This article explores radio frequency (RF) rotary joint-depth depth, covering their basic principles, various types, components, design considerations, applications across industries, selection criteria, manufacturers, common issues, and future trends.

Introduction to Radio Frequency Rotary Joint

Radiofrequency rotary joint, often abbreviated as RF rotary joints, have established their significance in various applications due to their unique functionality and contribution to RF communication systems. An RF rotary joint, in its essence, is a sophisticated device designed to transmit signals across stationary and rotating parts of a system. This transmission is carried out at various frequency ranges depending on the specific application.

RF rotary joints are the backbone of many contemporary systems where signal transmission via rotation is integral. In diverse industries ranging from telecommunications to military, medical, and space exploration, these remarkable devices have become critical components. In telecommunications, for instance, they find extensive use in satellite antennae, facilitating precise signal transmission even as parts of the system rotate. In the military sector, they significantly underpin radar systems enabling rotation without losing the integrity of the However

However, the importance and relevance of RF rotary joints extend even further. They’ve proven crucial in the functioning of medical diagnostic tools such as MRI machines. In ever-advancing space exploration endeavors, they play a vital role in the positioning system of satellites and space stations.

Given their extensive range of applications, an understanding of RF rotary joints, their operation, and their design is of high interest to professionals and enthusiasts in relevant fields. In the following sections, we will delve deeper into the principles that guide their function, explore their various types, key components, essential design considerations, and much more, shedding light on this remarkable electromechanical device that shapes our world in hidden but powerful ways.

Basic Principle of Radio Frequency Rotary Joint

Understanding the basic principles of an RF rotary joint’s functionality requires delving into the fundamental interplay of electromechanics and signal transmission.

Explanation of How It Functions

RF rotary joints operate on a relatively straightforward principle even though their construction might seem intricate. In essence, they provide a link for the transmission of radio frequency signals between stationary and rotating sections of a system. This transmission takes place over rotating contacts, that accomplish the critical task of ensuring consistent connectivity between the moving and fixed parts, thereby allowing uninterrupted signal flow.

The ability of RF rotary joints to facilitate this kind of signal transmission proves pivotal in a variety of systems, particularly where rotation is integral, and signal integrity is of paramount importance. Notably, these joints allow for the uninterrupted transmission of energy without directly affecting the motion or causing undesirable energy loss.

The Basic Principles of Its Operation

The operation of an RF rotary joint is anchored around the fundamental principles of electromagnetics and mechanical systems. In the world of electromagnetics, a specific medium is required to carry the radio frequency signal. Typically this medium could range from coaxial cables, waveguides, or even optical fibers, depending on the design of the rotary joint and application.

Inside the rotary joint, these delivery mediums are skillfully integrated with mechanical components that aid rotation. The RF signal passes through these mediums across the rotation interface without signal loss or a reduction in the signal’s quality, thanks to the mechanical design.

The design specifics are thus influenced by several factors including the frequency range, size, power handling capacity, and more, depending on the application the RF rotary joint is designed for.

Overall, the crucial principle behind the operation of an RF rotary joint can be condensed into its ability to effectively transmit radio frequency signals across a rotating interface, marrying the world of electromagnetics with the mechaniefficiently and reliablynner.

Radio Frequency Rotary Joint Different Types

While the fundamental principle behind RF rotary joints is consistent, they arrive at the market in a variety of types. Manufacturers construct these variations to meet the diverse needs across different applications and industries. Let’s explore the different types commonly available:

Single-Channel Coaxial Rotary Joints

Single-channel coaxial rotary joints are the simplest kind, designed to transmit one channel of RF signal between a stationary and a rotating structure. They are widely used due to their simplicity and reliability and are commonly found in security systems, medical instruments, and communication equipment.

Multi-Channel Coaxial Rotary Joints

With the ability to transmit multiple RF signals simultaneously, multi-channel coaxial rotary joints take functionality a step further. The complexity of this type increases due to the need to avoid interference between channels and maintain a high level of signal integrity. These joints are particularly useful for applications in advanced radar systems, remote sensing, or where multiple signals need to be transmitted concurrently.

Waveguide Rotary Joints

Waveguide rotary joints aptly use waveguide technology to transmit high-frequency radio waves. Well-suited for high-power and low-loss applications, these joints are used primarily in radars, satellite communications, and other defense systems. They often come with larger and mechanically robust designs due to the waveguide’s shape and size.

Fiber Optic Rotary Joints

Expanding into the realm of optical signals, fiber optic rotary joints (FORJ) transmit optical signals between stationary and rotating parts. Catering to the needs of high-speed data transmission, they’re utilized in fiber optic communication systems, cable TV, and high-capacity internet networks.

Each of these types has its application niches, advantages, and limitations. Your choice will depend on the specific requirements of your application. However, with a robust understanding of the different types of RF rotary joints, you can make more informed choices and ensure the best performance in your system.

Radio Frequency Rotary Joint Components and Design

Designing and manufacturing an RF rotary joint is an intricate process, requiring a careful selection of components and adherence to certain core design considerations to ensure optimal performance.

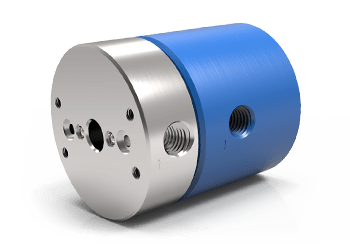

The Key Parts That Make up an Rf Rotary Joint

An RF rotary joint is made up of several components, each with a crucial role to play in its overall functionality.

- Rotating Contact System: This is arguably the heart of the rotary joint, which facilitates the actual transmission of the RF signals across the rotary interface.

- Housing: The housing protects the inner mechanisms of the rotary joint from environmental factors such as dust, moisture, temperature, or temperature variations.

- Bearings: Bearings are critical to enabling smooth, low-friction rotation of the joint. They must be designed to withstand the specific rotational speeds and loads that the joint will encounter.

- Connectors: Connectors are used to interface the rotary joint with the rest of the RF system.

- Electrical Shielding: Shielding is necessary to prevent interference from external electromagnetic fields, thus reducing signal loss and improving signal quality.

Core Design Considerations

Several factors need to be carefully considered and balanced when designing an RF rotary joint:

- Frequency Range: The joint should be able to transmit the entire range of required frequencies without distorting the signals.

- Insertion Loss: Designers seek to minimize the energy loss as the signal passes through the rotary joint.

- Power Handling: The joint needs to be able to handle the power levels of the signals it will carry without overheating or suffering damage.

- VSWR (Voltage Standing Wave Ratio): A measure of how efficiently the radio frequency power is transmitted from its source to its load. A lower VSWR signifies a better joint design.

- Rotational Life and Speed: The joint needs to be able to operate at the necessary rotational speeds and for the required lifespan.

- Environmental Conditions: Factors like temperature, humidity, dust, and corrosion can impact the joint’s performance and lifespan. The design should account for such conditions.

While these components and design considerations provide a broad overview, the specifics can be considerably nuanced. Therefore, in-depth technical knowledge and expertise are generally required to design a high-performing RF rotary joint.

Application of Radio Frequency Rotary Joints

Radiofrequency rotary joints are powerful electromechanical devices with broad-ranging applications across several industries. They underpin numerous systems where rotational signal transmission is critical. Let’s explore some of their specific uses in detail:

Military Industry

The military sector heavily relies on RF rotary joints in various mission-critical systems. They are extensively used in advanced radar systems and missile defense systems to enable constant rotational scanning while maintaining high-quality signal transmission. Further, satellite communications within military operations necessitate robust and reliable radio frequency connections which these joints provide efficiently.

Communication Industry

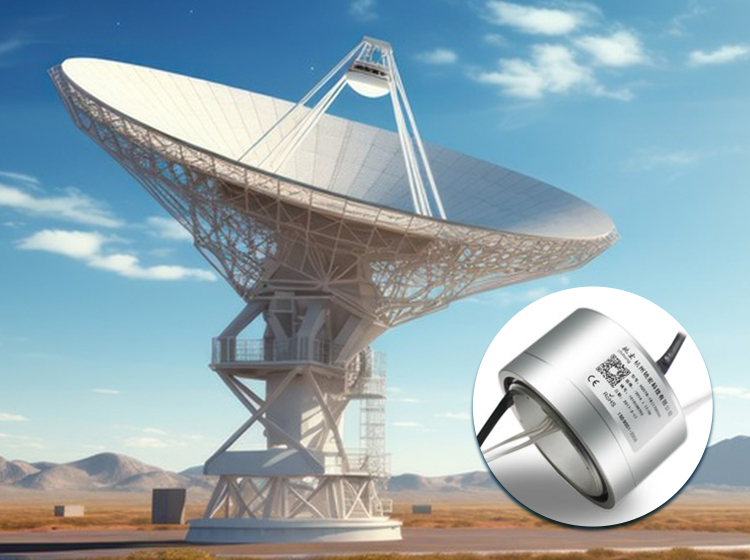

Within the communications industry, RF rotary joints find common usage in satellite dishes used for television broadcasting, remote sensing, and telecommunications. They’ve been integral in enhancing the performance of these systems by allowing the antenna to rotate, which enables it to cover vast areas or track multiple targets simultaneously.

Antenna Systems

The use of RF rotary joints extends to various radar antenna systems, including those on ships or other moving vehiclHigh-precisions antenna direction finding systems and tracking systems often need to rotate continuously or intermittently, requiring impeccable signal transmission during rotation. Similarly, the joint allows satellite antenna systems to change their pointing direction continuously while keeping track of mobile users or satellites moving in space.

Radar Systems

Radar systems require continuous rotation to scan the surrounding environment. RF rotary joints are a key component in these systems, providing an efficient means of transmitting signals from the rotating antenna to the stationary processing components. They are widely used in weather radars, air traffic control radars, marine radars, and more.

Medical Technology

In the medical field, RF rotary joints contribute to the improved performance of diagnostic tools such as computed tomography (CT scanners) machines and magnetic resonance imaging (MRI) machines. These devices need to rotate while transmitting signals, and rotary joints enable this seamless communication across stationary and rotating parts.

This extensive range of applications illustrates the versatility and critical role of RF rotary joints. They enable high-level functioning across many remarkable devices and systems, hence their understanding becomes fundamental to professionals operating within these realms.

Selection Criteria for Radio Frequency Rotary Joint

Choosing an RF rotary joint is not a one-size-fits-all decision, it requires attention to several key factors which can greatly influence the joint performance in a specific application. Given the variety and complexity of RF rotary joints available, understanding these criteria will empower you to make an informed choice.

Operating Frequency

The frequency or range of frequencies you need to transmit is one of the most crucial selection factors. Ensure your selected joint can operate efficiently within the required frequency range without distorting or losing the signal.

Power Handling

The chosen rotary joint must be able to handle the power levels the signals will carry in your system. Overlooking the power factor might lead to overheating or damage to the rotary joint and signal loss.

Insertion Loss

This refers to the signal power loss when the signal passes through the joint. A lower insertion loss means less signal degradation and is generally preferred.

Package Size

The size of the rotary joint must be considered based on the available space in your system. You should ensure the joint can fit into your system without causing any mechanical obstruction.

Rotational Speed

The rotational speed criteria are vital if your application involves rapid spinning or rotation. The chosen rotary joint needs to deliver consistent performance at the operation speed.

Vibration and Shock Resistance

In harsh environmental conditions or rugged applications, the joint should be able to withstand vibrations and shock while maintaining signal integrity.

Environmental Factors

Consider the conditions in which the joint will be installed. For example, if the joist is exposed to outdoor weather, it needs to be weather and corrosion-resistant. Similarly, in high-temperature environments, the joint should have adequate thermal management.

Connector Types

The connector type must be compatible with the rest of your RF system. Connector mismatch can hamper signal transmission and overall system performance.

To decide on the right RF rotary joint, you’ll want to carefully evaluate these factors in the context of your specific use case. It’s often worthwhile to consult with a specialist or the joint manufacturer to make the best choice.

Radio Frequency Rotary Joint Common Problems and Troubleshooting Tips

Using RF rotary joints optimally requires not just proper selection and installation but also the ability to troubleshoot common issues that might arise during operation. Here are some common problems and tips on how to tackle them:

Problem 1: Intermittent Signal Loss

This typically indicates wear and tear within the rotary joint, perhaps in its contacts or bearings.

Troubleshooting Tip: Make sure to regularly inspect your rotary joint for any signs of physical damage. It might be time for a replacement if the issue persists.

Problem 2: Corrosion

In an environment tackling moisture, dust, and other contaminants, corrosion can occur, which can degrade the performance of the joint.

Troubleshooting Tip: Ensure your rotary joint is appropriately rated for the environmental conditions it’s exposed to. Anti-corrosion coatings or seals may also extend the joint’s life.

Problem 3: Overheating

When rotary joints transmit a signal, some energy is lost as heat. If not managed well, this can cause overheating.

Troubleshooting Tip: Make sure your joint is rated for the power levels it’s handling. Employing heat sinks or other cooling mechanisms could also be beneficial.

Maintenance Tips

Effective maintenance can significantly enhance the lifespan and performance of your joint. Here are some additional tips:

- Regular Inspection: Keep a close eye on the RF rotary joint and its surrounding equipment for any signs of wear, corrosion, or other damage. Catching issues early can prevent more consequential damage later.

- Keep it Clean: Ensure that the rotary joint is kept clean and free from dust or dirt, which can impede performance. Use a soft, lint-free cloth and if necessary, use a non-corrosive cleaner.

- Regular Lubrication: Apply lubricants often, especially in the bearings, to minimize friction and prevent wear. However, ensure that the lubricant used doesn’t interfere with signal transmission.

These are just some of the issues that you might encounter with RF rotary joints. If the joint continues to malfunction despite your best troubleshooting efforts, it’s advisable to contact the manufacturer or a professional technician for further assistance.

Ready to upgrade your technology with Fiber Optic (FORJ) RF Rotary Joints? Let’s discuss your requirements. Inquire now!

Future Developments and Trends in Radio Frequency Rotary Joints

The scope of RF rotary joints continues to expand as technology advances. Predicting future trends provides valuable insights for professionals keeping pace with the evolution of this technology. Here are some foreseeable developments and trends.

Miniaturization

As devices and systems become more compact, there’s a growing demand for smaller RF rotary joints that can fit into restricted spaces while delivering superior performance. The trend towards miniaturization within the RF industry is expected to continue, necessitating more compact, lightweight, and efficient rotary joints.

Increased Channel Capacity

With the proliferation of complex modern systems that require the transmission of more data simultaneously, RF Rotary Joints are anticipated to evolve to support increased channel capacity. More channels will aid in supporting numerous simultaneous transmissions within the same system.

Higher Frequency Capacities

Applications like 5G telecommunications and advanced radar systems operate at extremely high frequencies. To support these applications, the development of RF rotary joints capable of operating effectively at these high frequencies is likely.

Environment Defensive Capabilities

The increasing use of RF rotary joint in rugged or harsh environments is pushing the need for products with improved resistance to shock, vibration, moisture, and temperature variations. So, we can expect to see more joints with enhanced durability and resistance properties.

Better Integration

To simplify system designs and improve efficiency, there’s a rising trend of integrating RF rotary joints with other components, such as slip rings for power and data transmission. This integration offers eased installation and maintenance, promising a more efficient system setup.

Smart Rotary Joints

With advances in digital technology and the Internet of Things (IoT), the future may witness the emergence of smart rotary joints. These joints could be equipped with sensors to monitor their performance, predict maintenance needs, or even adjust their operation in response to changing conditions.

The RF rotary joints industry is poised for significant technological advancements, driven by the evolving demands of various applications. By understanding these trends, professionals can make informed decisions while selecting, designing, or maintaining systems involving RF rotary joints.

Conclusion

Radio Frequency rotary joints play a crucial role in various industries and applications. Understanding the different types, components, and design considerations is key to choosing the right RF rotary joint for your needs. Staying up-to-date with current trends and advancements can help you make informed decisions and ensure the longevity of your systems.

See What We Can Do