Railway excavators are indispensable in the construction and maintenance of railway systems, and rotary unions are the critical components that keep these machines performing at their best. In this comprehensive guide, we will delve into the various types and features of railway excavator rotary unions, their importance in the excavator’s efficient functioning, and measures for selecting the right one. We will also cover installation, maintenance, and safety regulations, and address frequently asked questions, providing insights into real-world applications and future trends. This all-encompassing understanding of rotary unions in railway excavators will help users optimize performance, extending the machine’s life and ensuring smooth operation.

What are Railway Excavator Rotary Unions?

Railway excavator rotary unions are intricate mechanical components found within railway excavators — specialized machines designed to perform heavy-duty tasks in the construction and maintenance of railway systems. A rotary union, also known as a swivel joint or a rotating union, serves a fundamental purpose within these systems: it allows the transfer of fluid — typically hydraulic fluid, air, or coolant — from a stationary input into a rotating part, like the arm of the excavator.

Rotary unions are vital in various mechanical and electronic devices, but in the context of railway excavators, they are instrumental in facilitating the smooth, controlled movement of the excavator arm. This part is known for its role in executing rotational movements, which are central to the bulk of the work done by these machines such as digging, lifting, and depositing materials.

Every rotary union designed for railway excavators is configured to handle the specific demands of these machines, from the intensive work cycles to the harsh outdoor environments they often operate within. Thus, these unions are typically built for durability and reliability to sustain the excavator’s operating efficiency and prolong the life span of the machine.

Understanding the role and importance of railway excavator rotary unions is crucial in maintaining these machines’ optimal performance and efficiency. Early recognition of an issue can prevent an expensive repair or an inconvenient breakdown, so it’s worth getting to grips with these seemingly small, but incredibly significant components.

Types of Railway Excavator Rotary Unions

There are several types of rotary unions used in railway excavators, each one designed to perform a specific task and accommodate certain operating conditions. Let’s look at the various types along with their pros and cons.

Single-Passage Rotary Unions

As the name suggests, these rotary unions facilitate the transfer of a single medium (fluid or gas) from a stationary supply line to rotating equipment. They are simple in design and easy to install, making them a popular choice for many applications. However, they lack the versatility of multiple passage rotary unions.

Multi-Passage Rotary Unions

These allow for the simultaneous transfer of multiple different types of media. For example, hydraulic fluid and air can flow through the distinct passages without interference. This increases the complexity and versatility of the machinery but also makes the device larger and the installation and maintenance more challenging.

2-Passage Rotary Unions

◆ Can replace SMC series pneumatic rotary joint

◆ Can combine to transmit power and signals

◆ Standard ports M5, can be G1/8, G1/4, G3/8, G1/2, G3/4

◆ Specification can be customized

◆ Housing Material, Stainless Steel/Aluminum Alloy

◆ Working Temperature, -40℃-+80℃

◆ Working Humidity, 10-85% RH

◆ Protection Grade, IP51

4-Passage Rotary Unions

◆ Can replace SMC series pneumatic rotary joint

◆ Can combine to transmit power and signals

◆ Standard ports M5, can be G1/8, G1/4, G3/8, G1/2, G3/4

◆ Specification can be customized

◆ Housing Material, Stainless Steel/Aluminum Alloy

◆ Working Temperature, -40℃-+80℃

◆ Working Humidity, 10-85% RH

◆ Protection Grade, IP51

6-Passage Rotary Unions

◆ Can replace SMC series pneumatic rotary joint

◆ Can combine to transmit power and signals

◆ Standard ports M5, can be G1/8, G1/4, G3/8, G1/2, G3/4

◆ Specification can be customized

◆ Housing Material, Stainless Steel/Aluminum Alloy

◆ Working Temperature, -40℃-+80℃

◆ Working Humidity, 10-85% RH

◆ Protection Grade, IP51

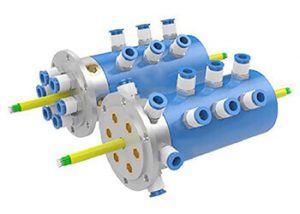

8-Passage Rotary Unions

◆ Can replace SMC series pneumatic rotary joint

◆ Can combine to transmit power and signals

◆ Standard ports M5, can be G1/8, G1/4, G3/8, G1/2, G3/4

◆ Specification can be customized

◆ Housing Material, Stainless Steel/Aluminum Alloy

◆ Working Temperature, -40℃-+80℃

◆ Working Humidity, 10-85% RH

◆ Protection Grade, IP51

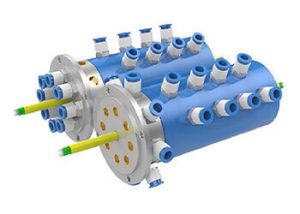

10-Passage Rotary Unions

◆ Support M5, G1 / 8, G1 / 4, G3 / 8, G1 / 2, G3 / 4, G1 thread for pneumatic

◆ Dynamic sealing technology

◆ With NSK high precision bearing

◆ Abrasion resistant, low torque, high speed

◆ Can be combined to transfer 2~96 circuits power and signal

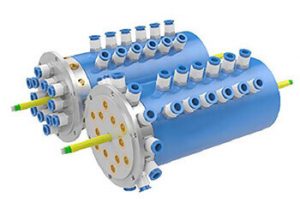

12-Passage Rotary Unions

◆ Can replace SMC series pneumatic rotary joint

◆ Can combine to transmit power and signals

◆ Standard ports M5, can be G1/8, G1/4, G3/8, G1/2, G3/4

◆ Specification can be customized

◆ Housing Material, Stainless Steel/Aluminum Alloy

◆ Working Temperature, -40℃-+80℃

◆ Working Humidity, 10-85% RH

◆ Protection Grade, IP51

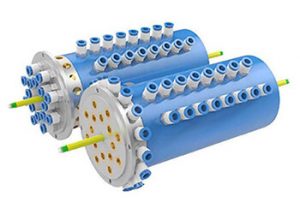

16-Passage Rotary Unions

◆ Can replace SMC series pneumatic rotary joint

◆ Can combine to transmit power and signals

◆ Standard ports M5, can be G1/8, G1/4, G3/8, G1/2, G3/4

◆ Specification can be customized

◆ Housing Material, Stainless Steel/Aluminum Alloy

◆ Working Temperature, -40℃-+80℃

◆ Working Humidity, 10-85% RH

◆ Protection Grade, IP51

Electric Rotary Unions

These facilitate the conduction of electrical currents or signals from a stationary structure to a rotating part of the machine. They are typically used in conjunction with traditional fluid-based rotary unions to enhance the functionality of the machine. However, these are relatively more complex and can have a higher cost.

The above examples are just a snapshot of the many diverse types of rotary unions available in the market. When it comes to choosing the suitable type, the selection often relies upon the specific needs of your excavator’s application. Factors such as the type and number of media to be transferred, the operating pressure and temperature, and the desired longevity and durability play crucial roles in this decision.

How Rotary Unions Work in Railway Excavators

The functioning of rotary unions within railway excavators, though complex, is integral to the overall operation of these machines. To grasp this, we must first understand that a rotary union is a device designed to transmit fluid (like water, hydraulic fluid, or coolant) from a stationary source to a rotating piece of machinery.

In a railway excavator, the rotary union is typically found at the machine’s base where the body meets the undercarriage. The rotary union’s primary function is to allow fluid to flow into the rotating superstructure of the excavator without leaking or losing pressure while simultaneously preserving the union’s rotational integrity.

This is achieved through a combination of precise engineering and specialized materials. The rotary union consists of a rotor (the rotating part attached to the superstructure) and a stator (the stationary part linked to the fluid supply). When the superstructure of the excavator rotates (or swings), the rotor turns within the stator, allowing fluid to pass into the rotating part while maintaining a high-pressure seal.

Now, let’s focus on the unique role of rotary unions in enabling the swing movement in excavators. The swing movement, which allows the entire upper assembly of the excavator (including the boom, arm, bucket, and cab) to rotate, is crucial for railway maintenance and construction activities. This rotation is made possible by the hydraulic motor, which receives high-pressure hydraulic fluid via the rotary union — this fluid powers the motor, causing the pinion to engage with the swing gear and resulting in the rotation of the superstructure.

Without the rotary union’s ability to reliably and continuously deliver hydraulic fluid to the system, the swing function of a railway excavator would be impossible. Thus, the rotational movements that excavators are known for, and their capability to execute tasks effectively, are largely attributable to the workings of the humble yet powerful rotary union.

Features of Railway Excavator Rotary Unions

Railway excavator rotary unions, though tiny components within the behemoth machinery, are packed with significant features that affect the overall machine performance. Here is a closer look at these features and their contributions:

Durability and Resilience

Rotary unions are constructed from robust and wear-resistant materials designed to withstand high-speed operation, intense load pressure, and tough duty cycles. This durability is essential as railway excavators often operate within harsh environmental conditions.

Sealing Mechanisms

Rotary unions come with specialized seals that can withstand high pressure, preventing any fluid leakage during transmission from stationary parts to rotating elements. The strength and integrity of these seals ensure consistent operation and contribute significantly to the excavator’s overall efficiency.

Temperature and Media Compatibility

Rotary unions are designed to handle a range of temperatures and can transfer different types of media, including hydraulic fluids, air, and coolants. This feature enhances their versatility and compatibility with various systems within the excavator.

Flexibility in Design

Rotary unions vary in design specifications to accommodate different use cases within the excavator. They can be single or multi-passage, straight or bent, large or small, matching the exact requirement of the application.

High Speed and High Pressure

Even under high rotational speeds and elevated pressures, rotary unions deliver consistent and reliable performance. This feature ensures the uninterrupted and smooth operation of the railway excavator.

These distinct features offer multiple benefits, contributing to the overall performance of the excavator. The robust rotary unions’ durability and resilience ensure long-term operation, reducing the need for frequent replacements. Reliable sealing mechanisms minimize fluid leakage, leading to effective power transmission and enhanced machine efficiency. The ability to handle different mediums and temperatures widens their application scope within the excavator system. The flexibility in design provides customized solutions for specific use cases, improving the productivity of the machine. Lastly, their ability to operate under high speed and pressure guarantees consistent performance, crucial for heavy-duty applications that railway excavators often undertake.

The Importance of Rotary Unions in Railway Excavators

Rotary unions play a crucial role in the operation and overall efficiency of railway excavators. Their unique function and features heavily influence these machines’ performance and their ability to execute tasks accurately and effectively.

Contribution to Machine Efficiency

Rotary unions are pivotal in transferring fluids under pressure from stationary components to rotating parts within the excavator. These fluids, often hydraulic, are what primarily power the movement and functions of these machines. The hydraulic fluid’s controlled circulation enables smooth movement and firm control over the excavator’s arms, contributing to quicker and more precise operations, and as a result, improved overall productivity.

The quality of a rotary union’s seals is vital in preserving system pressure and preventing fluid leakage. Any fluid loss directly impacts the system’s efficiency. By providing a high-pressure seal, rotary unions ensure that the hydraulic system can operate without loss of power, which in turn contributes to the machine’s optimal efficiency.

Facilitation of Key Excavator Movements

Rotary unions have a prominent role in ensuring the railway excavators’ key movements, particularly their renowned swing or rotational movement. By enabling the transmission of hydraulic fluid to the swing motor, the rotary union directly influences the excavator’s ability to rotate its upper assembly. This ability is integral to most tasks that railway excavators perform.

Without rotary unions, the fluid transfer to rotating machinery parts would be impossible, essentially immobilizing the machines.

Taking all of these into account, it becomes clear that the rotary unions are indispensable components in railway excavators. They ensure the effective functioning of the machine, leading to increased productivity, reduced downtime, and improved system durability. Therefore, understanding and managing these components well significantly contribute to the efficient and effective operation and maintenance of railway excavators.

Selecting the Right Rotary Union for Railway Excavators

Choosing the right rotary union for railway excavators is a critical task that can significantly impact the machine’s overall performance and utility. Here are some key factors and tips to consider:

Key Factors in Rotary Union Selection

Media Type: Rotary unions are designed to handle different types of media, including hydraulic fluid, air, water, and coolant. The choice of rotary union depends on the type of media it needs to transport.

Operating Pressure and Temperature: The rotary union must be able to withstand the operating conditions of the excavator. This includes pressures, temperatures, speeds, and duty cycles specific to the application.

Number of Passages: The number of media types that need to simultaneously pass through the union will determine if a single or multi-passage rotary union is required.

Size: The space available for the rotary union within the excavator might restrict the size of the union that can be installed. Measurements should be taken accurately to ensure a fit.

Durability: Consider the materials and build of the rotary union. It needs to withstand harsh environments and heavy-duty use often associated with railway excavator operations.

Choosing the Right Manufacturer

Here are some tips on selecting a rotary union provider or manufacturer:

Experience and Reputation: Choose a manufacturer with a proven track record and positive customer reviews in the field of rotary unions.

Quality and Specifications: The manufacturer should offer high-quality products that meet all your specific needs and requirements.

Customer Support: Good customer service is essential. The manufacturer should be able to provide technical assistance and support pre and post-purchase.

Delivery Times: The supplier should be able to meet delivery times to ensure that replacement or initial installation does not affect project efficiency.

Cost-Effectiveness: Finally, while quality should be prioritized, the price of the rotary union and its lifetime cost (including maintenance and part replacement needs) should fit within your budget.

Considering these aspects will not only help in choosing the appropriate rotary union but also ensure that it provides optimal performance, thereby ensuring the extended operational life and efficiency of your railway excavator.

Railway Excavator Rotary Unions Installation and Maintenance

In a railway excavator, the rotary union is an essential component whose proper installation and maintenance significantly influence the machine’s overall efficiency. Below, you’ll find a guide on installation, preventative maintenance, and troubleshooting of a rotary union.

Installation of Rotary Union

- Check the Rotary Union: When you first receive the Rotary Union, ensure that it’s the correct model and that its specifications fit your application. Make sure it is free of any damage.

- Prepare the Installation Site: Clean the area where the rotary union will be installed. Any debris, grime, or dust can compromise the seal and the integrity of the union.

- Install the Union: Attach the stationary part of the rotary union (usually the body) to the relevant stationary component of your machine. Connect the rotary part of the union to the rotating component of your machine. Be very careful throughout this to prevent the union from any kind of blunt-force damage.

- Connect the Fluid Line: Attach the plumbing lines properly to the appropriate ports on the rotary union.

- Test the Union: Start your machine and let the rotary union run while checking it thoroughly for any leaks or unusual noises. Address any issues before proceeding to full operation.

Routine Preventative Maintenance

Rotary unions typically require little maintenance, but a regular check can extend their lifespan.

- Regular Inspection: Regularly inspect the rotary union for any signs of wear and tear or damage. This should include checking for leaks around the seal. Even small leaks can lead to significant efficiency losses over time.

- Cleanliness: Keep the rotary union clean and free from dust and debris.

- Replacements: On observing any damage or changes in performance, arrange to repair or replace the rotary union as necessary.

Troubleshooting Common Problems

- Leaking Fluid: If the fluid is leaking, it could be due to a poor seal or excessive wear and tear on the rotary union. It may require a new seal or a total replacement.

- Unusual Noises: Noises may indicate internal damage, improper installation, or the need for the rotary union to be lubricated.

- Reduced Functionality: If the rotary union is not working as efficiently as expected, it may be clogged, damaged, or simply worn out. A thorough check or replacement might be required.

Remember, safety comes first. Always ensure that all maintenance and repairs are conducted when the machine is off to avoid accidents or further damage.

Understanding how to install and maintain your rotary union, as well as troubleshooting common problems, can massively extend its life span and improve your machine’s overall efficiency.

Railway Excavator Rotary Unions Safety Measures and Regulations

Safety is an indispensable aspect when it comes to operating heavy machinery like railway excavators. Practices need to be aligned with standard safety measures, and operations must comply with relevant regulations. Awareness and adherence to these can significantly reduce potential risks and the likelihood of accidents.

Safety Measures

Training: Before operating an excavator, proper training should be provided to the operators to understand the machine thoroughly and how to control it safely. Frequent refresher courses are equally important to keep up with changing safety standards and technology advancements.

Personal Protective Equipment (PPE): Operators should always wear appropriate PPE, including hard hats, high-visibility clothing, safety footwear, eye protection, and ear protection.

Regular Inspections: Many accidents can be prevented by conducting regular inspections of both the machine and the worksite. This action can help spot potential issues early and rectify them before they pose serious risks.

Safe Workspace: The area around the excavator should be clear of unnecessary equipment and personnel to avoid potential hazards.

Machine Safety Features: Excavators should be fitted with up-to-date safety features such as cameras and mirrors for visibility, roll-over protection structures, and harnesses.

Regulations Governing the Use of Railway Excavators

Safety regulations for the operation of heavy machinery are often established and enforced by occupational safety and health authorities.

Licenses and Certifications: In several jurisdictions, operators are required to hold valid licenses or certificates demonstrating they’ve been trained to operate these machines safely.

Regular Compliance Checks: Compliance with safety standards should be high on the priority list for businesses using excavators. Regular audits and inspections keep track of these regulations.

Reporting Accidents and Incidents: Any accident or near miss involving a railway excavator must be reported and investigated to prevent future occurrences. Reporting procedures are usually outlined in the safety regulations.

It’s fundamentally important for everyone involved to align with these safety measures and regulations for a safe and productive work environment. A culture of safety fosters greater efficiency, lowers accident rates, and ultimately saves lives.

Railway Excavator Rotary Unions Case Studies

Real-world situations provide a wealth of learning and reinforce the significance of rotary unions in railway excavators. Here are a couple of indicative case studies to demonstrate their applicability and importance.

Case Study 1: Enhancing Efficiency with the Right Rotary Union

A railway construction company was experiencing frequent breakdowns with their railway excavators, significantly slowing down their operations. On investigation, they discovered that the current rotary unions in their excavators were not effectively managing the hydraulic fluid, resulting in incorrect pressure transmission and thus erratic movements.

The company decided to replace these rotary unions with a more robust and efficient model designed specifically for their application. This change resulted in more precise control of the excavator movements, significantly reducing downtime, and increasing productivity. The importance of selecting the right rotary union for a specific application was the primary learning from this case.

Case Study 2: Maintenance Matters

Another railway company was facing a similar issue with their excavator’s rotary union. Despite using high-quality unions, they endured regular breakdowns. An external audit revealed that the company was not conducting proper and regular maintenance of the rotary unions, causing premature wear and tear.

Once implementing a comprehensive and regular preventative maintenance protocol, the lifespan of their rotary unions was extended drastically, consequently reducing costly breakdowns. The take-home message from this case is that even high-quality rotary unions require regular upkeep for optimal performance.

Through these real-world case studies, we can grasp two significant factors. First, using the correct type of rotary union for any specific use case is critical for the efficient operation of a railway excavator. Second, even with the right equipment, regular and systematic upkeep is crucial to ensure longevity and reliable operation.

Railway Excavator Rotary Unions Future Trends

Rotary union technology continues to evolve. With new advancements and trends in the industry, it is crucial to keep an eye on emerging trends and how they potentially impact railway excavators and other heavy machinery. Here are a few notable future trends and predictions:

Smart Sensors and IoT Integration

The integration of the Internet of Things (IoT) and smart sensors is transforming industrial machinery. Smart rotary unions may feature integrated sensors that continuously monitor fluid flow, pressure, temperature, and overall health. This information can be fed into centralized cloud systems, making data-driven maintenance, diagnostics, and predictive analysis feasible. This could ultimately improve efficiency, and performance, and reduce downtime.

Advanced Materials and Design

Material sciences are constantly evolving; hence, new materials are being tested and implemented. Using advanced materials such as carbon composites, graphene-based materials, or novel surface treatments would enhance durability and resistance to wear and tear. Improved designs, including optimized sealing structures and bearings, could result in longer-lasting and low-maintenance rotary unions.

Energy-efficient and Environment-friendly Solutions

Reducing energy consumption and environmental impact is increasingly important across industries. Rotary unions may see advancements focused on optimizing energy efficiency, reducing leakage, and utilizing environmentally friendly materials. This shift will help companies meet increasingly stringent sustainability standards and regulations.

Customization and 3D Printing

Customization-driven production is becoming more accessible and cost-effective, thanks to additive manufacturing or 3D printing. This trend allows for the production of highly customized rotary unions to meet specific requirements. Smaller batches and personalized specifications could enhance the overall performance and functionality of railway excavators.

These future trends in rotary union technology offer potential benefits across the industry. By embracing advancements and diligently adopting innovations, companies can gain a competitive edge, improve the performance of their equipment, and stay ahead of their peers. Ultimately, it is crucial to remain informed, adaptive, and ready to embrace new trends in the rapidly progressing field of rotary union technology.

Conclusion

Rotary unions play a critical role in railway excavators, with their functionality lying in their unique features, proper maintenance, and allegiance to set regulations. By understanding them fully, one can enhance their experience and operation efficiency while looking forward to future developments.

This guide offers a comprehensive view of everything you need to know concerning railway excavator rotary unions, addressing popular queries, and emphasizing their integral role in the operation of these machines. Understanding these components means becoming aware of your machinery, optimizing its performance, and staying ahead of the curve.

FAQs about Railway Excavator Rotary Unions

Below are some common questions and misconceptions about railway excavator rotary unions, along with concise and accurate explanations:

Q: Why are rotary unions important in railway excavators?

A: Rotary unions enable the efficient transmission of pressurized fluid, like hydraulic fluid, which powers the movement and functions of railway excavators. They facilitate key excavator movements, such as the swing or rotational movement, contributing to the machine’s overall efficiency and capability to carry out tasks accurately and effectively.

Q: Can one rotary union model be used for different media types?

A: While some rotary unions are designed to handle multiple media types, it depends on the specific model. It is essential to choose a rotary union that is compatible with the media type used in your specific application, as certain types may be more suitable for one media than another.

Q: What should I consider when selecting a rotary union for a railway excavator?

A: Key factors to consider include media type, operating pressure, operating temperature, number of passages, size, and durability. Additionally, it’s crucial to choose a reputable provider or manufacturer that offers high-quality products, excellent customer support, and cost-effective solutions.

Q: How do I maintain and troubleshoot a rotary union in a railway excavator?

A: Regular inspections for wear and tear, cleanliness, and fluid leaks can significantly extend the lifespan of a rotary union. Common problems, such as leaking fluid, unusual noises, or reduced functionality, may indicate a poor seal, internal damage, or the need for lubrication. Consult the manufacturer or a qualified technician for guidance on troubleshooting specific issues.

Q: What safety measures and regulations should I follow when operating a railway excavator with a rotary union?

A: Safety measures include proper operator training, wearing appropriate personal protective equipment, conducting regular inspections, maintaining a safe workspace, and adhering to machine safety features. Regulations governing the use of railway excavators often involve acquiring valid licenses, ensuring compliance with established safety standards, and reporting accidents and incidents as mandated by the relevant authorities.

Understanding and addressing common questions about railway excavator rotary unions can help operators make informed choices and maintain the machinery effectively, ensuring reliable performance and a safe working environment.

See What We Can Do