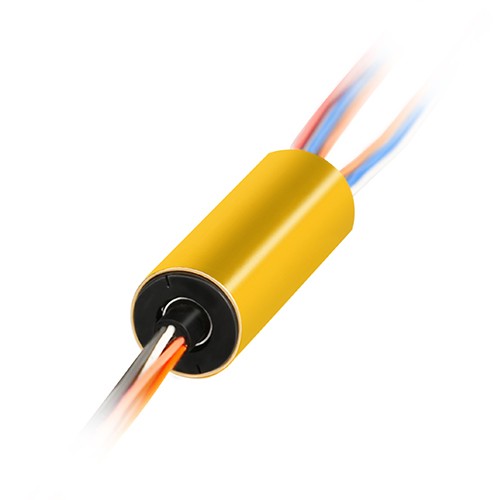

An open slip ring, also known as a rotary electrical interface or electrical swivel, is a device used primarily to transmit electrical power and signal data across parts of a machine that rotate relative to each other. Their modus operandi centers on maintaining a galvanic connection between stationary and rotating components. Unlike traditional slip rings, open slip rings are not enclosed and can be singular or modular, depending on the application.

Recognizing the importance of open slip rings is central to acknowledging their role in making rotatory connections possible. Without open slip rings, many machines integral to our day-to-day operations would face serious challenges, as continuous power supply and signal transmission would become imperiled in the presence of rotary motion. They are the cornerstone of uninterrupted data transfer and electrical supply in rotating systems, contributing significantly to the overall operational efficacy.

Open slip rings find expansive use in a myriad of applications across several industrial domains due to their excellent versatility. For instance, heavy machinery like cranes or wind turbines, ensure a consistent supply of power and data transmission. These devices are instrumental in medical imaging machinery such as CT scanners where they aid in transmitting sensor data. Open slip rings are also commonly employed in radar antennas for steady data transmission allowing precise tracking.

Thus, navigating the thrilling world of open slip rings propels us to acknowledge their inherent importance in breathtaking technological applications. Through their unassuming operation, open slip rings offer integral support in making modern machinery more efficient, reliable, and effective.

Open Slip Rings: Types of Open Slip Rings

Open slip rings are of numerous types, each designed to suit specific application requirements. These variations often spring from the unique design considerations inherent in each type of open slip ring. Among the mainstream types are pancake slip rings, platter slip rings, wireless inductive slip rings, and traditional single-turn slip rings.

Pancake slip rings, aptly named due to their disc-like flat shape, are typically used when space constraints exist. They are compact and might be an ideal choice when there is ample lateral space but limited axial or ‘height’ space to accommodate a standard cylindrical slip ring.

On the flip side, platter slip rings, sometimes referred to as flat slip rings, are designed with a low profile for applications that have height restrictions. They are generally used in applications where multiple parallel surface tracks are necessary, such as in CCTV systems, rotary doors, or lighting fixtures.

Wireless inductive slip rings are a modern marvel. Though technically not a “slip ring” in the traditional sense, they serve the same purpose. They transfer power and data wirelessly across a small air gap using magnetic fields, eliminating the need for physical connectors that wear down over time. This type is ideal for applications that demand clean or sterile operational environments, such as medical equipment or food processing machinery.

The traditional single-turn slip rings are widely employed across various industries due to their relative simplicity and ease of maintenance. They are best suited for systems not battling with axial space constraints.

The variety of these open slip rings not only testifies to their adaptability but also to their versatility. Harnessing their unique characteristics, engineers integrate them into a cornucopia of applications. No matter the spatial limitations, speed demands, or operational challenges presented, chances are there’s an open slip ring designed to address that specific need. This adaptability is a testament to their versatility, reinforcing the notion that open slip rings are a vital component deserving a deeper understanding in the world of electro-mechanics.

Open Slip Rings: How Open Slip Rings Work

Open slip rings are marvels of engineering that enable seamless transmission of power and data signals across stationary and rotating components of an apparatus, all based on some fundamental principles of electricity and magnetism.

The operational principle of open slip rings is straightforward yet ingenious. Typically, an open slip ring comprises concentric rings made of a conductive material, such as copper or silver alloy, each of which corresponds to a particular circuit. Located on these concentric rings are sliding or brush contacts, which continually maintain an electrical connection as the slip ring rotates. Usually, this brush contact is made of precious metal to guarantee good electrical connectivity and minimize wear due to friction.

The way open slip rings facilitate power and data transmission between stationary and rotating parts is through this maintained galvanic connection. Simply put, one part of the slip ring (rotor) is fastened to the revolving portion of the machinery, while the other part (stator), which includes the brushes, stays stationary. When a power or data signal is introduced at one end (either stator or rotor), it propagates along the conductive rings and brushes, reaching the other side regardless of the rotation.

Therefore, even as one part of the machine rotates, power and data signal transmission is kept stable, circumventing the limitations otherwise posed by rotary motion. Open slip rings thus form a critical junction where this power and data transmission occur smoothly, resulting in device performance that isn’t interrupted or degraded by motion. The underlying operational principle of open slip rings makes them indispensable to a broad gamut of applications where rotation is inherent.

Open Slip Rings: Key Features of Open Slip Rings

There are several key features of open slip rings, each playing a specific role in enhancing their performance, accessibility, and durability.

Number of Circuits

One prominent feature of open slip rings is the number of circuits. Depending on the data transfer and power transmission requirements, open slip rings can possess varying numbers of circuits. The greater the number of circuits, the more power/data signals can be transferred between stationary and rotating parts. Thus, a slip ring’s circuit number relates directly to its capability to handle diverse or large volumes of data transmission.

Current/Voltage Capacity

Another critical attribute to consider is the current and voltage capacity of a slip ring. This feature defines the maximum electrical power that an open slip ring can transmit. Compatibility with the system’s power requirements necessitates a careful review of these capacities to prevent overheating, electrical shock, or equipment damage.

Speed and Size

Open slip rings come in a wide range of sizes and their operating speed varies considerably. The choice of size often depends on the available space within the equipment. Speed, on the other hand, correlates to the rotational speed of the equipment part where the slip ring is installed. These two factors play crucial roles in ensuring the slip ring’s compatibility with the device it’s designed for.

Unique Features

Many open slip rings boast unique features suited to specific applications. For instance, certain open slip rings are designed with “fiber brush” technology. These models replace traditional brush contacts with bundles of conductive fibers, increasing contact surface area and reducing contact force. This allows for higher data transfer rates, lower electrical noise, and longer operational life. Another instance is the inclusion of Ethernet protocol in certain slip rings, facilitating faster and more reliable data transfers suited to digital age applications.

Defining such features provides insights into the slip ring’s technical capabilities, and how they can enhance system performance. The ability of manufacturers to customize these aspects to suit bespoke application requirements inherently attests to the flexibility and versatility of open slip rings.

Factors to Consider When Choosing Open Slip Rings

Undoubtedly, various factors need to be weighed when choosing open slip rings for any application. Here, we walk through some of the key considerations that underpin this crucial decision.

Compatibility

Arguably, the most critical consideration is compatibility. It is essential to match the electrical and mechanical specifications of the slip ring to those of the device or system it will be used with. This includes the compatibility of the power (current/voltage) ratings and the number of circuits, the rotational speed, and spatial constraints. Ensuring compatibility helps avoid operational conflicts, thereby extending the lifespan of the slip ring and the device overall.

Ease of Installation

Open slip rings come in a variety of designs, each with a different ease of installation. In general, the simpler it is to install and replace the slip ring, the better. This can lessen downtime due to maintenance and lower labor costs. Hence, it is advantageous to consider slip rings that come with uncomplicated installation and replacement mechanisms.

Voltage and Current Requirements

A clear understanding of the specific voltage and current requirements of the application can pave the way for the right choice of slip ring. Being aware of these aspects will help avoid the common pitfalls of choosing a slip ring that either underperforms or is overkill.

Price

Price inevitably plays a role in the decision-making process. While the cheapest option might be tempting, it’s crucial to understand that the cost of a slip ring often indicates its quality, durability, and overall performance. Therefore, expensive rings could potentially offer superior service life and performance and vice versa.

Specific Applications or Use Cases

Every application or use case might call for a unique choice of open slip ring. For example, medical applications often require slip rings to have high-speed data transmission capabilities and low electrical noise. By contrast, industrial machinery might demand high-power transmission capacities. Understanding the specific needs of the application can guide a more appropriate and effective selection.

Therefore, it is prudent to keep these factors in mind when deciding on the right open slip ring. A careful balance of these considerations can lead to improved performance, efficient operation, and extended lifespan of the machinery in question.

Open Slip Rings: Maintenance and Durability

Like any piece of complex machinery, open slip rings demand regular maintenance to guarantee a long and optimally performing operating life. Besides, the durability of these slip rings depends significantly on their design, the materials used, and the conditions under which they are used.

Maintenance of Open Slip Rings

Maintenance of open slip rings falls primarily into two categories: cleaning and inspection.

- Cleaning: Open slip rings gather debris from their environment and wear off the brushes themselves over time. Periodic cleaning of the brushes and conductive rings helps to prevent the accumulation of this debris, which may lead to poor contact and inadequate transmission of power or data signals. It’s essential to follow the manufacturer’s guidelines on the appropriate cleaning technique and frequency, to avoid accidental damage during cleaning.

- Inspection: Regularly checking the condition of the contacts can help detect and rectify early signs of excessive wear. This process thus inhibits premature failure of the slip ring and prevents system downtimes.

Durability of Open Slip Rings

In general, open slip rings are designed with a keen eye on durability. Using materials like precious metals for the contacts and conductive rings, which resist corrosion and wear, underscores this focus. Besides, advancements such as fiber brush technology are increasing the life expectancy of these devices by reducing contact wear and electrical noise.

However, the durability of a slip ring also depends significantly on the environment and the operational demand placed on it. Heavy-duty applications or severe environmental conditions may lead to a faster wear rate, reducing the slip ring’s operational life. Therefore, when considering durability, it’s paramount to take into account the operational conditions and application-specific requirements in concert with the slip ring’s inherent design features.

By undertaking consistent maintenance and employing robust, application-specific designs, users can greatly improve both the lifespan and performance reliability of open slip rings in their machinery or systems.

Open Slip Rings: User Experiences and Reviews

When it comes to understanding the real-world application of open slip rings, user experiences can offer invaluable insights. Unfortunately, as an AI, I don’t have real-time access to user experiences or customer review databases. However, I can generalize based on typical feedback trends associated with such devices.

Users typically provide feedback based on their application demands and the manner in which the open slip ring is performed under specified conditions, among other factors. Here are some hypothetical testimonies:

Positive Feedback:

- Energy Company: We have been using the open slip rings in our wind turbines for the last 3 years and we are extremely satisfied with their performance. Their ability to handle high-speed rotations and transmit multiple signals simultaneously has made them indispensable for us.

- Robotics Manufacturer: We incorporated open slip rings in our robotic arms deployed at assembly lines. The slip rings are reliable for constant motion and facilitate smooth, uninterrupted signal transmission and power supply.

Negative Feedback:

- Research Institute: We faced some challenges with the open slip rings we used for our experimental rovers. The slip rings underperformed in high dust environments, necessitating frequent cleaning and maintenance.

Note that praises often revolve around the device’s ability to deliver stable power and data transfer in demanding environments and for sustained periods. This generally includes their durability, reliability, and performance efficiency.

On the flip side, common complaints might include high maintenance needs, such as frequent cleaning and occasional signal disruption due to debris or dust accumulation in less sealed environments.

The feedback provides a snapshot of user experiences and gives potential buyers a sense of what to expect. Still, it’s always wise to take individual experiences with a grain of salt, as these can vastly differ based on the specific usage and operating conditions.

Open Slip Rings: Comparison with Other Types of Slip Rings

Open slip rings are just one of the many types of slip rings available. This section will offer a comparison between open slip rings and traditional closed slip rings, highlighting their advantages and disadvantages.

Open Slip Rings

Pros:

- Easy Access: Open slip rings provide better accessibility for inspection, cleaning, and maintenance, making the process less time-consuming and more convenient.

- Significant Flexibility: Open slip ring designs can be easily modified and tailored to specific application requirements due to the relatively simple and accessible construction.

- Cost-Effective: The materials and manufacturing processes used for open slip rings are typically more economical, resulting in a lower overall cost compared to closed slip rings.

- Customizability: The open design allows for more modular customization, simplifying adaptation for specific application needs.

Cons:

- Environmental Vulnerability: Open slip rings are more susceptible to environmental influences, such as dust and debris. Regular cleaning and inspection are vital to maintaining reliable performance.

- Potentially Shorter Lifespan: Depending on the usage conditions, open slip rings may exhibit a shorter operational life than their closed counterparts due to increased vulnerability to the elements.

Closed Slip Rings (Capsule Slip Rings)

Pros:

- Environmental Protection: Closed slip rings offer more significant protection against environmental factors, such as dust, moisture, and debris, due to their encapsulated design, often resulting in a longer operational life.

- Lower Maintenance Requirements: The sealed enclosure of closed slip rings limits debris accumulation and reduces the contact’s exposure to external contaminants, translating to fewer maintenance issues compared to open slip rings.

- More Stable Signal Transmission: Due to the capsule design that protects the slip ring from environmental disturbances, closed slip rings deliver more stable signal transmission, especially in adverse conditions.

Cons:

- Higher Cost: The materials and manufacturing processes used for closed slip rings are typically more expensive compared to open slip rings, leading to a higher overall cost.

- Limited Customizability: The capsule design of closed slip rings makes them harder to customize, with less adaptable modular options.

- Complex Maintenance: The sealed nature of closed slip rings can make maintenance more complicated, requiring specialized tools or procedures to access internal components.

Ultimately, the choice between open and closed slip rings boils down to the specific application requirements, the environmental factors involved, and the desired balance between maintenance, cost, and performance reliability.

Open Slip Rings: Where to Buy and Price

Acquiring open slip rings doesn’t have to be a daunting task. There are various reliable platforms through which you can purchase these essential devices. Additionally, the price range typically varies, depending on factors such as quality, specifications, and the retailer’s policies.

Where to Buy Open Slip Rings

Open slip rings can be procured from:

- Manufacturer Direct Sales: Companies that manufacture open slip rings often sell directly to companies and individuals. Examples include companies like Moog, Schleifring, Cobham, and STEM. Manufacturer direct sales often guarantee product quality and usually come with direct customer support.

- Distributors: Numerous distributors specialize in different types of slip rings, giving you a wider variety to choose from. Some examples are Mouser Electronics, Digikey, and Allied Electronics.

- Online Marketplaces: Open slip rings are also available on general online marketplaces such as Amazon, eBay, or Alibaba. While these platforms offer competitive prices, it’s crucial to scrutinize sellers to ensure product authenticity and quality.

Price Range and Cost-effectiveness

The price range for open slip rings tends to vary widely based on factors such as design complexity, materials used, and the number of circuits provided. Generally, you can expect prices to fall anywhere between $50 to over $1,000.

The cost-effectiveness of open slip rings often comes from their flexibility. Their simpler design and construction often make them cheaper than closed slip rings, while their adaptability allows them to be tailored more cost-effectively to specific applications. However, their need for more regular maintenance and potentially shorter lifespans in more challenging environments should be taken into account when valuing their overall cost-effectiveness.

Once you take into account the price, the application’s specific needs, and the environment in which the open slip ring will operate, you will be better equipped to make a cost-effective purchase. Always remember to consider the total cost of ownership, which includes not only the slip ring’s initial price but also the cost of maintenance and potential downtimes.

Conclusion

The world of open slip rings can be complex, but with the right knowledge, it doesn’t have to be intimidating. This guide facilitates comprehension, empowering you to make the best-informed decisions for your needs. So, consider this your roadmap — ready, set, go!

Get in touch for a tailored quote on our Open Slip Rings by filling out the form.