This article explores the versatile world of plastic slip rings—a core component of modern rotational devices, often overlooked but imperative in a variety of applications.

Introduction to Plastic Slip Rings

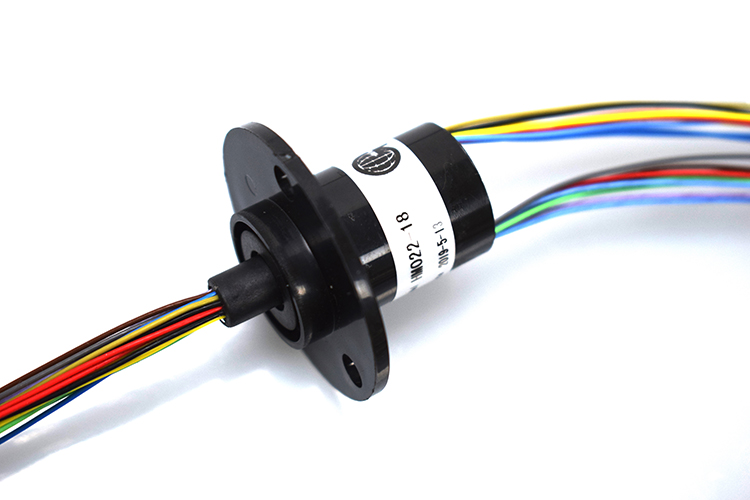

Plastic slip rings, a progressively popular component in the world of engineering and manufacturing, are revolutionizing the way we navigate the realm of rotating devices. They function as a rotating electrical interface, casting aside the conventional reliance on physical wires that would otherwise impede rotation.

Emerging as a unique blend of innovation and utility, plastic slip rings are lightweight, corrosion-resistant, cost-effective, and possess the ability to execute seamless transmission of power and electrical signals from a stationary structure to a rotating one. This stimulates smooth, unrestricted movement in numerous components and devices.

A primary differentiator that sets plastic slip rings apart from their metal counterparts is the plastic body. This singular feature bestows the slip rings with significant weight reduction and inherent resistance to corrosion – attributes that are rapidly gaining recognition and acceptance in a plethora of applications.

Common scenarios where plastic slip rings find their place are within lightweight unmanned aerial vehicles (UAVs) where weight is a critical consideration, wind turbines where corrosion resistance is valued, and in robotics and medical equipment where both lightness and resistance to rust are essential for optimum performance.

As we delve further into the nuances of this technological marvel, we will further explore the slew of features and benefits they bring to the table. Through this lens, we evaluate their rising applicability across diverse industries.

Benefits of Plastic Slip Rings

In any industrial application, every feature can make a significant difference in efficiency and performance. In the case of plastic slip rings, the benefits are multifold.

One of the foremost advantages of these components is their lightweight design. It’s well-understood that when it comes to rotational devices, particularly those in aeronautic or mobile robotics fields, weight plays a vital role. Reduced weight can drastically enhance operational efficiency and offer considerable power savings—areas where plastic slip rings excel due to the inherent lightness of their primary material.

Closely following the weight factor is the aspect of corrosion resistance. Given that various applications expose the slip rings to harsh and corrosive environments—think marine settings with high salinity or industrial machines plagued with acidic or alkali solutions—the material’s resistance to corrosion becomes a significant factor. Plastics, by their innate nature, are highly resistant to rust compared to metals, offering longevity that can save on replacement costs in the long term.

We live in a cost-conscious era where economical solutions are sought-after. Given their ease of production relative to metal slip rings, plastic slip rings are generally cost-effective without compromising on performance. The manufacturing process of plastic slip rings also allows for modification or customization at a lower cost than metals.

Material selection is certainly not a decision to be made lightly; choosing the appropriate material for a given application can mean a difference in the world when it comes to the operation, performance, and lifespan of an electronic device or machine. As compared to the conventional use of metal materials, plastic offers an alternative that is not only more economical but also more versatile.

Plastics can be finely machined or extruded to match the specifications of various applications, negating the need for additional insulating components due to the non-conductive nature of the material—leading to further cost-saving implications. Furthermore, some types of plastic come equipped with excellent self-lubricating properties reducing the necessity of maintenance.

All these factors combined make plastic a substantially beneficial choice compared to metal when it comes to slip rings, sure to be seen more prevalently in the future of various industries.

Applications of Plastic Slip Rings

The diverse benefits offered by plastic slip rings often make them the optimal choice across a variety of industrial applications as well as in consumer goods. The deciding factors generally echo the categories we’ve already discussed: weight, resistance to corrosion, and cost-effectiveness.

For starters, in aviation and aeronautic technology, most notably lightweight unmanned aerial vehicles (UAVs) or drones, every gram matters. This is where the unprecedented lightness of plastic slip rings gives them an edge. When these UAVs need to rotate cameras or other sensors, plastic slip rings provide the perfect, lightweight solution to transmit electrical signals between static and moving components, thus enhancing maneuverability and maintaining high-flying times.

In marine applications like offshore wind turbines or undersea remote-operated vehicles (ROVs), where the operational environment is inherently harsh due to high salinity and moisture, the corrosion resistance of plastic slip rings makes them a game-changer. The enduring performance of these slip rings in such corrosive conditions can increase the lifespan of the devices, thereby amplifying operational efficiency.

The application of plastic slip-rings extends to medical fields as well, where cleanliness and sterility are of paramount importance. In an MRI machine, for instance, plastic components are preferred over metal ones due to plastic’s non-magnetic properties. Plastic slip rings in these environments keep the machine functioning optimally, providing clean power and data signal transmission.

Robotic applications also stand to benefit immensely from plastic slip rings. Industrial robotic arms, for example, often require a high degree of movement freedom and need to avoid any signal disruptions. The versatile and robust nature of plastic slip rings in dealing with rapid and endless rotation makes them a choice component for these industrial settings.

The power of plastic slip rings also extends to everyday goods, for instance, in rotating displays or stands found in stores or exhibitions. Here, plastic slip rings manage to turn heads by ensuring uninterrupted power and signal supply, all while working silently in the background.

These real-world applications emphasize the advantage of plastic slip-rings, and as progress and innovation continue to stride hand in hand, the applications of these components are likely to expand exponentially.

Choosing the Right Plastic for Slip Rings

Selecting the correct type of plastic for the manufacture of slip rings is a nuanced process that must consider a series of pivotal factors, ensuring the performance of the slip ring is up to the demands of its application. This careful selection process is guided by key material properties including temperature resistance, wear resistance, and electrical properties.

Temperature resistance is a crucial criterion since the slip ring will often operate under varying thermal conditions. The chosen material must maintain its structural integrity and electrical insulating properties across the expected temperature range. Too much thermal variation can lead to expansion, contraction, or even degradation of the plastic, hindering the device’s operational reliability.

Wear resistance is equally important, as slip rings are subject to constant mechanical contact, which can lead to wear and tear over time. A material with high wear resistance is less likely to degrade, abrade, or change shape, which protects the integrity of electrical contacts and ensures consistent performance.

Lastly, the electrical properties of the plastic are significant, especially its dielectric strength and insulation resistance, which contribute to the safety and efficiency of the signal and power transmission. A plastic with suitable electrical characteristics minimizes the risk of electrical arcing and preserves the quality of signal transmission through the slip ring.

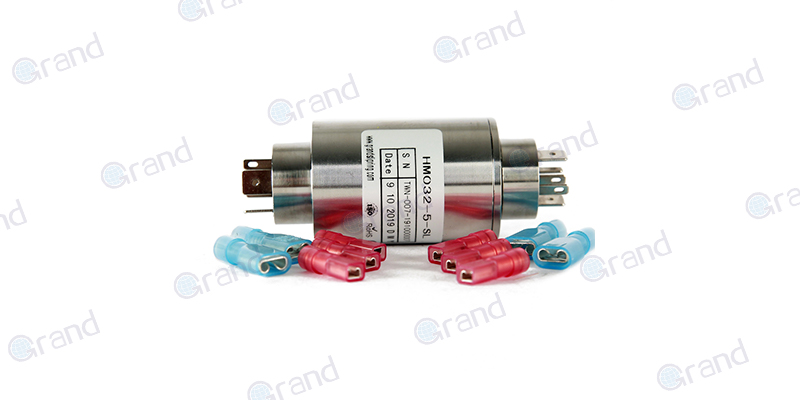

When it comes to the materials themselves, two commonly used plastics in slip ring manufacturing are PEEK (Polyether ether ketone) and POM (Polyoxymethylene).

PEEK is renowned for its excellent mechanical and chemical resistance properties and can operate in high-temperature environments which makes it a favored choice for aerospace and automotive industries. It possesses strong wear resistance which ensures its durability and long service life, especially in harsh environments.

POM, also known as Acetal, is another popular plastic material utilized in slip rings. It has good tensile strength, fatigue resistance, and low friction. It has a lower water absorption rate, making it suitable for wet environments. Although it may not match the high temperature and chemical resistance of PEEK, it is an excellent all-rounder, often selected for its balance of features and its more economical price point compared to PEEK.

By understanding the inherent characteristics of these plastic materials, designers can make informed decisions that influence the performance and longevity of slip rings. Other factors such as cost, availability, and ease of manufacturing also play a role in material selection, balancing the technical specifications with commercial practicality.

Performance and Reliability of Plastic Slip Rings

Doubts may naturally arise when comparing plastic slip rings to their traditional metal counterparts, given that plastics are usually associated with lesser strength and durability. However, the reality is far from this perception. The quality of performance and reliability provided by plastic slip rings not only match but often surpass those of metal slip rings in many contexts.

Electrically, plastic slip rings excel in several key areas. Given their extremely high insulation resistance and dielectric strength, plastic slip rings provide secure, reliable electrical connections, preventing undesirable short circuits and signal leakages. They maintain a remarkably secure path for current flow and can withstand high voltages – all critical for power and signal transmission quality. Furthermore, specific plastics can also be selected for their low electrical noise characteristics, which is particularly advantageous for signal integrity in data transmission applications.

The service life of plastic slip rings is another area where these units shine. The durability of plastic in terms of wear and corrosion resistance enables these slip rings to achieve a significantly long service life. Since plastic materials can be inherently self-lubricating, there isn’t a great need for external lubrication, this in turn reduces maintenance efforts and further extends the lifespan.

When it comes to reliability, plastic slip rings have proven their mettle in the most demanding environments. Whether it be resisting UV radiation in aerial applications, withstanding corrosive seawater in marine environments, or insulating against high voltages in industrial equipment, plastic slip rings have delivered time and time again.

Addressing the strength and durability concerns, it is critical to dispel the myth that plastic is inherently weaker than metal. Today’s engineering-grade plastics used in slip ring manufacturing, like PEEK or POM, display high mechanical strength and toughness, which can indeed rival some metals. It’s also crucial to note that strength isn’t the only parameter that defines a material’s suitability for slip rings; properties like corrosion resistance, electrical insulation, and temperature tolerance are equally, if not more, important, and here, plastics often outperform metals.

In summary, the performance and reliability of plastic slip rings are not areas where compromise is made. Through careful selection of suitable plastic materials, these devices are more than capable of replacing metal alternatives, delivering notable advantages not only in performance but also in cost, weight, and longevity.

Maintenance and Repair of Plastic Slip Rings

Maintenance and repair constitute a significant part of the lifecycle of any mechanical component, and plastic slip rings are no exception. However, the specific attributes of plastic offer certain advantages that streamline these processes when compared to other types of slip rings.

The first thing to note about plastic slip rings is that their maintenance requirements are generally less demanding. Some of the plastic materials used in slip rings come with an inherent self-lubrication feature that reduces the need for external lubrication. This inherently lessens the necessity for frequent maintenance checks for lubrication, unlike metal slip rings which typically require regular application of lubricating oil to prevent wear and tear.

In addition, as plastic is naturally resistant to corrosion, they don’t need as much regular checking for corrosion-related issues that can hound metal slip rings, especially those used in harsh environments like marine applications.

When it comes to repairs or replacements, it’s important to keep in mind that plastic materials are typically easier to machine and shape than their metal counterparts. This can translate into simpler, rapid, and more precise repair experiences. Since plastic components can be more readily produced than metal ones, replacement parts can often be fabricated more quickly and cost-effectively, reducing downtime and maintaining operational efficiency.

However, in case of severe damage, entire unit replacement might be more feasible given the cost-effectiveness of plastic slip rings. Therefore, having a proper understanding of the extent of the damage and the economic implications of repair versus replacement is crucial.

In application scenarios where cleanliness is paramount, such as in the food industry or medical devices, the ease of cleaning plastic parts is another notable advantage, as they tend not to harbor bacteria and other contaminants.

Maintenance and repair for plastic slip rings are generally easier and less frequent as compared to other types of slip rings. This advantage, in conjunction with their performance characteristics and cost-effectiveness, makes them a compelling choice for a broad range of applications.

Plastic Slip Rings: Purchasing Considerations and Vendor Selection

When selecting a plastic slip ring for purchase, several factors should be carefully evaluated to ensure the desired outcomes in terms of performance, reliability, and cost-effectiveness. These factors include cost, quality, support, and warranties, each playing a crucial role in the decision-making process.

Cost is often the first consideration. Competitive pricing is key, but it should not come at the expense of quality. Achieving a balance between affordability and ensuring that the slip ring can perform effectively over its intended service life is fundamental. Remember that initial cost savings may translate to higher operational costs if the product is substandard and requires frequent repairs or replacements.

Quality is next. It’s vital to verify the material and manufacturing standards upheld by the slip ring provider. Ensure that they comply with relevant industry certifications and quality control methodologies. High-quality plastic slip rings should exhibit exceptional durability, reliable electrical performance, and resistance to wear and environmental factors according to their specific application needs.

Support from the vendor is an essential factor. Reliable customer service and access to technical support can be invaluable when needing assistance with product selection, troubleshooting, and getting advice on maintenance. A vendor that offers strong post-purchase support demonstrates confidence in their products and commitment to customer satisfaction.

Warranties and guarantees protect the buyer from potential manufacturing defects or early wear. A solid warranty signifies the vendor’s trust in the lifespan and performance of their slip rings. It’s important to understand the extent of warranty coverage, what it entails, and the process for claiming warranty service.

When evaluating and comparing plastic slip ring vendors, use the following guidelines:

- Technical Specifications: Start by comparing the technical specifications of the slip rings to ensure they meet the application’s requirements. This includes ratings for voltage and current, insulation resistance, the number of channels and types (power, data, signal), and any specialized features needed such as signal integrity for specific applications.

- Material Data Sheets: Request and review material data sheets for the plastics used. These sheets can provide in-depth detail on the properties of the plastic, such as thermal stability, wear resistance, and electrical insulation.

- Customer Reviews and References: Look for customer testimonials, case studies, and industry references to gauge the real-world performance and reliability of the slip rings from various vendors.

- Lead Times and Availability: Assess the vendor’s consistency with lead times and availability, especially for custom-made slip rings. A dependable vendor should have a clear and reliable timetable for delivery.

- Compliance and Certifications: Ensure the vendor’s products are compliant with industry standards and certifications, which can include RoHS, CE, UL, or specific industry-related requirements.

- Additional Services: Evaluate if the vendors offer additional services like custom engineering solutions, rapid prototyping, or testing and certification services, which could provide added value.

In conclusion, a thorough assessment that weighs cost, quality, support, and warranty protection is critical when purchasing a plastic slip ring. Coupled with comprehensive vendor evaluation guidelines, these criteria can effectively guide buyers toward making an informed decision that aligns with their specific requirements.

Plastic Slip Rings: Sustainability and Environmental Impact

The adoption of more sustainable practices across various industries has elevated the importance of examining the ecological benefits associated with components like slip rings. Plastic slip rings, when thoughtfully designed and used, can contribute positively to these efforts.

One key advantage of plastic slip rings over their metal counterparts is related to recyclability. Many of the plastics used in slip ring fabrication, such as PEEK or POM, are recyclable. This implies that end-of-life plastic slip rings can be properly disposed of and their material reused, thereby reducing raw material needs and lowering the overall environmental impact.

However, it’s crucial to remember that all plastic is not created equally when it comes to recyclability. Buyers should openly discuss the recyclability of materials with suppliers, and whenever possible, opt for those that are recyclable or made from recycled content.

In terms of disposal, while plastic waste has been a cause for concern, many plastics can be incinerated safely for energy recovery. This process transforms waste into a valuable energy resource while offsetting fossil fuel use and reducing greenhouse gas emissions. Comparatively, metal-based slip rings may require more complex disposal procedures due to potential heavy metal contamination.

When it comes to manufacturing emissions, producing plastic slip rings typically uses less energy and therefore generates fewer greenhouse gases compared to metal slip rings. The lightweight nature of plastic also offers benefits during the transportation process, requiring less energy for shipping and hence fewer emissions.

Considering all of these factors, it can be argued that plastic slip rings offer several potential environmental benefits compared to their metal counterparts. However, to truly maximize these benefits and minimize the environmental impact, it’s crucial to encourage approaches such as recycling, energy recovery, and targeted design for disassembly. Furthermore, purchasing from vendors who adhere to strict environmental standards and constantly strive for more sustainable practices will help drive the momentum for sustainability in the industry.

Lastly, it’s important to keep the broader context in mind. The environmental impact of any product doesn’t solely rest on the material it’s made from, but also the way it’s designed, used, and disposed of. By choosing plastic slip rings, users become part of the solution, contributing to a circular economy and a more sustainable future.

Conclusion

As industries continually seek innovative and cost-effective solutions, plastic slip rings will keep gaining ground. With their unique advantages and usability in diverse applications, they’re set for a future of exponential growth.

FAQs about Plastic Slip Rings

Q: Are plastic slip rings as durable as metal slip rings?

A: Yes. High-quality plastic slip rings designed with suitable material and good design can match or even exceed the durability of metal slip rings.

Q: What kind of maintenance do plastic slip rings require?

A: While plastic slip rings typically require less maintenance than metal ones, occasional cleaning and periodic inspection are necessary to maintain their performance.

Q: Are plastic slip rings less durable than metal ones?

A: This is a common misconception. While metal is often associated with strength and durability, it’s important to note that modern engineering-grade plastics used in slip ring manufacturing, like PEEK or POM, exhibit significant mechanical strength and toughness, often rivaling or even surpassing some metals. Furthermore, plastics often display better resistance to wear and corrosion, extending the service life of the slip ring.

Q: Can plastic slip rings handle high voltages and currents?

A: Yes, depending on design factors and materials used, plastic slip rings can handle a wide range of voltages and currents. They have high insulation resistance and dielectric strength, successfully preventing short circuits and ensuring secure connections for power and signal transmission.

Q: Is the maintenance for plastic slip rings demanding?

A: On the contrary, plastic slip rings require relatively less maintenance compared to metal ones. Jane’s self-lubricating characteristics reduce the need for frequent external lubrication, and their corrosion resistance decreases the monitoring needs for potential corrosion-related issues.

Q: Are plastic slip rings environmentally harmful?

A: As with any material, environmental impact largely depends on how it’s used and disposed of. Many plastics used in slip rings are recyclable, and if recycled properly, this can significantly lessen their environmental impact. Furthermore, the production of plastic slip rings usually generates fewer emissions than metal ones. Buyers should opt for suppliers who uphold solid waste management and recycling practices.

Q: Do plastic slip rings generate more electrical noise than metal ones?

A: This is not necessarily true. While the level of electrical noise can depend partly on the material used, it greatly relies on the design of the slip ring. Certain plastic materials are known for their low electrical noise characteristics and can, therefore, ensure better signal integrity in data transmission applications.

See What We Can Do