Grand One-stop Solution Rotary Joints Transmission Application

Besides the slip ring business, Hangzhou Grand Technology also has other products. A rotary joint, also known as swiveling interface, is a rotary sealing device that connects rotating equipment and fixed pipelines. Rotary joints can be designed with multiple channels to manage multiple media types simultaneously. Thanks to the slip ring manufacturing business, Grand as rotary joints manufacturers have developed various types of multi-channel rotary joints to provide a one-stop solution for slewing transmission applications.

Rotary Joint All Products We Have

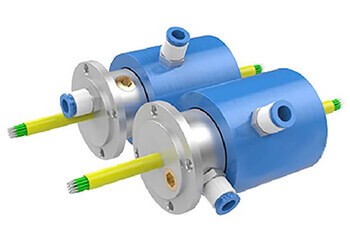

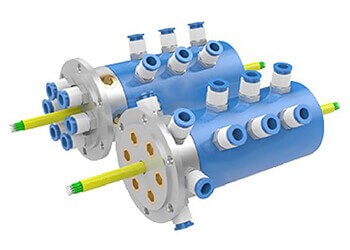

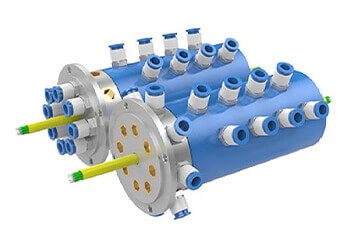

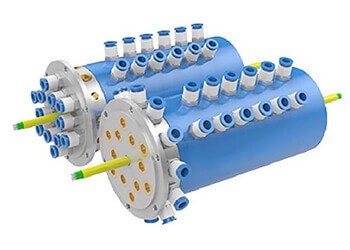

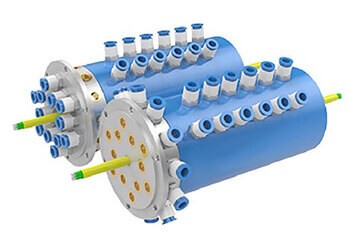

Pneumatic/Hydraulic Electrical Rotary Joints

Pneumatic electrical slip rings are devices that allow the transmission of electrical signals and power while also accommodating the flow of pressurized air or other gases. Hydraulic electric slip rings are devices that allow the transmission of power and signals while accommodating hydraulic fluid flow. Both consist of a rotor and a stator. Slip rings are customized to meet specific requirements for the number of circuits and the type of gas that needs to be transported.

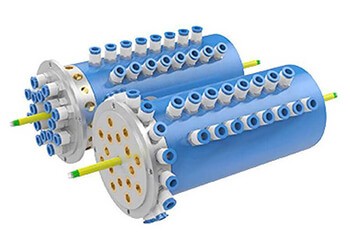

Pneumatic Rotary Unions

Pneumatic rotary joints, also known as pneumatic swivels, are devices that allow the transmission of compressed air or other gases while accommodating the rotational movement between two components. The Grand pneumatic rotary joint adopts the dynamic sealing technology of NSK high-precision bearings to meet the specific requirements for the number of channels, pressure level, and the type of gas that needs to be transmitted.

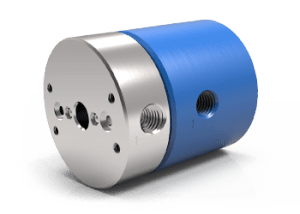

Hydraulic Rotary Unions

Hydraulic rotary joints, also known as hydraulic swivels, is a device that allows the transmission of hydraulic fluid while accommodating rotational movement between two components. Grand supports customized double high-precision maintenance-free bearing with UKS sealing parts.

Wind Turbine Hydraulic Rotary Joints

Wind turbine hydraulic rotary joints are specialized hydraulic swivels that are used in wind turbines to transfer hydraulic fluid between the rotating and stationary components of the turbine. Special hydraulic sealing structure designed for high-speed and high-pressure applications.

Rotary Swivel Joints Features

Rotary joints are mechanical devices used to connect rotating parts of machinery, such as shafts or pipelines while allowing for rotational movement between them. Some of the key features of revolving connectors include:

- Rotational freedom: Revolving connectors are designed to allow for 360-degree rotation between the connected parts, enabling free movement even as the machinery operates.

- Sealing mechanism: To prevent leakage of fluids or gases, revolving connectors typically feature a sealing mechanism, such as a gasket or O-ring, that helps to maintain a tight seal between the connected parts.

- Material selection: Revolving connectors are often made from materials that can withstand high temperatures, pressures, and corrosive environments. Common materials include stainless steel, brass, and various types of plastics.

- Size and shape: Revolving connectors come in a variety of sizes and shapes to accommodate different types of machinery and operating conditions. Some are designed for use in high-speed applications, while others may be more suitable for low-speed or heavy-duty applications.

Overall, revolving connectors are an important component of many types of machinery, helping to facilitate rotational movement while maintaining a secure and leak-free connection between rotating parts.

The Main Components of Rotary Joint

Rotary joints, also known as rotary unions or rotating unions, are mechanical devices that transfer fluids, gases, or other media between stationary and rotating components. The main components of a rotary joint are the housing, the rotor, the seals, and the bearings.

Housing

The housing is the external part of the rotary joint, designed to hold other components. It’s typically made of robust materials like stainless steel, brass, or aluminum. The housing prevents leakage, ensuring efficient operation.

Rotor

The rotor, connected to the rotating machinery, serves as the connection point for media transfer. It’s made of materials like stainless steel or brass and may have multiple media channels for the simultaneous transfer of different fluids or gases.

Seals

Seals are critical components of rotary joints, ensuring media containment and minimizing friction between rotating and stationary parts. Various types of seals can be used, including mechanical seals, O-rings, and lip seals. Material compatibility and reliable sealing are crucial.

Bearings

Bearings support the rotor and ensure smooth rotation within the housing. They reduce friction, wear, and heat generation. Various bearing types, such as ball bearings, roller bearings, or sleeve bearings, can be used depending on load capacity, rotational speed, and the operating environment.

In summary, the main components of a rotary joint—housing, rotor, seals, and bearings—work together to transfer fluids, gases, and other media efficiently. Proper material selection, design, and maintenance are crucial for their reliable and long-lasting operation.

Rotary Joint Installation Method

The installation of a rotary joint requires careful attention to detail to ensure safe and efficient operation. Here is a general installation procedure that typically applies, but always consult the manufacturer’s instructions, as procedures might differ due to variations in design between different rotary joints.

Initial Inspection and Preparation

Begin with the inspection of the rotary joint and its components. Ensure they are free of damage or wear. Then, prepare the installation site – it should be cleared and cleaned to prevent contaminants that can cause damage or inefficiency. The connection points on your machinery where the rotary joint will be installed should also be checked. They should be in good working order and clean.

Connection of Rotary Joint

Next, connect the rotary joint to the machinery. The method of connection will depend on your specific rotary joint design and the machinery. This is often done through threaded ports or flanged connections. It is vital to ensure that the connection is secure but not overly tight, as this can cause damage or strain to components.

Alignment

After the connection, the alignment process begins. This is critical as misalignment could lead to wear, leaks, or mechanical failures. You must ensure that the rotary union is perfectly aligned with the machine’s rotation axis. Some manufacturers will provide tools and guides to assist with this.

Sealing and Testing

The final step in the installation process is sealing the rotary joint and testing it. Apply appropriate sealing to prevent leaks and ensure the joint’s integrity. After sealing, carefully check for leaks while the machinery is in operation. Also, check the functionality of the rotary joint, ensuring it rotates smoothly without unusual noise or vibration.

In summary, the installation process for a rotary joint involves an initial inspection and preparation, connection of the rotary joint to the machinery, alignment, sealing, and testing. It is extremely important to follow the manufacturer’s instructions to ensure safe and effective operation.

Types of Liquids That Swivel Joints Can Transport

Swivel joints are versatile components that are critical to the functioning of various types of equipment and systems. They are designed to allow rotation and movement while maintaining a seamless flow of substances. Swivel joints can transport a variety of liquids, including but not limited to:

- Chemicals

- Coolants

- Food Products

- Gases

- Oils

- Steam

- Water

What Are the Different Types of Swivel Joints?

Swivel joints are robust mechanical devices that provide a rotating connection between two components, typically allowing a 360-degree rotation. They are heavily utilized across a wide range of industries due to their versatility and durability. There are several types of swivel joints distinguished by their construction, usage, and the number of planes on which they allow rotation.

Single-Plane Swivel Joints

Single-plane swivel joints are types of swivel joints that allow rotation on a single plane only. They are simple in design and often used in applications with less complex movement requirements, such as hose reels or simple rotary machines. They enable fluid transfer while performing basic rotation.

Multi-Plane Swivel Joints

As the name implies, multi-plane swivel joints allow rotation on multiple planes. This feature makes them ideal for more complex applications and machinery that require greater flexibility, such as robotic arms and industrial manipulators. They allow for multidirectional movement while guaranteeing a seamless flow of substances.

Loading Arms Swivel Joints

Specifically designed for loading arms in the petroleum and chemical industry, these swivel joints facilitate a safe and efficient fluid transfer process when loading or unloading tank trucks, railcars, or ships. They often feature heavy-duty, high-pressure designs and corrosion resistance to accommodate harsh environments and fluids.

Ball Bearing Swivel Joints

These swivel joints incorporate ball bearings into their design to minimize friction while rotating, resulting in a smoother, more efficient operation. They are ideal for use in high-pressure and high-speed applications or where low friction is a priority.

Food and Beverage Industry Swivel Joints

These swivel joints are used for food-grade applications, designed to transfer edible fluids without contamination. They are typically made of non-corrosive, easy-to-clean, and food-safe materials like stainless steel.

In summary, swivel joints come in various types, catering to a broad range of applications across different industries. Factors like the type of movement required, the substance being transferred, and the specific industry requirements will often determine the choice of swivel joint type.

Understanding the Rotary Joint Working Principle: How Rotary Unions and Rotary Swivels Function

Rotary joints, also referred to as rotary unions, are essential components that allow the transfer of fluids or electrical signals between stationary and rotating parts. The rotary joint working principle revolves around maintaining a sealed connection while enabling continuous rotation. Whether for fluid or electrical transmission, rotary unions ensure the uninterrupted flow of resources in systems with rotating components. This mechanism is particularly crucial in industries such as manufacturing, robotics, medical devices, and energy generation. We will explore how rotary joints work, the rotating joint mechanism, and various types of rotary unions, including the use of rotary unions with slip rings.

How Do Rotary Joints Work?

Understanding how rotary joints work begins with recognizing their role in fluid and electrical transmission. The basic function of a rotary joint is to transfer either fluids or electricity from a stationary part to a rotating one:

Fluid Transmission: The joint rotary allows fluids such as water, air, or oil to flow between stationary and rotating components. The stationary housing is connected to the fluid source, while the rotating component continues to turn without disrupting the fluid flow.

Electrical Transmission: In rotating union with slip rings, electrical signals or power are transferred from a stationary source to a rotating part. The conductive rings are connected to the rotating components, and brushes make continuous contact to ensure a steady flow of electricity.

Sealing Mechanism: The key element in the rotary joint working principle is the seal. The seals ensure there is no leakage, enabling the uninterrupted transmission of fluids or electricity even during rotation.

The Rotating Joint Mechanism

The rotating joint mechanism is what allows rotary joints to function effectively while transmitting fluids or electrical signals. Here’s how it works:

Fluid-Based Systems: In fluid systems, rotary unions use seals to prevent leakage while allowing rotation. Materials such as elastomers, PTFE, or metal seals are commonly used to withstand high pressure and temperature variations, which are often present in fluid transmission systems.

Electrical Systems: Rotary unions with slip rings are designed to transfer electrical power or signals from stationary parts to rotating components. These unions use conductive rings and brushes, ensuring reliable electrical contact while the system rotates.

Sealing Technology: The integrity of the rotational joint depends on the sealing technology used. A well-designed rotary union joint ensures that no fluid leaks and that electrical transfer remains uninterrupted, even in the harshest operating environments.

Types of Rotary Unions and Swivels

There are various types of rotary unions and swivel joints, each designed to meet the demands of different applications. These include:

Rotary Swivel Joints: Also known as rotary swivels, these joints are specifically designed for applications requiring fluid or electrical transfer while allowing rotation. They are commonly used in rotating equipment, such as cooling systems, robotic arms, and industrial machinery.

Rotating Pipe Joints: These are specialized rotary unions used in systems where pipes rotate. For instance, rotating pipe joints are used in cooling systems or lubrication systems, where the pipes are in constant motion but need to maintain a continuous fluid supply.

Rotary Union with Slip Ring: Rotary unions with slip rings are used to transfer electrical power or signals in applications where continuous rotation is needed. The slip rings allow electrical signals to flow between rotating and stationary parts without interruption.

How Does a Rotary Joint Work in Fluid and Electrical Systems?

Understanding how a rotary joint works in both fluid and electrical systems is essential to appreciate its role in various applications:

In Fluid Systems: Rotary unions maintain a sealed pathway for the flow of fluids. Seals within the rotary joint prevent leakage while maintaining the flow of liquids or gases even under high pressure or extreme temperatures. This feature is crucial in systems like hydraulic systems, cooling mechanisms, or lubrication systems.

In Electrical Systems: In systems requiring electrical power or signal transfer, rotary unions with slip rings are utilized. As the rotating part turns, brushes make contact with conductive rings, enabling the smooth transmission of electricity. This design is essential in applications such as radar systems, wind turbines, and automated machinery.

Applications of Rotary Unions and Rotary Joints

Rotary unions and rotating joints have diverse applications across various industries, thanks to their ability to provide continuous transmission of fluids or electricity while enabling rotation:

Printing and Packaging Industry

In the printing industry, rotary joints are essential for maintaining the proper temperature of inks and dyes during the printing process. They are used in cooling or heating drums, transferring heat transfer oil, steam, or water to ensure that printing drums operate at optimal temperatures. This is crucial for achieving high-quality prints and preventing inconsistencies.

In the packaging industry, rotary joints play a vital role in the operation of rotary packaging, labeling machines, and laminators. They enable the smooth flow of adhesives or glue, ensuring that the packaging process remains continuous and efficient. By providing reliable fluid transfer in rotating components, these rotary unions help maintain production speed and precision.

Rubber and Plastics Industry

The rubber and plastics industries rely on rotary joints for temperature control in processes such as injection molding and extrusion. In injection molding machines, rotary unions are used to provide heating or cooling to the molds, allowing for precise control over the mold’s temperature during the manufacturing of various plastic and rubber components.

Additionally, rotary joints are essential in the continuous extrusion process, where they help cool the extruder screw. By preventing overheating, these rotary joints ensure the smooth operation of the extrusion process, improving product quality and minimizing downtime.

Steel Industry

In the steel industry, temperature control is crucial for maintaining the quality of steel production. Rotary joints are used in continuous casting machines to cool the rotating components involved in the casting process. These rotary unions facilitate the transfer of cooling fluids, ensuring that the machinery remains at optimal temperatures and preventing overheating. Effective temperature control in these systems is critical for producing high-quality steel with minimal defects.

Paper Industry

Rotary joints are vital in the paper industry, particularly in large papermaking machines. These joints are used in the drying cylinders to facilitate the heating and cooling processes. By transferring steam, water, or thermal oil, rotary unions maintain the necessary drying conditions, ensuring efficient paper production. The ability to control the temperature of the drying cylinders directly affects the quality of the final paper product.

Food and Beverage Industry

In the food and beverage industry, rotary joints are employed in various machinery that requires heating or cooling during production processes. They are commonly used in pasteurization or cooking systems, where temperature control is essential for food safety and quality.

Additionally, rotary unions play a key role in the filling systems of bottles, cans, or jars, where they allow for the transfer of fluids or other materials while maintaining the movement of components. These rotary joints ensure that the filling processes remain smooth, efficient, and uninterrupted, contributing to the overall productivity of the food and beverage manufacturing lines.

Types of Rotating Joints and Their Applications

Rotating joints are essential components used in a variety of mechanical systems to enable smooth and efficient transfer of power, fluids, and signals between rotating and stationary parts. There are several types of rotating joints, each designed to cater to specific needs, whether for electrical transfer, fluid passage, or motion. This article will explore the different types of rotating joints and their applications in various industries, incorporating the types of rotating joints, types of rotary joint, and other related terms throughout the discussion.

Electrical Rotating Joints (Slip Rings)

Electrical rotating joints, also known as slip rings or electrical rotary joint, are designed to transfer electrical signals or power between rotating and stationary parts. These joints are critical in applications where continuous electrical connection is necessary, such as in wind turbines, medical equipment, or radar systems. The rotary union electrical functions by allowing an electrical current to flow through rotating components without interruption, using brushes that maintain contact with the rotating slip ring. The choice of materials, such as precious metals for conductivity and corrosion resistance, is vital for the reliability and lifespan of these components. A more specific variant, the hydraulic slip ring, integrates fluid and electrical transfer, providing dual functionality in high-tech environments where both fluid and electrical systems operate together.

Fluid and Hydraulic Rotating Joints

Fluid and hydraulic systems often use hydraulic rotary joints or hydraulic rotary unions to transfer fluids such as water, oil, or hydraulic fluid between rotating and stationary parts. The fluid rotary unions plays a crucial role in ensuring continuous fluid transfer in machinery that requires rotation, such as in robotics and heavy industrial equipment, without any leakage or loss of pressure. While hydraulic rotary joints are essential for systems that require high pressure or continuous fluid flow, like in industrial manufacturing, aerospace, or heavy machinery. The hydraulic rotary union is designed to prevent fluid leaks while allowing rotation, and hydraulic rotary swivel joints are commonly used in systems where fluid needs to be transferred with rotational motion. Hydraulic rotary swivel is an important part of many hydraulic systems, facilitating fluid movement without causing damage or leakage during rotation. In these systems, rotary hydraulic technology ensures that machinery operates efficiently, minimizing downtime due to leaks or maintenance.

In some cases, the same technology is applied to steam systems, such as rotary steam joint, steam rotary joint, or rotary joint for steam. These joints are specifically designed to handle high-temperature steam in systems like power plants or large industrial heating systems. The rotary union for steam allows steam to pass through rotating components without disrupting the flow, providing a crucial function in energy systems.

Pneumatic Rotating Joints

Pneumatic rotating joints are designed for the transfer of compressed air or gases between rotating and stationary parts. These joints are commonly used in industrial automation, robotic systems, and applications where pneumatic actuators or tools need continuous air supply. The pneumatic rotary unions and rotary union pneumatic help maintain an airtight connection while allowing the system to rotate freely. The rotary joint pneumatic facilitates this process by sealing compressed air or gas in such a way that it doesn’t escape during rotation. Systems that require precise pneumatic control often rely on these joints to ensure that air pressure is maintained and there are no leaks, ensuring smooth operation of the equipment.

Hydraulic and Pneumatic Swivel Joints

Rotary swivel joints, often referred to as swivel joints, are used in both hydraulic and pneumatic systems to provide the ability for rotational motion while maintaining fluid or gas transfer. The rotary swivel joint can handle multiple types of fluids and gases, and it is designed to work effectively in high-torque and high-pressure environments. The distinction between swivel vs rotate in these contexts often refers to the specific mechanisms by which these joints facilitate smooth rotational motion without affecting the integrity of the fluid or air flow.

In hydraulic systems, hydraulic rotary swivel and rotary swivel joint hydraulic provide an effective way to transfer fluids or power while allowing rotation. These types of joints are particularly useful in machinery like cranes, conveyor systems, or robotics, where fluid transfer needs to be continuous despite movement.

Specialized Rotating Joints for Air and Other Applications

For air systems, rotary air union and air rotary joint are employed to maintain the transfer of compressed air between rotating components. The air rotary union is specifically designed to work under conditions where air needs to flow through rotating parts without leakage or disruption. Similarly, rotary union for hydraulics and rotary union hydraulic are used in high-demand industrial settings where hydraulic fluid must be transferred between rotating and stationary parts with minimal friction and wear.

Rotary unions for hydraulics and rotary unions hydraulic are common in hydraulic machinery, while rotary union for steam is used in steam-based systems. These rotating joints ensure that the transfer of energy or fluid is seamless, providing a reliable connection for various mechanical systems. The rotary union hydraulic can handle higher pressure and is often found in heavy machinery and vehicles.

The variety of types of rotating joints plays an essential role in ensuring the smooth operation of mechanical, hydraulic, pneumatic, and electrical systems. Whether it’s the electrical rotary union, hydraulic rotary swivel, pneumatic rotary joint, or steam rotary union, each type of joint has been designed to fulfill specific requirements for fluid, power, or signal transfer across rotating parts. By integrating these various types of joints into advanced machinery, manufacturers can optimize performance, reduce downtime, and enhance overall system reliability. Understanding the differences and applications of rotary swivel joints, rotary hydraulic, and other related components is critical for selecting the right joint for any system, ensuring both efficiency and durability across a wide range of industries.

Swivel Union Market: Trends, Demand, and Applications

The swivel union market refers to the global demand for swivel unions, specialized rotating connectors used to transfer fluids or gases between rotating and stationary components. These components are critical for ensuring smooth operation in various industrial applications that require rotational movement along with continuous fluid or gas transfer, such as in machinery, robotics, hydraulic systems, and pneumatic equipment.

Market Overview of Swivel Unions

Swivel unions are indispensable in industries where rotating parts need to transfer fluids or gases without compromising performance. They allow for the seamless movement of media while maintaining the integrity of the system. The swivel union market is experiencing robust growth, driven by the increasing need for automation, efficiency, and precision in sectors such as manufacturing, aerospace, automotive, and energy. The rise in industrial automation and robotic systems has particularly increased the demand for rotary equipment installation and reliable fluid and gas transfer solutions.

A significant aspect of this market is the role of rotary union manufacturers, who specialize in designing and producing highly customized products to meet specific industry needs. Many of these manufacturers offer custom rotary union solutions, ensuring that companies can find rotary unions tailored to their systems’ unique requirements. This customization is crucial for industries where one-size-fits-all solutions are not adequate, such as in high-pressure hydraulic systems or sensitive pneumatic processes.

Key Factors Driving the Swivel Union Market

Industrial Automation and Customization: The shift toward automated manufacturing and production systems is one of the key drivers behind the demand for swivel unions. With this shift, there is also a growing need for rotary equipment installation that can efficiently transfer fluids, gases, or power. Furthermore, the growing demand for custom rotary union solutions allows businesses to tailor components to their specific operational requirements, ensuring optimal performance.

Growth in Aerospace and Automotive Sectors: Industries such as aerospace and automotive require rotary / swivel joints for efficient fluid and electrical transfer in rotating parts. The development of new technologies in these sectors drives the demand for high-performance swivel unions capable of operating under extreme conditions.

Energy and Oil & Gas: The oil and gas industry remains a major consumer of hydraulic union solutions, particularly in offshore drilling operations. Hydraulic rotary swivel repair in PA and other maintenance services are crucial to keeping these systems running smoothly. Swivel unions are used to transfer hydraulic fluid to rotating parts of drilling rigs, ensuring high-pressure operations continue without failure.

Maintenance and Durability: The need for rotary joint hydraulic systems that are durable and require minimal maintenance has led to increased investment in high-performance swivel unions. Industries are prioritizing systems that reduce downtime and increase the reliability of machinery, pushing the swivel union market towards more robust solutions that can handle both fluid and rotational stresses effectively.

Regional Trends in the Swivel Union Market

North America: North America is a major market for swivel unions due to the region’s strong industrial base, with significant investments in aerospace, automotive, and energy sectors. The demand for rotary union manufacturers in this region is high, as companies seek reliable, durable, and customizable solutions.

Europe: The European market for swivel unions is driven by the manufacturing sector, particularly the automotive industry, and the growing demand for sustainable energy solutions. Rotary joint assembly services are in demand as manufacturers need efficient connectors for energy systems.

Asia-Pacific: The Asia-Pacific region is experiencing rapid industrialization, leading to a rise in demand for swivel unions, particularly in China, Japan, and India. With the increase in rotary / swivel joints used in machinery and manufacturing, the demand for rotary union hydraulic solutions in high-pressure environments is also growing.

Middle East and Africa: In the Middle East, where the oil and gas industry dominates, the demand for hydraulic rotary swivel and hydraulic union solutions is significant. Offshore drilling and other high-pressure fluid transfer applications are driving the need for these specialized components.

FAQs about Rotary Joint

Do You Offer Pneumatic or Hydraulic Rotary Joints with Electrical Slip Rings?

Pneumatic rotary unions, also known as rotary joints.Let us see the details, in some case rotary joint and slip ring can be integrated together and GRAND have electrical + pneumatic/hydraulic solutions. For example, you can find our ML A series can not be combined with slip ring.

What Are Examples of Rotary Joints?

Rotary unions are used in various industrial applications where there is a need to transfer fluids or gases between stationary and rotating equipment. Some examples of rotary joints or rotary unions include:

Hydraulic rotary unions: These are used to transfer hydraulic fluid between stationary and rotating components in machinery such as cranes, excavators, and construction equipment.

Pneumatic rotary unions: These are used to transfer compressed air or other gases between stationary and rotating parts in applications such as wind turbines, packaging machinery, and printing presses.

Wind turbine hydraulic rotary joints: Wind turbines typically use hydraulic systems to adjust the pitch angle of the blades, which helps optimize the turbine’s aerodynamic efficiency. Hydraulic swivel unions are used to transfer hydraulic fluid between the stationary parts of a turbine and the rotating blades.

Electrical rotary unions: These are used to transfer electrical power or signals between stationary and rotating parts in equipment such as wind turbines, robots, and medical imaging machines.

Overall, rotary joints or rotary unions play an important role in various industries and applications, enabling the transfer of fluids, gases, or electricity between stationary and rotating components in a safe and efficient manner.

Where is the Rotary Joint Used?

Rotary joints or rotary unions are used in various industrial and commercial applications where there is a need to transfer fluids or gases between stationary and rotating equipment. Some common applications of rotary joints include:

Manufacturing machinery: Rotary joints are used in manufacturing equipment such as printing presses, paper mills, and textile machines to transfer fluids such as ink, water, or chemicals between stationary and rotating parts.

Food processing equipment: Rotary joints are used in food processing equipment such as mixers, blenders, and conveyors to transfer liquids such as oils, sauces, or flavors between stationary and rotating parts.

Energy and power generation: Rotary joints are used in power plants, wind turbines, and other energy-generation equipment to transfer fluids such as steam or hydraulic fluid between stationary and rotating components.

Marine propulsion: Rotary joints are used in marine propulsion systems to transfer fluids such as water or lubricants between stationary and rotating parts.

Medical equipment: Rotary joints are used in medical imaging machines such as CT scanners and MRI machines to transfer electrical signals between stationary and rotating components.

Overall, rotary joints play an important role in a wide range of industrial and commercial applications, enabling the transfer of fluids or electricity between stationary and rotating parts of machinery in a safe and reliable manner.

What is the Warranty Period?

One year for retail and have policies for distributors.

Do You Have Rotary Joint in Stock?

Yes. Strandard models in stock like ML A, MQR, MH series. We also open ideas for stock regarding repeat orders.

What is the Custom Rotary Joint Delivery Time?

It is depend on the detail situation, it will take 30 days normally.

What are rotating joints?

Rotating joints are specialized mechanical devices that allow for the transfer of fluids, gases, or electrical signals between a rotating and a stationary part of a machine or system. These joints are essential in systems where components need to rotate continuously without interrupting the flow of energy or media between them. Rotating joints are used in applications ranging from hydraulic systems to pneumatic equipment, to steam and fluid transfer. They come in different designs, including hydraulic rotary unions, pneumatic rotary unions, and electrical rotary joints, depending on the type of medium being transferred. Rotating joints are crucial in minimizing wear and tear on machinery and ensuring that the system operates efficiently over time. Their applications span across various industries such as robotics, automotive, energy, and aerospace, providing reliable connections that maintain functionality while allowing for movement.

What does a rotary coupling do?

A rotary coupling, also known as a rotary union, is a device that enables the transfer of fluid, gas, or electrical signals between a rotating and a stationary component. The primary purpose of a rotary coupling is to maintain continuous fluid or power flow without interruption, even as the connected parts rotate. Rotary couplings are used in a wide variety of applications, including machinery, industrial systems, and aerospace technologies. They come in several variations, including hydraulic rotary unions, pneumatic rotary unions, and electrical rotary unions, depending on the specific medium being transferred. Rotary couplings are essential for applications where the rotating part needs to remain connected to a system that provides power or resources. Their primary benefits include minimizing leakage, reducing wear on components, and enhancing the efficiency of rotating systems. By providing a reliable and seamless connection, rotary couplings ensure the smooth operation of complex systems that require continuous motion.