This article aims to shed light on the often-overlooked component in pneumatic and automation fields – the Rotary Union for Air. By unpacking its functionality, types, and applications, and addressing common concerns, we provide a well-rounded understanding that caters to both newcomers and seasoned professionals.

Introduction to Rotary Union for Air

In the world of machinery and automation, where the integration of moving and stationary components is commonplace, facilitating a seamless and efficient transfer of media is crucial. This is where the Rotary Union for Air, a pivotal yet often understated device, comes into play. It serves as a bridge, allowing air to be transferred from a non-moving source to a moving part or machinery, without leakage. This dynamic component finds its utility in a myriad of applications ranging from simple tool operations to complex automated systems, showcasing its versatility and indispensability.

The Rotary Union for Air is ingeniously designed to maintain a tight seal between the stationary and rotating parts, ensuring that air pressure is consistently delivered to operate machinery without interruption or loss of efficiency. Its role, although seemingly straightforward, encompasses a wide array of design complexities and engineering intricacies tailored to meet the diverse needs of different applications – from high-speed production lines to precision manufacturing processes.

This article aims to shed light on the intricacies of the Rotary Union for Air, offering readers a panoramic view of its operational principles, types, and applications. By navigating through the detailed exposition of its working mechanism, and potential uses, and addressing common user concerns, this piece endeavors to equip readers with a comprehensive understanding of rotary unions. Whether you are a seasoned engineer looking to refine your knowledge or a newcomer curious about pneumatic systems, this guide promises to enhance your understanding of rotary unions for air, ensuring you are well-informed to make decisions regarding their selection, operation, and maintenance.

Through a thorough delineation of the subject matter, the article intends to demystify the complexities surrounding Rotary Unions for Air, transforming a topic that might seem daunting at first glance into approachable and digestible content. Readers can expect to gain not only a foundational understanding of rotary unions but also insights into best practices for selection and usage, maintenance tips, and an appreciation of the technological advancements in this field. Ultimately, this guide serves as a testament to the ingenuity of mechanical design and its critical role in the efficient operation of modern machinery and industrial systems.

What is a Rotary Union for Air?

A Rotary Union for Air, in its essence, is an innovative mechanical device designed to provide a methodical and secure passage of air from a stationary source, such as a compressor or airline, to a rotating part like a drum, spindle, or cylinder. It enables the transfer of air while maintaining a tight seal, regardless of the motion involved. This seamless transmission is critical in ensuring that pneumatic systems function effectively, by providing consistent air pressure vital for mechanical movement and control functions without the complication of tangled hoses or the risk of leakages which could lead to inefficiencies or even hazardous situations.

The fundamental operation of a rotary union for air is a synchronized dance of precision engineering. Inside the union, a rotor, typically connected to the rotating part of the application, turns within a stationary housing or body. This body has an inlet channel through which the air enters. What follows is an elegant management of forces and mechanics: As the rotor spins, specialized seals — often meticulously created from materials designed to withstand the pressure and friction involved — ensure a consistent and leak-proof connection between the rotating and stationary parts. This mechanism ensures that the air is delivered exactly where it is needed, in exactly the right amount, without interruption, every time the machine cycles, be it hundreds or even thousands of times an hour.

Understanding the intricacies of a rotary union’s operation is not just an academic endeavor. It has practical implications for extending the efficiency and reliability of pneumatic systems in industrial applications. A properly functioning rotary union plays a pivotal role in minimizing maintenance needs, reducing operational costs, and enhancing the safety and longevity of the equipment it serves. With this knowledge, one can better appreciate the art and science behind what may seem to be just another component in an expansive system but is, in reality, a linchpin of industrial operations.

Types of Rotary Unions for Air

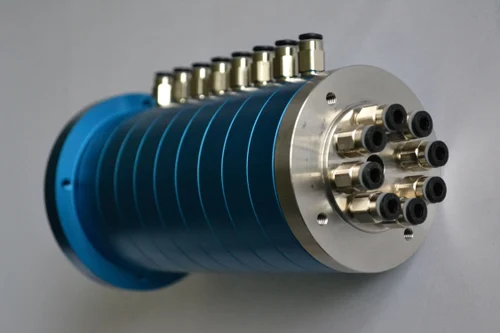

The realm of rotary unions for air encompasses a diverse array of designs, each tailored to meet specific requirements of air transfer in various machinery and application settings. This diversity not only demonstrates the versatility of rotary unions but also highlights their indispensable role in enhancing operational efficiency across multiple industries. Three primary variants dominate the market: Single-Passage Units, Multi-Passage Units, and High-Pressure Models. These types cater to a wide spectrum of pneumatic applications, from the simplest to the most complex and demanding environments.

Single-passage units are the simplest form of rotary unions, designed to transfer air through a single channel. Their straightforward design makes them ideal for applications where a solitary airflow is required. Due to their simplicity, single-passage units are renowned for reliability and ease of maintenance, making them a favored choice for operations where minimalism and efficiency are key, such as in light machinery or single-acting cylinder operations.

Multi-Passage Units, in contrast, are engineered for complexity and versatility. These units feature multiple channels, allowing for the simultaneous transfer of air (and sometimes other media like water or hydraulic fluid) to support intricate machine functions. Multi-passage units find their place in sophisticated machinery where different operations or motions are controlled simultaneously, such as in automated manufacturing lines or complex rotational molding machines. The design complexity of multi-passage unions accommodates the nuanced demands of these applications, providing a cohesive solution for multi-channel air transfer.

High-pressure models are built to withstand and operate under significantly higher air pressures than their single or multi-passage counterparts. Their robust construction ensures a leak-proof operation even under extreme conditions, making them indispensable in applications where high pressure is a norm, including pneumatic clamping systems, high-force actuation, or high-speed rotation equipment. High-pressure models are synonymous with durability, designed to meet the demands of intense applications where operational integrity and safety are paramount.

Understanding the nuances between these types opens up a strategic approach to selecting the right rotary union for air. Single-passage units offer simplicity and reliability for straightforward applications, multi-assage units cater to complex systems with multiple air transfer needs, and High-Pressure Models are the go-to for applications where extreme pressure handling is non-negotiable. Each type’s potential applications underline the importance of identifying the specific requirements of your pneumatic systems before making a selection. Whether it’s the operational simplicity and efficiency, the need to manage multiple channels simultaneously, or the demand for high-pressure tolerance, there’s a rotary union design that aligns with every pneumatic challenge, ensuring optimal performance and reliability of machinery in diverse industrial settings.

How Does a Rotary Union for Air Work?

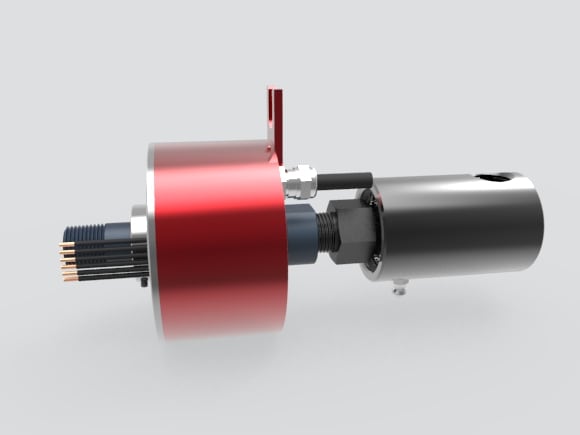

The workings of a Rotary Union for Air are a compelling showcase of mechanical elegance and precision. At its core, it resolves the complex problem of transferring air from a stationary source to rotating equipment without loss of pressure or leakage. To appreciate how this device operates, it is critical to understand its anatomy and the role each component plays in creating a dynamic yet leak-proof seal.

Functioning and Anatomy of a Rotary Union for Air

The basic components of a rotary union for air include housing, a shaft, bearings, and seals. The housing, often stationary, contains the air inlet and is affixed to the air supply. The shaft, also known as the rotor, is attached to the rotating part of the machinery and is fitted within the housing.

Seals: Central to the union are the seals. These are typically made of materials chosen for their durability and resistance to wear, such as PTFE (Polytetrafluoroethylene) or NBR (Nitrile Butadiene Rubber), designed to handle air’s abrasive nature under pressure. These seals engage the shaft and create a tight barrier that prevents air from escaping.

Bearings: Bearings support the shaft within the housing, allowing it to rotate smoothly while maintaining alignment. They absorb the loads and reduce the friction during rotation, ensuring the union’s longevity and efficiency.

The air is introduced into the stationary housing and passes through it toward the shaft. A precisely machined channel within the shaft allows the air to move along its length to reach the point of use. As the shaft rotates, the seal ensures that no air escapes the connection. The bearings, strategically positioned, ensure that the rotating and stationary parts do not grind against each other, which would damage the union and cause a failure.

Illustrative Aids for Understanding

While a detailed textual explanation offers a thorough understanding, illustrative aids substantially enhance comprehension. Imagine a cross-sectional diagram of the rotary union showing:

- The stationary housing with an air inlet,

- The rotating shaft positioned centrally within the housing,

- Seals depicted as rings creating a tight contact with the shaft,

- Bearings are represented as circular elements cradling the shaft, allowing for its rotation.

A step-by-step illustration would also help, visualizing the path air takes:

- Air enters through the inlet into the housing.

- Air travels through the channel in the rotating shaft to the rotating machinery.

- Seals prevent any leakage by maintaining contact with the rotating shaft.

- Bearings allow the shaft to rotate smoothly within the stationary housing.

This graphic representation can simplify the complexity of a rotary union’s working mechanism, making it more approachable for individuals regardless of their technical background. Visual aids can prove especially beneficial for those involved in selecting, installing, or maintaining these devices. Understanding the anatomy and functioning of rotary unions for air through descriptive imagery can ensure clarity and confidence in handling such specialized components within various applications.

Applications of Rotary Unions for Air

Rotary Unions for Air are quintessential in a breadth of industrial and commercial applications. Their capacity to maintain pressure and avoid leaks makes them vital in scenarios where stationary and rotating parts must be interconnected without compromising the air supply’s integrity. The sectors that benefit from these devices are ever-expanding but can be clustered into several primary categories.

Industrial and Commercial Scenarios

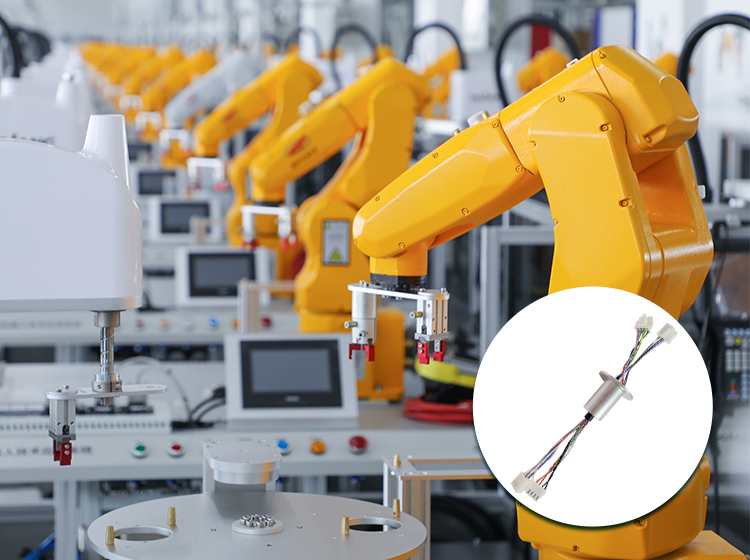

Automated Manufacturing Systems: In the realm of automation, precision and reliability are paramount. Rotary unions are crucial here to power pneumatic actuators and control systems that drive the robotics and assembly lines. They help maintain the necessary air pressure to ensure that the robotic arms function with the swift and steady motion required for tasks like assembling cars or packaging goods.

Printing and Paper Industries: High-speed printing presses utilize rotary unions to supply air to control tension in paper rolls, ensuring a smooth feed of paper through the press, which is crucial for maintaining print quality and reducing paper waste. In the paper industry, they are also used to apply uniform pressure in rollers for the proper thickness and texture of paper.

Textile Machinery: Air is essential in operating looms and other intricately designed textile equipment. Here, rotary unions allow for the transfer of compressed air to spinning and weaving machines, a critical process for ensuring the even handling and production of textiles.

Machine Tool Equipment: Many machine tools used for cutting and shaping metals or other materials require precise control, often provided by pneumatic systems. Rotary unions in these systems offer a continuous air supply to pneumatic clamps and other control mechanisms integral to the machine’s operations.

Real-life Examples or Case Studies

Case Study: Automotive Industry: An automotive factory might use rotary unions in their robotic assembly arms. A particular case involved retrofitting an existing assembly line with new rotary unions to improve efficiency. The introduction of advanced air rotary unions cleared frequent maintenance issues and downtime. The new seals in the design provided longevity and reduced air leakage, resulting in a smoother assembly process, less wasted time, and increased production rates.

Example: Wind Turbines: Modern wind turbines employ rotary unions to deliver de-icing compressed air to the blades during cold weather. In a specific instance, turbines were underperforming in frigid climates due to ice build-up. Installing a custom-made rotary union system that functioned even at low temperatures and high altitudes allowed for consistent airflow, preventing ice formation and enhancing energy output.

Case Study: Printing Industry: A famous global printing press company faced an issue with air leakage in their rotary unions, leading to paper wastage and lost production time. They collaborated with a rotary union manufacturer to develop specialized seals and bearings that could handle the high-speed operation of their presses. The upgrade resulted in a drastic downtick in downtime and a significant improvement in print quality, illustrating the profound impact of appropriately chosen and well-functioning rotary unions.

Rotary unions for air integrate seamlessly into the operational fabric of countless machinery and equipment, with each application benefiting from the unique adaptation of their design to meet specific needs. From enhancing product quality in the print industry to improving uptime in automated manufacturing and beyond, the success stories are a testament to their essential role in modern industry. As industries evolve, so too will the applications and technology of rotary unions, opening new doors for efficiency in the boundless landscape of machinery and manufacturing.

User Concerns in Selecting and Using a Rotary Union for Air

When it comes to selecting and using a rotary union for air, potential users navigate a landscape of essential considerations that can significantly affect their operations’ efficacy and efficiency. Understanding these concerns is paramount for making an informed decision that aligns with their application requirements and operational goals.

Reliability and Durability

Concerns: Users prioritize the product’s ability to perform under a wide range of conditions without failing. The lifespan of a rotary union and its build quality are crucial, as any failure can lead to operational downtime, compromising productivity and safety.

Insights: To ensure reliability and durability, users should look for rotary unions crafted from high-grade materials resistant to wear and corrosion, and designed to withstand the specific conditions of their application, whether that be high speeds, extreme temperatures, or corrosive environments. Investigating the seal technology and bearing designs can provide good indicators of the unit’s durability.

Maintenance and Safety

Concerns: The upkeep of rotary unions and the safety of those who handle them are significant considerations. Inadequate maintenance can lead to premature wear and accidents, posing risks to both personnel and machinery.

Insights: Regular inspection and lubrication (if applicable) can prolong the union’s life and ensure its safe operation. Users should follow the manufacturer’s maintenance guidelines and train staff on safety procedures. Equipping the workforce with knowledge of the signs of wear or failure can preempt dangerous situations and costly repairs.

Installation and Compatibility

Concerns: The ease with which a rotary union can be installed and its compatibility with existing systems are frequent user worries. Incorrect installation or incompatibility can lead to operational inefficiencies, leakage, and equipment damage.

Insights: Ensure that the chosen rotary union matches the specifications required by your machinery, including size, media type (air, in this case), pressure, and temperature ratings. Users should also consider the available space and access for maintenance. Seeking out products designed with simple installation and universal connection features can mitigate these concerns. Consulting with the manufacturer or an expert can provide clarity on compatibility and installation requirements.

Cost-effectiveness

Concerns: Beyond the initial purchase price, users evaluate the operational costs and the value for money of a rotary union. They weigh considerations like energy consumption, maintenance expenses, and potential downtime costs against the purchase price.

Insights: While opting for cheaper models might be tempting, investing in a high-quality, energy-efficient rotary union can lead to lower operational costs over time due to fewer maintenance requirements and reduced downtime. Evaluating the total cost of ownership, including long-term savings in operational and maintenance costs, provides a more accurate picture of cost-effectiveness.

Manufacturer Support

Concerns: After-sales service, technical support, warranty terms, and the manufacturer’s reputation are pivotal in users’ decision-making processes. These factors offer reassurance about the product’s reliability and the manufacturer’s commitment to customer satisfaction.

Insights: Selecting a rotary union from a manufacturer known for robust after-sales support and credible warranty policies can significantly benefit users. This support can range from troubleshooting and repair services to guidance on optimal usage. Reputable manufacturers typically provide comprehensive technical documentation, access to spare parts, and customer service that can assist with any concerns post-purchase.

Addressing these concerns requires diligent research and consultation with manufacturers to ensure the selected rotary union aligns with the specific needs and challenges of the intended application. Acknowledging these aspects not only enhances the purchasing decision but also contributes to a smoother, safer, and more efficient operational workflow.

Conclusion

A Rotary Union for Air is a fundamental yet intricate component that serves a vital role in numerous pneumatic applications. Understanding its functionality, types, and key considerations when selecting one will ensure that your pneumatic systems operate efficiently and reliably. As innovations continue to evolve in this field, staying informed will help you leverage the latest advancements for your applications.

FAQs about Rotary Union for Air

Q: Can rotary unions for air be customized for specific applications?

A: Yes, many manufacturers offer bespoke solutions tailored to unique operational requirements, ensuring optimal performance.

Q: How can I extend the life of my rotary union for air?

A: Regular inspection, proper installation, and adherence to maintenance schedules are key factors in extending the lifespan of rotary unions.

Q: Are there rotary unions suitable for both air and fluid?

A: Yes, hybrid models exist that can handle both air and fluids, offering versatility for applications requiring the transfer of multiple media.

Q: What is the significance of the pressure rating in a rotary union for air?

A: The pressure rating indicates the maximum air pressure the union can handle, which is crucial for ensuring compatibility with your system’s requirements.

Q: Can a single rotary union be used for multiple types of media?

A: Generally, rotary unions are designed to handle specific types of media – air, hydraulic oil, water, etc. Using a rotary union designed for air with other media could result in leaks, premature wear, or failure. It’s essential to use a union that’s designed for the particular media you intend to use.

Q: What are the signs that a rotary union needs maintenance or replacement?

A: Indicators of a need for maintenance or replacement include noticeable leaks, unusual noises during operation, a drop in system pressure, or inconsistent performance. Regular inspections should uncover any wear or damage that may lead to these issues. Replacing seals or bearings as needed can extend the life of the unit.

Q: How often should maintenance be performed on a rotary union for air?

A: The frequency of maintenance depends on the operating conditions, such as speed, temperature, and load. Follow the manufacturer’s recommendations. At a minimum, an annual inspection is advised, although more demanding environments may necessitate quarterly or even monthly check-ups.

Q: Are there any safety precautions to follow when installing a rotary union?

A: Always ensure the system is depressurized and the power is off before attempting installation or maintenance. Use appropriate personal protective equipment and follow any specific safety guidelines provided by the manufacturer.

Q: How do I choose the right size and type of rotary union for my application?

A: Selecting the proper size and type depends on factors such as the maximum pressure and flow rate requirements, the size of the passages within the system, and the physical space available. Consulting with the manufacturer or an expert can provide the necessary guidance to make an informed choice.

Q: Can rotary unions for air operate at any rotational speed?

A: No, rotary unions are rated for specific rotational speeds, and exceeding these limits can cause premature wear or failure. It’s critical to select a union that matches the operational speed of your machinery.

Q: Does altitude or temperature affect the performance of a rotary union for air?

A: Yes, extreme temperatures and altitudes can affect seals and lubrication, which may impact performance. It’s important to consider these factors when selecting a union and to look for models that are rated for the environment in which they will be used.

Q: Is it possible to repair a rotary union for air, or do they always need to be replaced when they malfunction?

A: Some rotary unions can be repaired, especially if they’re modular or designed with replaceable components like seals and bearings. Always consult the manual or manufacturer before attempting a repair to ensure you’re not infringing on any warranties or safety guidelines.

Q: How does improper installation affect a rotary union’s performance?

A: Improper installation can lead to misalignment, which may cause leaks, excessive wear, and premature failure. Follow installation guidelines closely or consult with a professional to ensure proper setup.