In high-stakes military operations, slip rings are indispensable for seamless signal and power transmission in rotating systems, where even minor disruptions can compromise mission success. Electromagnetic interference (EMI) poses a severe threat in mission-critical applications like radar arrays, UAVs, and armored combat vehicles, risking data corruption and operational failures. Grand Slip Rings delivers battle-tested solutions as a trusted innovator of military-grade slip rings and rotary joints, engineered with advanced EMI/RFI shielding, ruggedized materials, and precision contact technology to exceed MIL-STD-810/461 compliance—ensuring flawless performance in the world’s most hostile electromagnetic environments.

Why Anti-Interference Design Matters in Military Slip Rings

In military operations, slip rings serve as the lifeline for transmitting power, data, and signals across rotating platforms, where failure is not an option. The unique challenges of military environments demand slip rings engineered to withstand not just mechanical stress but also the invisible yet devastating threat of electromagnetic interference (EMI).

Military Operating Environments: A Crucible of Extremes

Military systems operate in some of the harshest conditions on Earth—and beyond. Slip rings embedded in radar turrets, unmanned aerial vehicles (UAVs), or armored combat vehicles must endure:

- Extreme temperatures: From desert heat (+55°C) to Arctic cold (-40°C), thermal expansion and contraction can degrade contact materials.

- Relentless vibration: High-G shocks from artillery fire, rough terrain, or aircraft carrier landings risk dislodging connections.

- Corrosive exposure: Salt fog, humidity, and chemical agents accelerate wear, threatening electrical continuity.

However, the most insidious challenge is EMI/RFI (radio frequency interference). Modern battlefields are saturated with high-frequency emissions from:

- Radar systems: High-power pulses that can induce noise in unshielded circuits.

- Communication arrays: Dense RF traffic from encrypted radios, satellite links, and jamming systems.

- Electronic warfare (EW) systems: Deliberate EMI attacks designed to disrupt enemy sensors and communications.

Consequences of Failure: When Signals Become Casualties

In mission-critical scenarios, EMI-compromised slip rings can cascade into catastrophic outcomes:

- Signal degradation: Noise disrupts video feeds from UAVs, blinding operators during reconnaissance.

- Data corruption: Encrypted communications between command centers and field units become unreliable.

- System downtime: A radar array failing mid-engagement leaves a warship defenseless against incoming threats.

Such vulnerabilities not only jeopardize mission objectives but also endanger lives. For example, a slip ring in a combat vehicle’s targeting system corrupted by EMI could misdirect firepower, risking fratricide or mission failure.

Grand Slip Rings’ Focus: Engineering Immunity to Interference

To combat these risks, Grand Slip Rings designs slip rings and rotary joints that adhere to military-grade standards, including:

- MIL-STD-810: Validated against temperature extremes, vibration, and humidity.

- MIL-DTL-38999: Ensures connectors withstand EMI, shock, and corrosive environments.

- MIL-STD-461: Certifies EMI/RFI shielding effectiveness for both emissions control and susceptibility.

Our solutions integrate:

- Multi-layer EMI shielding: Combination of conductive polymers, Faraday cage designs, and fiber-optic hybrid systems to block interference.

- Ruggedized contact materials: Gold-gold or silver-graphite brushes tested for 10 million+ rotations under load.

- Isolated pathways: Segregated channels for power, data, and RF signals to prevent cross-talk.

By exceeding these standards, Grand Slip Rings ensures electromagnetic compatibility (EMC) even in congested spectral environments. Whether enabling 360° radar sweeps on a destroyer or maintaining UAV datalinks in contested airspace, our slip rings deliver zero-compromise reliability—because in combat, there’s no room for interference.

Key Anti-Interference Strategies in Military-Grade Slip Rings

In the electromagnetic battleground of modern warfare, slip rings must act as both conduits and shields. Grand Slip Rings employs cutting-edge strategies to neutralize interference while ensuring uninterrupted performance in the most demanding military applications.

EMI/EMC Shielding: Neutralizing the Invisible Enemy

- Conductive Shielding

- Gold-Plated Contacts: Used in Military Slip Rings, gold’s low electrical resistance minimizes arcing and EMI generation, even under high-speed rotation. For example, in airborne radar systems, gold-plated brush assemblies ensure stable signal transmission during 360° sweeps, resisting interference from nearby jamming systems.

- Multi-Layered Faraday Cages: Encapsulating critical circuits in conductive materials (e.g., copper-nickel alloys) blocks external RFI/EMI. This is critical for RF Rotary Joints in electronic warfare pods, where stray signals could reveal a platform’s position.

- Hybrid Fiber Optic Designs

- Fiber Optic Rotary Joints (FORJ): Integrated into Hybrid Slip Rings, fiber channels transmit data (e.g., HD video from UAVs) with zero susceptibility to EMI. A naval surveillance radar, for instance, might combine fiber optics for data and traditional rings for power, ensuring clear imagery despite high-power radar pulses nearby.

- EMI-Immune Signal Paths: Fiber-optic integration in Satcom Rotary Joints prevents noise from corrupting satellite uplinks in mobile command centers.

- Grounding Techniques

- Low-Impedance Grounding: Through Hole Slip Rings in rotating gun turrets use dedicated grounding rings to dissipate static buildup and EMI-induced currents, preventing false triggers or sensor errors.

- Shielded Cable Routing: Cables in High Current Slip Rings for combat vehicle turrets are grounded to chassis, diverting interference away from sensitive fire-control systems.

Material and Structural Resilience: Built to Survive, Engineered to Perform

- Military-Spec Sealing

- IP68-Rated Waterproof Slip Rings: Utilized in submarine periscopes and naval sonar arrays, these feature MIL-SPEC O-rings and potted electronics to resist saltwater intrusion at depths exceeding 100 meters.

- Hermetic Seals: For UAVs operating in sandstorms, sealed housings prevent particulate ingress that could degrade contact surfaces.

- Corrosion-Resistant Housings

- Stainless Steel Enclosures: Deployed in Armored Vehicle Slip Rings, these withstand prolonged exposure to de-icing agents and chemical contaminants. Compliant with MIL-DTL-38999, they maintain shielding integrity even after ballistic impacts.

- Anodized Aluminum: Used in High Voltage Slip Rings for missile launch systems, offering lightweight durability against thermal cycling and vibration.

Advanced Signal Integrity Solutions: Precision Under Fire

- Fiber Optic Hybrids

- Dual-Channel Systems: In UAV Slip Rings, hybrid designs separate power (up to 400A) and fiber-optic data streams, allowing a Predator drone to transmit encrypted video while charging its batteries—all without crosstalk.

- Coaxial Integration: Satellite Communication Slip Rings combine fiber for data and coaxial lines for RF signals, enabling real-time telemetry for hypersonic missile test platforms.

- Low-Noise Design

- Servo Encoder Slip Rings: Precision-machined contacts and shielded wiring in these systems reduce electrical noise to sub-millivolt levels, critical for guiding laser-directed artillery shells.

- Twisted Pair Wiring: Applied in Combat Vehicle Slip Rings, this configuration cancels EMI-induced noise in CAN bus networks controlling autonomous driving systems.

- Frequency Isolation

- Bandpass Filtering: Radar Slip Rings incorporate embedded filters to block out-of-band EMI, ensuring clean returns for phased array systems tracking stealth targets.

Grand Slip Rings’ Battlefield-Proven Edge

By combining MIL-STD-validated shielding, rugged materials, and signal integrity innovations, our slip rings are engineered to outlast and outperform in contested environments. Whether maintaining a destroyer’s radar during electronic warfare or ensuring a combat drone’s datalink survives an EMP burst, we deliver zero-failure tolerance—because the cost of interference is measured in missions, not milliseconds.

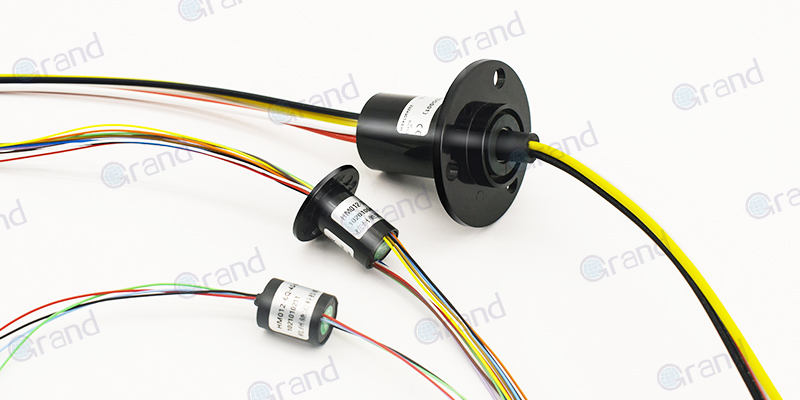

Grand Slip Rings’ Anti-Interference Product Highlights

Military Slip Ring Series

Grand Slip Rings offers a specialized series of military-grade slip rings designed to meet the most demanding requirements of defense systems, ensuring exceptional performance even in extreme environments. These products are engineered for maximum durability and reliability, with anti-interference solutions tailored to military standards.

Through Hole Slip Rings: Central Bore Design for Cable Routing in Surveillance Platforms

Through Hole Slip Rings are specifically designed to facilitate efficient cable routing through the center of rotating systems, making them ideal for applications where space is limited and functionality is critical, such as in military surveillance platforms.

- Design Features and Benefits:

- Central Bore for Cable Routing: The central bore design provides a convenient and organized pathway for cable management, ensuring smooth operation in systems with limited space, such as surveillance systems on rotating platforms or radar systems.

- Anti-Interference Capabilities: These slip rings are equipped with advanced electromagnetic interference (EMI) shielding to ensure that the system’s signals remain intact and clear, even in the presence of high-frequency systems, such as radar and communication arrays.

- Durability for Harsh Environments: Built to withstand harsh operational conditions such as extreme temperatures, vibrations, and moisture, the Through Hole Slip Rings are a robust solution for military surveillance applications.

High-Speed Slip Rings: EMI-Shielded Models for Radar Antennas and UGVs

High-Speed Slip Rings are engineered to meet the high-speed data transfer demands of modern military equipment, such as radar antennas and unmanned ground vehicles (UGVs), where rapid data transmission is essential for real-time decision-making and control.

- Design Features and Benefits:

- Optimized for High-Speed Data Transfer: These slip rings are designed for high data rates, ensuring that real-time communication and control are maintained without delay or data loss. This makes them ideal for radar systems, UGVs, and other critical military platforms where timing and accuracy are paramount.

- EMI Shielding for Signal Integrity: Equipped with advanced EMI shielding, these slip rings ensure that electromagnetic interference from surrounding systems does not disrupt the signal, preserving the integrity of high-speed data transmission.

- Applications for Radar Antennas and UGVs: High-Speed Slip Rings are essential for military applications, such as radar antennas, which require fast, reliable data exchange to track targets and maintain situational awareness. These slip rings are also well-suited for UGVs, ensuring seamless operation in environments with high EMI.

Fiber Optic Rotary Joints (FORJ): Zero-Interference Data Transfer in Electronic Warfare Systems

Fiber Optic Rotary Joints (FORJ) offer a unique solution for data transmission that eliminates the risk of electromagnetic interference (EMI), making them ideal for sensitive applications like electronic warfare systems, where uninterrupted and secure data transfer is crucial.

- Design Features and Benefits:

- Zero-Interference Signal Transfer: Unlike traditional metal-based slip rings, FORJs use optical fibers to transmit signals, providing a high-bandwidth, zero-interference solution. This is critical in electronic warfare environments, where the integrity of communications and data is non-negotiable.

- High Bandwidth for Complex Systems: FORJs support high-speed, high-frequency signals, making them ideal for applications that require high-bandwidth data, such as military satellites, UAVs, and electronic warfare systems. The high bandwidth allows for real-time data transmission without delays or signal degradation.

- Increased Durability and Reliability: Fiber optics are resistant to electromagnetic interference, offering superior reliability in electronic warfare scenarios, where traditional metal wires may be susceptible to disruptions. The design is also optimized for long-term durability, ensuring continuous, high-quality signal transmission under extreme conditions.

Custom Solutions: Tailored Slip Ring Military Applications (e.g., Military Class Ring Configurations for Submarines)

At Grand Slip Rings, we understand that military applications often require unique configurations. Our custom solutions are designed to address the specific needs of each defense platform, offering tailored slip ring designs for mission-critical operations.

- Design Features and Benefits:

- Military Class Ring Configurations for Submarines: For submarines and other specialized military platforms, we provide custom Military Class Rings that adhere to strict military specifications. These slip rings are designed to handle extreme pressure, water resistance (IP68-rated), and other challenging environmental factors, ensuring reliable operation even in the depths of the ocean.

- Tailored Designs for Unique Military Applications: Our custom solutions can integrate power, signal, and fiber optic channels into one unified slip ring design, tailored to meet the specific requirements of advanced military systems such as missile guidance, radar, sonar, and satellite communications.

- Collaborative Design Process: Our team works closely with military contractors to understand the operational needs and design custom slip ring that integrate seamlessly into existing systems, ensuring compatibility, performance, and reliability in demanding environments.

Grand Slip Rings is committed to providing the most advanced, reliable, and tailored slip ring solutions to support military operations across a wide range of applications. Each product is built to ensure optimal performance under the harshest conditions, from surveillance platforms to electronic warfare systems.

Military-Grade Slip Ring Anti-Interference Design: Compliance and Testing

At Grand Slip Rings, ensuring that our products meet the highest standards of quality, reliability, and performance is our top priority. Our military-grade slip rings are designed to adhere to strict military specifications and undergo rigorous testing to ensure they perform optimally in challenging defense environments. Below is a breakdown of the key compliance standards and testing procedures that validate the reliability and durability of our products.

Military Standards: Compliance with MIL-SPEC, IEC 61000-4-21 (EMC), and IP68/69K

Our slip rings are built to comply with the most stringent military standards, ensuring that they meet or exceed the operational requirements of defense systems around the world.

MIL-SPEC Compliance:

- Grand Slip Rings are designed and manufactured to meet various MIL-SPEC standards, including MIL-STD-810 (environmental conditions testing), MIL-DTL-38999 (connector specifications), and MIL-STD-704 (electrical power systems). These standards ensure that our slip rings are ready for extreme environments, whether in military vehicles, radar systems, or surveillance platforms.

- MIL-SPEC compliance guarantees that our products are durable, reliable, and capable of operating in harsh conditions, such as high altitudes, extreme temperatures, and vibrations, that are commonly encountered in military operations.

IEC 61000-4-21 (EMC):

- This standard deals with Electromagnetic Compatibility (EMC Slip Ring) and ensures that the slip rings can operate without causing or being affected by electromagnetic interference (EMI). Adhering to IEC 61000-4-21 ensures that our products meet international standards for minimizing the impact of EMI in sensitive environments, making them ideal for defense and aerospace applications.

- Our slip rings undergo testing to verify that they can function reliably in high-EMI environments without compromising the performance of surrounding electronic systems, which is critical in applications such as radar, communications, and electronic warfare.

IP68/69K (Ingress Protection):

- To ensure protection against dust and water ingress, Grand Slip Rings are designed to meet the IP68 and IP69K standards. These classifications indicate that our products are fully protected against dust and capable of withstanding submersion in water at depths of over 1 meter, which is especially important for applications in naval systems, submarines, and underwater surveillance.

- The IP69K standard also guarantees resistance to high-pressure water jets, ensuring that our slip rings continue to function properly in extreme conditions encountered by military vehicles, armored vehicles, and marine platforms.

Quality Assurance

Grand Slip Rings implements a robust quality assurance program to ensure that every product meets the highest standards for performance, durability, and reliability. Our quality assurance process includes extensive testing for shock, vibration, and electromagnetic compatibility (EMC) to ensure that our slip rings can withstand the most demanding military environments.

MIL-STD-883 Testing for Shock/Vibration Resistance:

- MIL-STD-883 is a military standard that specifies the testing procedures for the shock and vibration resistance of electronic components. Grand Slip Rings are subjected to rigorous testing under this standard to ensure they can withstand high levels of mechanical stress without failure.

- The tests simulate conditions such as sudden impact, rapid acceleration, and vibrations typical in military operations, including missile launches, vehicle movements, and airborne platforms. Our slip rings are designed to remain functional and reliable even under these extreme conditions.

EMI/EMC Validation in Military Aerospace Applications:

- Electromagnetic interference (EMI) and electromagnetic compatibility (EMC) testing is critical in military aerospace applications, where electronic systems must operate without interference from other devices or external electromagnetic sources.

- Our slip rings undergo extensive EMI/EMC testing to ensure they comply with military standards, such as MIL-STD-461, which governs the electromagnetic emission and immunity of systems used in military aerospace and defense. These tests ensure that our products do not emit harmful EMI that could interfere with other equipment and that they are immune to external electromagnetic threats.

By adhering to military standards like MIL-SPEC, IEC 61000-4-21, and IP68/69K, and undergoing rigorous quality assurance testing for shock, vibration, and EMI/EMC performance, Grand Slip Rings guarantees that our products are reliable, durable, and ready for the toughest military applications. Each slip ring is meticulously tested to ensure that it can withstand extreme environmental conditions, ensuring mission-critical systems perform seamlessly in the field.

Military-Grade Slip Ring Anti-Interference Design: Real-World Applications

Grand Slip Rings’ military-grade solutions are employed across various critical defense systems where reliability, durability, and anti-interference features are essential. Below are three detailed case studies that demonstrate the practical benefits of our products in real-world military applications.

Case Study 1: Slip Rings in Armored Vehicles – Anti-Interference Design for 360° Turret Systems

Application Overview:

In modern armored vehicles, 360° turret systems are critical for providing all-around defense capabilities. These turrets are often equipped with radar, cameras, and weapon systems that require continuous data and power transmission to remain functional while rotating. Ensuring reliable and uninterrupted communication in these systems is essential for situational awareness and defensive operations.

Challenge:

Armored vehicle turret systems are exposed to harsh operating conditions, including extreme vibrations, shock from movement, and high electromagnetic interference (EMI) from the vehicle’s own systems, such as communication radios, radars, and weapon systems. The turret’s continuous rotation introduces the challenge of maintaining a stable signal transfer while protecting against interference that could disrupt real-time decision-making.Grand Slip Rings Solution:

Grand Slip Rings’ Through Hole Slip Rings and High-Speed Slip Rings were deployed in this scenario. These slip rings feature EMI shielding and high-speed data transfer capabilities that maintain uninterrupted signal transmission in the presence of high EMI and vibration.- Anti-Interference Design: Our slip rings feature robust EMI shielding to prevent disruption from the armored vehicle’s electromagnetic environment. This ensures continuous and accurate signal transmission between the turret and control systems, even under intense interference.

- Vibration and Shock Resistance: Designed to comply with MIL-STD-810 shock and vibration resistance standards, these slip rings can handle the mechanical stresses experienced in mobile military vehicles without failure.

Result:

The integration of Grand Slip Rings in the turret system ensured uninterrupted communication, precise control of the turret’s movement, and stable data exchange, even in the harshest combat environments.

Case Study 2: FORJ in UAVs – Ensuring Uninterrupted Communication in High-EMI Environments

Application Overview:

Unmanned Aerial Vehicles (UAVs) are frequently used in military surveillance, reconnaissance, and communication roles. These UAVs must transmit large amounts of data in real-time, including video feeds, sensor data, and control signals. UAVs often operate in environments where electromagnetic interference (EMI) from other communication systems, radar, or jamming systems can disrupt signal integrity.

Challenge:

In high-EMI environments, such as electronic warfare zones or crowded airspace with multiple communication systems, ensuring secure, uninterrupted communication is crucial for the UAV’s success in its mission. Conventional slip rings may suffer from EMI, leading to signal degradation or failure.Grand Slip Rings Solution:

Grand Slip Rings’ Fiber Optic Rotary Joints (FORJ) were chosen for this application due to their ability to transfer data with zero EMI interference. By integrating FORJs into the UAV’s communication system, the UAV can transmit and receive high-bandwidth data without being affected by external electromagnetic fields.- Zero-Interference Signal Transmission: The fiber optic design of the FORJ ensures that there is no risk of electromagnetic interference, guaranteeing clean and uninterrupted data transmission.

- High-Bandwidth Capability: FORJs allow the UAV to handle large amounts of real-time data, including high-definition video and sensor data, which is critical for surveillance and reconnaissance operations.

Result:

By using Grand Slip Rings’ FORJ technology, the UAV was able to operate reliably in high-EMI environments, providing real-time data transfer without disruptions. The system’s resilience to interference ensured successful mission execution, even in contested electromagnetic environments.

Case Study 3: Waterproof Slip Rings for Naval Systems – Combining Military-Spec O-Rings with EMI Shielding

Application Overview:

Naval systems, such as radar arrays, communication systems, and sonar devices, often require slip rings that can withstand harsh marine environments, including exposure to water, salt, and corrosion. These systems also need to maintain reliable data and power transmission even while rotating or moving in dynamic environments.

Challenge:

Naval platforms face extreme environmental conditions, including saltwater exposure, high humidity, and potential submersion. Additionally, these systems must operate in environments with high EMI from other onboard equipment and external sources. The slip rings must be able to withstand corrosion while providing interference-free data transmission.Grand Slip Rings Solution:

Grand Slip Rings’ Waterproof Slip Rings, equipped with military-spec O-rings and EMI shielding, were selected for this application. These slip rings feature IP68-rated seals that prevent water ingress, making them ideal for use in submarines, ships, and other marine systems.- Waterproof Design: The IP68-rated waterproof slip rings are designed to withstand prolonged submersion in water, ensuring reliable operation even in underwater environments, such as those encountered in naval systems.

- EMI Shielding: To address the risk of electromagnetic interference, these slip rings feature advanced EMI shielding, which protects the communication systems and radar arrays from disruption.

- Corrosion Resistance: Military-spec O-rings and corrosion-resistant housings (made from stainless steel or aluminum) ensure the slip rings can endure exposure to saltwater and other corrosive elements, maintaining functionality over extended periods of operation.

Result:

The waterproof slip rings with EMI shielding successfully supported continuous, interference-free operation of the naval systems, even in the challenging marine environment. The durable design ensured long-term reliability, reducing maintenance costs and downtime for the naval fleet.

These case studies highlight the versatility and reliability of Grand Slip Rings in real-world military applications. Whether in armored vehicles, UAVs, or naval systems, our slip rings provide critical anti-interference capabilities, robust protection against environmental challenges, and continuous, high-quality data transmission. With each solution tailored to meet the specific needs of the defense industry, Grand Slip Rings ensures the success of mission-critical operations in even the harshest conditions.

Why Choose Grand Slip Rings for Your Military Applications

When it comes to mission-critical military systems, reliability, durability, and precision are paramount. Grand Slip Rings has earned a reputation for providing high-quality, military-grade slip rings that meet the rigorous demands of defense and aerospace industries. Below, we highlight why Grand Slip Rings should be your go-to partner for military slip ring solutions.

Proven Track Record in Defense

Grand Slip Rings has been a trusted provider of advanced slip ring solutions for military and aerospace applications for decades. Our extensive experience has enabled us to become a reliable supplier to top defense contractors and agencies worldwide.

Decades of Experience in Military and Aerospace Industries:

With years of expertise in designing and manufacturing military-grade slip rings, we understand the complex and varied needs of defense systems. Whether for ground vehicles, naval platforms, or aerospace systems, our slip rings have proven to be reliable and effective in the most demanding environments.Successful Deliveries for High-Stakes Defense Projects:

We have a strong track record of delivering slip rings for critical defense systems, from missile guidance systems to radar arrays and electronic warfare platforms. Our products are integral components of many high-profile military programs, ensuring that the systems they support function seamlessly in operations where failure is not an option.Testimonials from Top Defense Contractors and Agencies:

We take pride in the testimonials and repeat business from leading defense contractors and government agencies who have trusted Grand Slip Rings for their military applications. Our clients value our commitment to quality, timely delivery, and the performance of our slip rings in complex, high-risk environments.

Customization and Adaptability

Every military platform has its unique set of requirements, and at Grand Slip Rings, we understand that a one-size-fits-all approach does not work for mission-critical systems. That’s why we offer tailored slip ring solutions designed to meet the exact needs of each military application.

Tailored Solutions for Unique Military Platforms and Environments:

Whether you’re working with unmanned vehicles, submarines, radar systems, or mobile command centers, we offer slip rings that are custom-engineered to meet the specific demands of each platform. We take into account factors such as space limitations, environmental conditions (extreme temperatures, moisture, pressure), vibration, EMI/EMC concerns, and data transmission requirements.Collaboration with Clients for Perfectly Tailored Designs:

We work closely with our clients, from initial consultation to product deployment, to ensure that the slip ring solution is fully optimized for their systems. Our engineers collaborate with your team to understand your technical specifications and operational environment, ensuring that every aspect of the design aligns with the mission’s objectives. Whether it’s a hybrid fiber optic slip ring for high-speed data transfer or a rugged, waterproof slip ring for naval operations, we adapt our solutions to your precise needs.Innovative and Flexible Designs:

Our ability to innovate and develop custom solutions sets us apart from other suppliers. We are capable of designing slip rings that combine power, data, and fiber optics in a single compact unit, perfect for advanced systems like UAVs, satellite communications, and missile guidance. We also offer specialized slip ring designs, such as through-hole configurations for surveillance platforms or high-speed models for radar antennas.

Why Grand Slip Rings?

Reliability in Mission-Critical Systems:

Our slip rings are designed to deliver consistent performance even in the harshest environments. From high-speed data transmission to low-noise designs for missile guidance, every product is engineered to meet military-grade standards and ensure mission success.Long-Term Durability and Performance:

Grand Slip Rings products are built to withstand extreme conditions, including shock, vibration, corrosion, and electromagnetic interference. Our products are rigorously tested to ensure that they operate reliably over extended periods, reducing maintenance costs and downtime for military systems.Comprehensive Support and Expertise:

In addition to providing high-quality slip rings, we offer comprehensive support to ensure that our solutions integrate seamlessly into your system. From design consultation to post-installation support, our team is here to assist at every step.

Grand Slip Rings is the trusted partner for military applications, offering decades of experience, a proven track record, and a commitment to delivering customized, adaptable solutions. Whether you need a slip ring for a ground-based defense system, an aerospace platform, or a naval application, we are ready to provide the perfect solution to ensure your mission’s success.

The Future of Military-Grade Slip Ring Anti-Interference Design

As military technology continues to evolve, the demand for advanced, high-performance slip rings grows. To keep pace with the evolving needs of modern defense systems, military slip ring technology is undergoing significant advancements. These developments focus on making systems more efficient, compact, and capable of handling complex data streams. At Grand Slip Rings, we are committed to being at the forefront of these innovations, ensuring that our products continue to meet the demanding needs of future defense applications.

Emerging Trends in Military Slip Ring Technology

The landscape of military operations is rapidly changing, and with it, the technologies that support these operations. The following are key emerging trends in military slip ring technology:

Integration with Advanced Digital Communication Systems:

- As digital communication systems become more complex and essential in military operations, slip rings must evolve to handle high-bandwidth, real-time data transmission. The future of slip rings lies in their ability to support these advanced communication systems, such as secure satellite communications, high-definition video feeds, and real-time sensor data processing.

- Fiber Optic Integration: One significant trend is the integration of fiber optic channels in military slip rings. By combining power and fiber optics in a single unit, these slip rings enable fast, interference-free data transfer, crucial for the modern battlefield where communication and data integrity are paramount. Military systems that rely on high-speed, high-frequency data—such as UAVs, drones, and radar arrays—require slip rings capable of supporting these intense data demands.

Development of Smaller, Lighter, and More Efficient Slip Rings for Modern Defense Applications:

- As military equipment becomes more compact and mobile, the demand for smaller, lighter slip rings that do not sacrifice performance is growing. Military systems, especially those on unmanned aerial vehicles (UAVs), robotic systems, and wearable technologies, require slip rings that are not only compact but also energy-efficient.

- Miniaturization and Space Efficiency: Slip rings are being designed to occupy less space while offering increased performance. This trend toward miniaturization is essential for applications in aerospace and advanced mobile systems, where every ounce of weight counts and space is limited.

- Energy Efficiency and Low Power Consumption: As military systems aim for energy efficiency, slip rings are being developed with features that reduce power consumption while maintaining high levels of reliability and performance. This is particularly important for long-duration missions, such as those in satellite systems and UAVs, where power conservation is critical.

Grand Slip Rings’Role in Future Defense Systems

At Grand Slip Rings, we are dedicated to staying ahead of these trends by continually innovating and evolving our products. Our ongoing research and development efforts are focused on meeting the ever-changing requirements of modern military systems, ensuring that we provide the most advanced and reliable slip rings for future defense applications.

Ongoing Research and Development to Meet Evolving Military Requirements:

- We continuously invest in research and development to enhance the capabilities of our slip rings. As new defense technologies emerge, we strive to integrate cutting-edge materials, designs, and technologies into our slip rings to ensure that they remain at the forefront of military applications.

- Collaboration with Military Partners: We work closely with defense contractors, engineers, and military agencies to ensure that our slip rings meet the specific needs of each program. Our R&D efforts focus on developing innovative solutions that address the challenges posed by new defense technologies and operational environments.

- Adapting to Technological Advancements: As military systems become more autonomous and complex, such as the integration of AI in defense platforms and the development of hypersonic systems, we are adapting our slip ring technologies to support these advanced systems. This includes developing high-speed, high-capacity slip rings capable of supporting AI-based sensor networks, real-time communications, and rapid data processing.

Focus on Miniaturization and Enhanced Performance in Next-Gen Military Equipment:

- The next generation of military systems, such as autonomous vehicles, smart weapons, and advanced robotics, will demand even more efficient and high-performance slip rings. Grand Slip Rings is already at the cutting edge of miniaturization, creating ultra-compact slip rings that provide high reliability in tight spaces without compromising on power or signal integrity.

- Advanced Materials and Technologies: We are exploring the use of advanced materials, such as carbon nanotubes, graphene, and other high-performance composites, to further enhance the performance of our slip rings. These materials will enable us to reduce the size of slip rings while improving their durability, reliability, and performance in extreme environments.

- Enhanced Data Transfer and Power Handling: As military systems require higher bandwidth and more power-efficient solutions, we are developing slip rings that can simultaneously handle high-speed data transmission and power delivery. This will be crucial for next-gen defense systems like drones, satellite communication systems, and electronic warfare platforms, where simultaneous power and data flow is essential.

The future of military slip rings is focused on advancing the performance, efficiency, and adaptability of these critical components. At Grand Slip Rings, we are committed to driving innovation to meet the evolving demands of the defense industry. From the integration of fiber optics for high-bandwidth data transmission to the miniaturization of slip rings for more compact systems, we are preparing for the next generation of military technology. Our continuous R&D efforts ensure that we remain a trusted partner in delivering cutting-edge solutions that support mission success and military readiness for years to come.

See What We Can Do