might affect their performance.

Regular cleaning and maintenance can significantly extend the lifespan of slip rings and ensure they continue to perform efficiently.

Q: What is a slip ring also known as?

A: A slip ring is also known by several other terms, depending on the application and industry:

- Rotary Electric Connector

- Rotary Joint

- Rotary Transmission Device

- Electric Rotary Union

These terms describe the core function of slip rings—ensuring a continuous electrical connection between rotating and stationary parts.

Q: How do you test a slip ring?

A: To test a slip ring, you can follow these steps to ensure it is functioning properly:

Visual Inspection: Check for signs of wear, corrosion, or physical damage. Look for any buildup of dust or debris that could affect performance.

Resistance Testing: Use a multimeter to test the continuity of each circuit within the slip ring. A good slip ring should show low resistance across all circuits, indicating that the electrical connection is intact.

Brush Condition: Inspect the brushes that make contact with the rings. Check for wear or unevenness, as these could cause poor contact and signal degradation.

Signal and Power Testing: For applications where the slip ring is used for signal or power transmission, test the signal integrity or power continuity to ensure there is no interruption, noise, or loss in transmission.

Rotation Test: Rotate the slip ring by hand (if applicable) and check for smooth movement. Any resistance or jerky movement could indicate issues with the internal components.

Regular testing ensures the slip ring is performing optimally and can prevent unexpected failures.