As our era becomes increasingly dominated by technological progress, with a particular emphasis on equipment and systems revolving – literally and metaphorically – around movement and rotation, a small but crucial component has become particularly important: the modular slip ring.

Modular slip rings are sophisticated electrical devices that allow for the transmission of power and data between stationary and rotary parts of a system, thereby enabling the smooth functioning of equipment that requires rotation. Virtually unseen yet profoundly important, these components form the backbone of numerous systems spanning a myriad of industries.

From wind power generators, where they allow for the transfer of electricity from the constantly rotating turbine to a static grid, to medical equipment like CT scanners, which rely on the rotation of the scanner around the patient – modular slip rings play an integral role. Their far-reaching applications also extend into fields including but not limited to defense mechanisms, telecommunications, and industrial manufacturing processes.

But what makes the slip rings ‘modular’? The term ‘modular’ comes from the inherent design flexibility of these components. Unlike their conventional counterparts, modular slip rings offer versatility, being able to cater to varying power and signal transmission needs precisely and conveniently by adding or removing modules as required.

Essentially, the broader context and immense significance of modular slip rings lie in their ability to support the continuous operation of rotational systems – an element foundational to modern technological applications. As the pivotal linchpin in enabling unbroken, unrestricted rotational mobility, the modular slip ring facilitates countless modern-day operations that are core to our civilization’s infrastructure.

As we delve deeper into the facets and implications of modular slip rings, a greater understanding of their context in modern technology applications is gained, reinforcing their undeniable significance seasoned with the potential for technological advancements.

Understanding Modular Slip Rings

At their core, modular slip rings are specialized electromechanical devices that facilitate the transmission of power, electrical signals, and data between stationary and rotating components in a broad range of equipment. The incorporation of a modular slip ring eliminates the need for wires that may otherwise become tangled and cause hindrances during continuous rotation. As a result, the equipment can operate uninhibited, bolstering efficiency.

Modular slip rings comprise a series of electrically conductive rings and brushes, wherein, the brushes slide over the rings as the machine rotates. Here, the brushes maintain electrical contact, stiffly riding on the rings and transmitting electrical current from the stationary part to the rotating part. This central function enables the perpetual transmission of power and data regardless of the angle of rotation.

What sets modular slip rings apart from conventional slip rings is their inherent design versatility. Consisting of separate modules – each with varying power, signal, and data transmission capabilities – the modular slip rings can be easily stacked, customized, and rearranged to meet the requirements of a wide array of applications. This modular design permits precise customization according to the users’ needs, offering unmatched adaptability that cannot be delivered by traditional slip rings. In addition, certain modular slip rings integrate advanced features, such as fibre-optic rotary joints, which cater to the demand for high-speed data communication in contemporary systems.

Understanding the operation and distinctive characteristics of modular slip rings is instrumental in appreciating their rightful place within the vast domain of modern technology applications. This comprehension sheds light on the importance of modular slip rings and how they stand out, not only as an improvement of conventional slip rings but also as an essential component in the future of technology and industry.

Applications of Modular Slip Rings

The versatility of modular slip rings enables their broad application across numerous industries, solidifying their global demand. Because they ensure uninterrupted transmission of power and data between rotating and stationary parts, modular slip rings are integral to any system where smooth, continuous rotation is necessary.

Equipment in the renewable energy sector, particularly wind turbines, heavily relies on modular slip rings. Wind turbines must continuously adjust their blades to capture the changing wind direction for optimal energy generation. The slip rings allow for this rotation while transmitting generated power from the constantly moving parts to the static utility grid.

Within the field of medicine, modular slip rings play a crucial role in advanced imaging systems, such as MRI and CT scanners. These systems need to rotate around the patient to create a detailed and comprehensive image of the body’s interior. Modular slip rings enable this rotation while providing steady power and signal transmission, resulting in high-resolution output images.

In the defense sector, especially within radar systems, modular slip rings are a powerful asset. These systems require rotational elements to transmit and receive signals in all directions. This is where modular slip rings come into play, allowing radar antennas to revolve freely and consistently, ensuring precision and reliability of data, crucial in critical missions.

Robotics is another field that harnesses the power of modular slip rings. Robots often involve moving parts that should work synchronously while maintaining electrical connections. Modular slip rings thus ensure the uninterrupted operation of the robots while promoting their adaptability to various tasks.

These real-world examples underscore the broad-ranging impact of modular slip rings across multiple sectors. Their diverse applications demonstrate how these essential components are integral to a host of crucial technologies and industries, bringing practicality and advancement to our day-to-day lives. The intensive use of modular slip rings is a testament to their reliability, adaptability, and essential role in powering a significant portion of today’s emerging technologies.

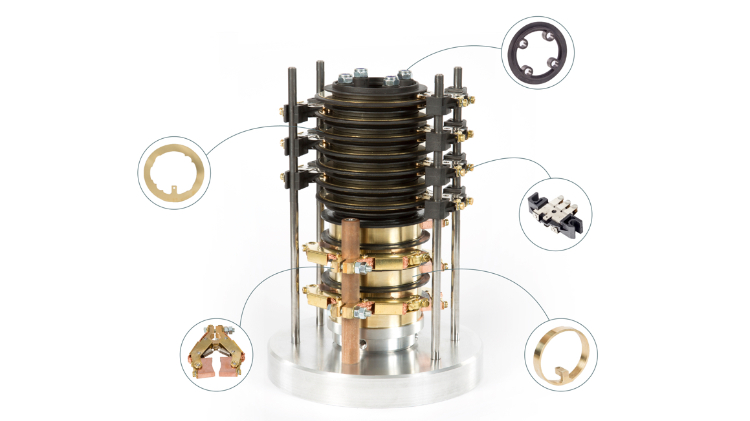

Design and Structure of Modular Slip Rings

The modular slip ring design is a pinnacle of technical innovation, seamlessly marrying function and flexibility. A basic modular slip ring is typically made up of two primary components: the rings and the brushes. The rings are conductive circles typically made of copper or other conductive metals, whereas the brushes, made up of precious metals or graphite, maintain sliding electrical contact with the rings.

The magic of the modular design comes alive in its unique assembly. The slip ring unit comprises multiple independent modules stacked together, each tailoring to a specific signal or power transmission need. Each module corresponds to a pair of a ring and a brush, forming a separate electrical path. These modules can easily be added or removed depending on the needs of the application.

This design flexibility enables modular slip rings to meet an extensive range of technical requirements. Whether a system needs higher current transmission, faster data transfer, or protected signal paths, these needs can be met by selectively combining the appropriate modules. Further, their stackable nature allows them to fit within varying spatial constraints, making them adaptable to use in diverse devices and systems.

For example, a modular slip ring intended for a wind turbine would require modules that can handle high current transmission, given their purpose of transferring generated power from the turbine rotor to the static electrical grid. Meanwhile, a slip ring for a defense radar system may integrate modules for secure signal transmission, given the sensitive nature of data in such applications.

It is this intrinsic design and structural flexibility that sets modular slip rings apart from their traditional counterparts and contributes significantly to their broad adaptability. This understanding of their design intricacies helps us appreciate their invaluable role in aligning technology applications to the ever-evolving demands of the modern world.

Benefits and Advantages of Modular Slip Rings

The invention of modular slip rings marked a new dawn in addressing the limitations of traditional slip rings. With their advanced design and superior functionality, modular slip rings offer numerous benefits over standard alternatives.

One of the most significant advantages of modular slip rings is their adaptability. Unlike standard slip rings, which have a single-built design, modular slip rings can be easily customized. Made up of various interchangeable modules, they offer the freedom to increase or decrease their size, add or subtract channels, or modify the type of transmissions – electrical, data, or signals – as required.

Another key benefit offered by modular slip rings is their superior performance. Owing to their enhanced design, these types of slip rings are capable of facilitating high-speed data transfer and uninterrupted power transmission whether in a stable environment or under high-speed rotation. They also offer better contact performance thanks to the use of advanced materials, ensuring superior function against a wide range of environmental conditions.

Modular slip rings are also more durable and require less maintenance compared to traditional types. Due to their customizable nature and the module’s ability for replacement, it is easier to replace a single, specific defective module instead of having to replace the entire assembly, as is the case with non-modular types.

From a cost perspective, modular slip rings shine in their competency. While their initial cost could be higher, their long-term maintenance, repair, and replacement costs are significantly lower than traditional slip rings. This results due to their modular nature, making single-part replacement and upkeep more manageable and cost-efficient.

Compared to other types of slip rings, the benefits of modular slip rings are unequivocal in their performance, reliability, flexibility, and cost-effectiveness. This set of advantages not only makes them a superior technological choice but also paves the way for innovative applications across various industrial sectors, thus echoing their far-reaching benefits and vast potential.

Factors to Consider when Choosing a Modular Slip Ring

Choosing a modular slip ring for a specific application might seem complex due to the myriad options available. However, certain key factors can guide this decision-making process, simplifying the selection and ensuring the best fit for the intended application.

For starters, one must consider the type and number of signals or data types the slip ring needs to transfer. This factor is largely determined by the nature of the application. For instance, a slip ring for a radar system would need modules supporting high-frequency data transmission, whereas a wind turbine application may require modules that can manage high electrical currents.

Secondly, the environmental conditions under which the slip ring will operate are pivotal. Modular slip rings can be designed to withstand a wide range of temperatures, humidity levels, and frequencies. Therefore, assessing the environmental requirements — such as whether the application is indoor or outdoor, subjected to extreme heat or cold, high humidity, or exposure to dust and dirt — ahead of time will guide an appropriate selection.

Durability and maintenance requirements are other important considerations. Modular slip rings designed with robust materials and a provision for easy module replacement can enhance the device’s lifespan while reducing the time and cost associated with maintenance. Some modular slip rings also include a built-in testing mechanism for quick diagnosis and potential module malfunctions, further contributing to ease of maintenance and longevity.

Lastly, cost should be taken into account. While modular slip rings may have a higher initial price, their customizable nature and enhanced durability can lead to lower long-term maintenance and replacement costs, making them a more cost-effective solution in the long run.

By keeping these considerations in mind — the nature of the application, the operating environment, durability and maintenance requirements, and cost — users can efficiently determine the most suitable modular slip ring for their specific needs. This understanding aids users in leveraging the full potential of modular slip rings, benefiting from their versatility, performance, and value, and propelling their operations towards greater efficiency and success.

Modular Slip Rings Installation and Maintenance Guide

Correct installation and maintenance of a modular slip ring have a significant impact on its performance and lifespan. Here is a simple guide to assist users in both practices:

Installation:

- Unboxing: Begin by carefully unpacking the new modular slip ring. Verify all the elements are present, undamaged, and match the product specifications.

- Preparation: Identify a suitable placement for the slip ring that allows for unobstructed rotation and easy access for eventual maintenance. Ensure that the host equipment is powered off as a safety measure.

- Mounting: Carefully mount the stationary part of the slip ring — usually the base with the wire leads — onto the fixed section of the host system. Use the appropriate fixing methods, such as screws or clamps, according to the user manual.

- Connection: Connect the rotating part (often the part with the ring) of the slip ring with the spinning component of the host machine. Ensure that it is secured properly to allow smooth rotation.

- Wiring: Wire up the slip ring, adhering to the instructions provided in the user manual. Make sure to match the wire color or numbering with that of the host system.

- Initial Operation: Once all the connections are set, switch on the host equipment cautiously, checking for regular rotation and any signs of malfunction.

Maintenance:

- Periodic Checks: Conduct regular inspections for any signs of wear or damage on the brush contacts or rings. Monitor for unusual noises or shakiness during operation.

- Cleaning: Use an approved cleaning solution and a non-abrasive cloth to clean the unit. Regularly clean the contacts to remove accumulated carbon dust or debris.

- Component Replacement: If any module in the slip ring is malfunctioning, it can and should be replaced. Follow the user manual instructions or consult a professional for this task.

- Lubrication: Certain models might require periodic lubrication. For these, use the manufacturer-recommended lubricant to reduce friction and extend the lifespan of the unit.

- Documentation: Keep track of all maintenance activities to help predict possible future issues and develop a preventative maintenance schedule.

Following these simple steps and best practices enhances the lifespan and performance of modular slip rings. Over time, with regular checks and occasional troubleshooting, users might find that their modular slip rings are as resilient and essential as any other major component of their equipment.

Modular Slip Rings Industry Leaders and Popular Brands

In the landscape of modular slip ring manufacturers, several companies have established themselves as reliable industry leaders. Here’s a comparison and review of some popular brands, looking at the strengths, weaknesses, and unique offerings of each.

| No. | Manufacturer | Website |

|---|---|---|

| 1 | Hangzhou Grand Technology | https://www.grandslipring.com/ |

| 2 | Moog Inc. | https://www.moog.com/ |

| 3 | Stemmann-Technik | https://www.stemmann.com/en/home |

| 4 | Schleifring | https://www.schleifring.com/ |

Hangzhou Grand Technology

Hangzhou Grand Technology Co., Ltd. started as a special slip ring manufacturer in 2011. Grown into slip rings, rotary joints, and slip ring assembly experts of today with 6,000 square meter manufacture complex.

Obtained ISO9001, Rosh, CE, and GJB9001B certificates a number of slip rings, rotary joint patents, and proud of our products can meet military grade. Collaborated with universities, institutes, and renowned factories across Asia and Europe including Panasonic, SIEMENS, CSIC, SAMSUNG, HUAWEI, etc.

Moog Inc.

Moog is a leading supplier of high-performance slip rings for various industries, including aerospace. Among their offerings, Moog’s SR Series Slip Rings are designed for the demanding environments of helicopters, excelling in performance, reliability, and customization potential.

Stemmann-Technik

Stemmann-Technik, a part of the Conductix-Wampfler Group, offers a broad range of slip rings, including solutions for helicopters. Their Livietta Slip Ring Assemblies are designed explicitly for harsh and demanding environments in the aviation sector, providing reliable signal and power transmission.

Schleifring

Schleifring is a well-known manufacturer of electromechanical systems, including slip rings customized for various industries. Their Aircraft Slip Rings cater specifically to helicopters, offering robust performance, low wear, and high reliability to meet the challenges of aviation applications.

If you want to know more about other slip ring manufacturers, you can read Top 10 Slip Ring Manufacturers in China, Top 10 Slip Ring Manufacturers In the USA Market 2023, and Top 10 Slip Ring Industry Key Manufacturers 2023.

The Future of Modular Slip Rings

The modular slip ring industry is rapidly evolving, driven by technological advancements and increasing demand for sophisticated communication and power transfer solutions. Looking ahead, several trends and upcoming progressions are likely to shape the future of modular slip rings.

Wireless Data Transmission:

As technology advances toward wireless systems, slip rings are also expected to incorporate wireless data transmission capabilities. This technology will allow data to be transferred without the need for physical contact, reducing wear and tear and the subsequent maintenance requirements.

Integration of Sensors:

The integration of sensor technology into modular slip rings could be the next significant development. Sensors can provide real-time status updates, health monitoring, and early failure detection of the slip rings, ultimately improving their reliability and operational efficiency.

Higher Speeds and Data Rates:

As the need for fast, reliable data transfer continues to grow, so does the demand for slip rings capable of handling higher speeds and data rates. Future modular slip rings are expected to take on this challenge, offering advanced solutions capable of handling high-speed digital data transmission.

More Compact Designs:

As space comes at a premium in many applications, the push for more compact, lightweight, and efficient slip ring designs is apparent. The future may see the emergence of micro-modular slip rings, providing the same capabilities as their larger counterparts but in much smaller footprints.

Eco-Friendly Materials:

With sustainability becoming a significant concern, the use of eco-friendly materials in manufacturing modular slip rings is likely. This shift not only reduces environmental impact but can also enhance product life and performance.

In summary, the future of modular slip rings is bright, with promising advancements on the horizon. These future adaptations aim at making them more efficient, reliable, and fitting for an increasingly digital and eco-conscious world. As technology continues to advance, the modular slip ring is well-positioned to meet the evolving requirements of various industries, thus solidifying its indispensable role.

Looking for a specific slip ring solution? Let us know your requirements through this form.

Conclusion

Understanding the operation, benefits, and future trends of modular slip rings is key for anyone involved in selecting or maintaining them. As the demands of modern technologies evolve, modular slip rings will continue to adapt, serving a wide variety of applications across diverse industries.