Slip Ring Application in CNC Machines is a comprehensive guide that provides insights into the integral role this small but significant technology holds in modern machining operations. The article initially highlights an introduction to CNC machines and slip rings, the science behind their application, and key reasons for their essential role in these machines. It goes on to classify various types of slip rings and their specific use-cases in CNC machines. An in-depth look into the benefits, challenges, and practical solutions concerning the employment of slip rings in CNC machines forms a critical segment of the discussion. The narrative concludes by exploring innovations, current advancements, prospective trends in slip ring application, and their transformative impact on CNC operations.

Introduction to Slip Ring Application in CNC Machines

The Evolution of Precision: A Journey Through CNC Machines

Computer Numerical Control (CNC) machines are the backbone of modern manufacturing. The inception of this technology has spawned an era of unprecedented precision and automation, allowing for the creation of intricate designs that were once deemed impossible. From sculpting aerospace components to engraving minute electrical circuits, CNC machines have revolutionized every sector they’ve touched.

CNC machines operate on digital instructions derived from a computer-aided design (CAD) file. The journey starts when an engineer meticulously crafts a design in a CAD program. This digital model is then translated into a language that the CNC machine can understand, instructing it to cut, shape, and form materials with a level of precision that human hands simply cannot match. Here, materials can be as diverse as metal alloys, plastics, woods, and even composites, pushing the boundaries of innovation in fabrication.

Bridging Movements and Power: The Role of Slip Rings in CNC Machines

Nestled within the heart of many CNC machines is a component as critical as it is ingenious: the slip ring. A marvel of electrical engineering, slip rings provide a neat solution to an age-old problem—transmitting electrical power and signals to rotating platforms. Picture a milling machine’s spindle: it turns endlessly, shaping metal into a desired form. How then does it maintain electrical continuity without tangling wires? Enter the slip ring.

Slip rings serve an essential function in CNC machinery, allowing a seamless and continuous transfer of power and data between stationary and rotating parts. Imagine the unassuming slip ring as the conductor of an orchestra, subtly nestled amidst the instruments, yet pivotal in the synchronization of an entire symphony. This component expertly facilitates the flow of control signals to the spinning parts of the machine, ensuring that the CNC machine can carry out intricate rotational cutting, grinding, or drilling operations with uncompromised precision.

Real-World Application

Take, for example, the case study of a high-speed CNC lathe used in the automotive industry. The lathe’s spinning chuck, equipped with a slip ring, manufactures camshafts with startling accuracy, meeting the strict tolerance requirements necessary for peak engine performance. Here, the slip ring is the unsung hero, maintaining the steady stream of power and critical data to the lathe’s sensors and actuators without a single hiccup during the high-speed rotation.

Slip rings are not just facilitators but enablers of innovation in CNC technology. As the complexities in manufacturing grow, so does the demand for versatile slip ring assemblies that can handle higher power loads, data rates, and diverse environmental conditions—all while maintaining their core promise of reliable power and data transmission to machines’ most dynamic parts.

The introduction of slip rings in CNC machines is not just a technical evolution; it represents the harmonious dance between static structure and dynamic movement—a ballet that allows machines to more elegantly craft the products that shape our world. In the subsequent sections, we will delve deeper into the fascinating workings of slip rings and their indelible impact on CNC machine capabilities.

Common Misconceptions

A common misconception is that the inclusion of slip rings may introduce instability or maintenance challenges. However, with advancements in slip ring technology and proper application design, these concerns are largely mitigated, allowing for both reliability and efficiency in modern CNC machine operations.

As we continue to explore the slip ring application in CNC machines, we’ll address these points of contention, offer actionable advice, and unveil how today’s sophisticated slip ring assemblies are not just surviving but thriving in the harsh operating realms of CNC machinery.

The Science Behind Slip Ring Application in CNC Machines

The Ingenious Mechanism: Working Principle of Slip Rings

Slip rings, also known as rotary electrical joints, are born problem-solvers. They resolve a century-old puzzle: how to ensure uninterrupted power and data transfer between stationary and rotating components without a twisted mess of wires.

The essence of slip rings lie in their fundamental design – a rotating part (the rotor) and a stationary part (the stator). The rotor is typically connected to the rotating structure of the machine, while the stator maintains its position. Sandwiched between these two are conducting rings and brushes. As the rotor turns, it carries the rotating electrical contacts over the brushes set against the rings, cycling power and signals from the stationary source to the rotating part.

The construction makes sure uninterrupted power and data flow are maintained, regardless of the direction or speed of rotation. It might seem simple, but it’s this elegant model that allows the mighty CNC machine’s components to function in harmony, powering the incredible feats of precision-enabled by these devices.

Why Slip Rings are a Cornerstone in CNC Machines

Delivering Uninterrupted Precision

The operation of CNC machines depends greatly on the precise movement of their components. Unlike traditional machinery, the parts rotate at high speeds while simultaneously receiving power and control signals without interruption. Slip rings play a pivotal role here, enabling the smooth transfer of control signals to the rotating components, hence helping the CNC machine maintain a high level of precision.

Facilitating Multi-channel Transmissions

Modern CNC machines are intricate systems that require the simultaneous transmission of multiple electrical signals. Incorporating slip rings allows these machines to handle electrical, signal, and data transmission all at once. It’s a feature that firmly cements the role of slip rings in the CNC realm.

Enhancing Machine Lifespan

The wear and tear that a rotating system might experience due to a range of physical strains, including friction or stress from tangled wires, can be mitigated by the use of slip rings. The result? A significantly extended lifespan for the CNC machine.

Real-world Application

To illustrate, let’s consider the example of a large CNC milling machine used in an aerospace company. This machine rotates on multiple axes to mill complex 3D components out of a solid block of metal, like a turbine blade. The different parts rotate at varying angles and speeds to shave off material and bring out the detailed 3D shape from the block. Slip rings, installed at the base of the rotating spindle, transmit not just power for the rotation but also control signals that dictate how fast and at which angle the spindle should rotate.

The absence of slip rings would have made such a signal transfer a really tough problem, possibly requiring re-engineering the whole system to facilitate stationary wiring or experimenting with cumbersome wireless technologies. It’s clearly evident that slip rings work tirelessly in the background to ensure the operations run smoothly.

Addressing Misconceptions

One common misconception is that slip rings introduce a weak link into the system, being prone to wear and tear. While it’s true that, like any mechanical component, slip rings require maintenance, advances in technology have made modern slip rings extremely durable. Carefully chosen materials for the contact brushes, precise engineering of the rotational balance, and the use of sealed assemblies have all contributed to the longevity and reliability of today’s slip rings.

Diving deeper into this subject, we will realize how slip rings today have adapted to diverse challenging contexts, foreseeing a promising future in the realm of CNC machines.

Various Types of Slip Rings and Their Applications in CNC Machines

The world of CNC machines is vast and varied, and the slip rings that dwell within them are equally diverse. Selecting the right slip ring for a CNC application is not a one-size-fits-all endeavor. Instead, it requires a nuanced understanding of the different types of slip rings available and their specific applications within these sophisticated machines.

A Spectrum of Slip Rings: From Simple to Complex

The Classic Ring and Brush Assembly

Pioneering the basics of slip ring design is the classic ring and brush assembly. This is the original, the archetype from which all other slip rings evolve. In its simplest form, it’s a metallic ring with brushes that maintain electrical contact as the machine rotates. These are commonly used in CNC applications that require basic power and signal transfer, and their simplicity makes them reliable and easy to maintain.

Mercury Wetted Slip Rings

For applications needing a connection with incredibly low electrical resistance and minimal noise, mercury wetted slip rings are often the answer. As the name suggests, these slip rings utilize a pool of liquid mercury to ensure an electrical connection. They are coveted for their smooth operation and longevity, supporting high-speed data and sensitive analog signals in precision CNC machining.

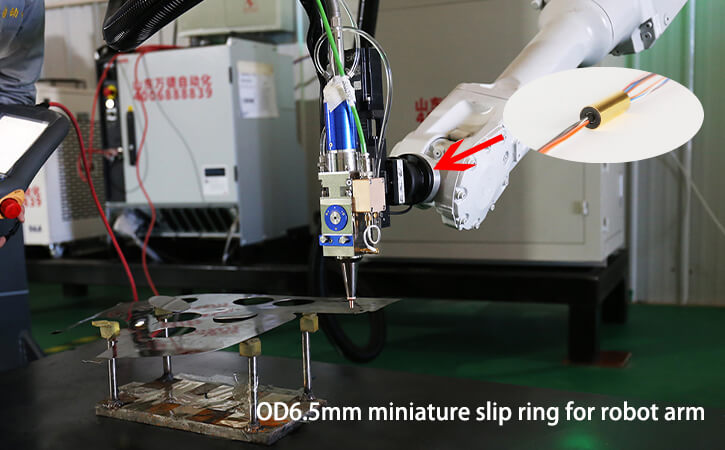

USB Slip Rings

USB slip rings are designed to transfer high-speed data signals and power between rotating and stationary parts of equipment, specifically for USB interfaces. These slip rings are compact and efficient, offering a solution for devices that require data transmission through USB connections while maintaining continuous rotation. While their size and design may be more specialized, USB slip rings are ideal for applications like robotics, medical equipment, and automated systems where USB data must pass seamlessly during operation.

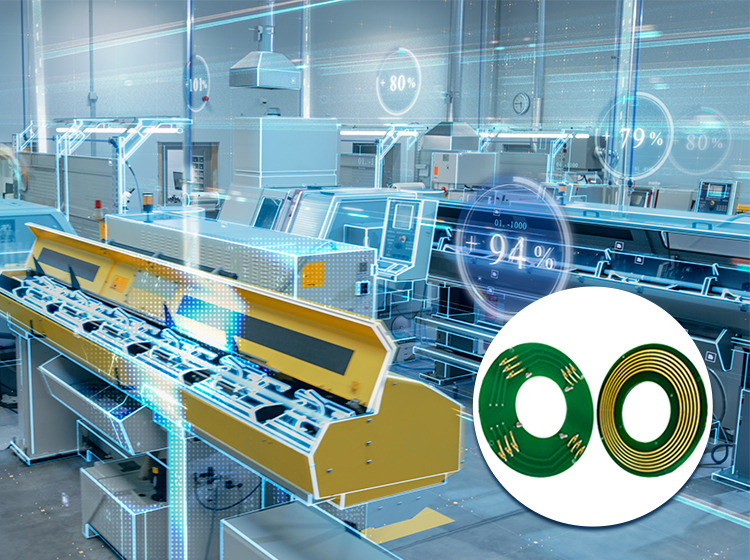

Pancake Slip Rings

CNC machines with limited axial length but ample diameter space may opt for pancake slip rings. They have a flat, disc-like shape, thus the name ‘pancake.’ Though their shape can lead to a larger footprint than the cylindrical designs, they offer a solution for equipment requiring a large number of circuits in a small axial length.

HDMI/SDI Slip Ring

HDMI/SDI slip ring is electromechanical devices that transfer HDMI and SDI signals between rotating and stationary components. They are essential in applications like broadcasting, video production, and camera systems, ensuring high-quality transmission of both video and audio signals without cable tangling. These slip rings offer flexibility and durability, providing uninterrupted signal flow in rotating environments.

Fiber Optic Rotary Joints (FORJs)

With the dawn of the information age, speed and data integrity have become objectives as vital as the power transfer. Fiber Optic Rotary Joints are an advanced type of slip ring designed for the transfer of optical signals. They maintain the integrity of the signal across rotational interfaces in high-speed CNC communications and data systems.

Wireless Slip Rings

Defying the traditional concept of physical connections, the latest advancements have led to the development of wireless slip rings. These use electromagnetic fields to transfer power and data across a rotational interface. Especially useful in CNC applications with extreme environments or where minimal maintenance is a necessity, wireless slip rings represent a step into the future of rotation transmission technology.

Specialized Slip Ring

Specialized slip ring are utilized in various CNC applications that demand high performance, precision, and reliability. In CNC machines, these slip rings support critical functions such as precise motion control, data feedback, and uninterrupted signal transfer during rotation. Whether it’s high-speed precision machining, automated manufacturing, or complex robotics, specialized slip rings ensure smooth, reliable operation, enabling the CNC systems to perform at their best.

Tailored Applications: CNC Machines At Their Best

Each type of slip ring mentioned above finds a home in the world of CNC machines, crafted for very specific tasks. Addressing the rigors of every unique application, here is how these variants shine:

Precision Machining and Heavy Loads

Robust metal ring and brush slip rings are typically found within the heart of heavy-duty CNC machining centers, dealing with the weight of high-powered operations and ensuring that no signal is lost during the translation of the heaviest materials into finely milled products.

Aerospace and High-Resolution Devices

Mercury wetted slip rings, thanks to their high-quality signals and minimal electrical noise, are perfect for aerospace CNC applications where even the slightest interference can compromise the integrity of high-precision machined parts.

Compact and Constrained Environments

Pancake slip rings take the stage when equipment structures are compressed or flattened. Imagine a CNC machine designed for creating intricate jewelry or specialized electronics where precise control is needed in a limited space.

High-Speed Data Environments

In cases where a CNC machine operates as part of a smart factory or is involved in high-frequency data-driven manufacturing, FORJs play a critical role. These provide the necessary bandwidth and data integrity required for intricate operations.

Harsh and Demanding Conditions

Finally, for CNC machines that operate in challenging environments—perhaps underwater, in explosive atmospheres, or situations where maintenance access is severely limited—the wireless slip rings are the unsung heroes of the manufacturing floor.

Benefits and Advantages of Slip Ring Application in CNC Machines

The integration of slip rings into CNC machinery doesn’t just mark a technological innovation; it signifies a leap towards operational excellence. Below, we explore the profound impacts of slip ring technology on the efficiency, reliability, and cost-effectiveness of CNC machines, unraveling its transformative effects through engaging narratives and real-world validations.

Unleashing Efficiency and Precision

The Power of Seamless Operation

Imagine a world where the most intricate components are crafted without halt or hesitation. This is the reality in modern CNC operations, thanks to the humble slip ring. By ensuring continuous power supply and signal transmission, slip rings empower CNC machines to operate with a fluidity that was once unattainable.

Case Study: Aircraft Turbine Manufacturing

Consider the precision required in manufacturing aircraft turbines. Any interruption in the machining process can lead to defects that compromise the component’s integrity. A leading aerospace manufacturer reported a marked improvement in the production of turbine blades upon integrating advanced slip rings into their CNC equipment. The continuous and reliable transfer of power and data rendered the operations not just more efficient but also significantly improved the precision of each cut, translating into safer, more reliable aircraft engines.

Precision: The Heart of Innovation

Slip rings facilitate precision by maintaining a constant flow of communication between the CNC controller and its moving parts. This uninterrupted dialogue ensures that every movement is executed with exactness, a critical factor in industries where a micron’s miscalculation can lead to significant losses.

Elevating Machine Reliability

A New Era of Endurance

Reliability in CNC machines is not merely a preference—it’s a mandate. The integration of slip rings translates into a new era where downtime becomes a rarity. Through the reduction of wear and tear associated with traditional cable connections, slip rings extend the operational life of CNC machines.

Real-World Insights: Automotive Assembly Lines

In the high-demand environment of automotive assembly lines, downtime is the nemesis. A renowned automotive manufacturer revealed how the introduction of slip rings to their CNC machinery reduced their maintenance needs by 40%. This was primarily due to the elimination of cable failures, which were frequent in the high-motion environment of automotive parts production.

Addressing Misconceptions: Durability Concerns

A common question arises: Aren’t slip rings prone to wear? While it’s true that all mechanical parts have a lifecycle, modern slip rings are engineered for durability. Advances in materials science and design have led to slip rings that can withstand millions of rotations with minimal maintenance, debunking the myth of their fragility.

The Cost-Effectiveness of Long-Term Usage

Reducing Operational Costs

The initial cost of integrating slip rings into CNC machinery might seem like an added expense, but it’s an investment that pays off in the long run. By enhancing the efficiency and reliability of CNC operations, slip rings drastically reduce the need for repairs and downtime.

Illustrative Example: Custom Furniture Production

A boutique furniture company specializing in custom, intricate designs shared their financial journey post-slip ring integration. The continuous operation allowed by slip rings meant faster production times and less wear on machinery. Over a year, the company noted a 30% reduction in operational costs, affirming the cost-effectiveness of slip rings in their production process.

Navigating the Market: Choosing the Right Slip Ring

Selecting the appropriate slip ring is paramount. The market offers a wide range, each suited for different applications. Consulting with experts and conducting a thorough needs assessment can guide CNC operators toward the slip ring that not only fits their current needs but also accommodates future expansions.

The Transformative Impact of Slip Rings

The application of slip rings in CNC machines is more than a technical advancement; it’s a catalyst for operational excellence. Through enhancing efficiency, reliability, and cost-effectiveness, slip rings play a pivotal role in modern manufacturing landscapes. Whether it’s crafting precision aerospace components or producing bespoke furniture, slip rings have proven their worth as invaluable allies in the relentless pursuit of perfection.

As we move forward, it’s clear that slip rings will continue to evolve, further pushing the boundaries of what’s possible in CNC machining and beyond. Embracing this technology not only means staying ahead in the competitive world of manufacturing but also paving the way for innovations that we have yet to imagine.

Innovations and Future Trends of Slip Ring Application in CNC Machines

As we venture into the era of smart manufacturing, slip rings in CNC machines are not just witnessing a phase of innovation but are at the forefront of pioneering a revolution in robotics and automation. These small yet significant components are evolving to meet the demands of precision, efficiency, and connectivity that define the factories of the future.

Harnessing Current Advancements

High-Performance Materials: A Leap into Longevity

With the adoption of graphite and silver-based composites, today’s slip rings boast enhanced conductivity and reduced wear. These materials are at the heart of a new generation of slip rings that promise longer service lives even in the harshest industrial environments.

Trailblazing Example: Aerospace Component CNC Machines

The aerospace sector, with its unforgiving need for reliability, has been an early adopter of these high-performance slip rings. Companies report significantly enhanced machine uptime and reduced maintenance intervals, attributing these gains to the improved material properties of their slip rings.

Digital Integration: Smart Slip Rings

The digital transformation of manufacturing has led to an increase in smart slip rings that offer integrated sensors and data transmission capabilities. These slip rings not only conduct power but also gather crucial operational data, feeding into real-time monitoring systems to enable predictive maintenance.

Case Study: Precision Electronics Fabrication

In the highly competitive electronics industry, a producer of precision components integrated smart slip rings into their CNC machines. The result was a dramatic improvement in predictive maintenance, reducing unexpected machine failures by 60% and enhancing overall production efficiency.

Envisioning Future Trends

Coalescing with IIoT: The Rise of Connected Slip Rings

The Industrial Internet of Things (IIoT) is setting the stage for interconnected manufacturing ecosystems where every component can communicate. Slip rings are expected to serve as critical nodes, transferring not only power and data but also contributing to the vast mesh of IIoT devices.

Prospecting the Horizon: Intelligent Fabrication Networks

Envision intelligent networks where CNC machines with advanced slip rings communicate with each other, adjusting operations in harmony for optimal efficiency. This level of integration could define the smart factories of tomorrow, reducing waste, maximizing output, and allowing for unprecedented levels of custom automation.

Material Science Innovations: Beyond Traditional Wear

The potential for new materials to revolutionize slip ring durability is immense. Research into carbon nanotube composites and other nano-scale materials promises to deliver slip rings that are not only incredibly robust but also capable of self-repair, dramatically reducing the need for replacements.

Predictive Analytics: Smart Maintenance Evolved

In the near future, slip rings could harness machine learning algorithms to predict their own maintenance needs. By analyzing operational data, these intelligent systems will schedule their servicing, thereby optimizing the machine’s productivity with minimal human intervention.

The Exciting Future Beckoning

The realm of slip ring application in CNC machines is on the cusp of revolutionary change, driven by the relentless pursuit of innovation and efficiency. As industry 4.0 gains momentum, slip rings will evolve into sophisticated, intelligent components that not only support the operational needs of today’s CNC machines but also pave the path for the smart factories of tomorrow.

In embracing these innovations, manufacturers will unlock new levels of productivity, precision, and profitability, securing their place in the future of manufacturing and beyond.

Innovations and Future Trends of Slip Ring Application in CNC Machines

As we venture into the era of smart manufacturing, slip rings in CNC machines are not just witnessing a phase of innovation but are at the forefront of pioneering a revolution in robotics and automation. These small yet significant components are evolving to meet the demands of precision, efficiency, and connectivity that define the factories of the future.

Harnessing Current Advancements

High-Performance Materials: A Leap into Longevity

With the adoption of graphite and silver-based composites, today’s slip rings boast enhanced conductivity and reduced wear. These materials are at the heart of a new generation of slip rings that promise longer service lives even in the harshest industrial environments.

Trailblazing Example: Aerospace Component CNC Machines

The aerospace sector, with its unforgiving need for reliability, has been an early adopter of these high-performance slip rings. Companies report significantly enhanced machine uptime and reduced maintenance intervals, attributing these gains to the improved material properties of their slip rings.

Digital Integration: Smart Slip Rings

The digital transformation of manufacturing has led to an increase in smart slip rings that offer integrated sensors and data transmission capabilities. These slip rings not only conduct power but also gather crucial operational data, feeding into real-time monitoring systems to enable predictive maintenance.

Case Study: Precision Electronics Fabrication

In the highly competitive electronics industry, a producer of precision components integrated smart slip rings into their CNC machines. The result was a dramatic improvement in predictive maintenance, reducing unexpected machine failures by 60% and enhancing overall production efficiency.

Envisioning Future Trends

Coalescing with IIoT: The Rise of Connected Slip Rings

The Industrial Internet of Things (IIoT) is setting the stage for interconnected manufacturing ecosystems where every component can communicate. Slip rings are expected to serve as critical nodes, transferring not only power and data but also contributing to the vast mesh of IIoT devices.

Prospecting the Horizon: Intelligent Fabrication Networks

Envision intelligent networks where CNC machines with advanced slip rings communicate with each other, adjusting operations in harmony for optimal efficiency. This level of integration could define the smart factories of tomorrow, reducing waste, maximizing output, and allowing for unprecedented levels of custom automation.

Material Science Innovations: Beyond Traditional Wear

The potential for new materials to revolutionize slip ring durability is immense. Research into carbon nanotube composites and other nano-scale materials promises to deliver slip rings that are not only incredibly robust but also capable of self-repair, dramatically reducing the need for replacements.

Predictive Analytics: Smart Maintenance Evolved

In the near future, slip rings could harness machine learning algorithms to predict their own maintenance needs. By analyzing operational data, these intelligent systems will schedule their servicing, thereby optimizing the machine’s productivity with minimal human intervention.

The Exciting Future Beckoning

The realm of slip ring application in CNC machines is on the cusp of revolutionary change, driven by the relentless pursuit of innovation and efficiency. As industry 4.0 gains momentum, slip rings will evolve into sophisticated, intelligent components that not only support the operational needs of today’s CNC machines but also pave the path for the smart factories of tomorrow.

In embracing these innovations, manufacturers will unlock new levels of productivity, precision, and profitability, securing their place in the future of manufacturing and beyond.

FAQs about Slip Ring Application in CNC Machines

Q1: What is a slip ring and how does it work in CNC machines?

A: A slip ring is an electromechanical device that allows the transmission of power and electrical signals from a stationary part to a rotating part. In CNC machines, slip rings enable the transfer of control signals and power to the rotating parts of the machinery, such as the spindle or the table, allowing for seamless 360-degree movement without tangling wires.

Q2: Why are slip rings important for CNC machines?

A: Slip rings are crucial for CNC machines because they enhance the machine’s capability to perform complex and precise machining tasks. They eliminate the need for mechanical commutation, reduce wear and tear on moving parts, and allow for the continuous transfer of power and data, thus improving the machine’s efficiency and lifespan.

Q3: Can slip rings transmit data in addition to power?

A: Yes, slip rings can transmit both power and data. Modern slip rings are designed to carry various types of signals, including Ethernet, USB, and other forms of data communication, alongside electrical power. This dual functionality is essential for CNC machines that require both power for operation and data transfer for control and monitoring purposes.

Q4: How do slip rings affect the maintenance needs of CNC machines?

A: Slip rings can both reduce and specify the maintenance needs of CNC machines. By design, they are meant to decrease the wear associated with mechanical commutation, which can extend the intervals between maintenance. However, slip rings themselves require regular inspection and maintenance to ensure optimal performance, particularly in high-demand industrial environments.

Q5: Are there any alternatives to slip rings for CNC machines?

A: While slip rings are widely used due to their reliability and efficiency, there are alternatives like wireless power transfer systems and optical rotary joints (for signal transfer). Fiber Optic Rotary Joints (FORJs), for example, can be used for high-speed data transfer without electrical contact, but they can’t transmit power. Each alternative has its own set of advantages and limitations, depending on the specific application within the CNC machine.

Q6: How are slip ring advancements impacting the development of CNC machines?

A: The advancements in slip ring technology, including the use of high-performance materials, smart slip rings with integrated sensors, and designs optimized for minimal electromagnetic interference, are significantly impacting CNC machine development. These innovations allow for more complex and precise machining processes, extended machine lifespans, and increased automation and connectivity, aligning with the goals of Industry 4.0.

Q7: What is the future outlook for slip ring application in CNC machines?

A: The future outlook for slip ring applications in CNC machines is highly promising, with ongoing advancements expected to further enhance their performance, durability, and functionality. Innovations in material science and digital integration are set to make slip rings even more critical to the operation of next-generation CNC machines, which will likely be more autonomous, connected, and capable than ever before.

See What We Can Do