Discover the critical role slip rings play in the functioning, safety, and efficiency of amusement park rides. Learn about different types, key selection parameters, common concerns, and future trends surrounding the technology. A comprehensive guide for amusement park operators, technicians, ride designers, and tech enthusiasts.

Introduction to Slip Ring Applications in Amusement Park Rides

The world of amusement park rides is a marvel of engineering, providing us with exciting experiences that challenge our sense of space and speed. While we primarily associate these rides with leisure and fun, a lot is going on behind the scenes to ensure a thrilling yet safe experience for all. One crucial aspect of this backstage wizardry is the use of slip rings, the unsung heroes of many amusement park rides. This article aims to unravel the integral role that these relatively less-talked-about components play and to illuminate their operation, applications, and challenges.

A slip ring, also known as a rotary electrical joint, rotating electrical connector, or electrical collector, is a device that allows for power and/or data transmission between a stationary and a rotating component. Its simple yet effective principle of operation is based on the conductive circle’s ability to carry an electric current—even during continuous rotation.

In personal computers, it’s the slip ring that ensures the fan spins to cool the processor. In wind turbines, it’s a slip ring that transmits electricity produced at the spinning generator down the static tower. In the realm of amusement parks, it’s a slip ring that helps bring the magic to life by powering our favorite carousel, swirling teacups, or heart-stopping roller coaster.

As we delve further into the article, we’ll explore how slip rings contribute to the operation of various amusement park rides, the types of slip rings typically used, the factors to consider when selecting slip rings, some typical concerns and issues, and the potential future trends in slip ring technology. We’ll provide insights that will be valuable not just for amusement park operators and ride designers, but also for those interested in the applied mechanics that enhance our leisure experiences.

The Role of Slip Rings in Amusement Park Rides

Slip rings fulfill a vital function in the operation of many amusement park rides, playing an integral role in providing power, transmitting data, ensuring safety, and adding to the overall thrill of the ride experience.

Consider how many rides at an amusement park involve rotating motions. It could be the gentle, nostalgic spin of a carousel, the slow but panoramic revolution of a Ferris Wheel, or the rapid, adrenaline-inducing spiral of a roller coaster. Behind the scenes, it’s the slip ring that makes these motions possible.

Powering Rides:

For these rides to rotate, move, or otherwise function, there needs to be an unbroken flow of power between the stationary component (usually the power source or control panel) and the moving parts. For example, a carousel’s stationary center column acts as the power and control hub, while the platform with the horses or other seats rotates around it. The slip ring, often situated where these components meet, carries the electrical current that keeps the carousel lights flashing and horses moving, even when in a full spin. The same principles apply to the operation of other rotating rides like Ferris wheels and roller coasters, ensuring fluid motion and powering associated features like lights and sounds.

Data Transfer and Monitoring:

Apart from power, slip rings also play an essential role in transmitting data from the moving parts of the ride to the stationary control units. Sensors placed on various parts of the ride pick up valuable data, such as speed, rotation angles, temperatures, and mechanical stress. This information is vital for monitoring ride health and safety parameters. It allows ride operators to maintain a real-time understanding of how the ride is performing, facilitating preemptive measures to address any anomalies before they become serious issues.

In this way, slip rings contribute to the overall safety and smooth operation of amusement park rides. They serve as a fundamental, hard-working element in the thrilling experiences we enjoy at amusement parks. As we proceed further into the article, we’ll look at the different types of slip rings typically used in these rides, alongside key considerations for their selection, some of the common concerns and issues that can arise, and potentially transformative future trends.

Types of Slip Rings Used in Amusement Park Rides

Amusement park rides come in various forms and sizes, from gentle, slow-moving carousels to giant, high-speed roller coasters. Each ride imposes unique mechanical demands and technical requirements. Consequently, ride designers and operators rely on a range of slip ring types to meet these diverse challenges. We’ll now take a closer look at some of the most common slip rings used in amusement park rides, considering their distinct features, strengths, and applications.

Pancake Slip Rings

As the name suggests, pancake slip rings boast a compact, flat, and disk-like design. The rotating and stationary components consist of concentric circles with contact brushes arranged around the ring’s circumference. This design excels in axial space limitations, where height restrictions may prevent the use of other forms of slip rings. The compact dimensions of pancake slip rings make them ideal for applications where minimal vertical space is available, such as in carousels or low-profile rides.

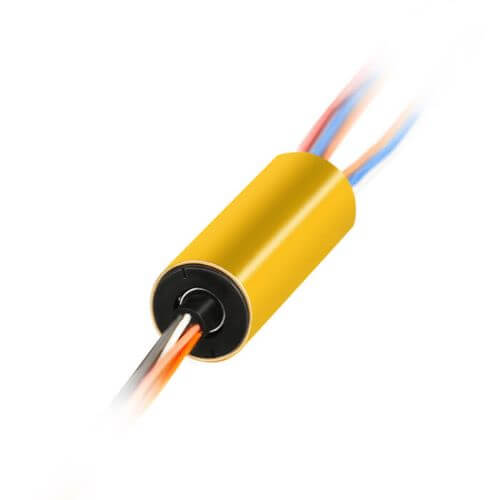

Capsule Slip Rings

Capsule slip rings exhibit a cylindrical form factor, housing multiple circuits within a compact capsule-like enclosure. Each circuit includes a rotating ring and a stationary brush that maintains contact as the ring rotates. The streamlined design of capsule slip rings facilitates their use in rides with tight space constraints or those requiring a lightweight solution. Examples of their application include lighting and sound systems in compact rides, such as teacup-like rides, spinning coasters, or other small-scale rotating attractions.

Large Current Slip Rings

Amusement park rides, particularly those that demand high power loads or feature multiple, power-hungry devices (such as amplifiers, motors, and lighting), often rely on large current slip rings. These heavy-duty variants of slip rings can carry high currents, ranging from tens to thousands of amperes. They’re designed to withstand extreme temperatures and, in most cases, are capable of simultaneously transmitting power, control signals, and data. Their robust construction makes them well-suited for substantial rides like Ferris wheels, roller coasters, or other attractions with significant power needs.

While these are the most commonly used types of slip rings in amusement park rides, other custom-designed offerings, tailored to specific ride requirements, are also employed. As the industry progresses and ride designs become increasingly intricate, new slip ring forms may arise to cater to their evolving demands. In the following sections, we will further discuss the crucial factors guiding slip ring selection and address some of the common concerns and difficulties these versatile devices may face.

Key Considerations for Selecting Slip Rings for Amusement Rides

The selection of slip rings for amusement park rides is not a one-size-fits-all process. It requires a meticulous and tailored approach, taking into account a range of factors that can significantly influence the ride’s performance, safety, and longevity. Let’s explore the critical parameters that guide the selection of slip rings in more detail.

Load Capacity

Load capacity is a principal factor when choosing a slip ring. This measure refers to the amount of electric current that a slip ring can carry without overheating or suffering damage. For high-power rides, such as large Ferris wheels or roller coasters with significant lighting or motor requirements, choosing slip rings with a high load capacity is essential. On the other hand, smaller, less power-hungry rides may only require slip rings with a lower load capacity.

Required Number of Circuits

The complexity and functionality of the ride often determine the necessary number of circuits in a slip ring. A ride requiring the simultaneous transmission of power, data, and control signals may need a slip ring with multiple circuits. For example, a ride like a roller coaster, which may need separate circuits for lighting, motor control, and sensor data, will necessitate a multi-circuit slip ring.

Operating Environment

The slip rings should be able to cope with the environmental conditions that they need to operate in. For amusement park rides, this typically implies outdoor usage, which places demands on durability and weather resistance. A useful slip ring should offer resistance to moisture, dust, temperature extremes, and other environmental factors. It is crucial to consider these environmental aspects when choosing a slip ring for an amusement park ride, to ensure a longer lifespan and consistent performance.

Safety Regulations

Amusement park rides must adhere to strict safety regulations to protect riders and operators. Consequently, the selected slip rings must comply with these regulations as well. It involves selecting slip rings with the appropriate certifications, ensuring they have undergone extensive testing, and ensuring they meet or exceed safety requirements for electrical and mechanical components. Furthermore, rides frequently need to undergo routine inspections and maintenance, so choosing slip rings designed for easy inspection and maintenance can be a beneficial consideration.

These factors must be balanced to select the appropriate slip ring type for each amusement park ride. Careful selection ensures reliable performance, long service life, and ride safety, enhancing the experience for both park operators and visitors. In the next section, we’ll discuss some common issues and concerns that may arise with the use of slip rings, and how to resolve them.

Common Concerns and Challenges with Slip Rings in Amusement Rides

Given the continuous movement and high-stress environment that amusement park rides operate in, slip rings are susceptible to a range of concerns and challenges. Addressing these may help extend their lifespan, enhance performance, and maintain safety. Let’s take a closer look at some of the most common user concerns and discuss possible solutions.

Maintenance Requirements

Regular maintenance of slip rings is vital for their optimal functioning and prolonged service life. This process typically includes cleaning and replacing brushes, inspecting electrical contacts, and checking overall performance. As a user concern, it’s crucial to choose slip rings with ease of maintenance in mind, such as those with accessible components or well-documented maintenance guidelines. Following manufacturer recommendations for maintenance intervals and procedures can help ensure the slip ring remains in optimal working condition, reducing the risk of failures.

Lifespan and Durability

Users are often concerned about the durability and lifespan of their slip rings due to the harsh conditions they may operate in. Investing in high-quality slip rings that use premium materials and robust designs can help enhance durability. Some advanced slip rings utilize contact materials that offer low wear or self-lubricating properties to increase service life further. Additionally, proper maintenance and timely replacement of worn components can help maximize a slip ring’s lifespan.

Sensitivity to Vibrations and Impacts

Amusement park rides frequently subject their components to significant vibrations and impacts throughout their operational life. Slip rings must be able to withstand these forces to maintain reliable electrical connections. When addressing this concern, it is essential to select slip rings designed to handle the specific impact and vibration loads imposed by the ride. Robust, high-quality slip rings can better handle the stresses generated by repetitive and dynamic amusement park rides, ensuring uninterrupted data and power transmission.

Cost-effectiveness

When it comes to slip rings, there is often a balance between cost and performance. Users must weigh the benefits of investing in a higher-priced, high-quality slip ring against the potential for increased maintenance, shortened lifespan, and reduced performance of a more affordable, lower-quality counterpart. The most cost-effective choice will depend on the specific requirements of the amusement ride and the user’s preferences. Factors such as the ride’s power demands, expected service life, and safety requirements can help guide this decision.

By addressing these concerns and challenges, amusement park ride operators can help ensure the optimal performance, safety, and longevity of their slip rings. This process ultimately benefits both the operators and their guests by providing thrilling, dependable, and safe ride experiences.

Troubleshooting Common Issues with Slip Rings in Amusement Rides

As robust and reliable as they are, slip rings in amusement park rides are not immune to issues and complications. Some of the most common problems include signal loss, overheating, and excessive noise. It’s essential to diagnose and address these issues promptly to ensure a safe and enjoyable ride experience for visitors. Let’s take a look at how to troubleshoot these common slip ring issues:

Signal Loss

Signal loss or intermittent communication can seriously impact a ride’s operation. It might result from various problems, including wear of the brush or contacts, contamination, or inadequate contact force. To troubleshoot, first, inspect the slip ring for visible signs of wear or damage. If the brush or contacts appear worn out, replace them as needed. In case of contamination – usually by dust or debris – clean the slip ring meticulously. Finally, ensure each brush is applying the right amount of pressure to maintain good contact: too much pressure can cause excessive wear, while too little might result in broken signals.

Overheating

Overheating can be a potential problem, especially if the slip ring is operating at (or beyond) its rated load capacity for extended periods. This issue can result in the slip ring’s premature failure and may even pose safety risks. If a slip ring is overheating, check whether its current load exceeds the specified rating. If it does, consider redistributing the load, upgrading to a higher-capacity slip ring, or implementing a cooling system. Regular inspection and preventive maintenance can help nip this problem in the bud, preventing the slip ring from reaching a damaging temperature.

Excessive Noise

Excessive noise from the slip ring is usually an indicator of a mechanical issue – such as misalignment, excessive rotatory speed, or worn-out components. To troubleshoot this, first, check for proper alignment: a misaligned slip ring can create unusual noises as well as wear down faster. Additionally, ensure the rotational speed is within the manufacturer’s specified range. If the noise persists, inspect the components for wear and tear – replacing any worn-out brushes or contact rings as needed.

By staying vigilant to these common slip ring issues and troubleshooting them promptly and effectively, ride operators can preserve their equipment, ensure their visitors’ safety, and provide a smooth and enjoyable ride experience. In the next section, we will delve further into the future trends and technological advancements in the world of slip rings.

Slip Ring Applications in Amusement Park Rides: Maintenance and Inspection

Even with innovative engineering and robust construction materials, the potential for wear and tear in slip rings is an inherent part of their operation in demanding environments such as amusement rides. Regular maintenance and routine inspection play critical roles in ensuring ride safety, mitigating downtime, and preventing unexpected failures.

Importance of Regular Maintenance

Regular maintenance is crucial for several reasons. First, safety is paramount in amusement rides, and properly functioning slip rings are integral to maintaining safe operations. Worn-out or damaged components could disrupt critical operations or cause accidents, making maintenance a non-negotiable task.

Secondly, regular maintenance significantly reduces ride downtime. Unplanned ride shutdowns due to component failure can lead to lost revenue and damage the amusement park’s reputation for reliability and customer satisfaction. Regular preventative maintenance helps identify problems before they escalate into significant issues or complete failures, ensuring the ride operates smoothly to entertain guests throughout the year.

Lastly, maintenance extends the lifespan of the slip rings and, thus, the amusement ride. By routinely servicing and replacing components as necessary, the slip ring can meet or even exceed its intended service life, providing a greater return on investment.

Role of Routine Inspections

Routine inspections supplement regular maintenance by helping identify potential issues before they turn into failures. A thorough examination will check for common signs of wear or damage on the brushes and contact rings, ensure all electrical connections are secure and functioning correctly, and identify any abnormalities like overheating or excessive noise.

Routine inspections often allow for preemptive action in replacing worn or damaged components, which improves the safety and reliability of the ride’s operation. Regular inspection also enhances the predictability of maintenance schedules, allowing operators to better plan and manage resources for refurbishment or repairs.

In summary, regular maintenance and routine inspections of slip rings in amusement park rides are crucial procedures that safeguard ride safety, reliability, and longevity, ensuring uninterrupted fun and thrills for visitors. Proper planning and dedication to these procedures will deliver optimal outcomes for both the amusement parks and their guests.

Slip Ring Applications in Amusement Park Rides: Case Study

To better understand the critical role of slip rings in amusement park rides, let’s explore a real-life application – the iconic Ferris wheel. While countless amusement rides use slip rings, the Ferris wheel provides a clear and relatable example of their functional importance.

A Ferris wheel’s central rotating structure is a perfect example of a situation where a slip ring would be implemented. These rides require transferring electric power and communication signals from the stationary part of the ride to the rotating part, specifically, the individual passenger cabins. This transfer allows cabins to be individually controlled for lights, music, or even climate control.

Let’s consider the case of a famous, high-tech Ferris wheel: the “High Roller” in Las Vegas, USA. Standing at 550 feet tall, it is one of the world’s largest observation wheels and uses slip rings for its dazzling LED lighting system. Each of the 28 cabins has its independent lighting, requiring uninterrupted power and signal transfer for the display to function correctly, regardless of the cabins’ position during rotation.

A high-performance, durable slip ring solution is used to transfer power for these LED lights. Without slip rings, the LED lights would be restricted in their operation, or extensive, complicated wiring would be incorporated, severely hindering the wheel’s smooth functioning.

Regular maintenance and inspection are carried out on these slip rings to ensure consistent performance, essential for the eye-catching light display, which is a significant attraction for the ride. Through this regular upkeep, the High Roller Ferris wheel successfully mitigates potential electrical and mechanical failures, providing a safe and visually stunning ride experience for its passengers.

This case study illustrates how slip rings are implemented in a real-world amusement park ride and has underscored the importance of regular maintenance and upkeep for ensuring reliability, safety, and optimal performance.

Future Trends in Slip Ring Applications in Amusement Rides

As technology continues to evolve at a rapid pace, so too does the potential for slip rings and their applications in amusement park rides. Looking ahead, we can expect advancements in slip ring technology to bring about increased efficiency, reliability, and new capabilities for rides, leading to an even more immersive and enjoyable experience for patrons. Let’s examine some potential future trends in this area.

Advanced Material Use

The future may see even more sophisticated materials used in slip ring construction. Researchers are continually looking for materials with better conductivity, less friction, and greater resistance to wear. The use of such advanced materials could enhance the efficiency and lifespan of slip rings, reducing maintenance needs and improving the overall reliability of amusement rides.

Integration with IoT

With the rise of the Internet of Things (IoT), slip rings could become more ‘intelligent.’ They might feature inbuilt sensors to monitor their performance in real-time, identify potential issues before they cause a failure, and even transmit their state of health to a centralized computer system for analysis and preventive action. Such proactive monitoring could lead to reduced downtime and safer, more reliable rides.

Miniaturization

As technology advances, we often see devices shrinking in size without compromising their functionality – a trend we might also see in slip ring design. More compact slip rings could be easier to fit and maintain, and their reduced size could make the construction of slimmer, sleeker rides possible.

Wireless Power and Data Transfer

While the principle of slip rings necessitates physical contact for power and data transfer, future innovations might make it possible to use inductive coupling or other methods to transfer power and data wirelessly. Such a leap could drastically reduce wear and tear, bringing slip ring durability and longevity to new heights.

Green Technology

As sustainability becomes increasingly important, we may see the development of ‘green’ slip rings that use energy more efficiently or are made from earth-friendly materials. Such eco-conscious innovations could reduce the environmental impact of amusement rides while enhancing their appeal to the growing number of environmentally-conscious consumers.

The potential advancements highlighted above make it an exciting time for the future of slip rings in amusement rides. With enhanced performance, new functionalities, and a stronger focus on sustainability, the next generation of slip rings could redefine our amusement park experiences.

Conclusion

In summary, slip rings play an essential role in powering the fun-filled, thrilling experiences at amusement parks worldwide. By enhancing safety, efficiency, and functionality, these unassuming devices promise even greater thrills on the horizon.

See What We Can Do