Slip rings, essential devices in the world of electromechanical systems, have found countless applications in a variety of fields. The “ravioli slip ring,” a unique type of slip ring, draws its evocative name from the Italian culinary staple due to its resemblance in size and shape. But beyond mirroring the shape of a beloved pasta dish, what exactly does this slip ring do, and what sets it apart from others in its category? These are the questions we aim to tackle in this article as we take a deep dive into the fascinating world of ravioli slip rings.

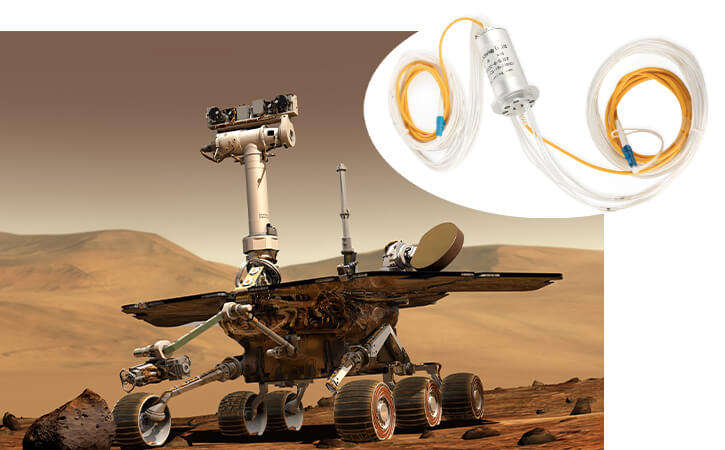

The primary purpose of ravioli slip rings, much like their traditional counterparts, lies in transferring power and data signals between stationary and rotating components within a system. However, ravioli slip rings have found their niche in scenarios that call for compact, yet high-capacity solutions. Their distinct design lends them the adaptability to be used in a multitude of applications, ranging from state-of-the-art medical devices to leading-edge robotic systems to wind energy turbines, to mention just a few.

The significance of these ravioli slip rings cannot be understated. As our world becomes increasingly connected and multiple industries strive towards more efficient designs and streamlined solutions, high-capacity, small-footprint devices like the Ravioli slip rings become essential. These slip rings not only enable the seamless operation of rotating machinery but also contribute towards more streamlined designs, improved performance, and more innovative technological solutions across a wide array of sectors.

In essence, the ravioli slip ring is a cornerstone in electromechanical technology – a small, unassuming device, perhaps, but one that packs a punch in its contributions to the ongoing technological revolution. As we delve deeper into this article, we’ll further explore their design, application, operation, and more, shedding light on just why these ravioli-shaped devices have won the favor of engineers and designers across the globe.

Design and Construction of Ravioli Slip Rings

Upon venturing into the heart of ravioli slip ring design, we immediately encounter a departure from the traditional structural forms of other types of slip rings. The inherent design of a ravioli slip ring is something of an engineering marvel – it manages to coalesce simplicity, sophistication, and innovative thinking into a format that’s as distinct as it is effective.

The ravioli slip ring’s fundamental design embraces a flattened, round, disc-like shape, mirroring the appearance of its namesake Italian pasta. This compact form is far from a random choice; it’s a design-oriented solution to enhance space efficiency in applications where a conventional tubular or capsule slip ring might be too cumbersome.

Materials facilitating the construction of ravioli slip rings are another facet of their ingenuity. Meticulously selected for optimal transmission characteristics, the materials usually include high-quality conduction metals, such as copper or silver alloys, for internal wiring, combined with durable yet lightweight external shell materials, like certain forms of hardened plastic or aluminum. The chosen materials must be capable of withstanding the rigors of various operational environments, reinforcing the durability and extended lifespan of the ravioli slip rings.

When we compare ravioli slip rings to other slip ring types, several unique features come to the fore. The most obvious is the compact, flat design offering significant space-saving capabilities. However, more subtle differences are also noticeable in their functionality. These include the high capacity for signal and power transmission, improved signal integrity, reduced electrical noise, and the ability to accommodate more circuits within a smaller volume, all things that aren’t always achievable with more conventional slip ring designs.

In conclusion, ravioli slip rings merge innovative design principles with high-quality material choices, resulting in a unique device with distinct advantages in the realm of signal and power transmission for an array of applications. The exploration of their design and construction offers a clear understanding of why these devices are rapidly carving out a substantial niche within the realm of electromechanical systems.

Operating Principle of Ravioli Slip Rings

Embarking on the voyage to understand the operational mechanics of ravioli slip rings, we journey into the realm of electromechanical engineering. While their peculiar shape might suggest otherwise, ravioli slip rings work on the same principles that govern more traditional slip rings: they essentially act as an interface between stationary and rotating parts of a system, allowing for the uninterrupted transmission of power and data signals from a static to a rotating unit, and vice versa.

The internal configuration of a ravioli slip ring consists of multiple circuits or channels. Each of these circuits contains brushes (conductive equipment designed to transfer current) and bands (conductive rings that carry the current). As the equipment connected to the slip ring rotates, the brushes, affixed to a stationary base, continually contact these rotating bands, creating an electric connection that allows information and power to be seamlessly transmitted between the stationary and rotating components. This continuous connection ensures that the data or power keeps flowing, even when the apparatus connected to the slip ring continues to revolve.

Since, despite their unique geometry, ravioli slip rings operate on these classic principles, they can be adapted to a myriad of applications where traditional slip rings might be used. However, they hold an advantage in situations requiring high data and power transmission within a restricted space or demanding high-capacity transmission over small distances due to their compact design and layout.

Their flat, disc-shaped profile, coupled with their high operational capacity, makes them ideal for use within the confined spaces of advanced robotics, medical devices, wind energy turbines, and other precision-driven rotary applications. By offering high efficiency in a compact form, ravioli slip rings are enabling new advancements and optimization in varied sectors—delivering innovation in a unique, compact package.

To summarize, while the operating principle of ravioli slip rings aligns with that of more traditional slip rings, their formal distinction and unique features make them invaluable for specialized applications. Their compatibility with diverse operational demands underscores just how adaptable and essential these little dynamos have become in the electromechanical landscape.

Applications of Ravioli Slip Rings

The ravioli slip ring’s impressive capabilities and distinctive design have rendered it a versatile and reliable solution for a wide array of applications. In this segment, we’ll explore some of the key sectors where ravioli slip rings have been making their mark, while also delving into real-world examples that showcase their adaptability and usefulness.

Robotics

In the cutting-edge world of robotics, ravioli slip rings are increasingly employed to facilitate efficient power and data transfer within intricately designed robotic systems. Their compact, flat design allows them to be effortlessly integrated into robotic arms, drones, and other complex machinery, where space is at a premium and precision is non-negotiable.

Ravioli Slip Ring Example in Robotics: Collaborative robots (cobots) utilized in manufacturing and assembly lines often require continuous power and data transmission to maintain fluidity in their movements and communications. Ravioli slip rings enable this seamless operation, ensuring minimal disruption to the workflow and streamlining the intricate processes within these robotic applications.

Medical Equipment

Medical equipment often demands precision, miniaturization, and uncompromising transmission capabilities. Ravioli slip rings fulfill these requirements by offering reliable signal transmission and high-capacity power management, all packaged within a small form factor.

Ravioli Slip Ring Example in Medical Equipment: Computer Tomography (CT) scanners use ravioli slip rings to facilitate the uninterrupted flow of power and data signals between the rotating gantry and stationary electrical components. This fluid transmission ensures that the rapidly spinning gantry generates detailed, high-resolution images, critical for diagnostics and treatment.

Radar Systems

Radar systems require high-performance, durable, and dependable slip rings for the transfer of data and power between stationary and rotating antenna components. Ravioli slip rings, with their high-capacity transmission capabilities, fit seamlessly into these applications.

Ravioli Slip Ring Example in Radar Systems: Air traffic control towers use radar systems equipped with ravioli slip rings to maintain a constant flow of power and data transmission between rotating antenna units and their stationary counterparts. These slip rings play a pivotal role in ensuring the accurate monitoring and tracking of various aircraft within controlled airspace.

Wind Turbines

Rotational motion lies at the heart of wind turbine operation. As such, ravioli slip rings prove to be essential components within these green energy systems, transmitting power and data across the yaw positioning system, which constantly adjusts the turbine nacelle’s orientation to capture optimal wind flow.

Ravioli Slip Ring Example in Wind Turbines: Onshore and offshore wind farms across the globe count on the rugged build and reliable performance of ravioli slip rings to manage the transfer of data and power in their wind turbines. The compact and lightweight nature of these slip rings, combined with their high-capacity transmission, plays an integral role in streamlining wind energy infrastructure.

Thanks to their compact and flexible design, ravioli slip rings have found their footing in diverse industries and applications. From refining the precise movements of robotic systems to enhancing the accuracy of medical devices and driving sustainable energy production, these unique devices have proven indispensable in our increasingly connected and technologically driven world.

Maintenance and Durability of Ravioli Slip Rings

As we look at the operational facets of the ravioli slip ring, an important but often overlooked aspect comes into focus: maintenance and durability. Indeed, while ravioli slip rings are lauded for their technical finesse and versatility, it’s their overall lifespan, ease of maintenance, and robustness against environmental factors that ultimately contribute to their widespread adoption and utility.

Ravioli slip rings, like any electromechanical component, require regular maintenance to ensure optimal functionality. Despite their compact size and intricate design, their maintenance needs are relatively uncomplicated, primarily focusing on the periodic inspection and cleaning of the internal contact surfaces. Over time, these surfaces accrue debris, wear, and tear, including scoring or pitting, which could impair the slip ring’s performance. Regular inspection and basic cleaning help mitigate these issues, enabling the ravioli slip ring to continue operating at its peak capacity.

The expected lifespan and durability of a ravioli slip ring largely depend on its operational environment, the quality of the materials used in its construction, and the manner in which it’s used. Nevertheless, these devices are generally built to a high standard, often employing precious metal alloys for contact surfaces to resist wear and corrosion. As such, with proper care and maintenance, one could anticipate a ravioli slip ring to perform consistently over extended periods, ranging from several years to over a decade, depending on the specific model and its usage terms.

Environmental considerations, too, play a role in the longevity and maintenance needs of ravioli slip rings. These slip rings are frequently deployed in environments that might expose them to a range of ambient conditions, including temperature fluctuations, humidity variations, dust, and corrosion-inducing agents. Typically, ravioli slip rings are designed to withstand these variables to a considerable extent. Designs might include sealed units to prevent dust and moisture ingress, or the use of corrosion-resistant or temperature-tolerant materials to withstand varying environmental conditions.

In conclusion, the maintenance, durability, and resilience of ravioli slip rings against environmental influences are key elements dictating their functionality. By offering an effective blend of lasting durability and manageable maintenance, ravioli slip rings continue to outshine their larger counterparts by providing reliable performance even under challenging conditions, making them a go-to choice for industries seeking compact and robust solutions for their power and data transmission requirements.

User Experiences and Reviews of Ravioli Slip Rings

As we continue our exploration into the realm of ravioli slip rings, direct feedback from those who interact with these components on a regular basis offers precious insights. User experiences and reviews form a critical facet in our analysis, contributing an authentic pulse of the market sentiment and the real-world advantages or disadvantages this equipment holds. Here, we synthesize user experiences to foster a more informed understanding.

While specific user testimonials vary depending on the context of use, the general consensus is largely positive. Ravioli slip rings are often hailed for their compactness and high-capacity performance. Users consistently laud them for their ability to fit into small spaces without sacrificing power and data transmission capabilities.

For example, an engineering technician in a robotics manufacturing firm might comment:

“Installing a ravioli slip ring in our new line of robotic arms significantly improved our data transmission capabilities while conserving space. Their high-performing and compact nature is truly impressive.”

Similarly, an equipment manager at a wind farm reported:

“Our on-site wind turbines, equipped with ravioli slip rings, have been much more efficient in data relay while the compact size of these components has simplified our maintenance schedules. Truly, a great addition to our setup!”

However, as with any product, there can be some points of dissatisfaction as well. While less common, certain concerns have been raised. The relatively higher cost of ravioli slip rings compared to their traditional counterparts is a recurring point of discussion among users.

A review from a medical equipment designer might reflect this sentiment:

“While the superior performance of these compact slip rings is undeniable, the initial expense can be significant. It is paramount to ascertain whether the higher cost is justified by the necessary performance enhancements for your specific application.”

Another noteworthy critique pertains to potential complications arising from their size during maintenance work. While their small, flat footprint is a bonus where space is limited, this same aspect can also pose challenges when it’s time for inspection or repair.

A maintenance engineer working in the radar industry might mention:

“For maintenance and repair, the compact and intricate design of ravioli slip rings can present a challenge. However, once you’ve obtained a knack for it, their immense benefits outweigh these initial hurdles.”

In essence, user experience reveals that ravioli slip rings are highly revered for their blending of compact layout with high-capacity transmission. While some concerns exist around costing and maintenance complexities, many users consider these manageable hindrances given the formidable performance enhancements these components bring to their respective applications.

Ravioli Slip Rings Comparison with Other Types of Slip Rings

When considering ravioli slip rings, it’s important not to overlook the various other types of slip rings available in the marketplace. Comparing ravioli slip rings with other common types can help provide deeper insight into their unique offerings and potential drawbacks. Here, we’ll contrast ravioli slip rings with their conventional counterparts, focusing on the pros and cons of each type.

Ravioli Slip Rings

Ravioli slip rings epitomize compactness and efficiency, making them ideal for use where space is limited or stringent performance demands exist.

Pros:

- Compact design: Their flat, plate-like structure allows for effortless integration into tight spaces and demanding applications.

- High-capacity transmission: Ravioli slip rings can accommodate both data and power transmission without compromising performance for their size.

- Versatility: They’re well-suited for diverse industries, including robotics, medical devices, radar systems, and renewable energy production.

Cons:

- Cost: Ravioli slip rings are typically more expensive than their bulkier counterparts.

- Maintenance complexity: Due to their small and intricate design, maintenance work can be more challenging, especially for inexperienced technicians.

Conventional Slip Rings

Conventional slip rings encompass a broad range of designs and sizes, typically featuring a cylindrical or drum-like structure. They’re widely applied across numerous systems requiring power and signal transmission between stationary and rotating interfaces.

Pros:

- Lower cost: Traditional slip rings are generally more affordable than ravioli slip rings.

- Accessibility: They are widely available and more familiar to many engineers, making it easier to source and integrate components.

- Maintenance simplicity: Conventional slip rings are usually larger and more straightforward, simplifying their inspection, maintenance, and repair processes.

Cons:

- Larger footprint: Traditional slip rings often occupy more space than their ravioli counterparts, making them less attractive for applications with space constraints.

- Potentially limited performance: Due to their size, conventional slip rings might face challenges in achieving comparable power and data transmission capacity rates to those of ravioli slip rings within tight confines.

In summary, while ravioli slip rings stand out for their compactness, adaptability, and high-performance capabilities, cost and maintenance challenges might factor into a user’s decision-making process. Conventional slip rings, on the other hand, offer accessibility, cost-effectiveness, and less complicated upkeep at the expense of a larger footprint and potentially reduced performance in certain space-constrained applications. Ultimately, selecting the optimal slip ring type will depend on the unique requirements and budgetary considerations of each individual project.

Where to Buy and Price of Ravioli Slip Rings

Deciding to incorporate ravioli slip rings into your project is only the first step of the journey. Equally significant is knowing where to source these components and understanding their relative cost-effectiveness. Thus, we shifted our focus towards the procurement aspect, covering trusted retailers, platforms, and price ranges for ravioli slip rings.

Ravioli slip rings can be procured from a wide range of sources, depending on the extent of your needs, the budget, and specific preferences. Specialized retailers like Moog, Schleifring, and Cobham are among the industry leaders known for the excellent quality and broad offering of their slip rings, including ravioli types. These companies often offer tailor-made solutions for individual project requirements, adding an extra level of customization.

Further, B2B e-commerce platforms such as Alibaba or DirectIndustry, also offer access to a diverse catalog of ravioli slip rings from numerous manufacturers worldwide. These platforms allow for the comparison of different brands and types, enabling a more informed decision.

Moreover, other electronics and robotics-focused shops such as DigiKey or Mouser Electronics often carry ravioli slip rings as part of their range, often catering to both individual and business consumers.

Now, onto the price range. Ravioli slip rings, given their advanced design and high-capacity offerings, tend to fall at a higher cost scale than some other slip ring types. The specific price can vary significantly based on factors like the number of channels, the materials used, the required current or data rate, and the level of customization. Typically, you could expect to pay anywhere from a few hundred to several thousand dollars per unit.

While the initial cost might seem high, it’s important to factor in their cost-effectiveness in the long run. The compact design of ravioli slip rings means less space requirement, thereby potentially reducing overall system costs. Additionally, their high-performance capability could lead to increased efficiency and lower operational costs, further justifying their higher initial price tag.

In conclusion, whether you purchase from trusted industry leaders, expansive online platforms, or specialized electronics retailers, make sure to do adequate research and consider not just the immediate cost, but also the long-term value provided by ravioli slip rings.

Conclusion

In the grand scheme of power and signal transmission devices, ravioli slip rings represent a specialized option, providing compact, high-capacity solutions adaptable to a wide variety of applications. Whether you’re a curious hobbyist, an industry professional, or somewhere in between, the world of ravioli slip rings has something to offer.

If you’re keen to explore further, remember: that understanding needs and constraints is the key to making the right choice when it comes to slip rings. Don’t hesitate to reach out to professionals in the field for more information.

Your custom Ravioli Slip Rings quote is just a form away. Complete it and we’ll get back to you promptly.